Assembling type rack frame structure

A prefabricated and cabinet technology, applied to substation/switchgear frames, detachable cabinets, cabinets, etc., can solve problems such as waste, unreported, waste of capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

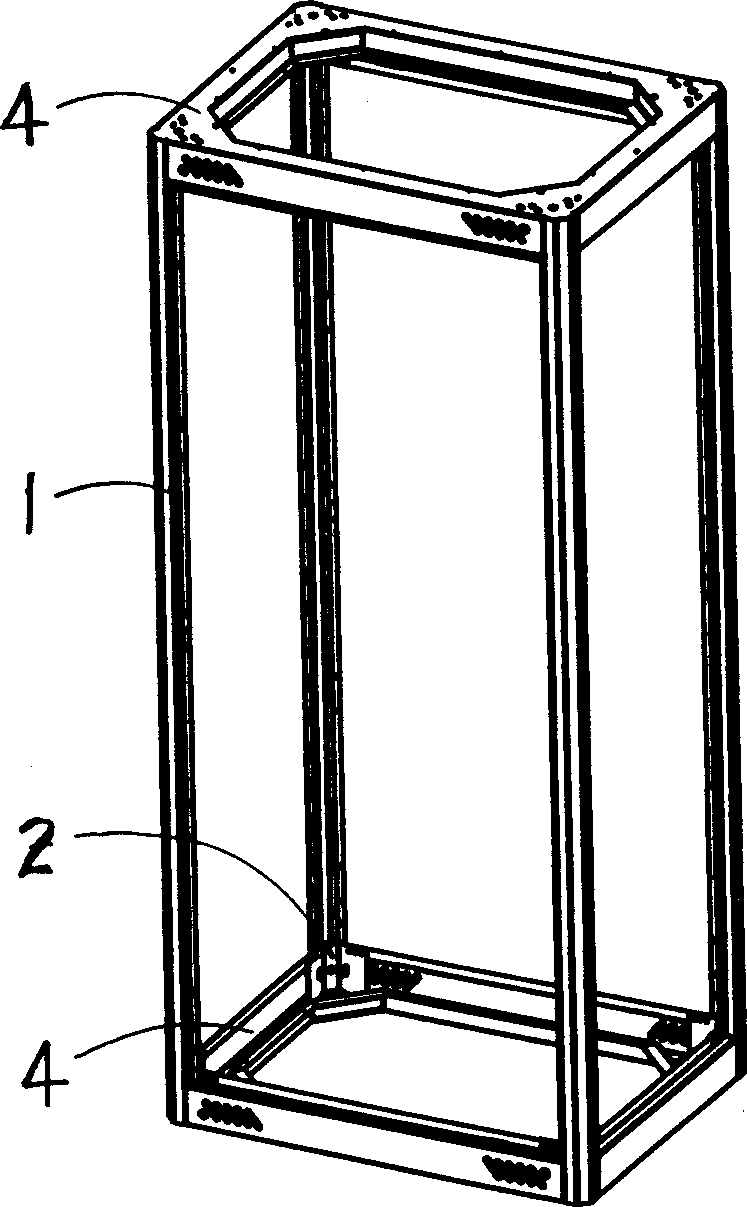

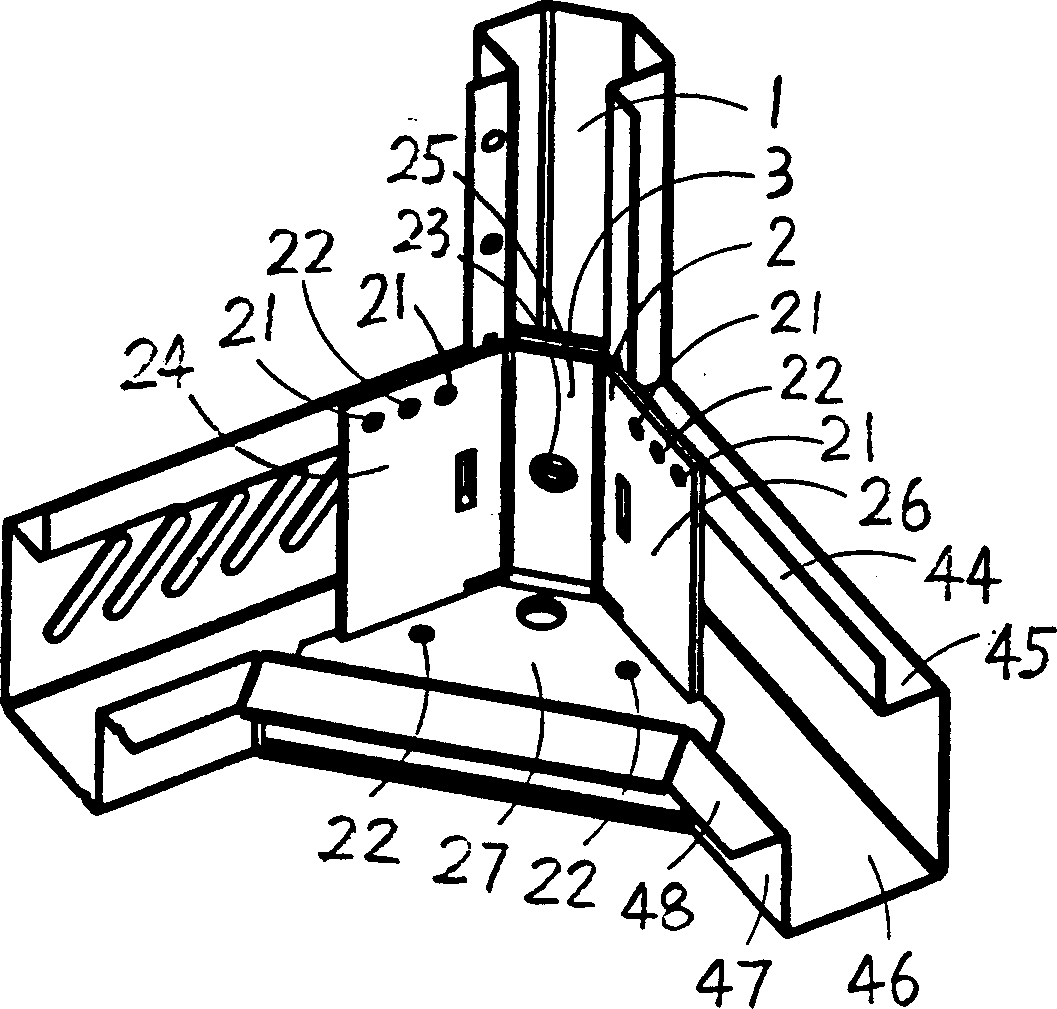

[0044] A frame with a height of 2 meters, a width of 0.6 meters and a depth of 0.6 meters is implemented through the following steps: (1) corner column 1: adopt 1.5 mm thick galvanized iron plate through stamping and bending. Forming a long 2-meter cross-section is a symmetrical hexagonal rhombus (such as figure 2 shown);

