Method and device for measuring main shaft rotary errors with capacity of installation eccentricity separation

A technology of rotation error and measuring device, applied in the direction of measuring device, instrument, etc., can solve problems such as complex calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

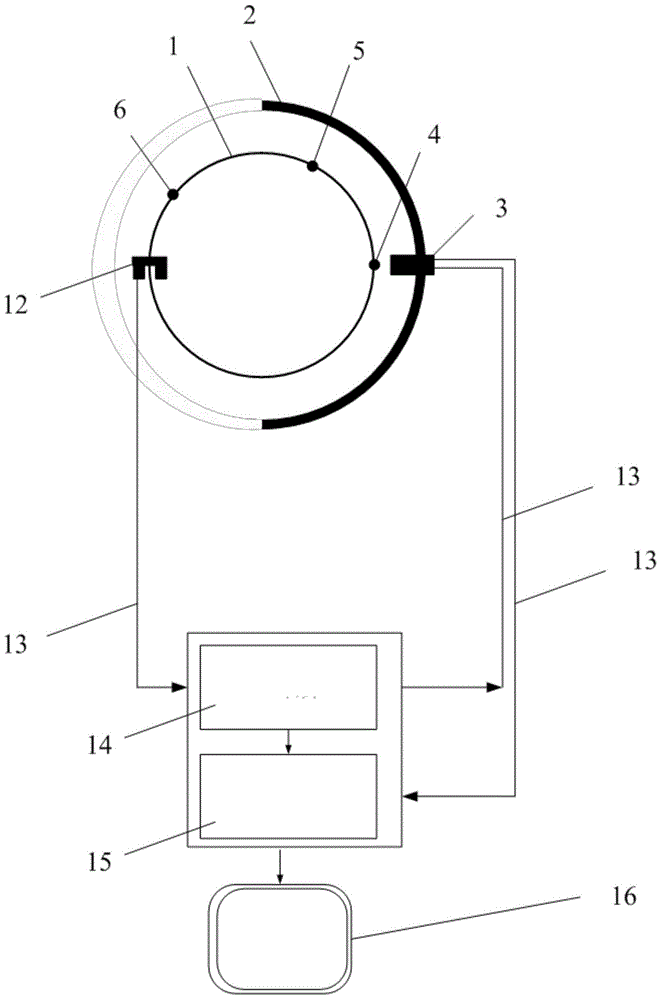

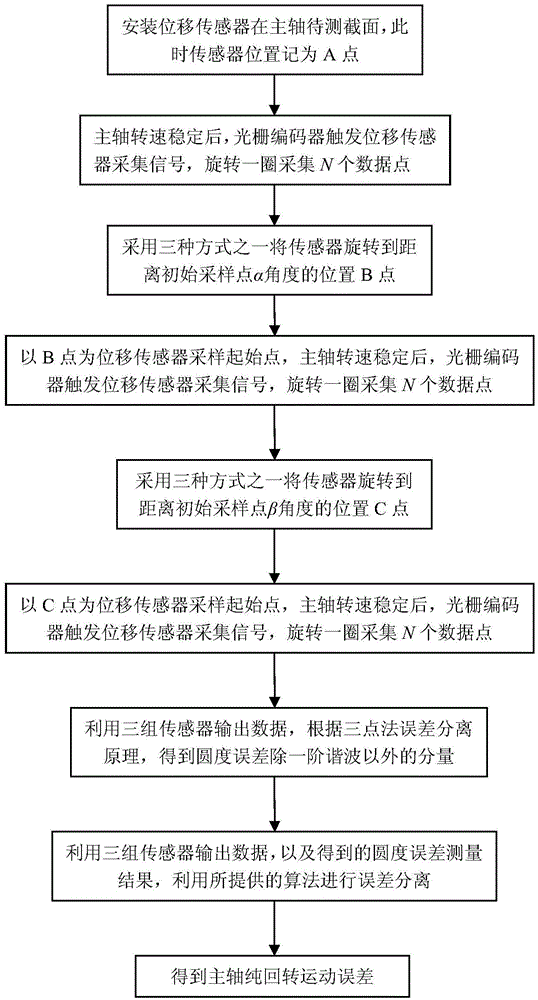

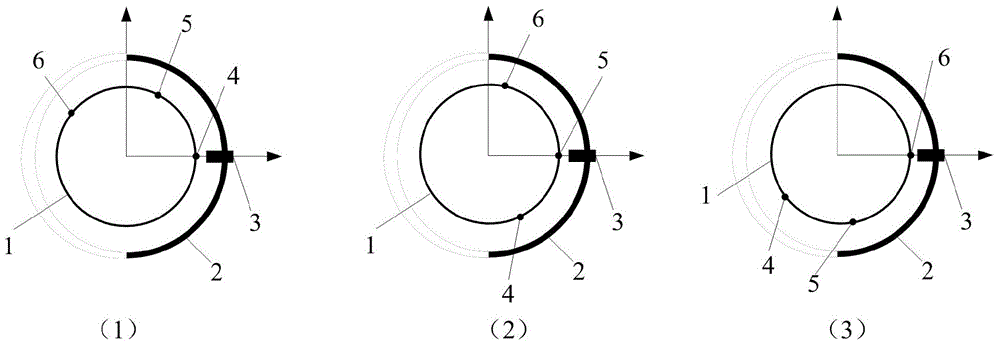

[0047] Such as figure 1 As shown: the displacement sensor (3) is installed on the displacement sensor holder (2), the sensitive axis of the displacement sensor (3) is aligned with the edge of the outer contour of the spindle or the standard ball, after the spindle (1) rotates at a stable speed, the grating encoder (12) is the trigger and positioning signal, the main shaft (1) rotates clockwise for one circle, and the displacement sensor (3) collects N displacement data, denoted as S 0 (θ). Such as figure 2 As shown, the displacement sensor holder (2) and the displacement sensor (3) remain stationary, and the driving spindle (1) is rotated clockwise by an angle α, which is used as the sampling starting point of the displacement sensor (3), and the spindle (1) is clockwise The hour hand rotates one circle, and the displacement sensor (3) collects N displacement data, denoted as S 1 (θ); Displacement sensor holder (2) and displacement sensor (3) remain still, drive the main s...

Embodiment 2

[0062] Such as figure 1As shown: the displacement sensor (3) is installed on the displacement sensor holder (2), the sensitive axis of the displacement sensor (3) is aligned with the edge of the outer contour of the main shaft (1) or the standard ball, after the main shaft (1) rotates at a stable