Self-separation peeling equipment

A self-separation and equipment technology, applied in the field of alloy profile processing, can solve the problems of reduced production efficiency, adhesion of processing components, and equipment cannot be continuously produced, and achieves the effect of improving automation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

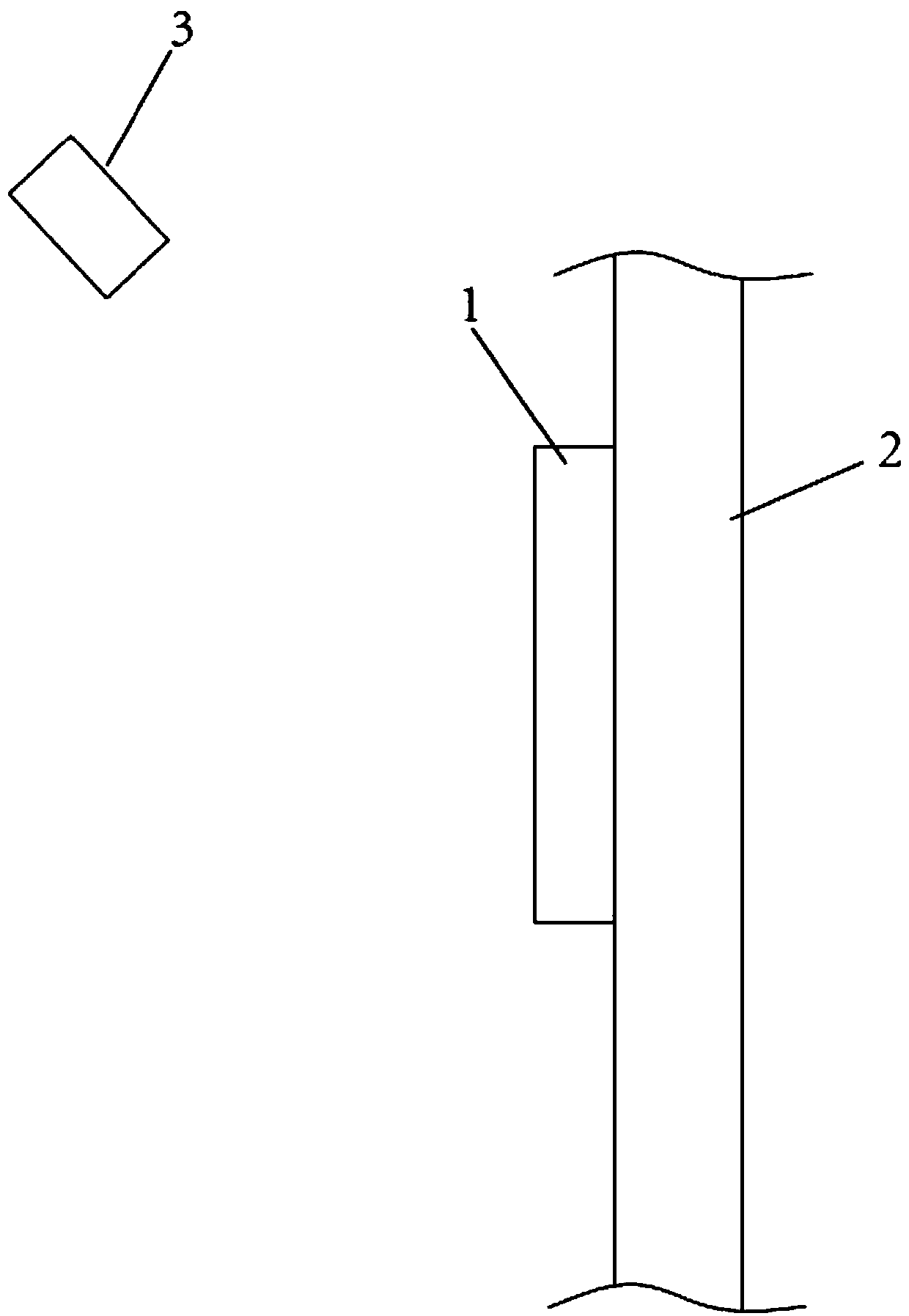

[0023] refer to figure 1 Shown, an embodiment of the self-separating peeling equipment of the present invention, it comprises:

[0024] The peeling tool 1 and the separation component 3, the peeling tool 1 is arranged on the frame 2, and is used for peeling the profiles; the separation component 3 is arranged on the side of the peeling end face of the peeling tool 1, and the separation component 3 transfers the auxiliary separator to the peeling end face On the other hand, the peeled leather can be easily separated from the peeling tool by its own weight, realizing the self-separation effect.

