Continuous axial fiber arrangement method and its equipment

An arrangement method and axial technology, applied in the field of general machinery and equipment, can solve the problems of low production efficiency, low tensile strength of short fibers, and inability to improve the overall quality of the pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

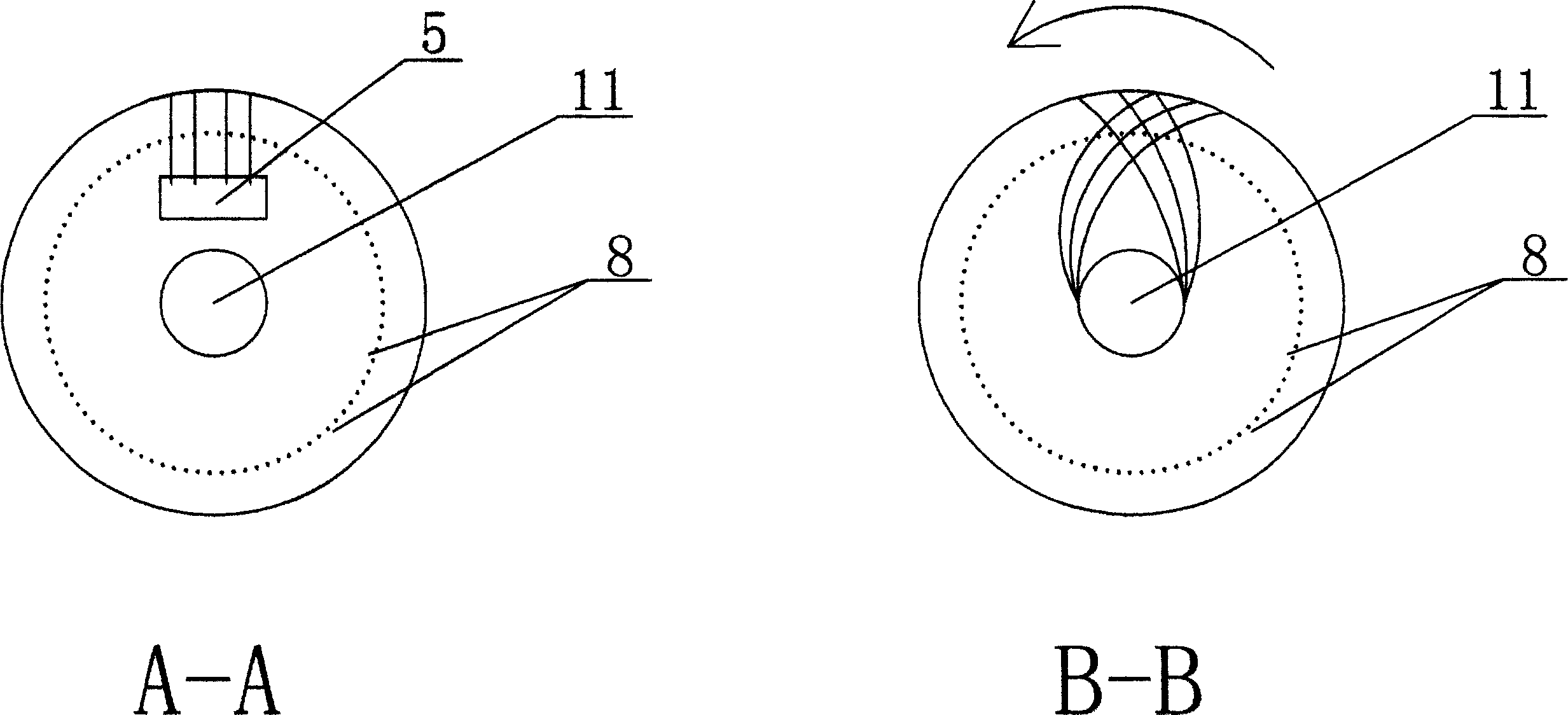

[0019] The arrangement of the continuous axial fiber bands with an angle of zero to the axial direction of the pipe is preferably arranged in such a way that the width of the continuous axial fiber bands is reciprocally arranged to be a multiple of π value or π value, because the circumference of a circle=π×diameter, such continuous The axial fiber bands can evenly cover the circumferential surface of the mold without overlap and leakage between the fiber bands.

