Method for carrying out diameter two-point six-transposition measurement on roundness error of large-scale shaft part and kinematic error of machine tool spindle

A technology for shaft parts and roundness error, which is used in the field of measuring the roundness error of large shaft parts and the motion error of the machine tool spindle at two points and six positions on the diameter, and can solve the problems of error separation and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The specific implementation of the present invention is described in detail as follows in conjunction with accompanying drawing:

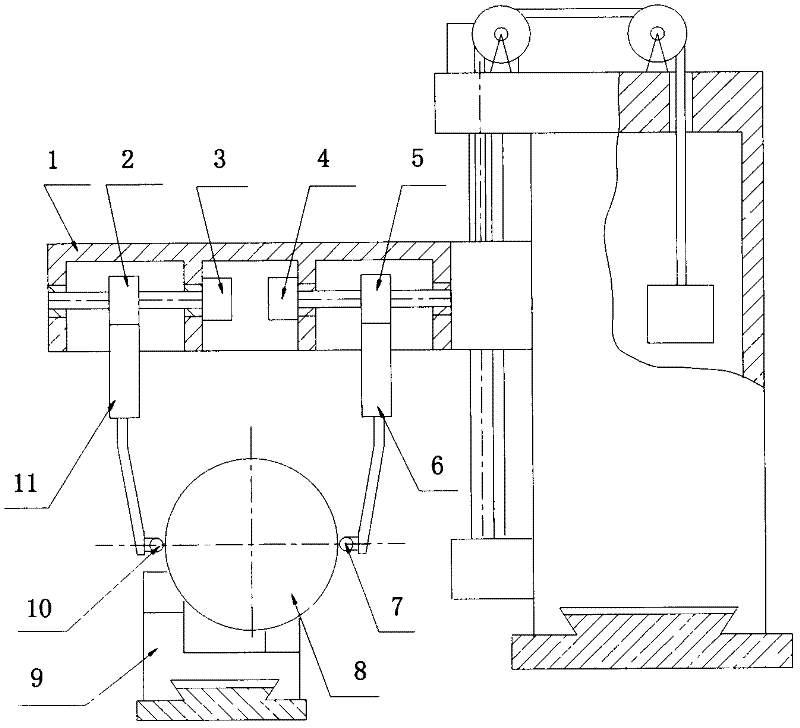

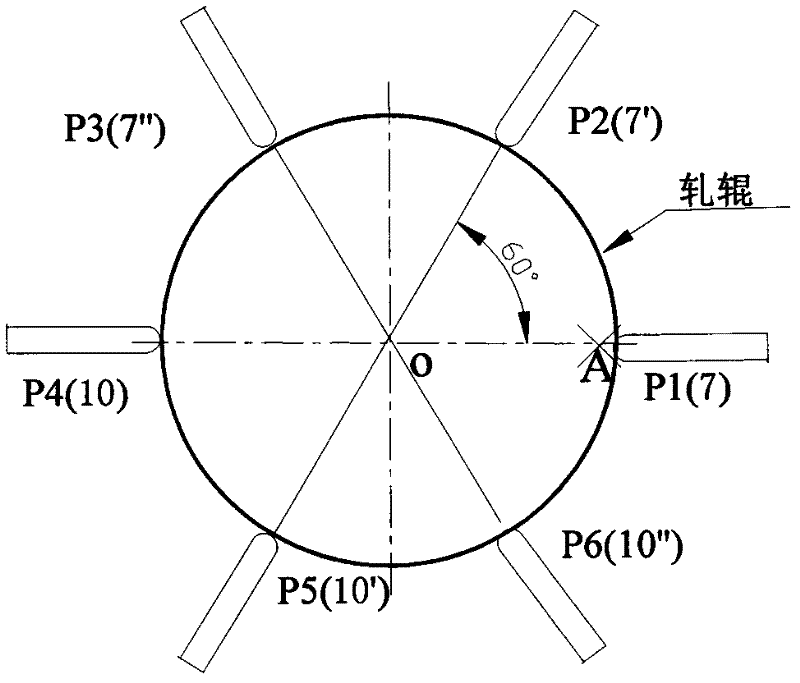

[0085] Such as figure 1 As shown, the ball screw pairs 5 and 2 are driven by the servo motors 3 and 4, so that the two sensor measuring heads 7 and 10 installed on the measuring arms 6 and 11 are located on the center line of the large shaft part 8. During the measurement process, the measurement of large shaft parts is measured three times with reference to the starting point A, and the two sensors obtain the measurement series values of six positions in total. At the same time, the rotation of large shaft parts must be accurately graduated. The rotation angle of large shaft parts relative to the measurement reference starting point A is shown in Table 1, and the speed of large shaft parts is shown in Table 2.

[0086] Symbol Description:

[0087] N: The weekly sampling points of the measurement sensor;

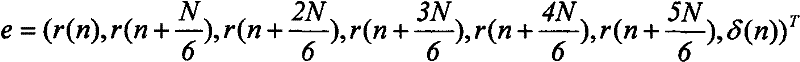

[0088] the y k (n): the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com