A rectangular winding fiberglass

A glass fiber reinforced plastic, rectangular technology, applied in the direction of glass/slag layered products, coatings, layered products, etc., can solve the problems of low stiffness, high construction requirements, large deformation, etc., to achieve high strength and improved axial tensile strength. , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

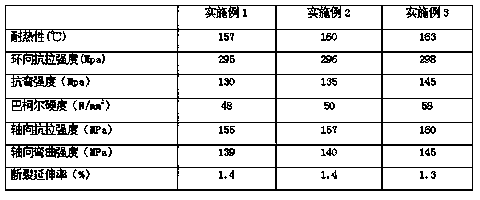

Embodiment 1

[0043]A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0044] The inner liner slurry is made of the following raw materials in parts by mass: 80 parts of vinyl resin, 80 parts of epoxy vinyl ester resin, 5 parts of curing agent, 6 parts of accelerator, 20 parts of glycerin, 16 parts o...

Embodiment 2

[0079] A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0080] The inner liner slurry is made of the following raw materials in parts by mass: 90 parts of vinyl resin, 60 parts of epoxy vinyl ester resin, 10 parts of curing agent, 2 parts of accelerator, 30 parts of glycerin, 10 parts...

Embodiment 3

[0115] A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0116] The inner liner slurry is made of the following raw materials in parts by mass: 88 parts of vinyl resin, 70 parts of epoxy vinyl ester resin, 5 parts of curing agent, 4 parts of accelerator, 25 parts of glycerin, 13 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com