Roundness error evaluating method based on EMD (empirical mode decomposition)

An empirical mode decomposition and roundness error technology, applied to measuring devices, instruments, etc., can solve problems such as difficult to obtain satisfactory results, different analysis results, difficult to master, etc., to achieve easy programming, fast and convenient analysis process, and easy to master Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

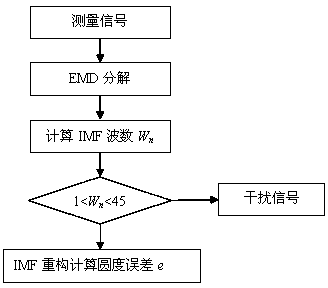

[0033] The method of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] figure 1 It is a flow chart of the roundness error estimation method based on empirical mode decomposition, and the specific implementation steps are as follows:

[0035] Step 1: Collect equiangular data from 0 to 360° around the rotation center of the workpiece, divide the circumference into N equal parts, and obtain the distance data from the edge to the rotation center, that is, the radius x(θ j ), where j is an integer from 0 to N, θ j =j*360 / N.

[0036] Step 2: EMD decomposition is performed on the measured radius data, and various components in the signal are decomposed into several IMF components and a residual component. The specific decomposition process is as follows:

[0037] (1) Determine the signal x(θ j ) all local extreme points, use cubic splines to connect all local maximum points to form an upper envelope, and then use cubic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com