Diameter and parallel multiple-position measurement method for roller roundness error and machine tool principal axis movement error

A technology of motion error and roundness error, which is applied in the field of diameter and parallel multi-position measurement of roll roundness error and machine tool spindle motion error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

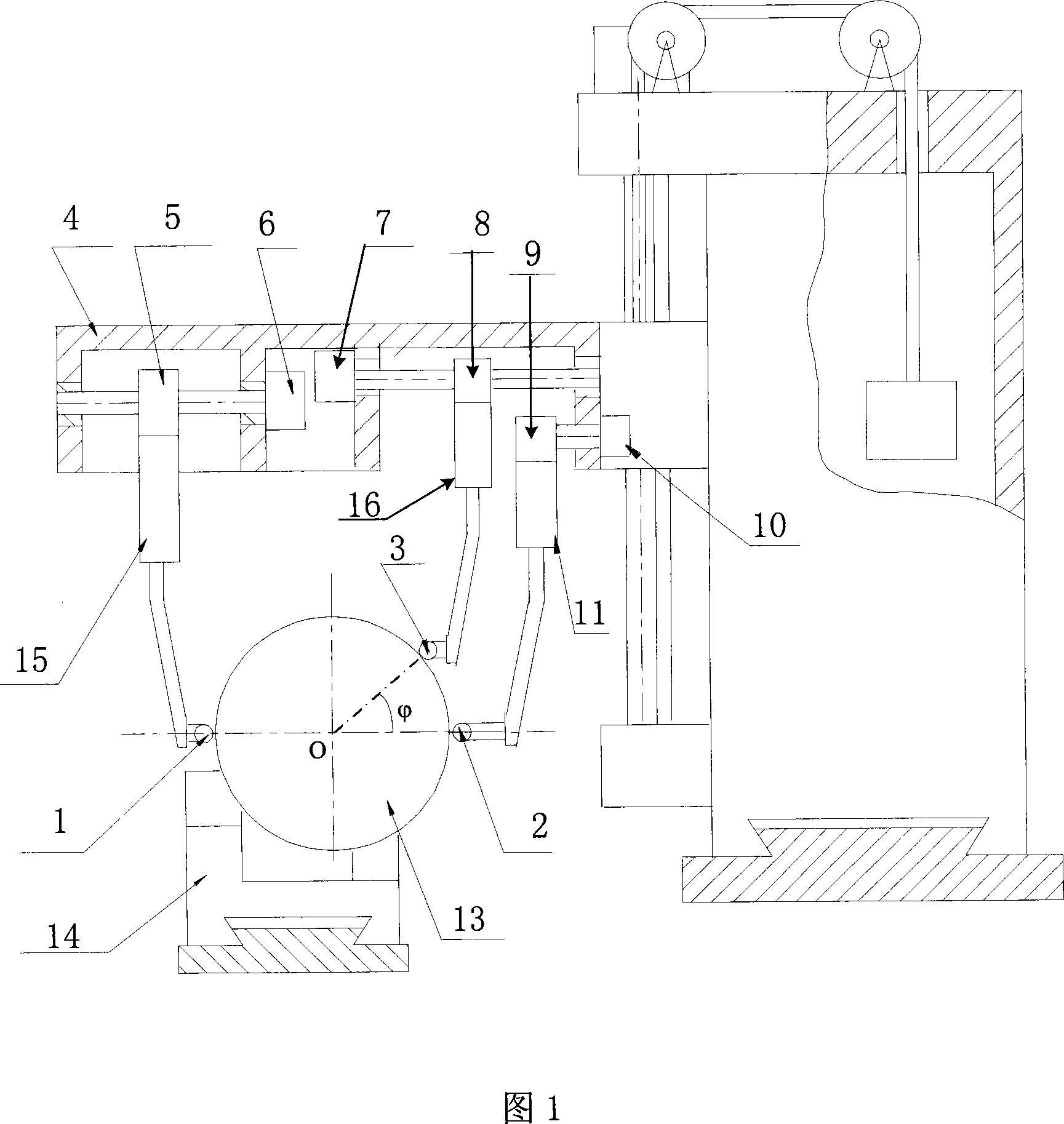

[0040] A preferred example of the present invention is described in detail as follows in conjunction with accompanying drawing:

