Method for separating nitride self-supporting substrate by utilizing stress gradient

A self-supporting substrate, stress gradient technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as restricting rapid development, complex procedures, and restricting AlGaN epitaxial layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

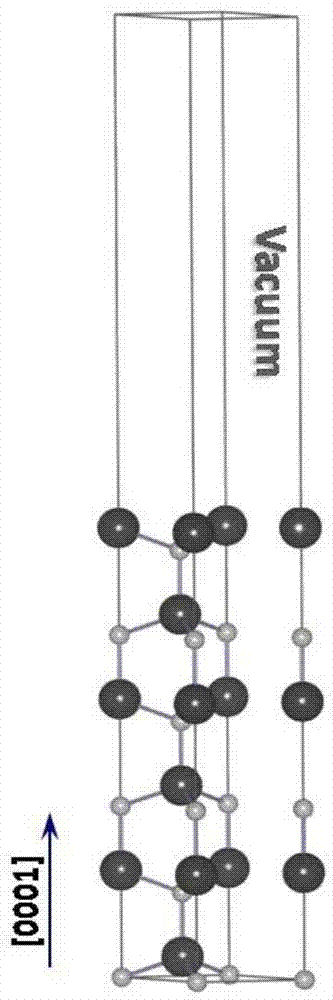

[0031] Firstly, first-principle calculations are used to analyze the properties of GaN to be studied. In order to obtain accurate results, the VASP package based on density functional theory, the electron-ion interaction is described by the projected additive wave pseudopotential method (PAW), and the plane wave The cut-off kinetic energy is taken as 550eV, and the sampling of the Brillouin zone uses the 8×8×1 Monkhorst-Pack k-point grid method. Constructed by 11 layers of atoms and The vacuum composition GaN supercell, such as figure 1 As shown, the dangling bonds of the surface atoms are preserved to obtain the properties of the surface localized electronic states.

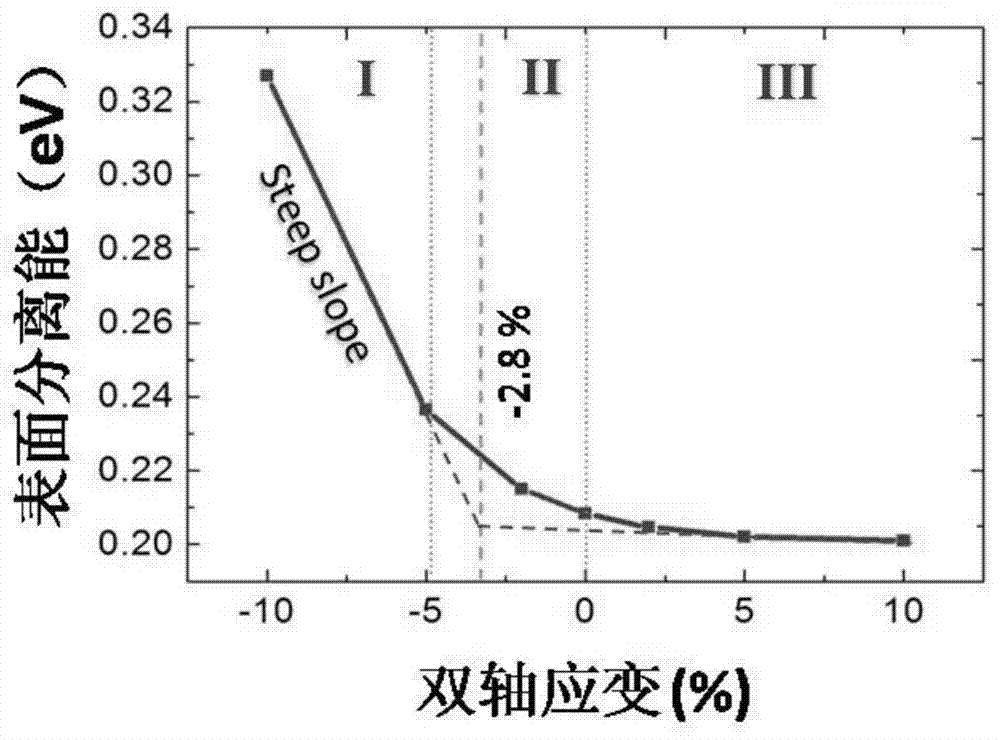

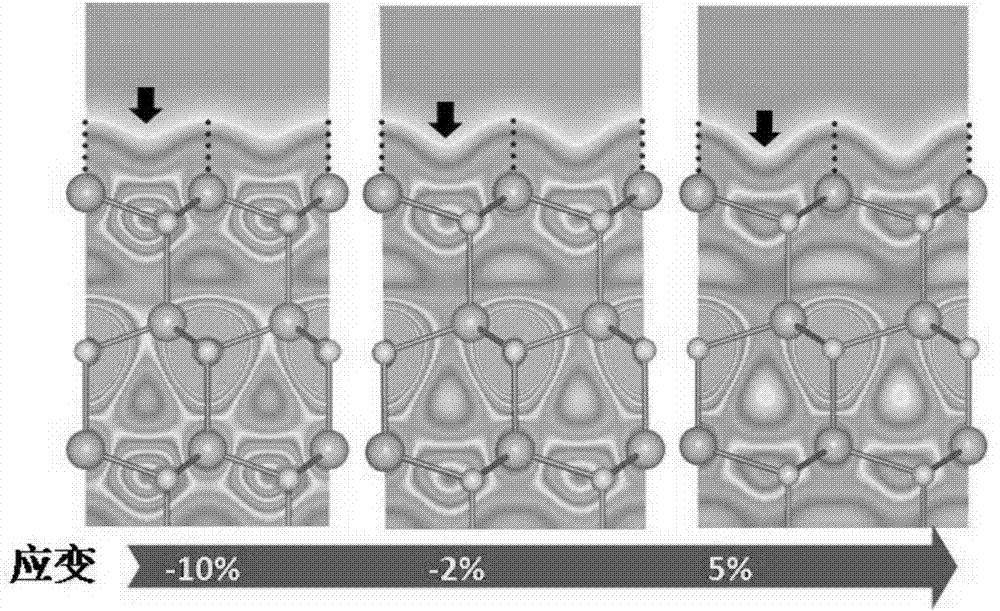

[0032] In order to simulate the stress of the system, the strain field is introduced by changing the original cell, so as to apply the required stress. For the GaN epitaxial thin film, the stress mainly comes from the biaxial stress caused by the crystal lattice decoupling of the sapphire substrate and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com