Reverse buckling type plate with gapless edge covering at all corners of the end face

An edge-wrapping and end-face technology, applied in furniture accessories, furniture parts, home utensils, etc., can solve the problems of uneven corners of thick plastic decorative surface materials, unsightly end-face bonding and instability of decorative panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

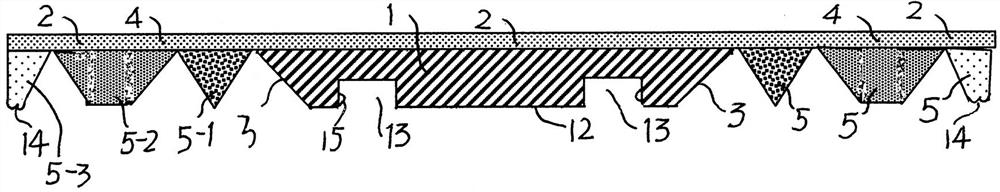

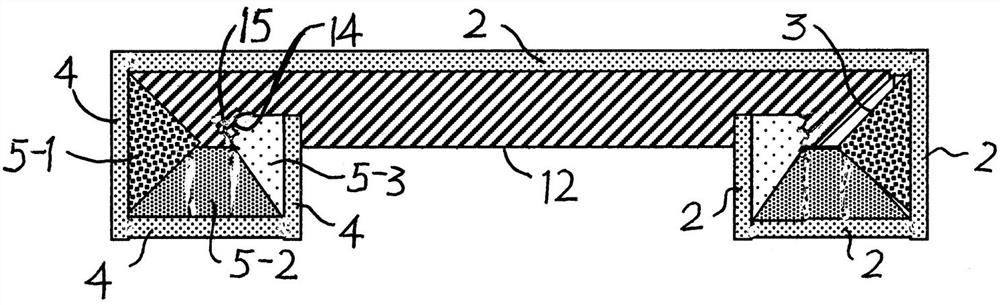

[0043] Embodiment 1. The buckle-type end face of the component strip embedded in the slot on the back of the substrate and the board with all corners on the back without gaps

[0044] Such as figure 1 , 2

[0045] It includes a substrate 1 and a decorative layer 2 pasted on the front of the substrate 1. On the end face 3 of the substrate 1 that needs to be edged, it also includes a decorative surface material 4 for edge wrapping that extends from the decorative layer 2 to the substrate 1 for edge wrapping. Each end face 3 is provided with a bar-shaped combined member, and the bar-shaped combined member on each end face 3 includes three auxiliary turning member bars 5, namely, a triangular auxiliary turning member bar 5-1, a double-slope trapezoidal auxiliary turning member bar 5-2 and a single auxiliary turning member bar 5-1. Inclined trapezoidal auxiliary turning member bar 5-3;

[0046] These three auxiliary turning member strips 5 are respectively arranged on the surfac...

Embodiment 2

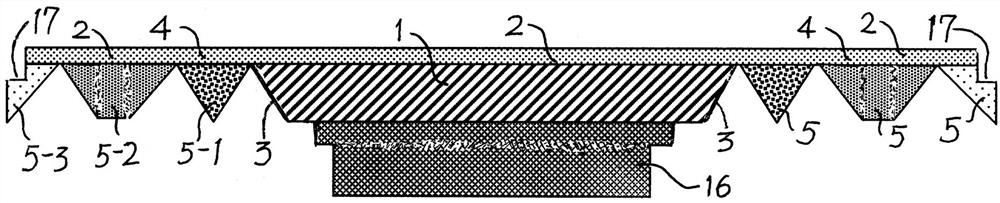

[0054] Example 2: The buckle-type end face of the component strip and the "T"-shaped trapezoidal plate on the back of the substrate and the plate with no gaps at all corners on the back

[0055] Such as image 3 , 4

[0056] It includes a substrate 1 and a decorative layer 2 pasted on the front of the substrate 1. On the end face 3 of the substrate 1 that needs to be wrapped, it also includes a decorative surface material 4 for wrapping that extends from the decorative layer 2 to the substrate 1 for wrapping. It is characterized in that : Each end surface 3 of the base plate 1 is provided with a strip-shaped composite member, and the strip-shaped composite member on each end surface 3 includes three auxiliary turning member strips 5, namely a triangular auxiliary turning member strip 5-1, and a double-slope trapezoidal auxiliary turning member strip 5 -2 and right-angled triangular auxiliary turning member bar 5-4;

[0057] The right-angle position of the right-angle missin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com