Patents

Literature

134results about "Substation/switching arrangement frameworks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cabinet frame

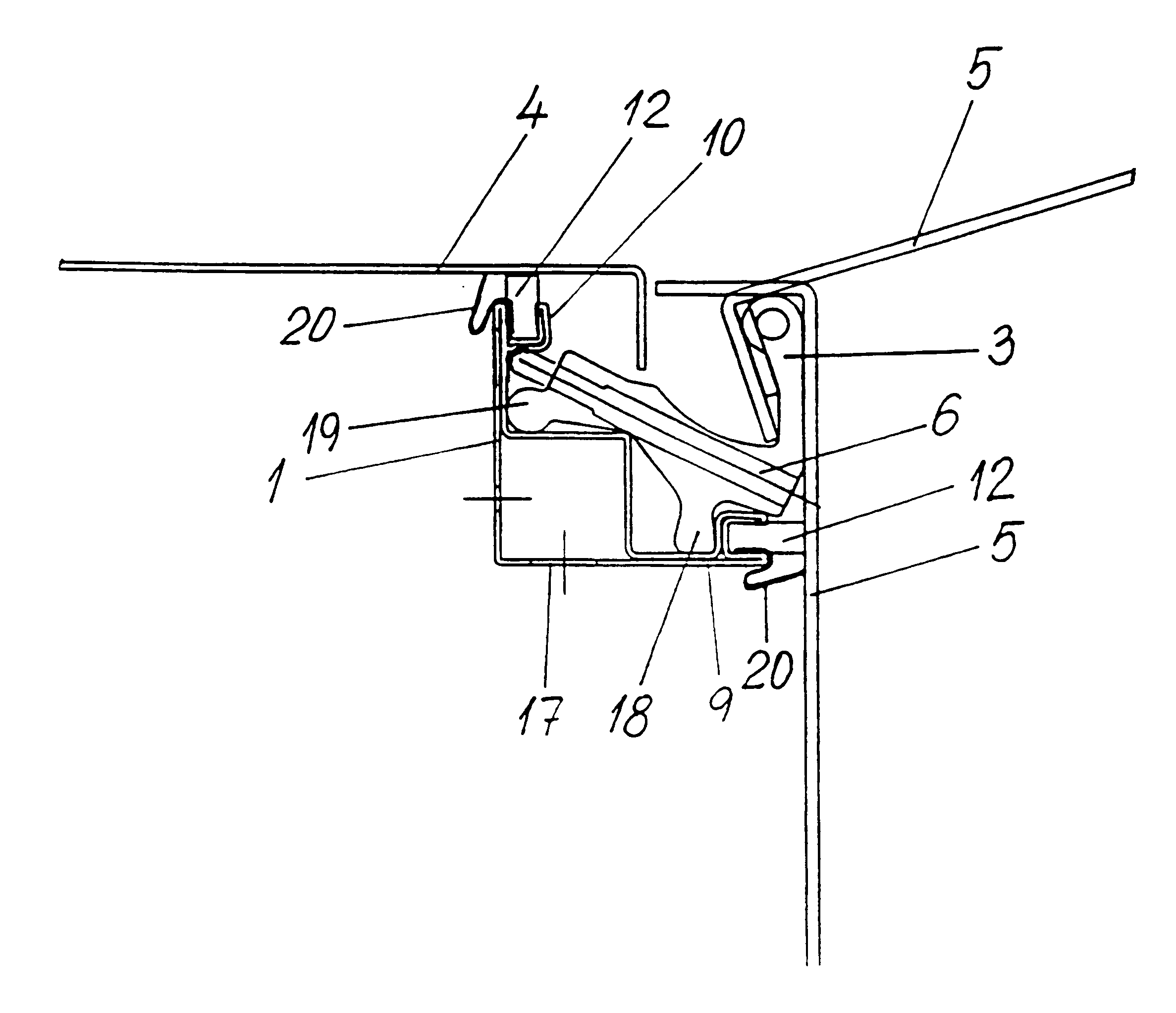

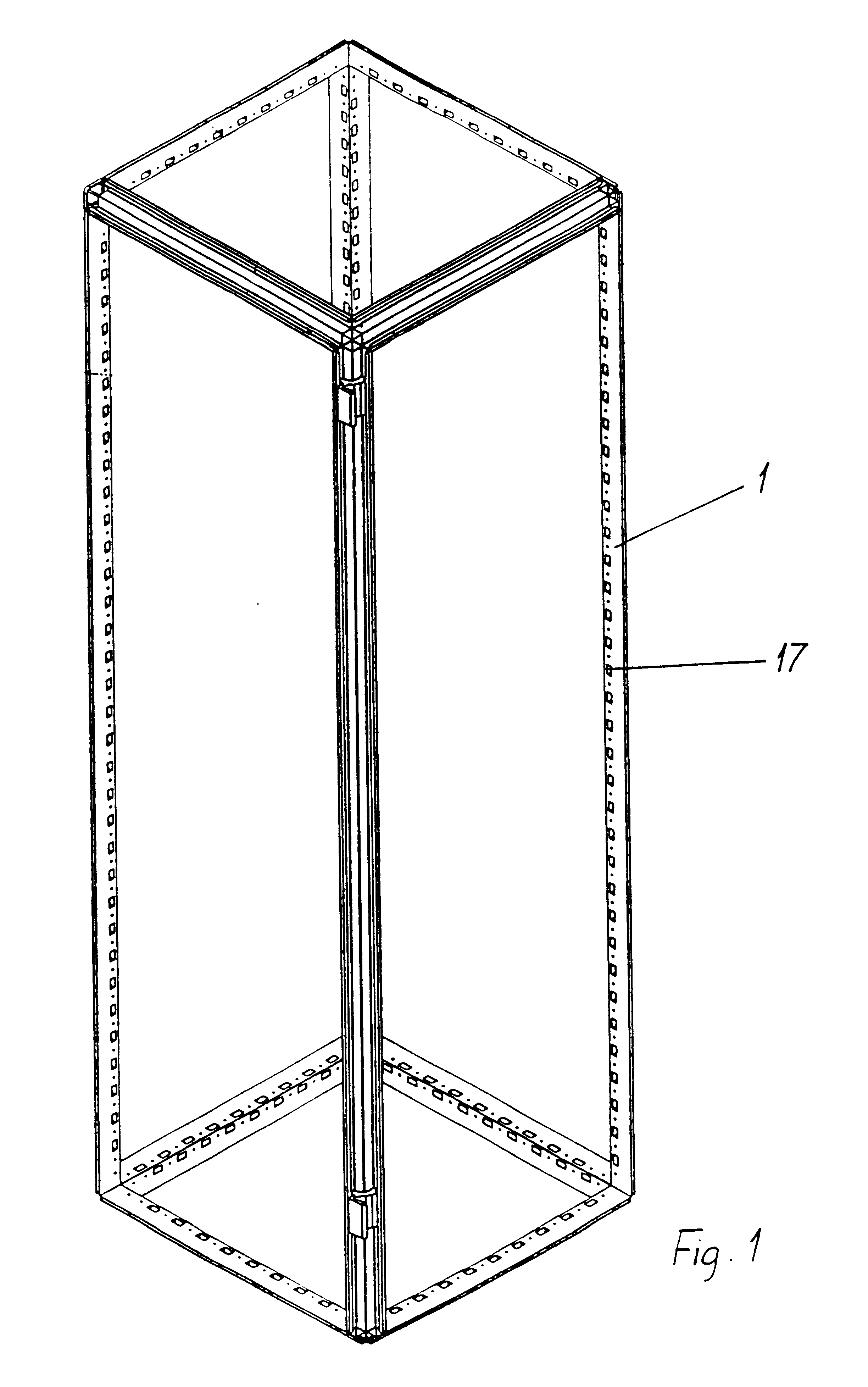

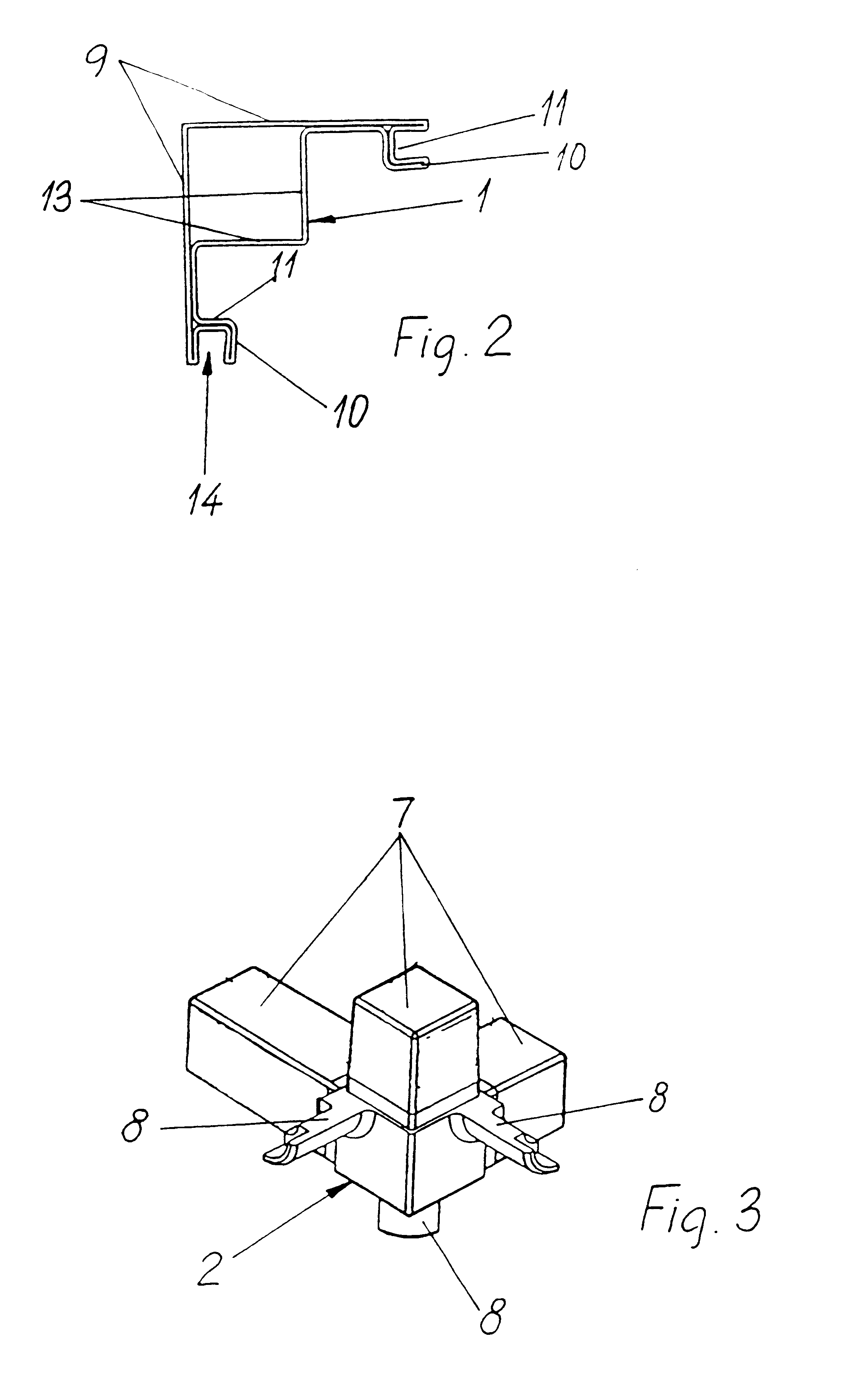

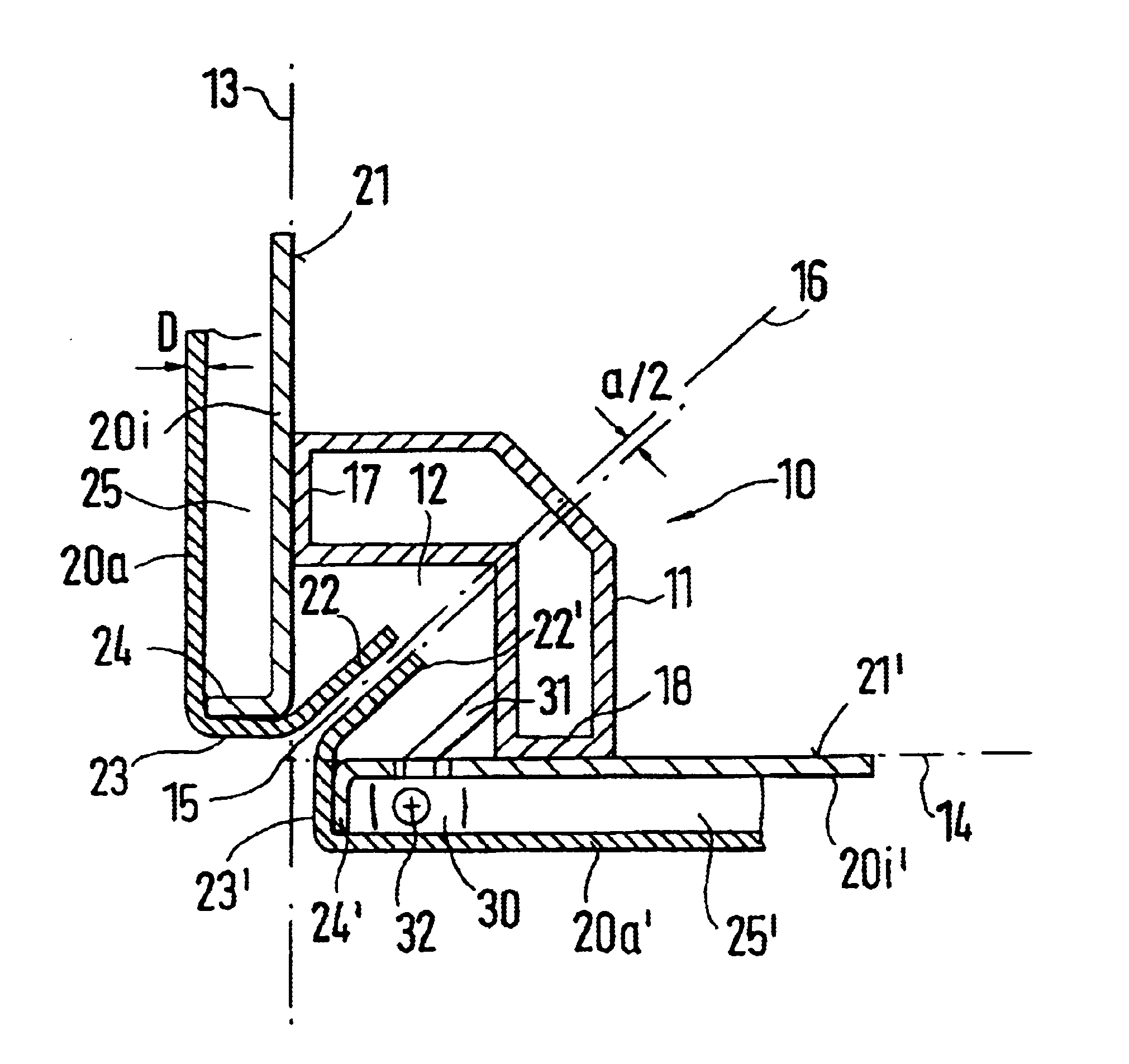

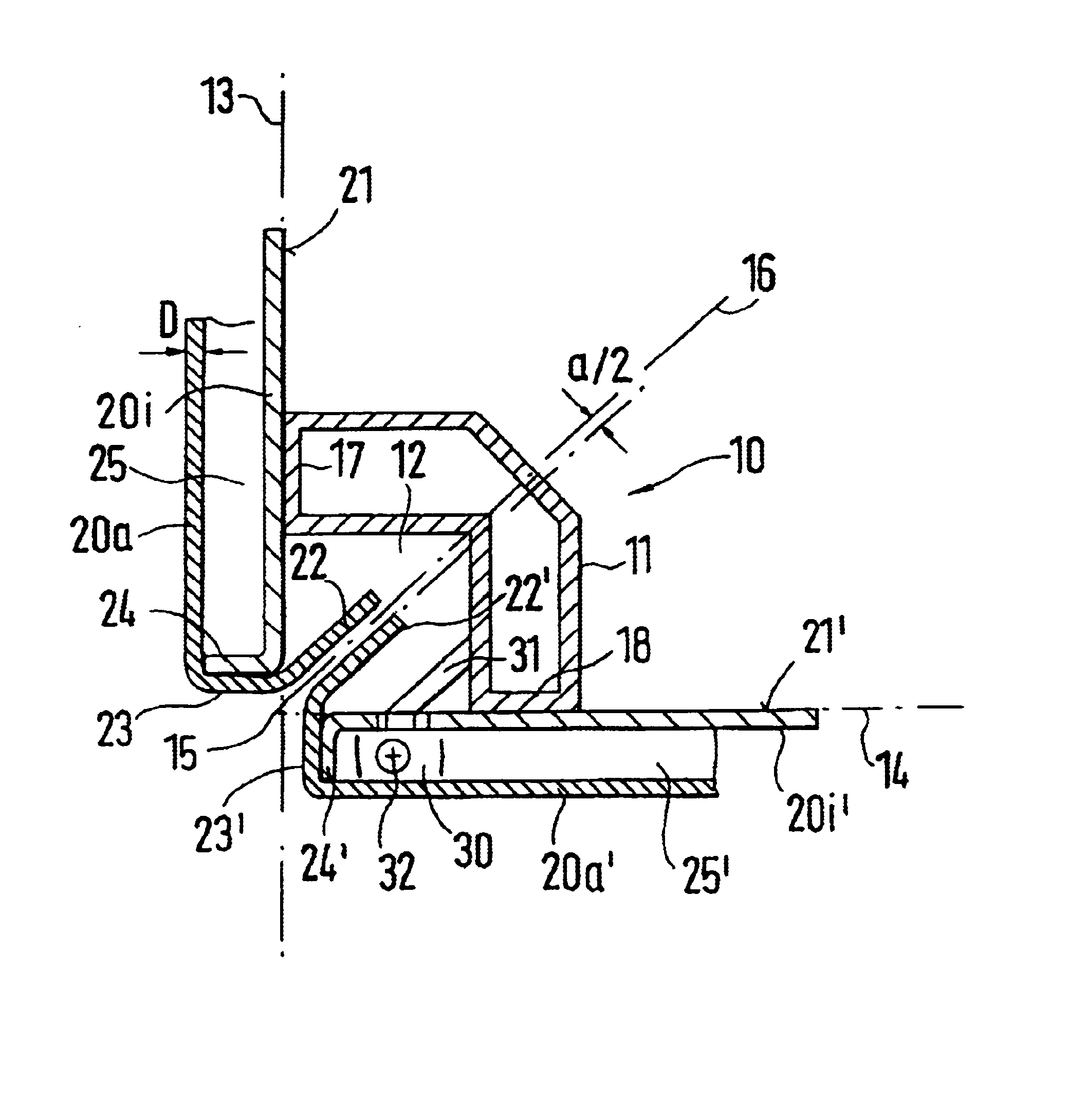

A cabinet having at least one door (5), in particular an electrical cabinet, comprising a framework made up of right angled metal profiles (1) which are mutually connected by use of corner members (2) having fastening elements (7) inserted in cavities in the profiles, whereby each profile is symmetrical about a plane in 45° relatively to two of the main directions of the cabinet and comprises two grooves (14) situated symmetrically about said plane, for sealing strips (12), said grooves (14) being directed outwardly from the interior of the cabinet, whereby the sealing strips (12) are in engagement with external wall panels, and whereby the bottom (11) of each groove (14) is situated inwardly of a respective profile wall (9) which delimits the profile towards the interior of the cabinet. The grooves (14) are situated along a respective free edge on the profile, whereby the profile is open from the external side, and the bottom (11) and / or the inner side wall (10) of each groove forms an abutment for fastening of hinge pans (3) at least in one of the profiles.

