Self-separation method for preparing self-supporting GaN substrate

A self-supporting and self-separating technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems that cannot meet the needs of practical applications, achieve cost and quality control, avoid pollution, reduce The effect of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The steps of the self-separation method for preparing a self-supporting GaN substrate include:

[0024] (1) The substrate sapphire is cleaned and treated, and the uniformly distributed Ga is grown on the sapphire substrate by halide vapor phase epitaxy. 2 O 3 For thin film, the reaction system mainly contains two temperature zones. In the low temperature zone, the metal gallium reacts with HCl to produce GaCl as the gallium source, the temperature is controlled at 860℃; the oxygen source is the oxygen source, and the GaCl and O 2 The mixture reacts to obtain a gallium oxide film, and the temperature in the high temperature zone is 950°C. The pressure is 1 atmosphere, O 2 / Ga input flow ratio is 5. By adjusting the growth time, gallium oxide films of different thicknesses can be obtained. Control Ga 2 O 3 The growth thickness of the film is 1 micron.

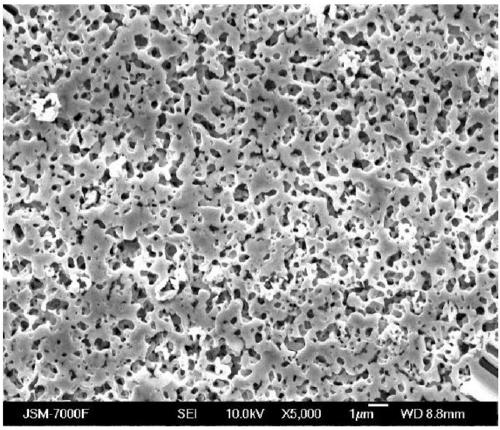

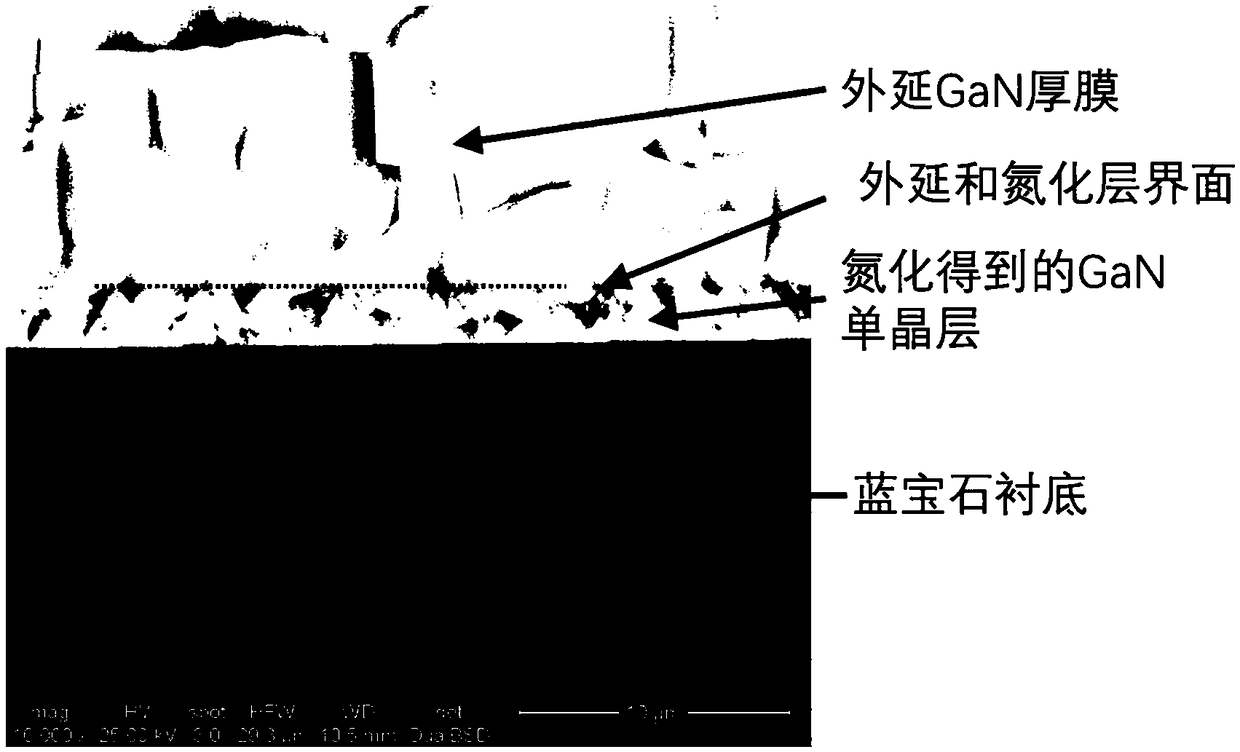

[0025] (2) The Ga 2 O 3 The film substrate is placed in a high-temperature tubular quartz furnace, and ammonia gas is passed...

Embodiment 2

[0029] The steps of the self-separation method for preparing a self-supporting GaN substrate include:

[0030] (1) The substrate sapphire is cleaned and treated, and the uniformly distributed Ga is grown on the sapphire substrate by halide vapor phase epitaxy. 2 O 3 Membrane, the reaction system mainly contains two temperature zones, in the low temperature zone, metal gallium and Cl 2 The reaction produces GaCl as a gallium source at a temperature of 850°C; oxygen as an oxygen source, GaCl and O in the high temperature growth zone 2 The mixture reacts to obtain a gallium oxide film, and the temperature in the high temperature zone is 850°C. The pressure is 1 atmosphere, O 2 / Ga input flow ratio is 1.5. By adjusting the growth time, gallium oxide films of different thicknesses can be obtained. Control Ga 2 O 3 The growth thickness of the film is 0.1 microns.

[0031] (2) The Ga 2 O 3 The film substrate is placed in a high-temperature tubular quartz furnace, and ammonia gas is passe...

Embodiment 3

[0035] The steps of the self-separation method for preparing a self-supporting GaN substrate include:

[0036] (1) The substrate sapphire is cleaned and treated, and the uniformly distributed Ga is grown on the sapphire substrate by halide vapor phase epitaxy. 2 O 3 For thin film, the reaction system mainly contains two temperature zones. In the low temperature zone, the metal gallium reacts with HCl to produce GaCl as the gallium source, and the temperature is 900℃; the oxygen source is the oxygen source, and the GaCl and O 2 The mixture reacts to obtain a gallium oxide film, and the temperature in the high temperature zone is 1050°C. The pressure is 1 atmosphere, O 2 / Ga input flow ratio is 15. By adjusting the growth time, gallium oxide films of different thicknesses can be obtained. Control Ga 2 O 3 The growth thickness of the film is 0.3 microns.

[0037] (2) The Ga 2 O 3 The film substrate is placed in a high-temperature tubular quartz furnace, and ammonia gas is passed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com