Preparation method of GaN substrate

A substrate and thick film technology, used in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve the problems of GaN substrate material crystal quality, low yield, and high price. Inexpensive, transfer stress distribution, easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

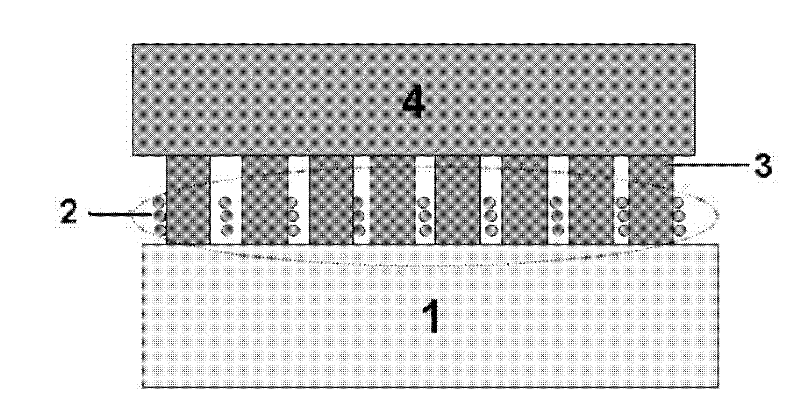

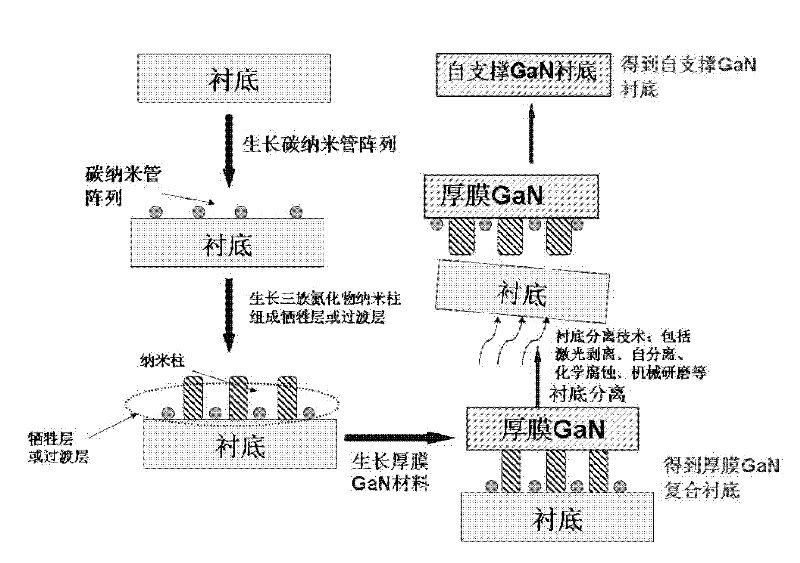

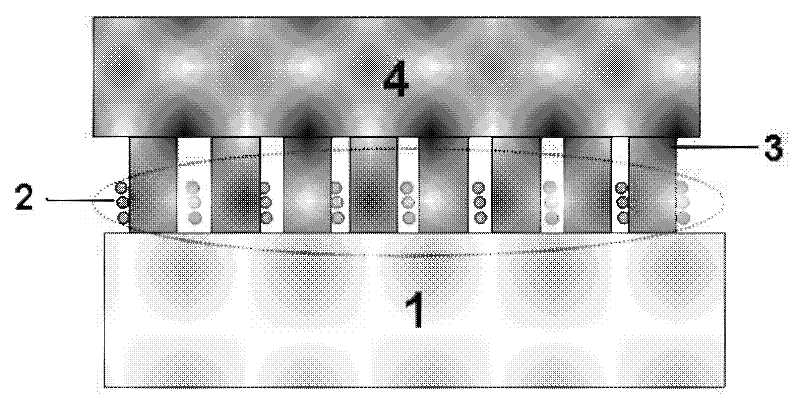

[0027] Embodiment 1. Preparation of c-plane self-supporting GaN substrate:

[0028] 1) The substrate can be sapphire, silicon carbide, Si and other substrates, or GaN, AlN, InN or other III-nitride material films grown on sapphire, silicon carbide, Si and other substrates; carbon nanotube arrangement The method is a parallel arrangement along the growth plane, and the arrangement method can be isoperiodic or periodic disordered structure. The carbon nanotubes can be a single carbon nanotube or a cluster of carbon nanotubes in a single-layer or multi-layer Various forms such as: the present embodiment selects the sapphire substrate of c surface, selects the three-layer carbon nanotubes that equiperiodically arranges along the vertical direction of the substrate reference edge; Nanometer; the period is 1-100 microns, preferably 1-10 microns, and 2 microns are used in this embodiment;

[0029] 2) On the above-mentioned substrate covered with carbon nanotubes, a GaN nanocolumn st...

Embodiment 2

[0035] Embodiment 2. Preparation of c-plane GaN thick film substrate:

[0036] 1) The substrate can be sapphire, silicon carbide, Si and other substrates, or GaN, AlN, InN or other III-nitride material films grown on sapphire, silicon carbide, Si and other substrates; carbon nanotube arrangement The method is a parallel arrangement along the growth plane, and the arrangement method can be isoperiodic or periodic disordered structure. The carbon nanotubes can be a single carbon nanotube or a cluster of carbon nanotubes in a single-layer or multi-layer Various forms such as: the present embodiment selects the sapphire substrate of c surface, selects the three-layer carbon nanotubes that equiperiodically arranges along the vertical direction of the substrate reference edge; Nanometer; the period is 1-100 microns, preferably 1-10 microns, and 2 microns are used in this embodiment;

[0037] 2) On the above-mentioned substrate covered with carbon nanotubes, use MOCVD growth technol...

Embodiment 3

[0043] Embodiment 3. Preparation of non-polar a-plane self-supporting GaN or thick film composite substrate:

[0044] 1) The substrate can be r-plane sapphire, silicon carbide, Si and other substrates, or GaN, AlN, InN or other III-nitride material films grown on sapphire, silicon carbide, Si and other substrates; The arrangement of the tubes is a parallel arrangement along the growth plane. The arrangement can be isoperiodic or periodic disordered structure. The carbon nanotubes can be a single carbon nanotube or a cluster of carbon nanotubes and other forms: In this embodiment, the r-plane sapphire substrate is selected, and research shows that a-plane GaN is obtained by epitaxy on the r-plane sapphire. Three-layer carbon nanotubes arranged in the vertical direction along the reference edge of the substrate are selected for use; the diameter of the carbon nanotubes is 1-100 nanometers, and 20 nanometers are used in this embodiment; the period is 1-100 microns, preferably 1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com