speed, The grating encoder (12) is a trigger and positioning signal, the main shaft (1) rotates one circle clockwise, and the displacement sensor collects N displacement data, denoted as S 0 (θ). Such as image 3 Shown: Rotate the displacement sensor holder (2) clockwise by the angle α, which is the sampling starting point of the displacement sensor (3), the main shaft (1) rotates clockwise for one circle, and the displacement sensor (3) collects N displacement data respectively , denoted as S 1 (θ). Then rotate the displacement sensor holder (2) clockwise by the angle β, and use this as the sampling starting point of the displacement sensor (3), the main shaft (1) rotates clockwi...

Embodiment 3

[0077] Such as figure 1 with Figure 4 As shown: the displacement sensor holder (2) is designed to have three displacement sensor installation holes, and the angles between the three displacement sensor installation positions are designed as follows: the first displacement sensor installation position and the second displacement sensor installation position The included angle between the positions is α, and the included angle between the installation position of the first displacement sensor and the installation position of the third displacement sensor is β. First, the displacement sensor (3) is installed at the position (11) of the holder, and the sensitive axis is aligned with the outer contour edge of the main shaft or the standard ball. After the main shaft (1) rotates at a stable speed, the grating encoder (12) is used as the trigger and positioning signal. The main shaft (1) rotates one circle clockwise, and the displacement sensor (3) collects N displacement data, den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com