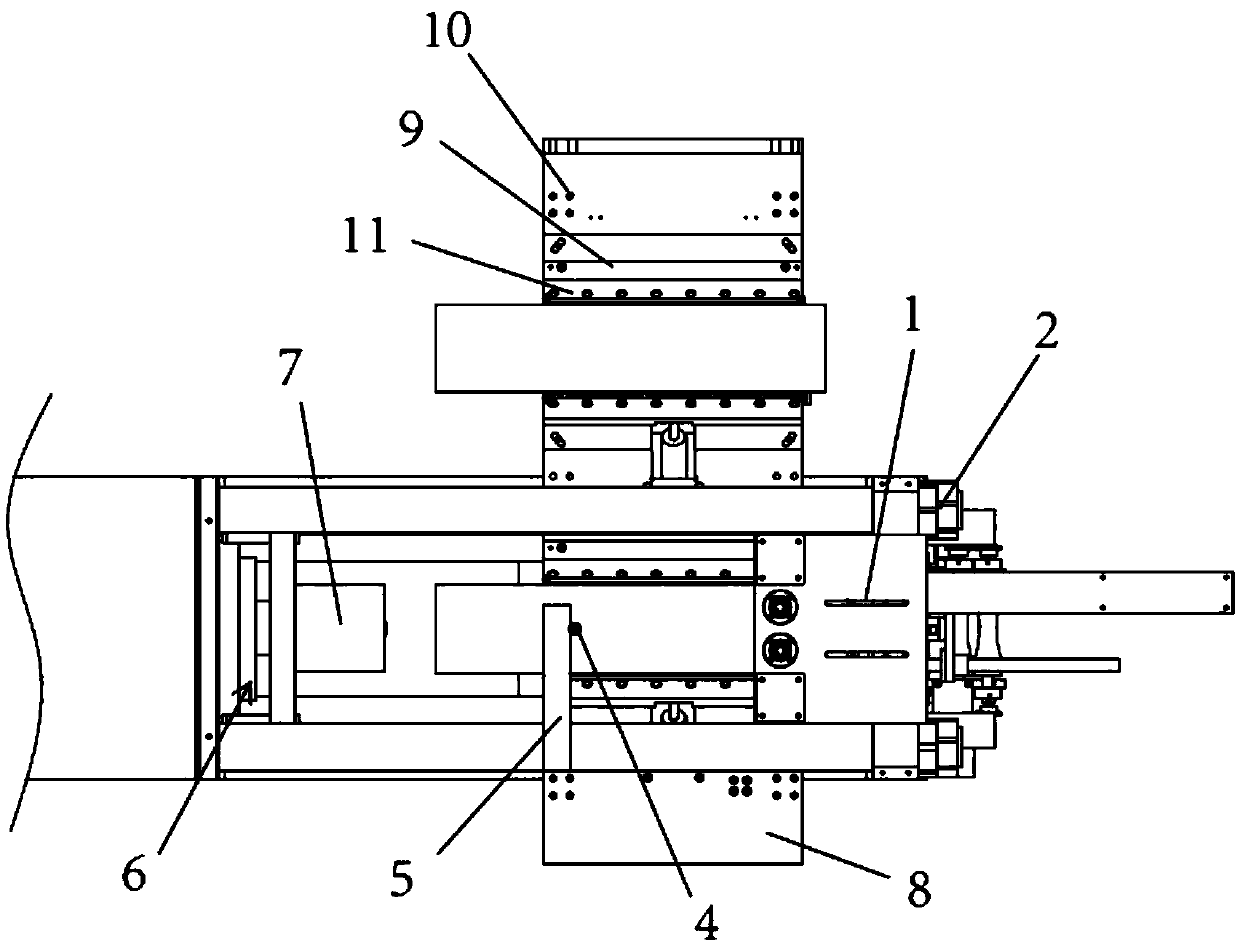

[0025] refer to figure 2 As shown, in one embodiment, the separation assembly 3 includes a spray head 4, the spray head 4 is connected to the spray part, and the spray part is used to supply pressure to the separation liquid, and then spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com