Nuclear power dragging abrasion-resistant cable

A technology for towing and cables, which is applied in the field of wear-resistant towing cables for nuclear power plants, can solve the problems of dragging, twisting and scratching of towing cables, fewer towing cables, and easy damage, etc., and achieves high rigidity, enhanced axial tensile strength, Good effect of cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

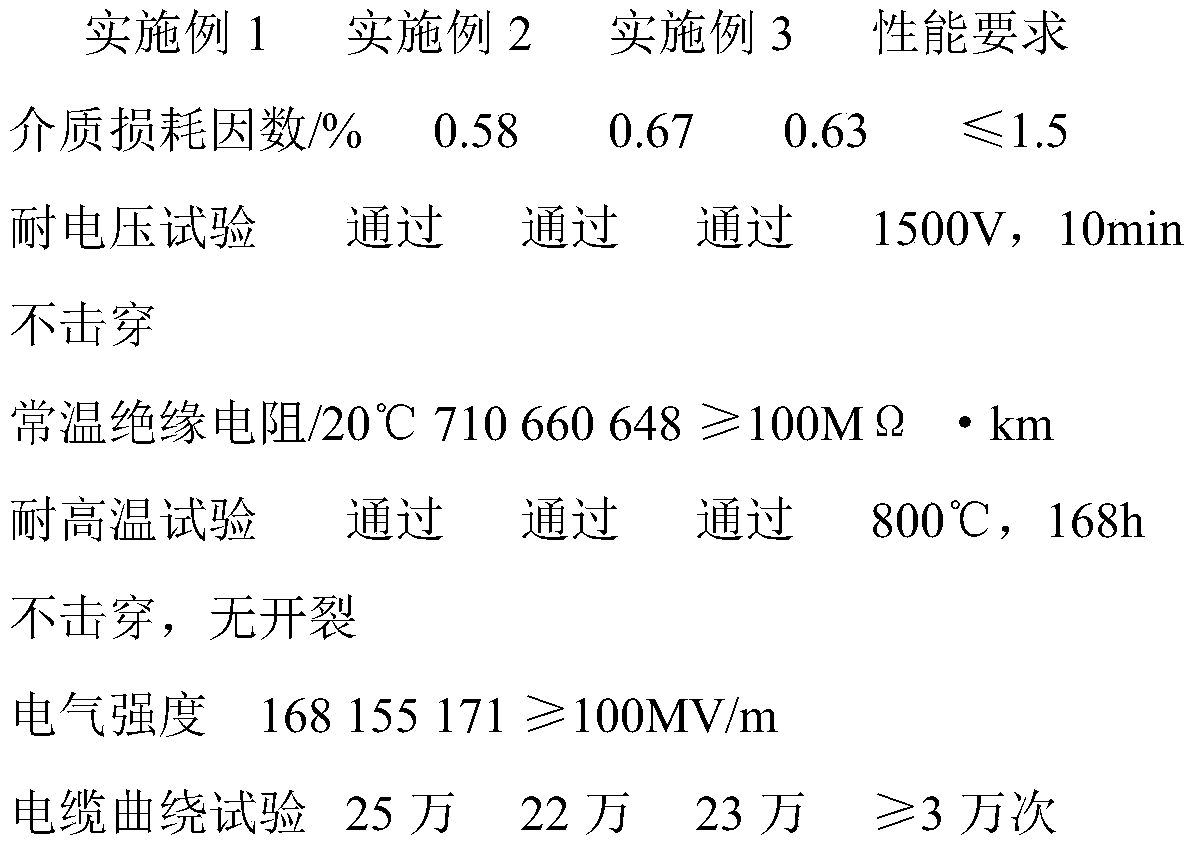

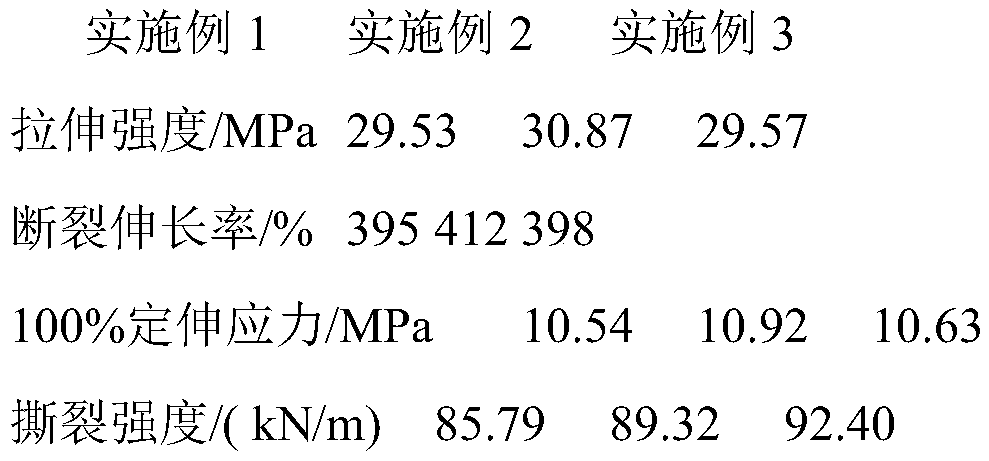

Embodiment 1

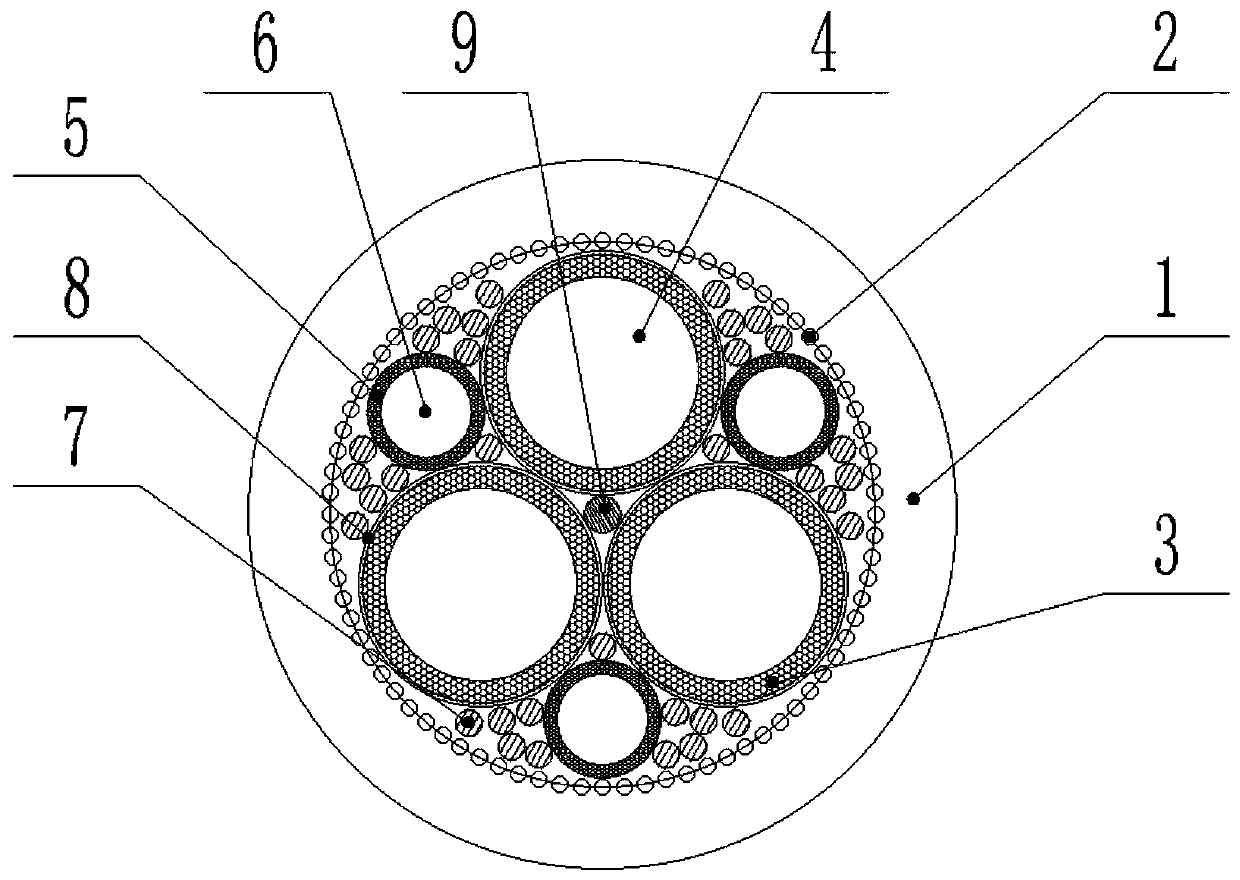

[0037] A wear-resistant towing cable for nuclear power, comprising an outer sheath 1, a shock absorbing sleeve 2, 3 main wires, 3 ground wires, multiple filling strips 7, and a cable core 9;

[0038] The outer sheath 1 is made of compound chain extender block modified TPU and wear-resistant masterbatch, and the outer sheath 1 is tightly covered on the outside of the shock-absorbing sleeve 2; the shock-absorbing sleeve 2 is made of reinforced natural rubber material; the main line Including the main line conductor 4 and the main line insulating sleeve 3 tightly wrapped on the outside of the main line conductor 4, the outer circumference