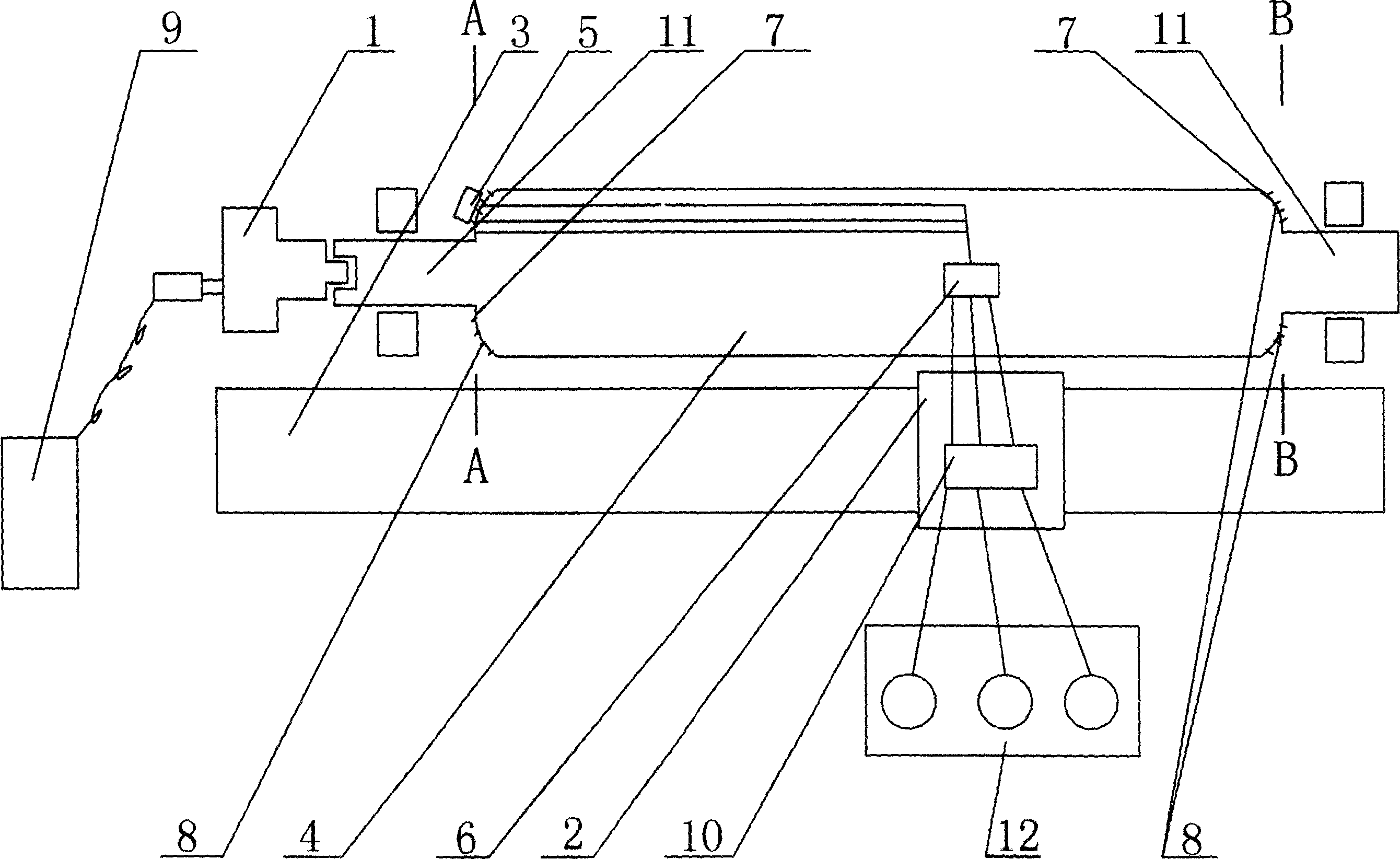

[0020] The specific implementation of the equipment is: the main shaft 1 of the winding machine is driven by a frequency conversion motor and connected to the computer control system 9; the main shaft 1 of the winding machine is locked together with the mold 4 in the form of a female and a female, and can be rotated and disassembled at the same time to facilitate the mold. The walking trolley 2 has a rolling shaft that moves smoothly on the working platform 3; the pressure roller 10 that provides fiber tension is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com