Owner:RASMUSSEN KNUD

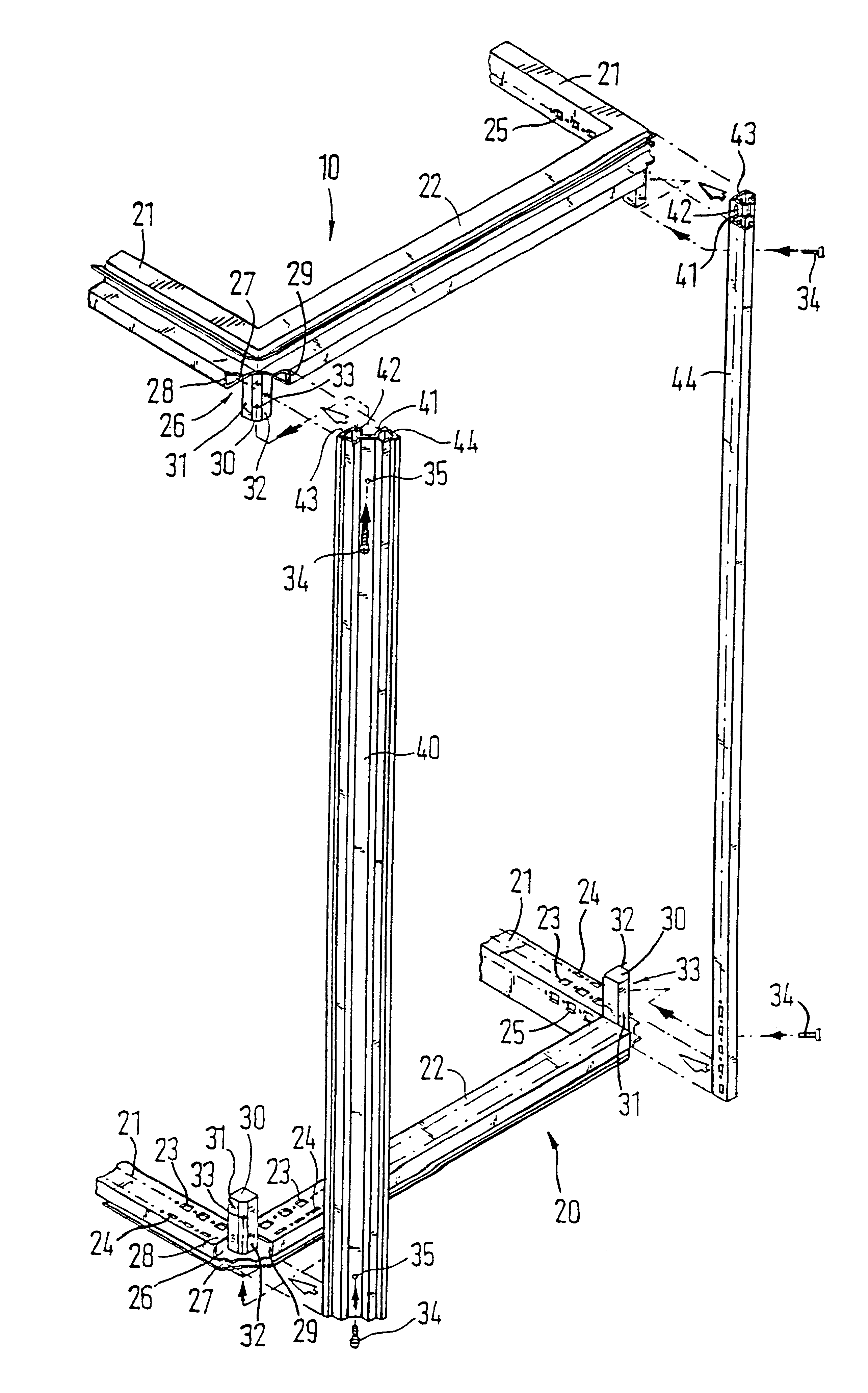

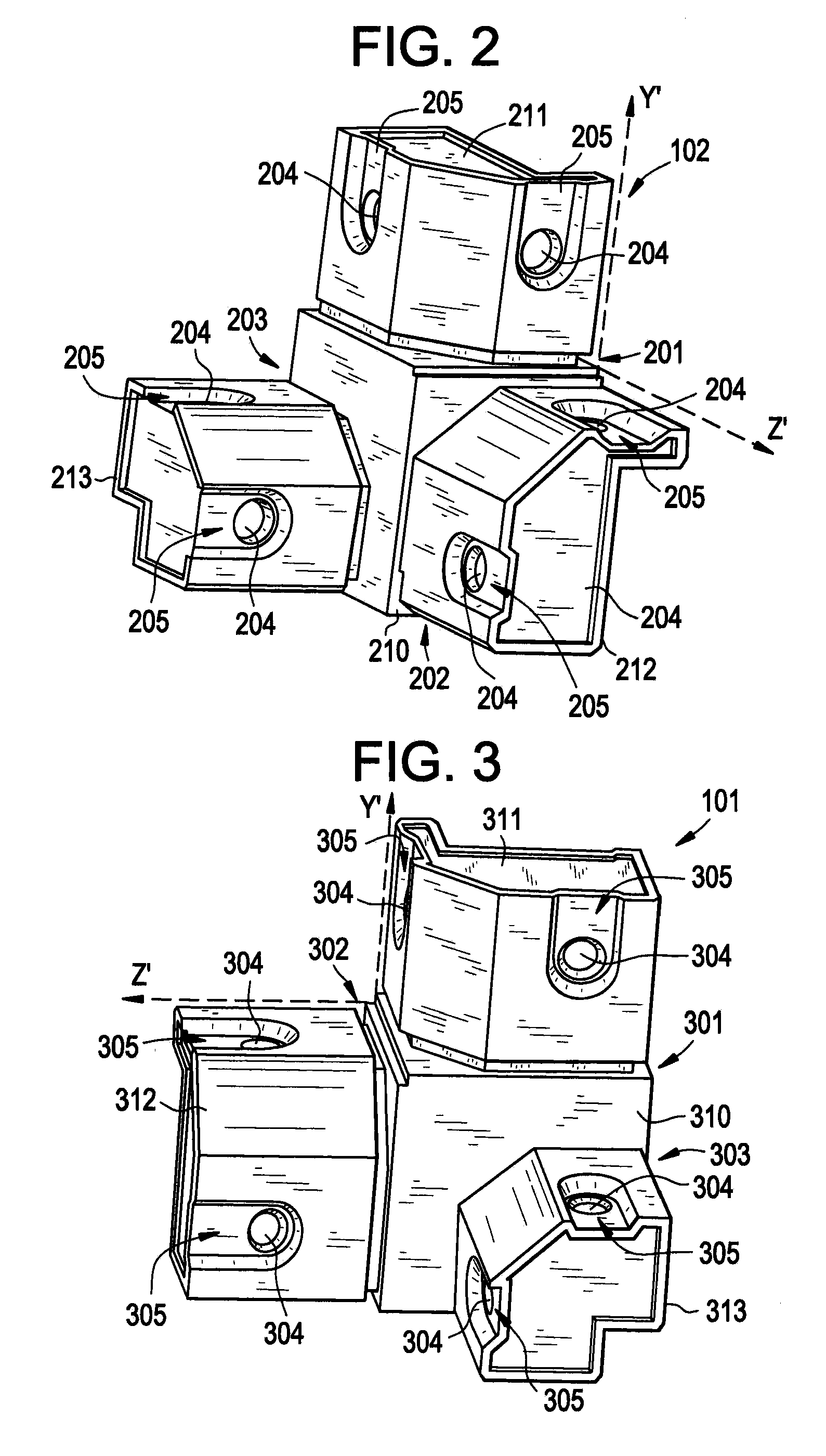

Kit for a rack with a corner connector for vertical frame pieces

InactiveUS6174034B1Substation/switching arrangement casingsRack/frame constructionMechanical engineeringEngineering

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Combined frame for an electromechanical box