of the main line is twisted with an aluminum-plastic composite film 8; the ground line includes a ground line conductor 6 and a ground line tightly wrapped on the outside of the ground line conductor 6 The insulating sleeve 5; the cable core 9 is arranged in the center, and the main wire is twisted along the cable core 9 in an equilateral triangl...

Embodiment 2

[0048] A wear-resistant towing cable for nuclear power, comprising an outer sheath 1, a shock absorbing sleeve 2, 3 main wires, 3 ground wires, multiple filling strips 7, and a cable core 9;

[0049] The outer sheath 1 is made of compound chain extender block modified TPU and wear-resistant masterbatch, and the outer sheath 1 is tightly covered on the outside of the shock-absorbing sleeve 2; the shock-absorbing sleeve 2 is made of reinforced natural rubber material; the main line Including the main line conductor 4 and the main line insulating sleeve 3 tightly wrapped on the outside of the main line conductor 4, the outer circumference of the main line is twisted with an aluminum-plastic composite film 8; the ground line includes a ground line conductor 6 and a ground line tightly wrapped on the outside of the ground line conductor 6 The insulating sleeve 5; the cable core 9 is arranged in the center, and the main wire is twisted along the cable core 9 in an equilateral triangl...

Embodiment 3

[0059] A wear-resistant towing cable for nuclear power, comprising an outer sheath 1, a shock absorbing sleeve 2, 3 main wires, 3 ground wires, multiple filling strips 7, and a cable core 9;

[0060] The outer sheath 1 is made of compound chain extender block modified TPU and wear-resistant masterbatch, and the outer sheath 1 is tightly covered on the outside of the shock-absorbing sleeve 2; the shock-absorbing sleeve 2 is made of reinforced natural rubber material; the main line Including the main line conductor 4 and the main line insulating sleeve 3 tightly wrapped on the outside of the main line conductor 4, the outer circumference of the main line is twisted with an aluminum-plastic composite film 8; the ground line includes a ground line conductor 6 and a ground line tightly wrapped on the outside of the ground line conductor 6 The insulating sleeve 5; the cable core 9 is arranged in the center, and the main wire is twisted along the cable core 9 in an equilateral triangl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com