Method for separating and handling thermal error, roundness error and turning error of main shaft of machine tool

A roundness error, machine tool spindle technology, used in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as simultaneous separation, and achieve the effect of improving accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

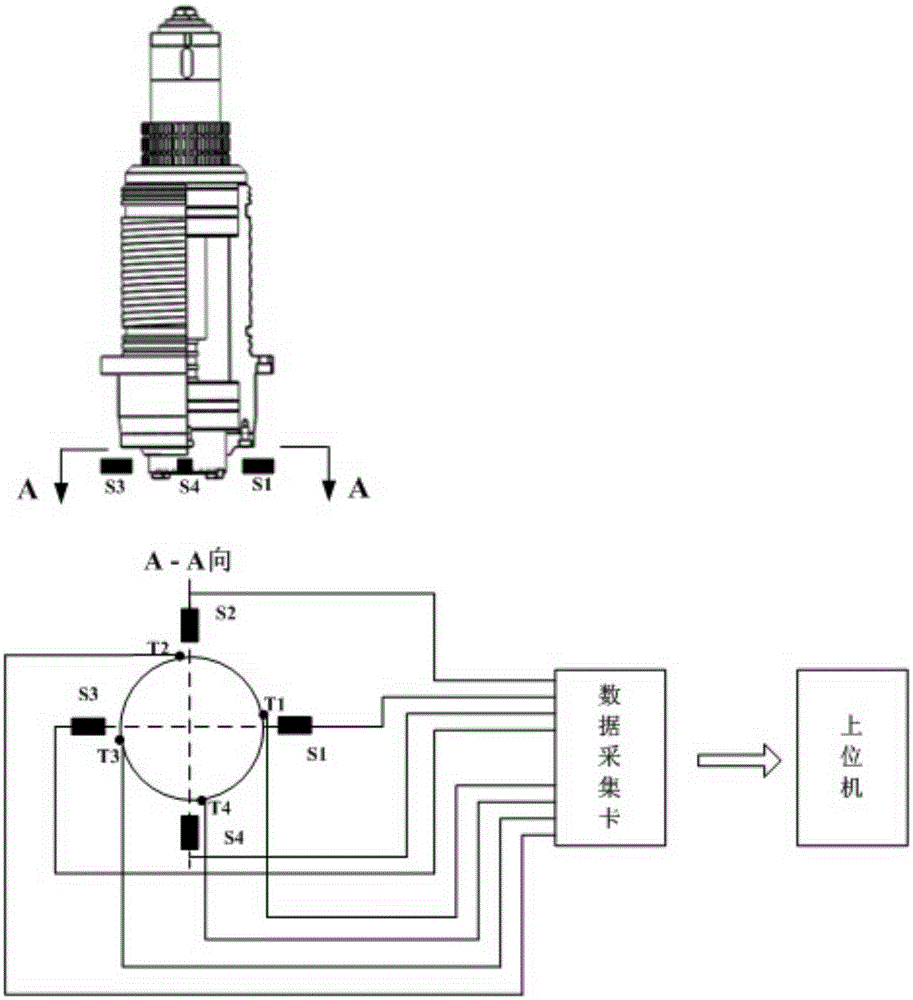

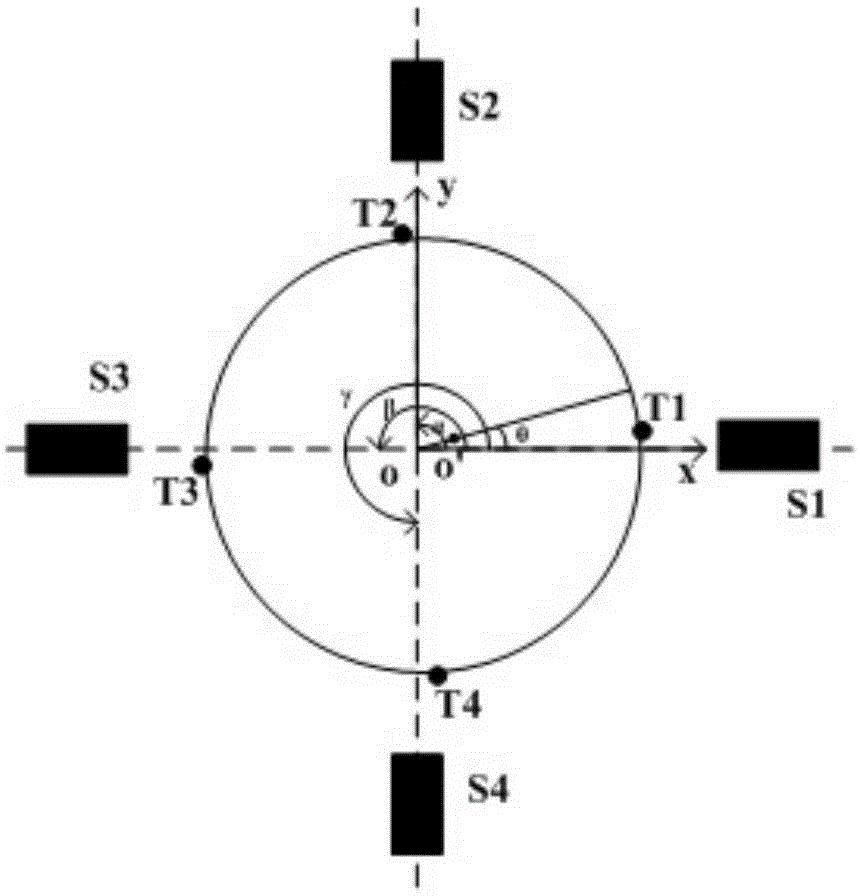

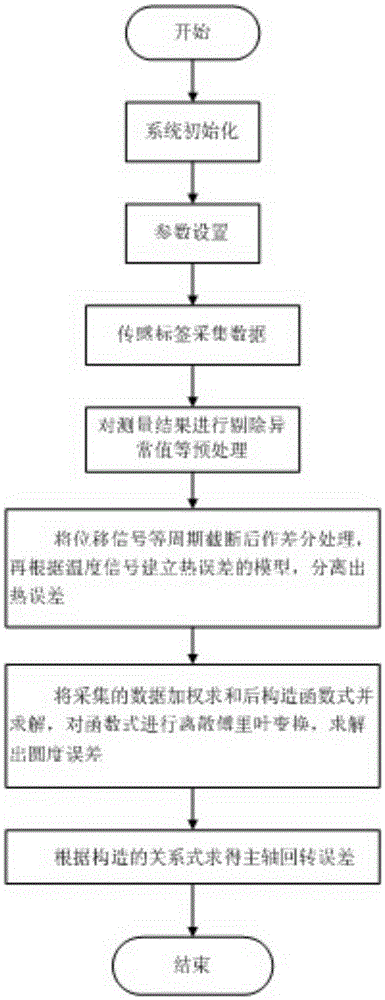

[0058] Such as Figure 1-3 Shown, T 1 , T 2 , T 3 , T 4 For the four temperature sensors, the digital integrated temperature sensor DS18B20 produced by DALLAS Company of the United States is selected. It is a digital signal output, with high detection accuracy, wear resistance and impact resistance, small size, and easy to use. S 1 , S 2 , S 3 , S 4 For the four eddy current sensors, choose the DH901 eddy current sensor from Donghua Testing Cable Co., Ltd., whose output signal is a voltage signal of -5 ~ +5V, with good reliability, high sensitivity, strong anti-interference ability, fast response speed, and no Affected by media such as oil and water. Four temperature sensors and four eddy current sensors are evenly distributed radially along the main shaft, and the signals collected by the sensors are transmitted to the upper computer system through the data acquisition card.

[0059] In the four-point error separation of the present invention, O is four eddy current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com