Composite material, preparation method thereof and quantum dot light-emitting diode

A technology of quantum dot luminescence and composite materials, which is applied in the field of composite materials and its preparation, quantum dot light-emitting diodes, can solve the problems of unsatisfactory carrier transport performance, etc., and achieve the advantages of electron transmission, surface defect reduction, and uniformity scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

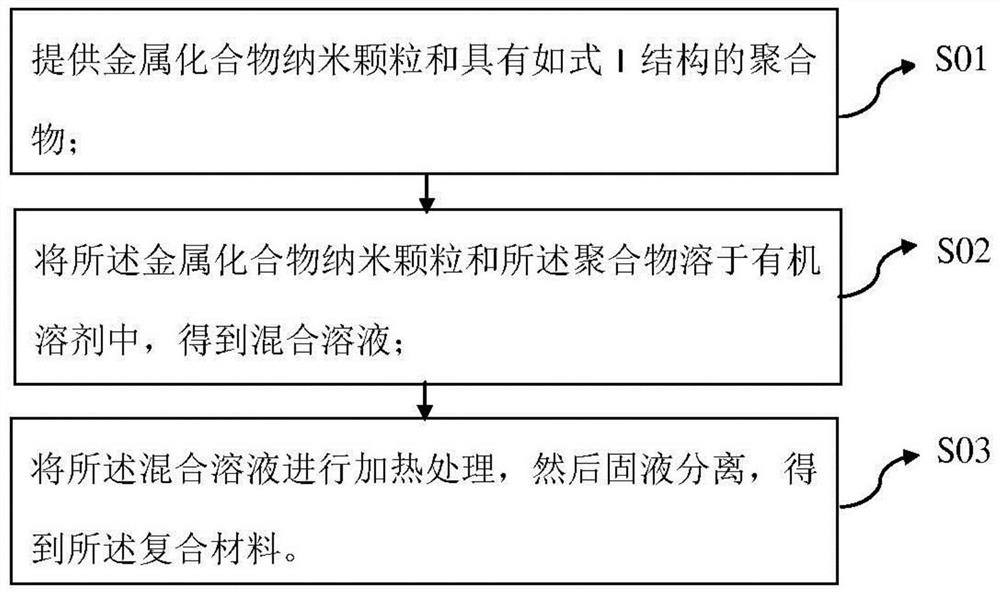

[0037] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, such as figure 1 Shown, this preparation method comprises the steps:

[0038] S01: providing metal compound nanoparticles and a polymer having a structure such as formula I;

[0039] S02: dissolving the metal compound nanoparticles and the polymer in an organic solvent to obtain a mixed solution;

[0040] S03: heat-treating the mixed solution, and then separating the solid and liquid to obtain the composite material.

[0041] The preparation method of the composite material provided by the embodiment of the present invention directly dissolves the metal compound nanoparticles and the polymer having the structure of formula I in an organic solvent and heats them, and then separates the solid and liquid to obtain the composite material, which has the advantages of simple process and low cost Features, suitable for large-scale, large-scale preparation, th...

Embodiment 1

[0078] The following uses zinc acetate, ethanol, potassium hydroxide, tetrahydrofuran (THF), 2,5-dibromo-3-hexylthiophene, and 2,5-dibromopyridine as examples for a detailed introduction.

[0079] 1) First, an appropriate amount of zinc acetate is added to 50ml of ethanol and stirred and dissolved at 70°C to form a zinc acetate solution with a total concentration of 0.5M. Then, potassium hydroxide was dissolved in 10ml of ethanol to obtain lye. mole ratio OH - : Zn 2+ =2:1 Mix the two to obtain a mixed solution with pH=12. Stirring was continued at 70 °C for 4 h to obtain a homogeneous transparent solution. Subsequently, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol, and the steps of precipitation and dissolution were repeated three times, followed by drying to obtain ZnO nanoparticles.

[0080] 2) Take an appropriate amount of 2,5-dibromo-3-hexylthiophene in 20ml of tetrahyd...

Embodiment 2

[0084] The following takes zinc nitrate, methanol, potassium sulfide, dimethylformamide (DMF), 2,5-dibromo-thiophene, and 2,5-dibromopyridine as examples for a detailed introduction.

[0085] 1) First, an appropriate amount of zinc nitrate was added to 50ml of methanol and stirred and dissolved at 60°C to form a zinc nitrate solution with a total concentration of 0.8M. Potassium sulfide was dissolved in 10ml of methanol to obtain lye. Massive S 2- : Zn 2+ =1.3:1, the two are mixed to obtain a mixed solution. Stirring was continued at 60 °C for 4 h to obtain a homogeneous solution. Subsequently, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of methanol, and the steps of precipitation and dissolution were repeated three times, followed by drying to obtain ZnS nanoparticles.

[0086] 2) Take an appropriate amount of 2,5-dibromo-thiophene in 20ml of dimethylformamide (DMF) to form a solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com