Owner:TAIWAN ENCLOSURE SYST CO LTD

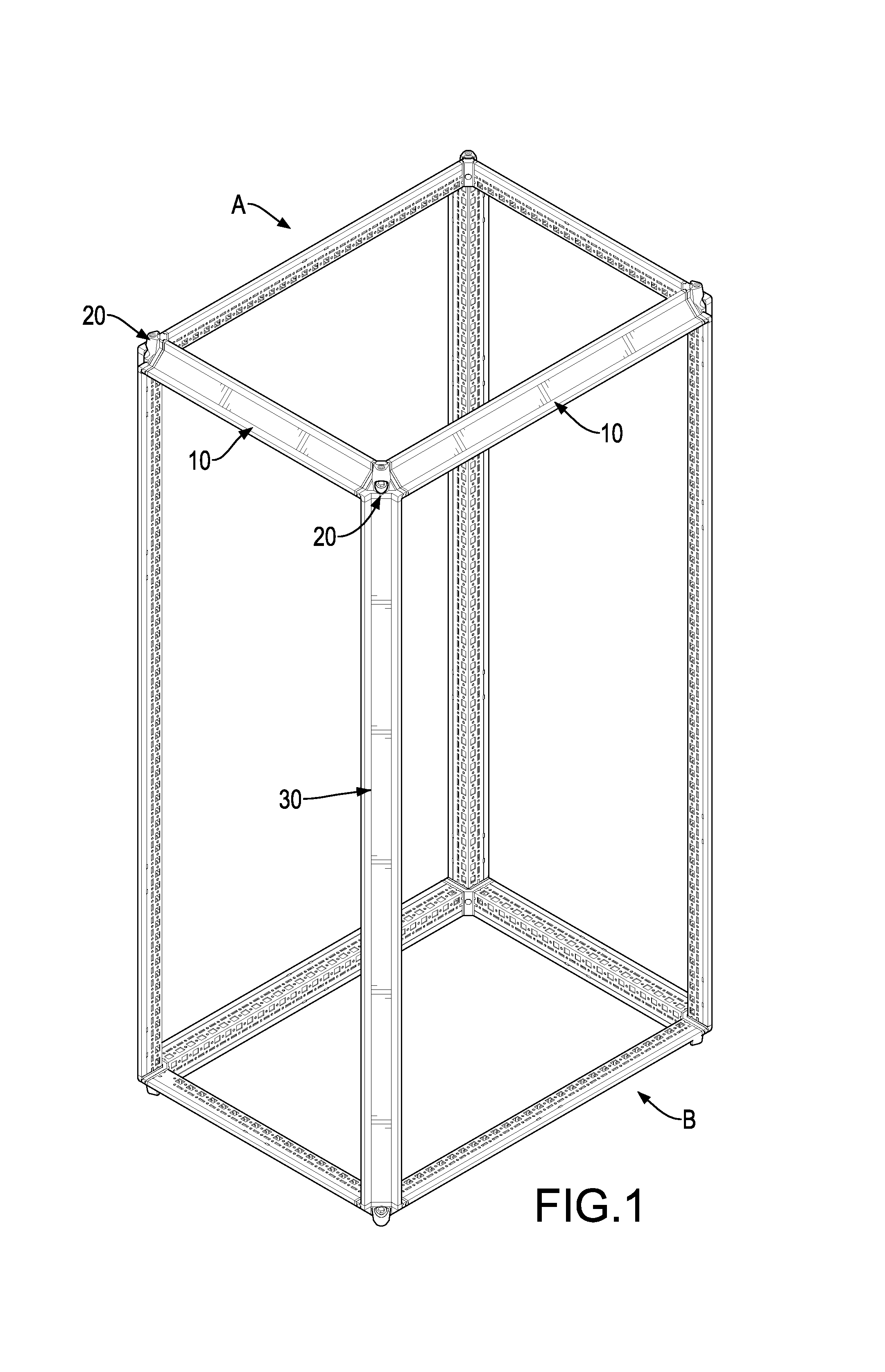

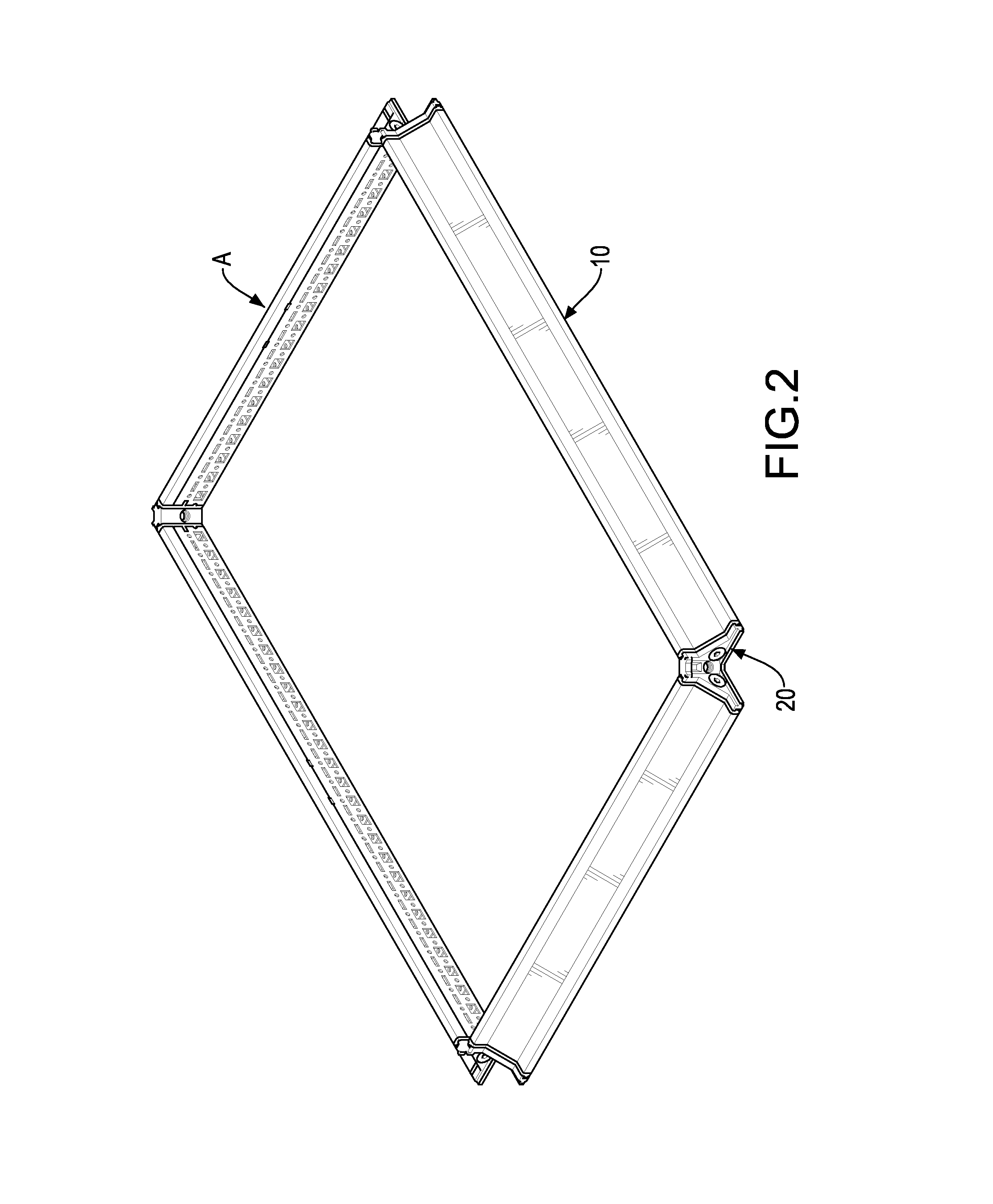

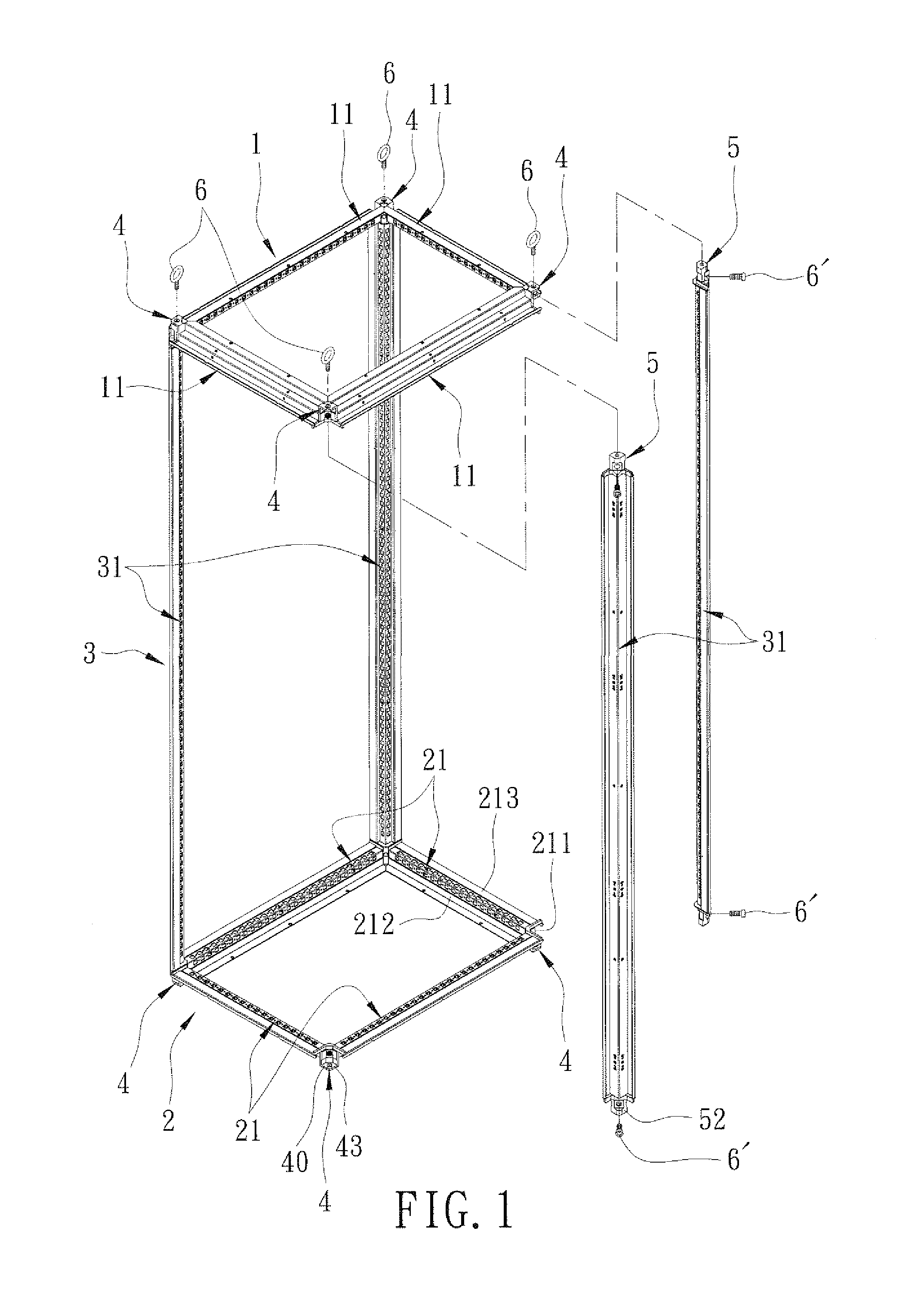

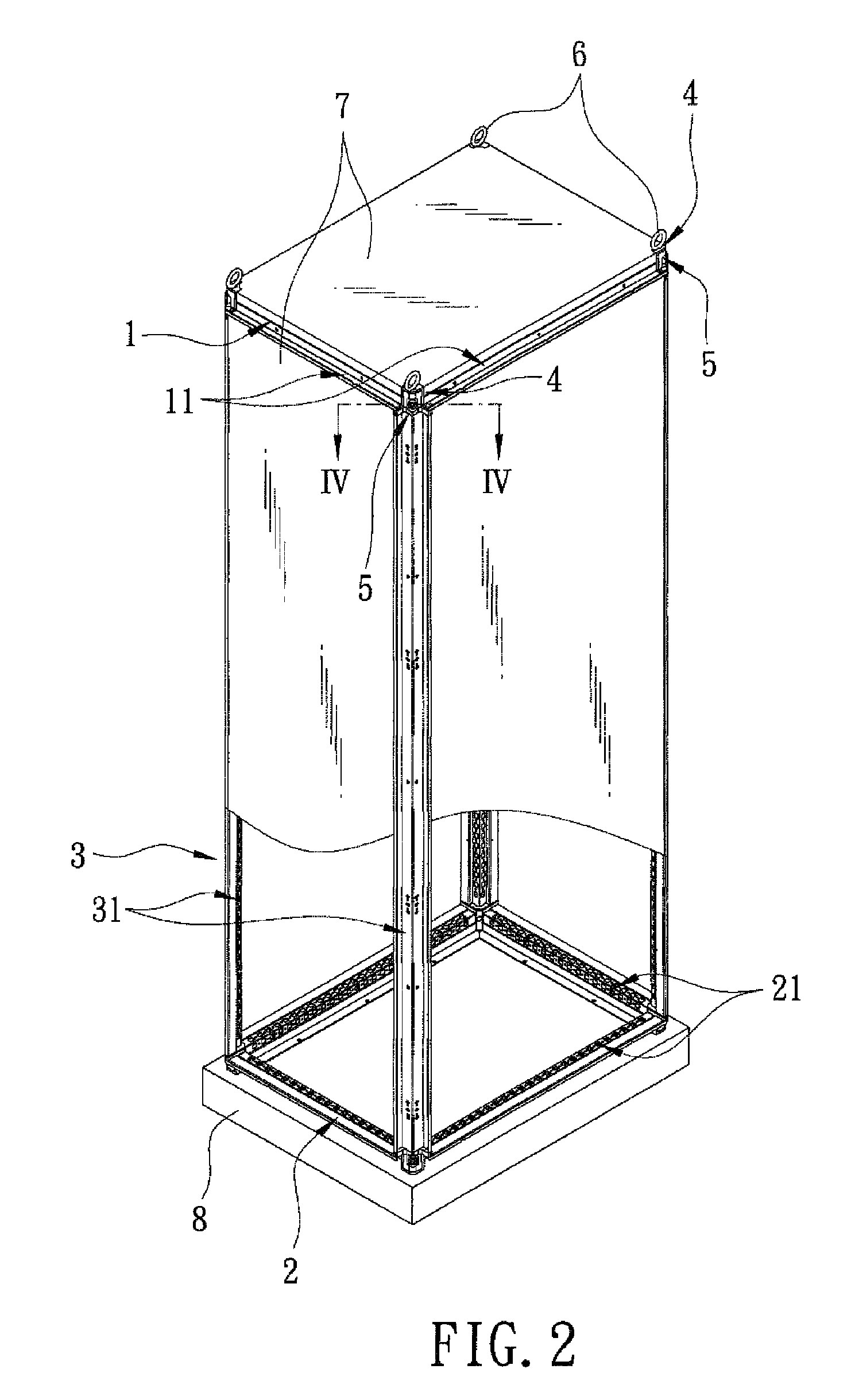

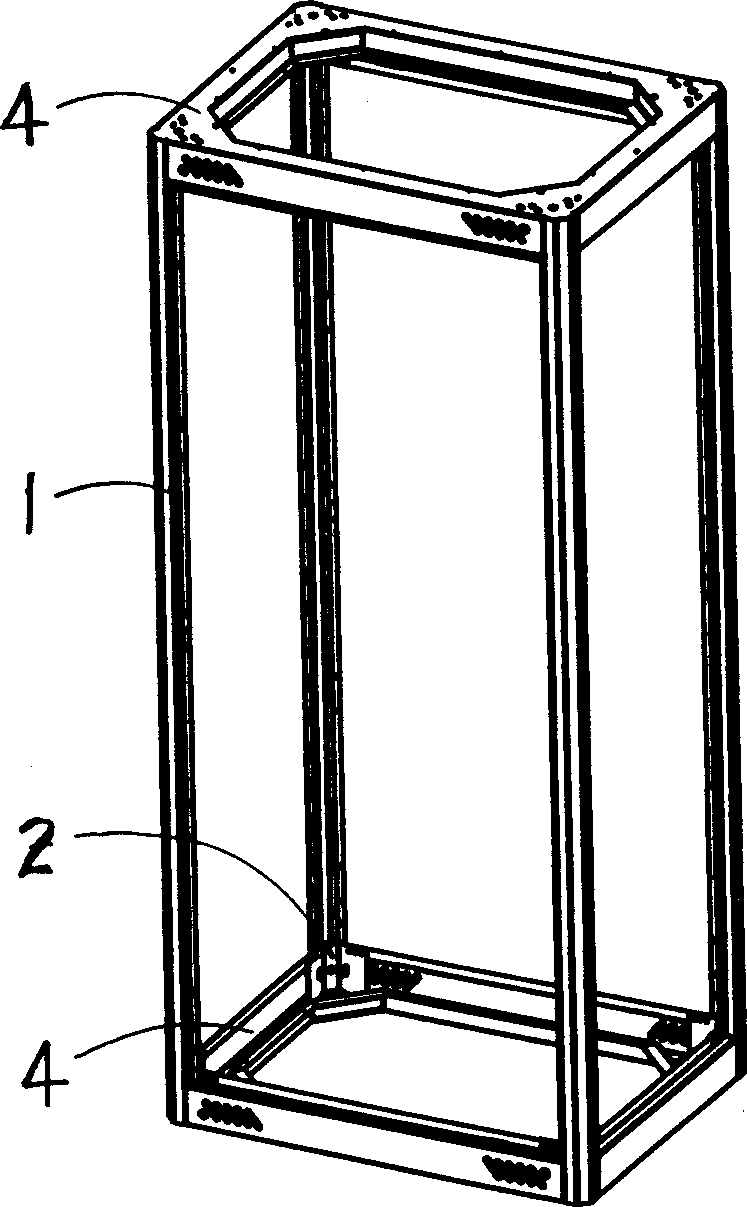

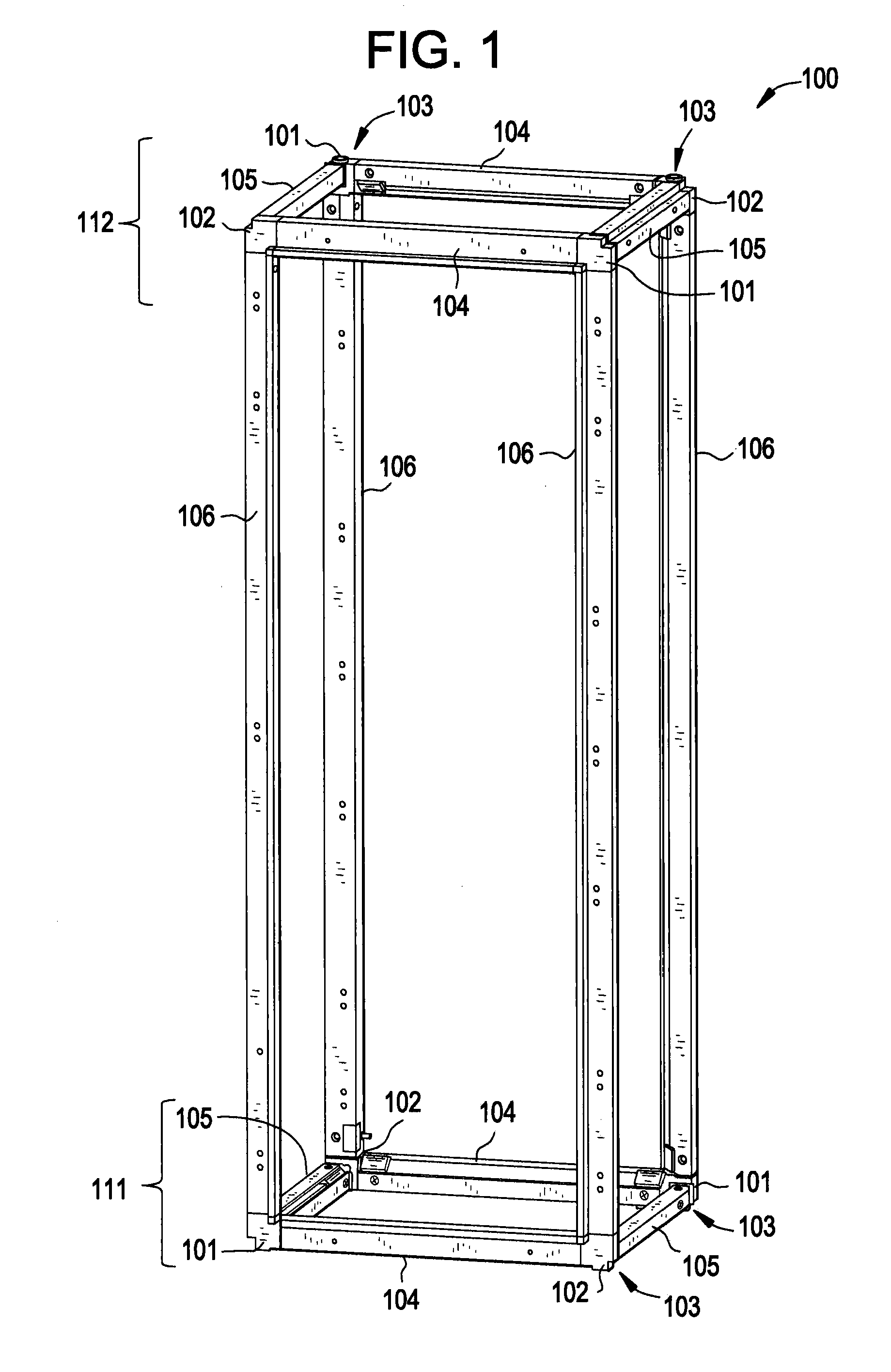

Frame assembly

InactiveUS20110309046A1Easy to assembleImprove structural strengthKitchen equipmentMetal-working hand toolsVehicle frameEngineering

A frame assembly includes upper and lower frame units, four vertical frame rods, four pairs of top and bottom female connectors, eight male connectors, and first and second bolts. Each frame unit includes four rectangularly-arranged horizontal frame rods. Each female connector interconnects an adjacent pair of the horizontal frame rods, and includes two horizontal tenons engaging respectively the adjacent pair of the horizontal frame rods. The male connectors are connected respectively to opposite ends of the vertical frame rods. Each male connector includes a vertical tenon engaging a respective one of the opposite ends of the vertical frame rods, and an engaging block mating with a respective one of the female connectors. The first and second bolts are for securing releasably and respectively the female connectors to the male connectors.

