Reinforced concrete precast member containing steel plate

A technology of reinforced concrete and prefabricated parts, applied in the direction of load-bearing elongated structural components, building components, structural elements, etc. Normal use and other problems, to achieve the effect of good durability, improved ductility, and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

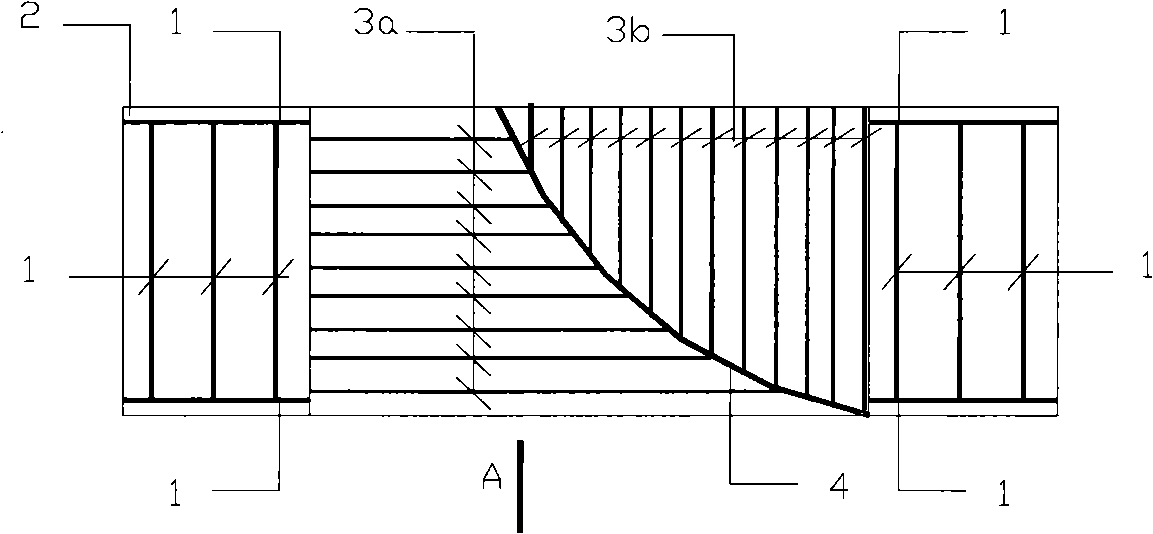

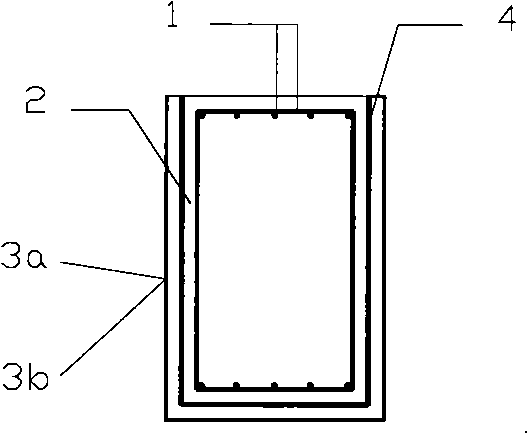

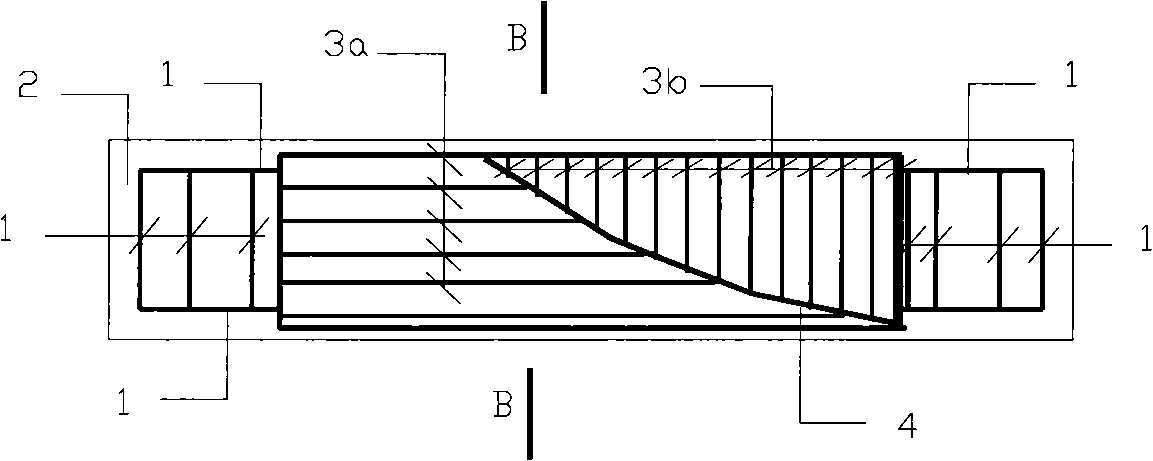

[0014] exist figure 1 In the preferred embodiment of the present invention shown, the beam is a prefabricated reinforced concrete structure prefabricated part of a certain building. The stress situation in the middle of the beam is relatively complicated and the environment is relatively harsh. In the case of a rich safety factor, cracks will still appear, resulting in Therefore, in the prefabrication process of beams, when the concrete is about to solidify, for areas prone to cracks, roll the cut steel plate 3 soaked with epoxy-based adhesive resin 4 on the concrete On the surface of the protective layer 2, the steel plate 3 used in this embodiment has a designed tensile strength of 210 MPa and a thickness of 5 mm. In this example, the double-layer reinforcement method is adopted. First, a layer of steel plate 3b is pasted along the vertical direction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com