Bar centerless grinding technology and special knife board adjusting device thereof

A centerless grinding and bar technology, applied in the field of machining, can solve the problem that the outer circular surface cannot guarantee the coaxiality, and achieve the effect of eliminating or reducing the original roundness error, convenient debugging and maintenance, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

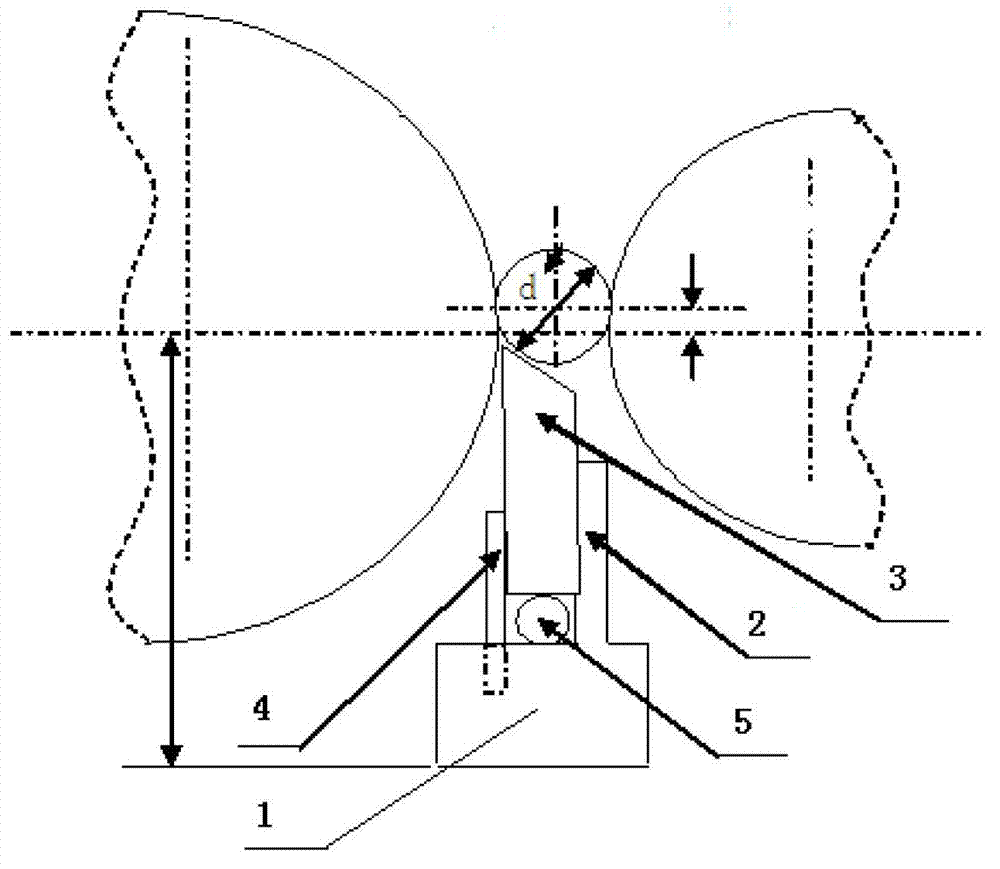

[0031] The present invention will be further explained below in conjunction with the drawings and embodiments.

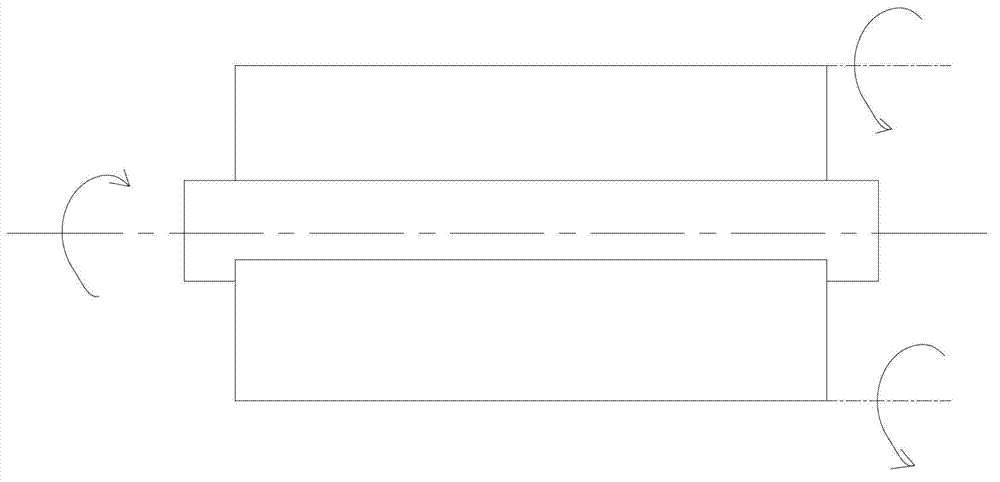

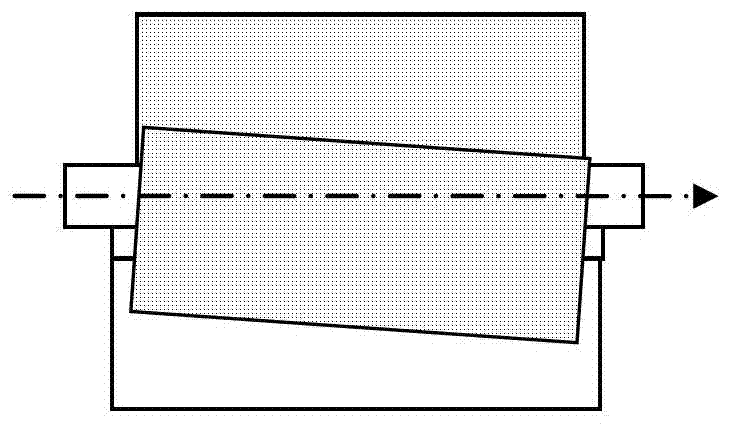

[0032] As attached image 3 As shown, a centerless grinding process for bar materials includes the following steps: first, rough machining the bar materials so that the workpiece allowance is between 0.3 and 0.5 mm, the roundness error is below 0.10 mm, and the straightness is within Within 1mm / m.

[0033] Then train the guide wheel, adjust the speed of the guide wheel to the fastest, turn on the hydraulic system and the guide wheel; trim the guide wheel before processing, adjust the speed of the guide wheel to the fastest, turn on the hydraulic system and the guide wheel. When correcting the guide wheel, adjust the diamond drill down little by little until it just touches the guide wheel. Then correct the guide wheel according to the scale on the corrector, and adjust 5 small divisions down at a time. The correction speed can be faster at the beginning and slower in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com