Owner:LEE YUNG YU

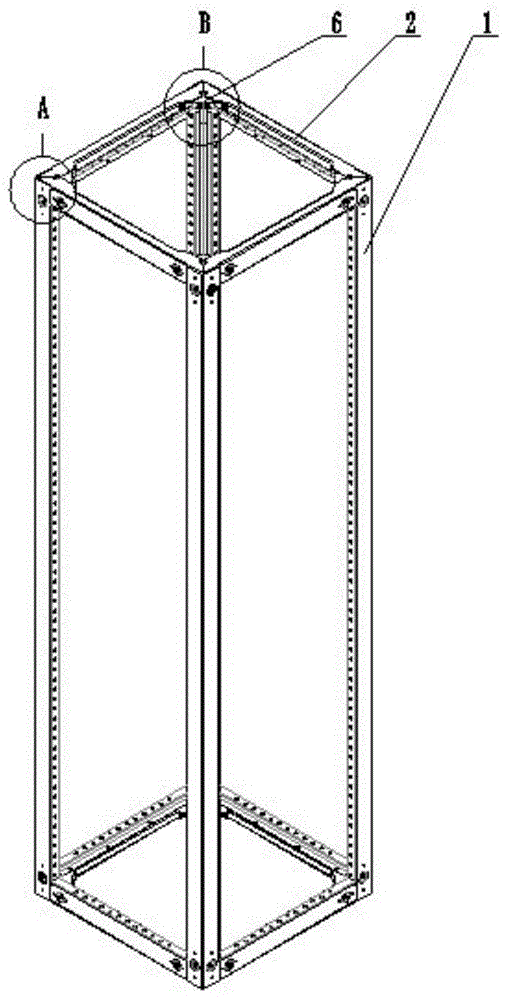

Switch cabinet with an assembly unit

InactiveUS6170673B1Simple attachmentEasy to introduceSubstation/switching arrangement casingsRack/frame constructionEngineeringElectronic component

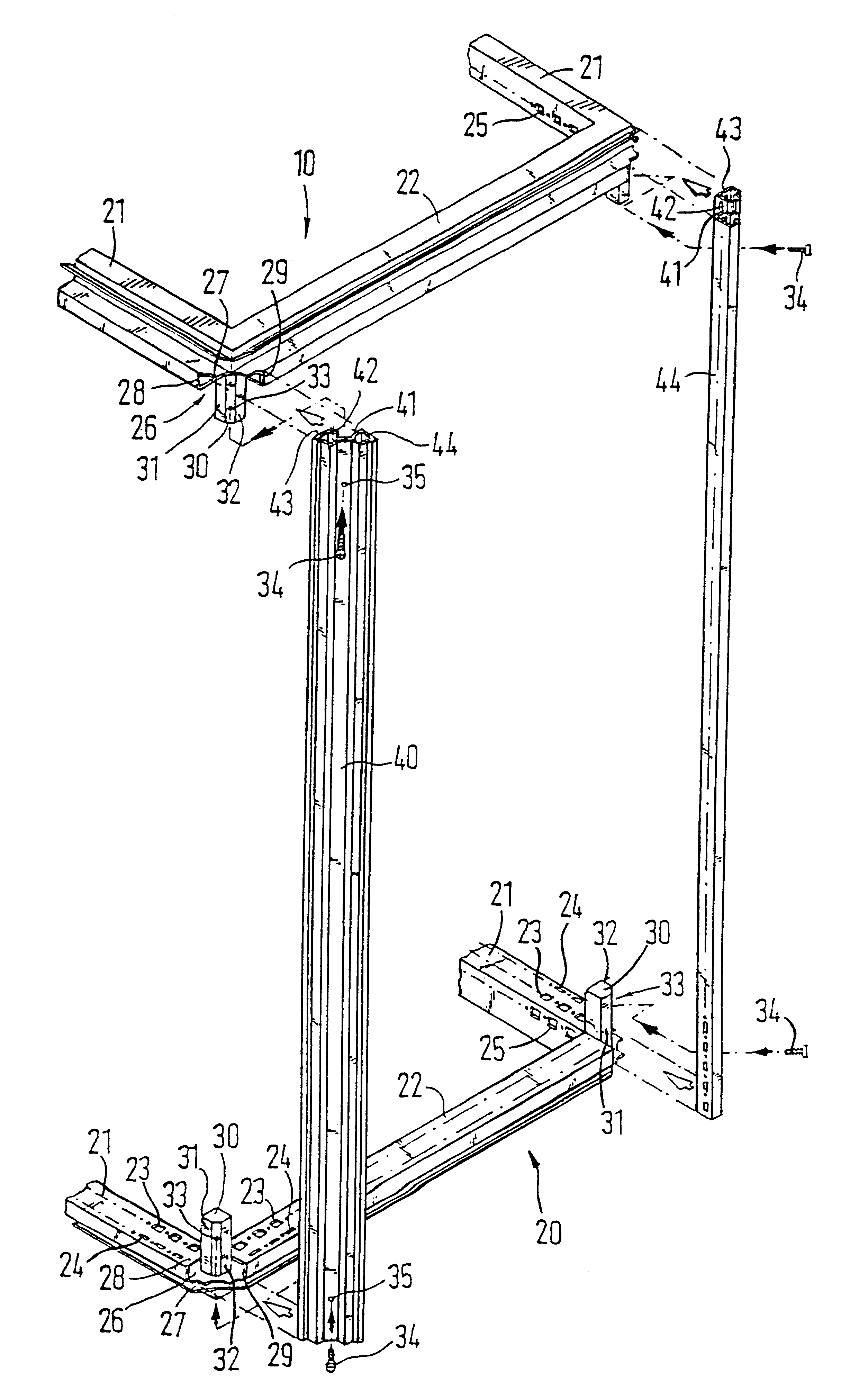

A switch cabinet having a rack with vertical frame pieces, wherein the vertical frame pieces are coupled to a lower unit or to an upper unit. Electronic components can be assembled by connecting two adjacent vertical frame pieces to a separate assembly unit with connecting elements and by fixing the components to be assembled.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Server rack assembly

A server rack assembly includes a frame, a support, and a securing component. The frame includes a first pole and a second pole. The support includes a first part and a second part. A first stopper portion is located on the first part, and a second stopper portion is located on the second part. The securing component includes a bottom portion mounted to the first and the second poles, a first securing portion and a second securing portion. A first positioning portion is disposed on the first securing portion, and a second positioning portion is disposed on the second securing portion. The first securing portion is attached to the first part, so the first positioning portion is engaged with the first stopper portion. The second securing portion is attached to the second part, so the second positioning portion is engaged with the second stopper portion.

Owner:HON HAI PRECISION IND CO LTD

Frame assembly for a switchboard and related frame and switchboard

An assembly for the frame of a switchboard is disclosed, which can include a hollow member which extends lengthwise along a reference axis and which has at least one slot. The assembly can include at least one connecting element for connecting the assembly to a corresponding corner joint element of the frame, and the connecting element can include an insulating body and a fixing metal plate which is associated to a carrying part of the insulating body. The carrying part can be at least partially inserted transversally with respect to the reference axis into the hollow member through the slot, so as to arrange at least a portion of the associated fixing metal plate into the hollow member transversally with respect to the reference axis.

