Improved three-point method for turning error and roundness error measurement

A technology of roundness error and rotation error, which is applied in the field of improving the three-point method, can solve the problem of limited improvement of the accuracy of the three-point method, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

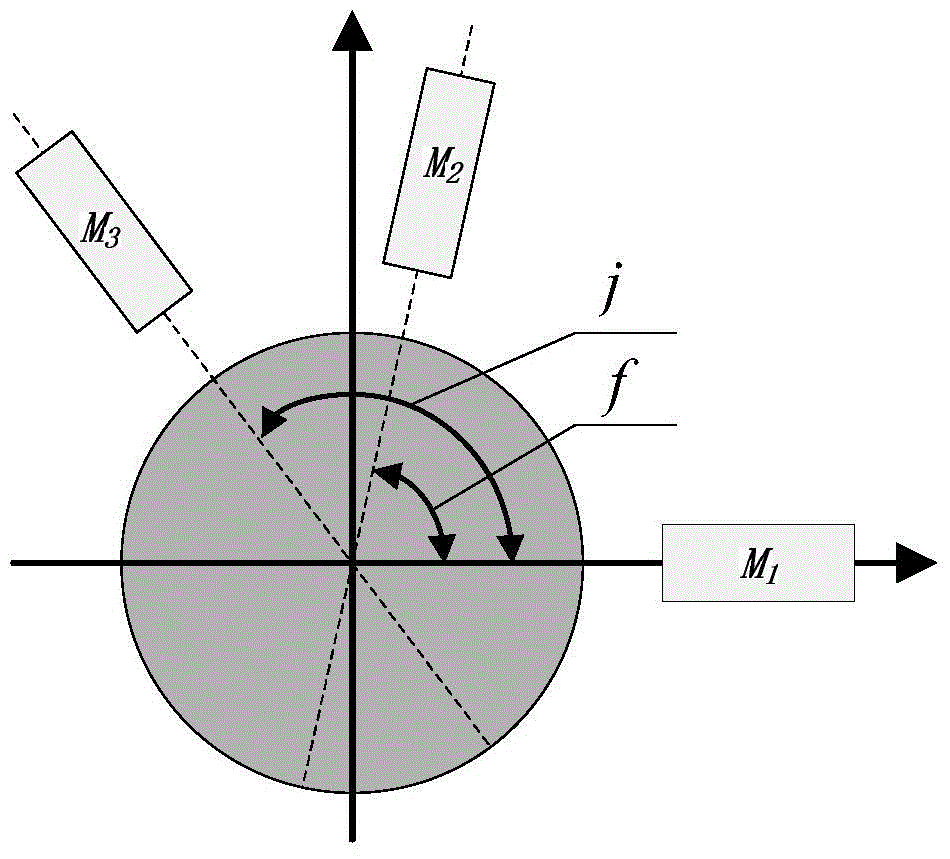

[0022] The traditional three-point method test such as figure 1 As shown, three laser displacement sensors measure the radial runout of the surface of the cylindrical inspection rod, and the Fourier coefficient of the roundness error of the inspection rod is calculated by the method of harmonic analysis, and then the roundness error is obtained through Fourier synthesis calculation.

[0023] An improved three-point method for measurement of rotation error and roundness error, comprising the following steps:

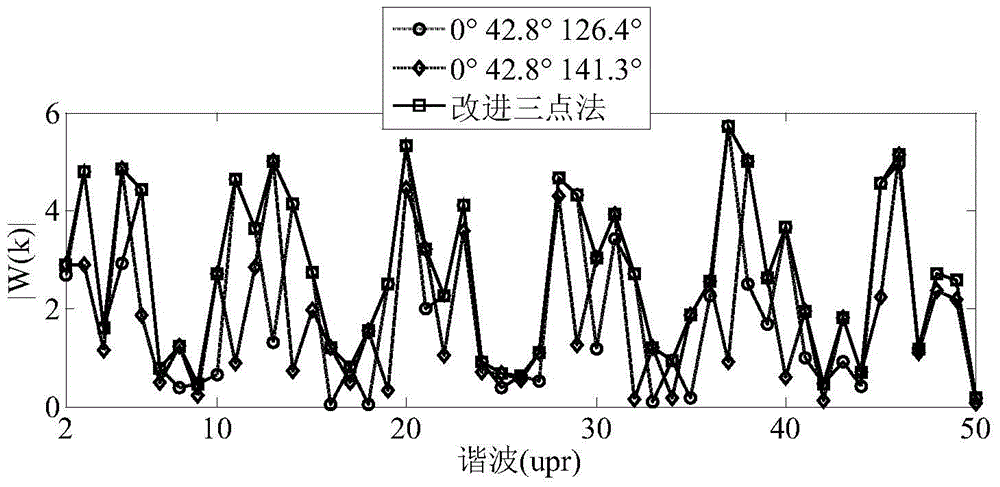

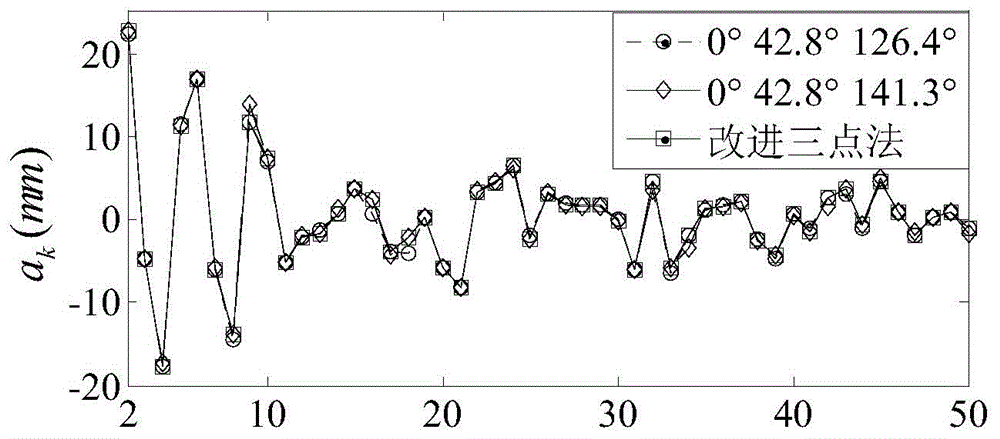

[0024] Step 1, the three laser displacement sensors M 1 ,M 2 ,M 3 Mounted at different angular positions with a magnetic base: [0°, 42.8°, 126.4°], record the sensor measurement results with a high-frequency data acquisition system, and then use the three-point error separation technique to calculate the roundness error r(q) Each harmonic Fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com