Polypropylene edge banding and preparation method

A polypropylene and edge banding technology, which is applied in the field of edge banding, can solve the problems of PVC edge banding environmental performance, peel strength, and surface printing performance to be improved, and achieve high environmental performance, high corrosion resistance, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

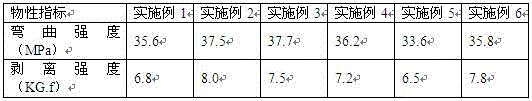

Examples

Embodiment 1

[0040] A polypropylene edge banding strip, which includes the following raw materials in parts by weight: 100 parts of polypropylene, 610 parts of polyamide, 4 parts of polyolefin grafts, 15 parts of nano-calcium carbonate, 0.6 parts of external slip agent, and 0.3 parts of ultraviolet absorber part, 0.3 part of antioxidant, and the parts by weight of colorant are 1 part.

[0041] A preparation method of polypropylene edge banding, it comprises the following preparation steps:

[0042] A. Drying: Dry the polyamide 6 in a dryer at 90°C for 6 hours;

[0043] B, material mixing: by weight, all the raw materials are added into the high mixer at one time, and the material is mixed for 8 minutes, and mixed evenly to obtain the mixed material;

[0044] C. Granulation: The mixed material is granulated by a twin-screw granulator to obtain polypropylene granules; the temperature of the granulator is: 170°C in the first zone of the barrel, 175°C in the second zone of the barrel, and 180...

Embodiment 2

[0050] A polypropylene edge banding strip, which includes the following raw materials in parts by weight: 90 parts of polypropylene, 610 parts of polyamide, 3 parts of polyolefin grafts, 15 parts of nano-calcium carbonate, 0.4 parts of external slip agent, and 0.5 parts of ultraviolet absorber part, 0.4 part of antioxidant, and the parts by weight of colorant are 2 parts.

[0051] A preparation method of polypropylene edge banding, it comprises the following preparation steps:

[0052] A. Drying: Dry the polyamide 6 in a dryer at 95°C for 5 hours;

[0053] B. Mixing: by weight, all the raw materials are added to the high mixer at one time, and the mixing is carried out for 9 minutes, and the mixture is evenly mixed to obtain the mixed material;

[0054] C. Granulation: The mixed material is granulated by a twin-screw granulator to obtain polypropylene granules; the temperature of the granulator is: 171°C in the first zone of the barrel, 176°C in the second zone of the barrel,...

Embodiment 3

[0060] A polypropylene edge banding strip, which includes the following raw materials in parts by weight: 110 parts of polypropylene, 68 parts of polyamide, 6 parts of polyolefin grafts, 10 parts of nano-calcium carbonate, 0.8 parts of external slip agent, and 0.3 parts of ultraviolet absorber part, 0.5 part of antioxidant, and the parts by weight of colorant are 3 parts.

[0061] A preparation method of polypropylene edge banding, it comprises the following preparation steps:

[0062] A. Drying: Dry the polyamide 6 in a dryer at 100°C for 3 hours;

[0063] B. Mixing: by weight, all the raw materials are added to the high mixer at one time, mixed for 10 minutes, and mixed evenly to obtain the mixed material;

[0064] C. Granulation: The mixed material is granulated by a twin-screw granulator to obtain polypropylene granules; the temperature of the granulator is: 173°C in the first zone of the barrel, 178°C in the second zone of the barrel, and 183°C in the third zone of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com