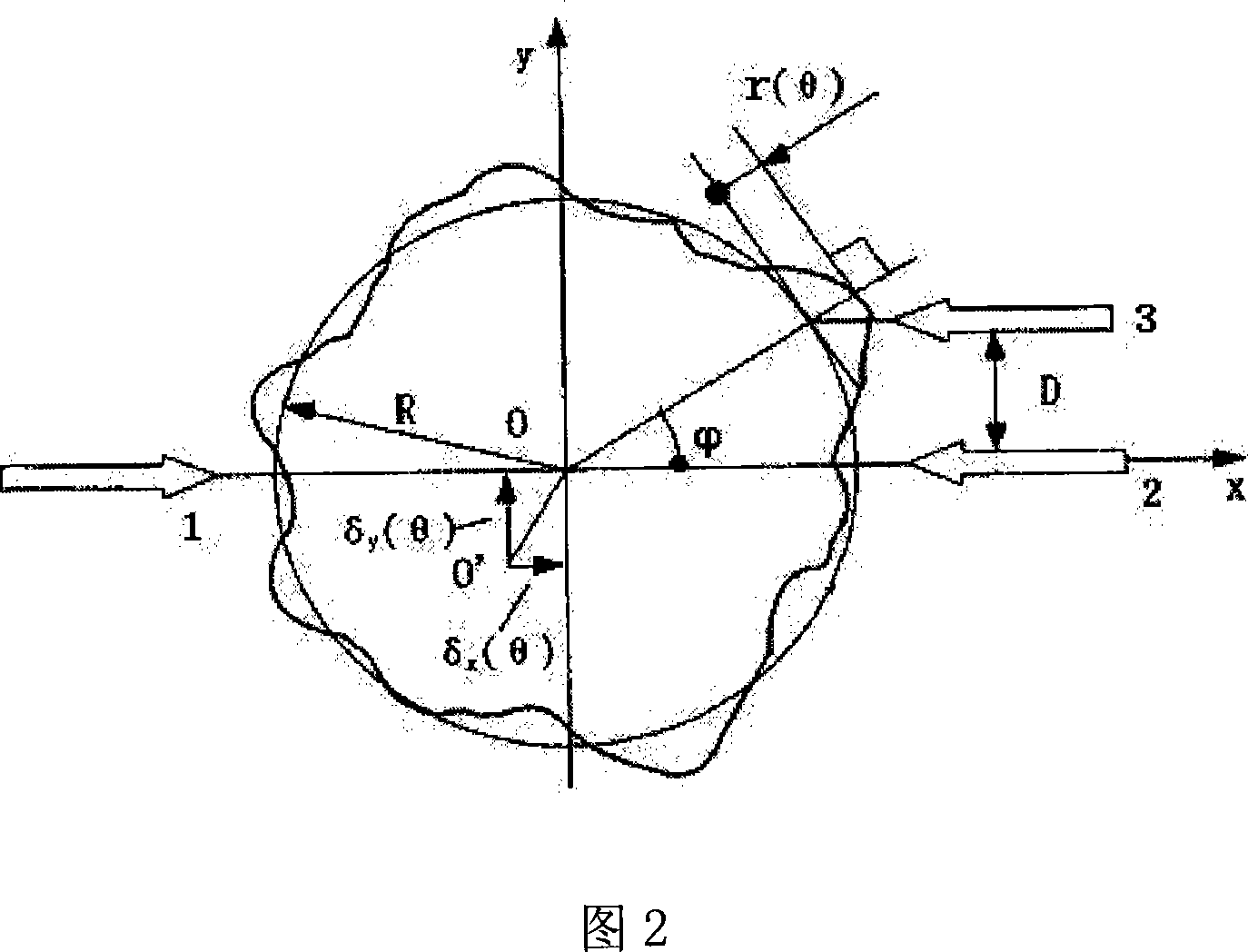

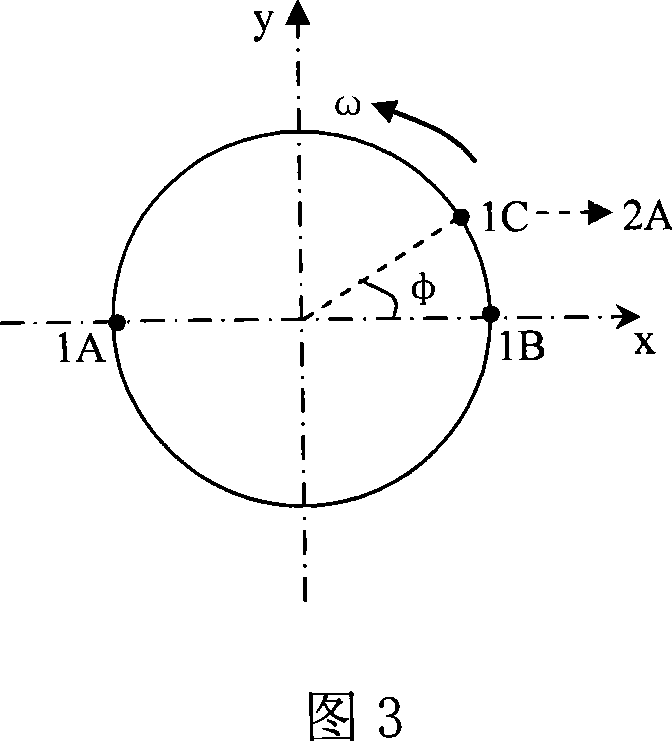

[0041] The method for measuring the roundness error of the roll and the error of the machine tool spindle in the diameter and parallel multi-position adopts the measuring device shown in Fig. , 7 and 10 drives, the ball screw pair 8 needs to set the critical position as the boundary line of the ball screw pair 9, so as to avoid collision with the ball screw pair 9 during the measurement process. The measuring heads of the two sensors 1 and 2 and the measuring head of the sensor 3 parallel to the sensor 2 are installed on the measuring arms 15, 11 and 16 respectively, and driven by the ball screw pairs 5, 8 and 9 respectively. come to contact the roll 13 on the central support 14, thereby realizing the measurement of rolls with different diameters. The sensor measuring heads 1 and 2 should be located on the center line of the roll 13, and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com