[0045] (2) Corner connection block 2: 3mm thick cold-rolled steel plate is used for stamping, bending, spot welding, and processed into a right-angled sheet metal component (such as figure 2 shown);

[0046] (3) Corner tight block 3: 3 mm thick cold-rolled steel plate is used for stamping, bending, and processed into three-fold tile-shaped sheet metal components (such as Figure 7 shown);

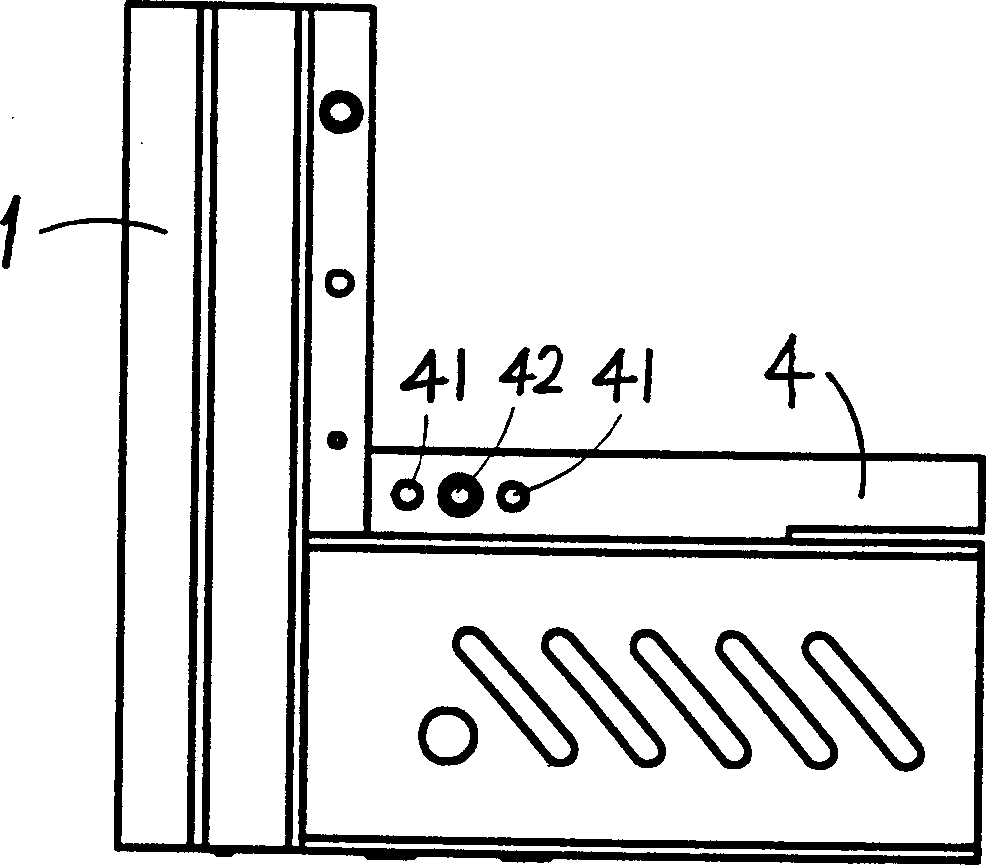

[0047] (4) Base 4: use 1.5 mm thick galvanized metal member after punching, bending, and processing into a rectangular frame sheet metal member of 0.6 m x 0.6 m, whose cross-sectional shape is like a rectangular tube with an opening at one corner (such as figure 2 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com