Self-separation fluxing agent of hot tinning and tin alloy and preparation method thereof

A technology of tin alloy and hot-dip tin, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing flux activity and failing to obtain melting point solid flux, and achieve the effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

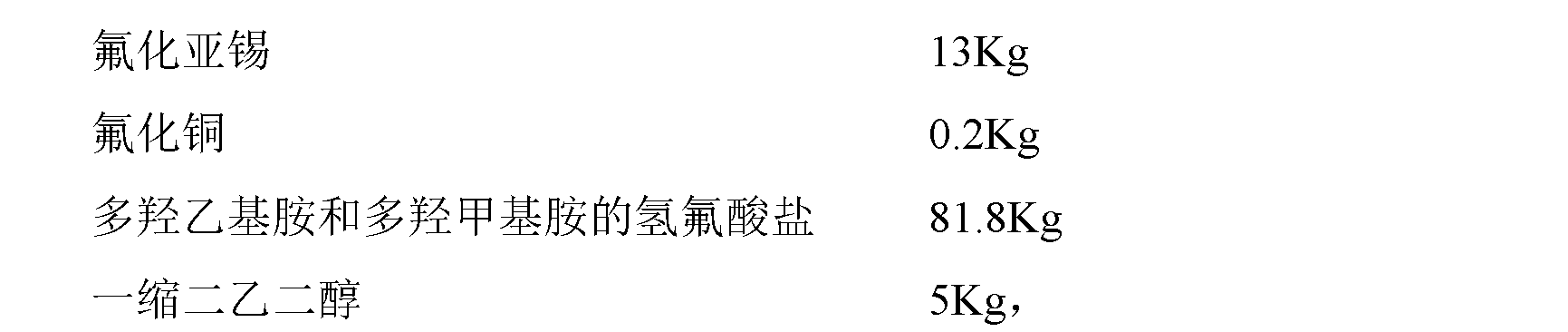

[0033] A self-separating flux for hot-dipping tin and tin alloys, its raw material composition and weight are respectively

[0034]

[0035] The preparation method steps of the self-desorption flux of above-mentioned hot-dip tin and tin alloy are:

[0036] (1) Preparation of hydrofluoric acid salts of polyhydroxyethylamine and polyhydroxymethylamine:

[0037] a. In this embodiment, polyhydroxyethylamine is composed of diethanolamine and hydroxyethylethylenediamine, and polyhydroxymethylamine is composed of trishydroxymethylaminomethane. The above-mentioned diethanolamine, hydroxyethylethylenediamine and Trishydroxymethylaminomethane is mixed in equal proportions (weight ratio) and placed in an evaporating pot with a corrosion-resistant coating, dissolved in water, and the weight ratio of the mixture of polyhydroxyethylamine and polyhydroxymethylamine to water is 1: 2. Heat to 120°C while stirring, and the aqueous solution in the evaporator boils slightly;

[0038] b. Add ...

Embodiment 2

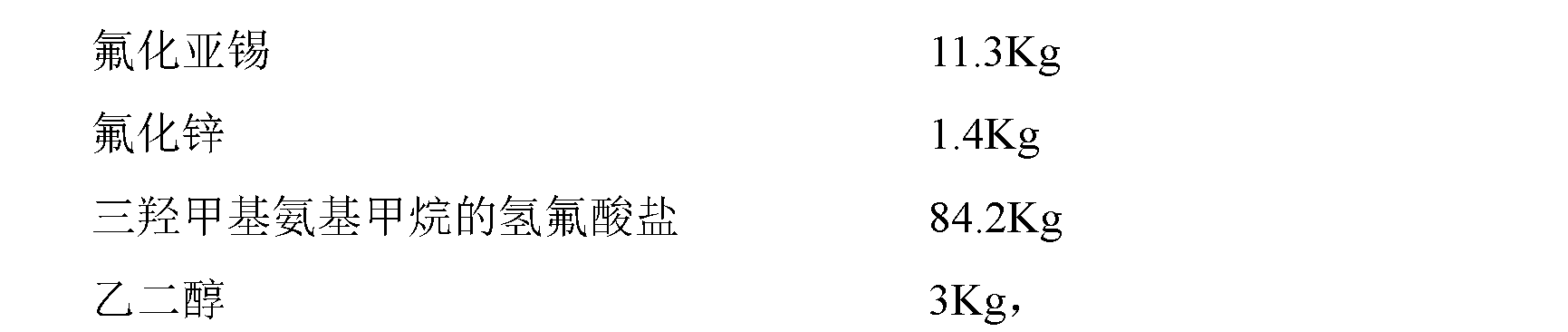

[0043] A self-separating flux for hot-dipping tin and tin alloys, its raw material composition and weight are respectively

[0044]

[0045] The preparation method steps of the self-desorption flux of above-mentioned hot-dip tin and tin alloy are:

[0046] (1) Preparation of hydrofluoric acid salt of Tris:

[0047] a. Put tris in an evaporating pot with a corrosion-resistant coating, add water to dissolve, the weight ratio of tris to water is 1:4, heat to 120°C while stirring, and the evaporating pot The inner aqueous solution boils slightly;

[0048] b. Add hydrofluoric acid aqueous solution with a mass fraction of 10% dropwise into the evaporator, keep the aqueous solution slightly boiling, adjust the pH value between 6 and 8, and stop heating;

[0049] c. put the material in the evaporating pot into a polypropylene container to cool, and wait until the material in the container is white waxy to obtain the hydrofluoric acid salt of tris;

[0050] (2) Heat the above tri...

Embodiment 3

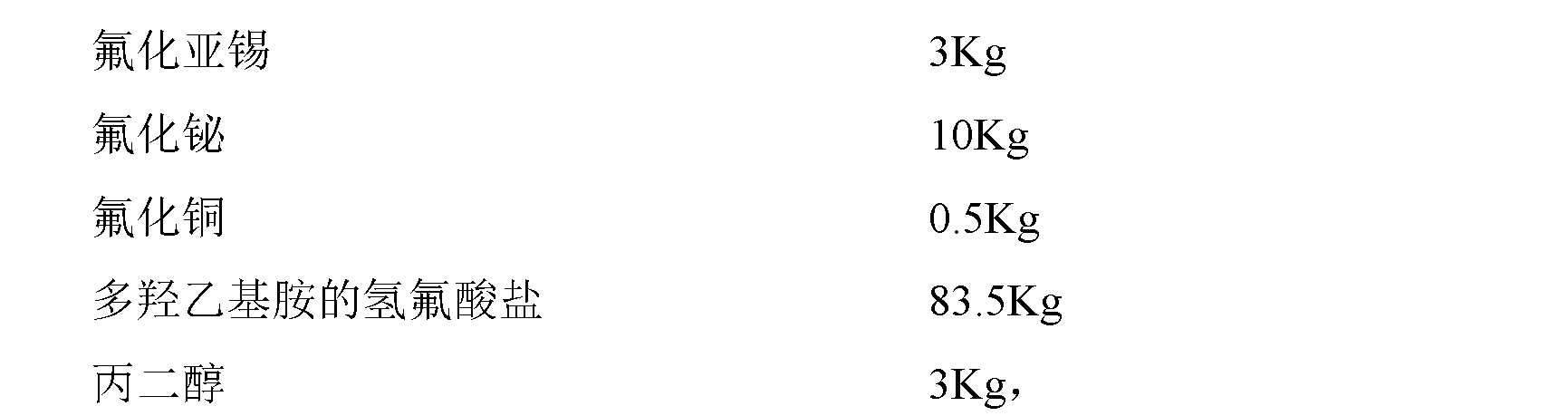

[0053] A self-separating flux for hot-dipping tin and tin alloys, its raw material composition and weight are respectively

[0054]

[0055] The preparation method steps of the self-desorption flux of above-mentioned hot-dip tin and tin alloy are:

[0056] In this example, the polyhydroxyethylamine is composed of monoethanolamine and hydroxyethylethylenediamine, and monoethanolamine and hydroxyethylethylenediamine are mixed in a ratio of 1:3 (weight ratio) and placed on a corrosion-resistant coating. In the evaporating pot of the first layer, add water to dissolve, the weight ratio of polyhydroxyethylamine to water is 1:3, heat to 120°C while stirring, and the aqueous solution in the evaporating pot boils slightly;

[0057] b. Add hydrofluoric acid aqueous solution with a mass fraction of 10% dropwise into the evaporator, keep the aqueous solution slightly boiling, adjust the pH value between 6 and 8, and stop heating;

[0058] c. put the material in the evaporator into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com