Owner:ABB SPA

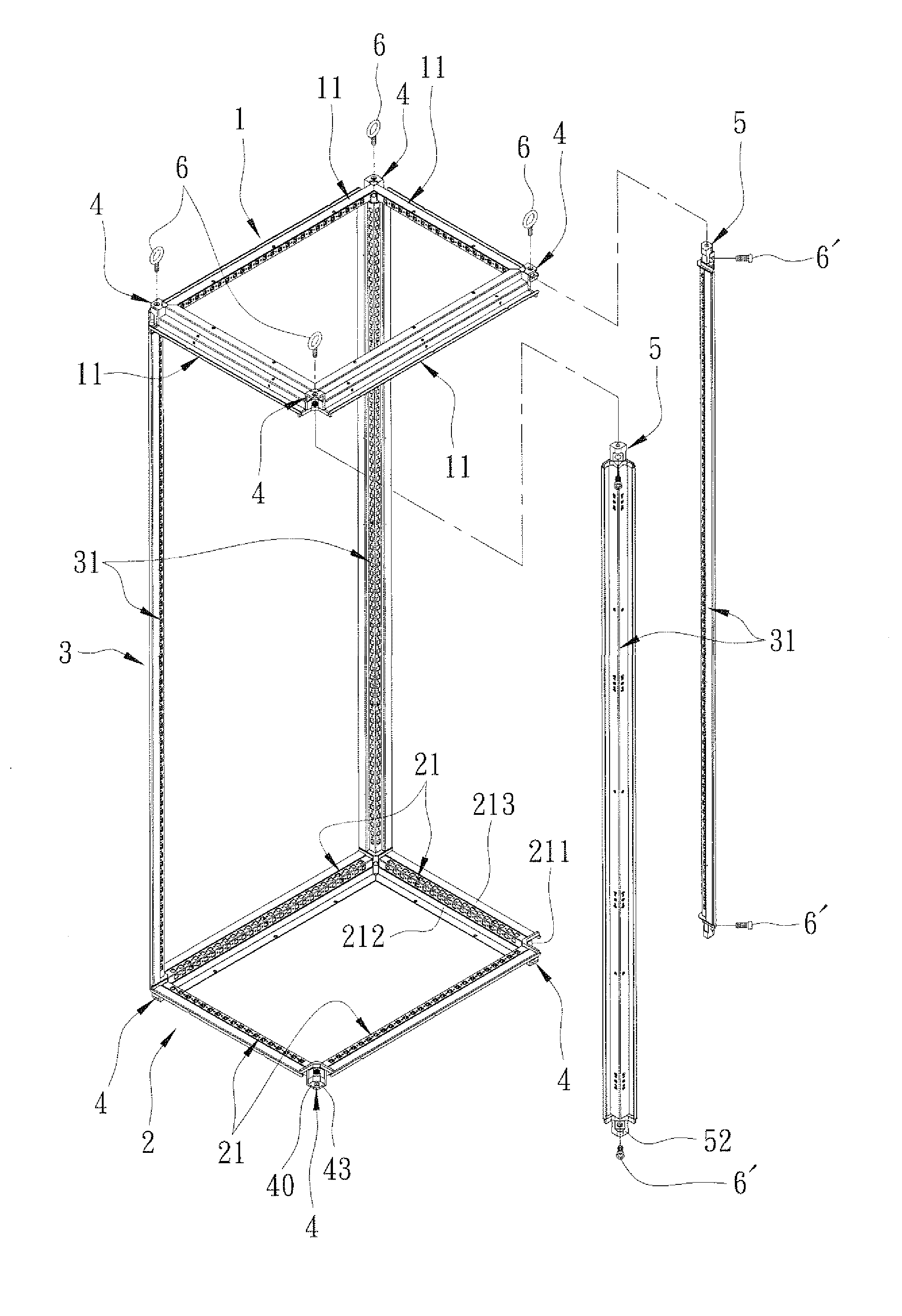

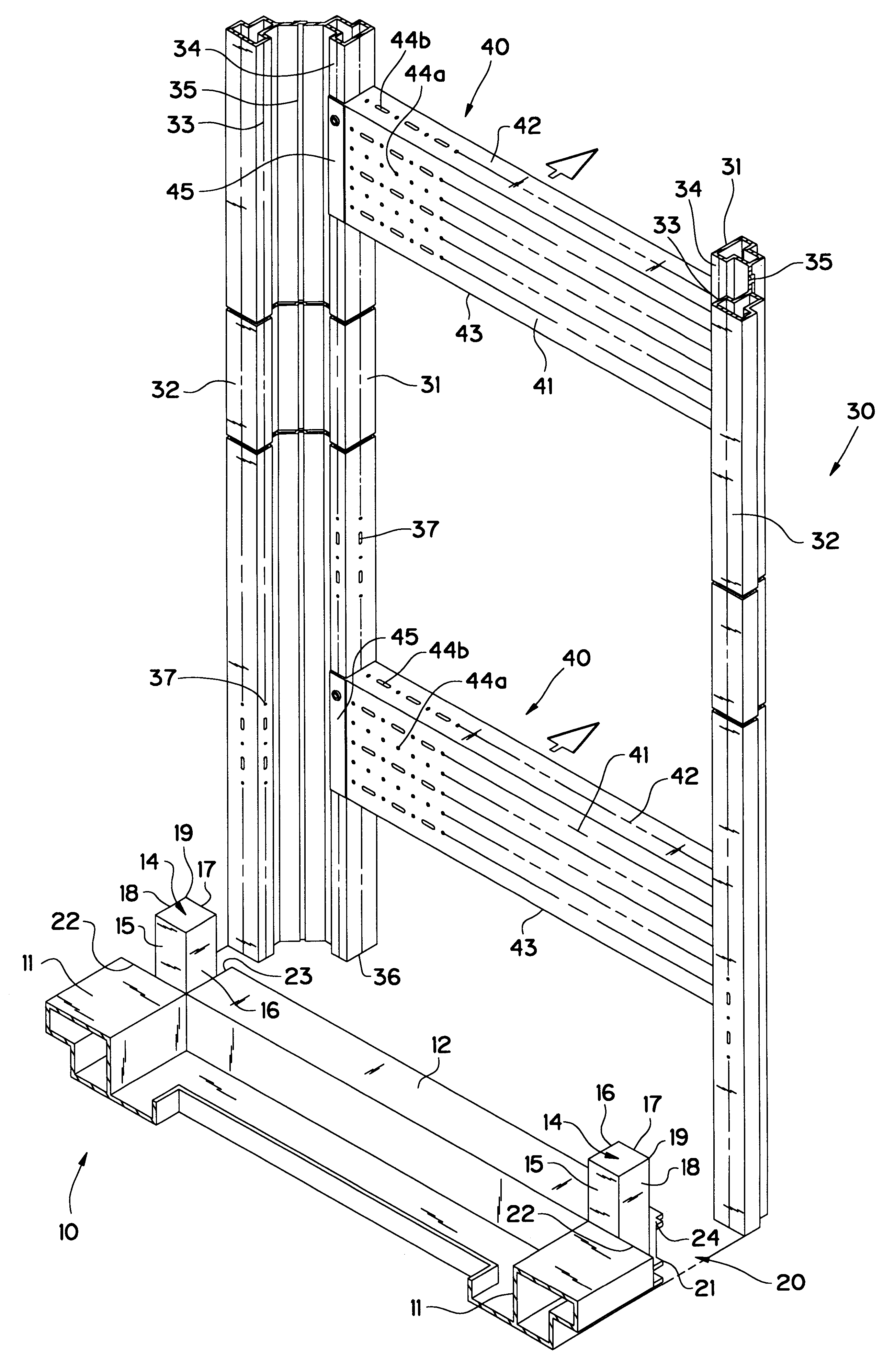

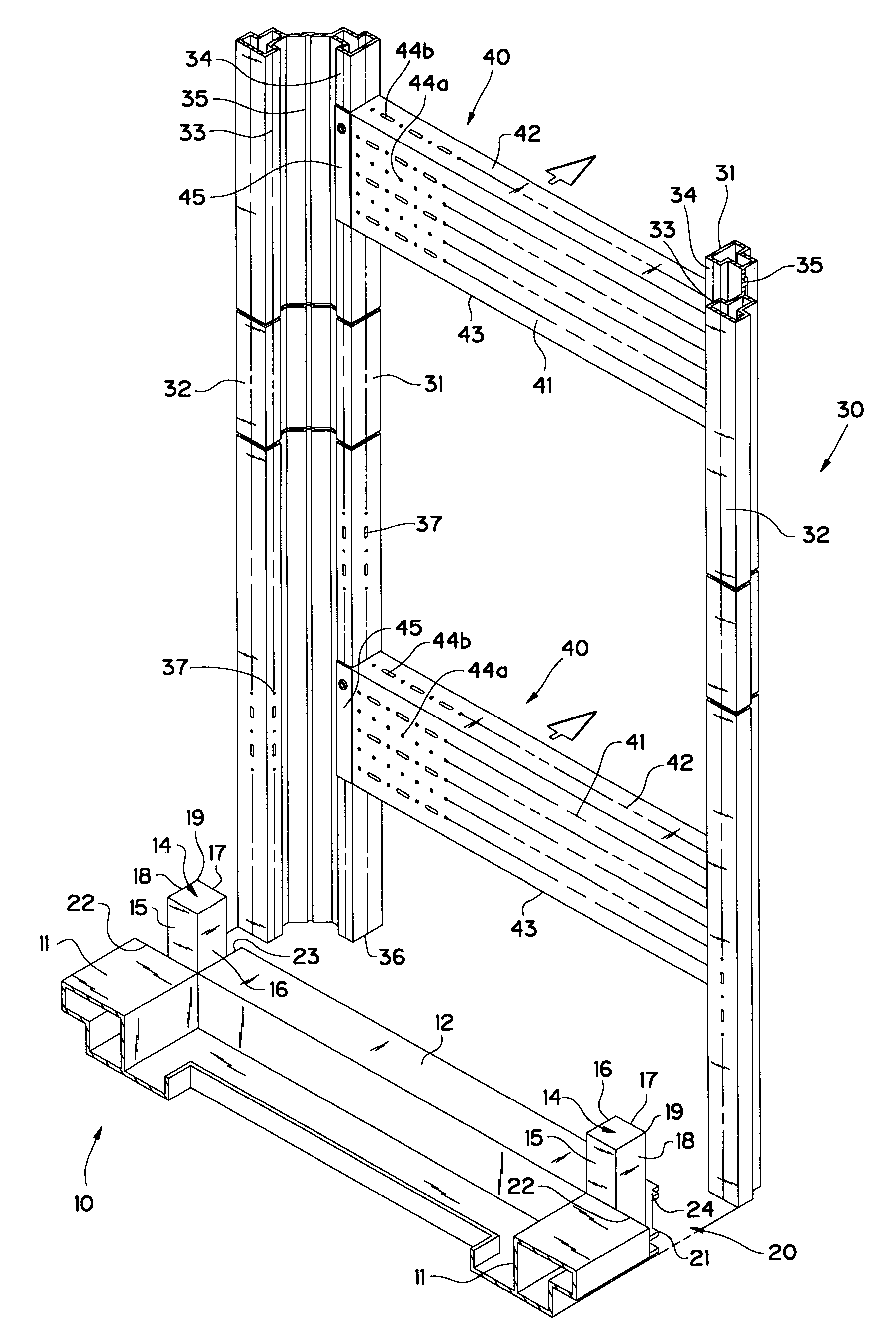

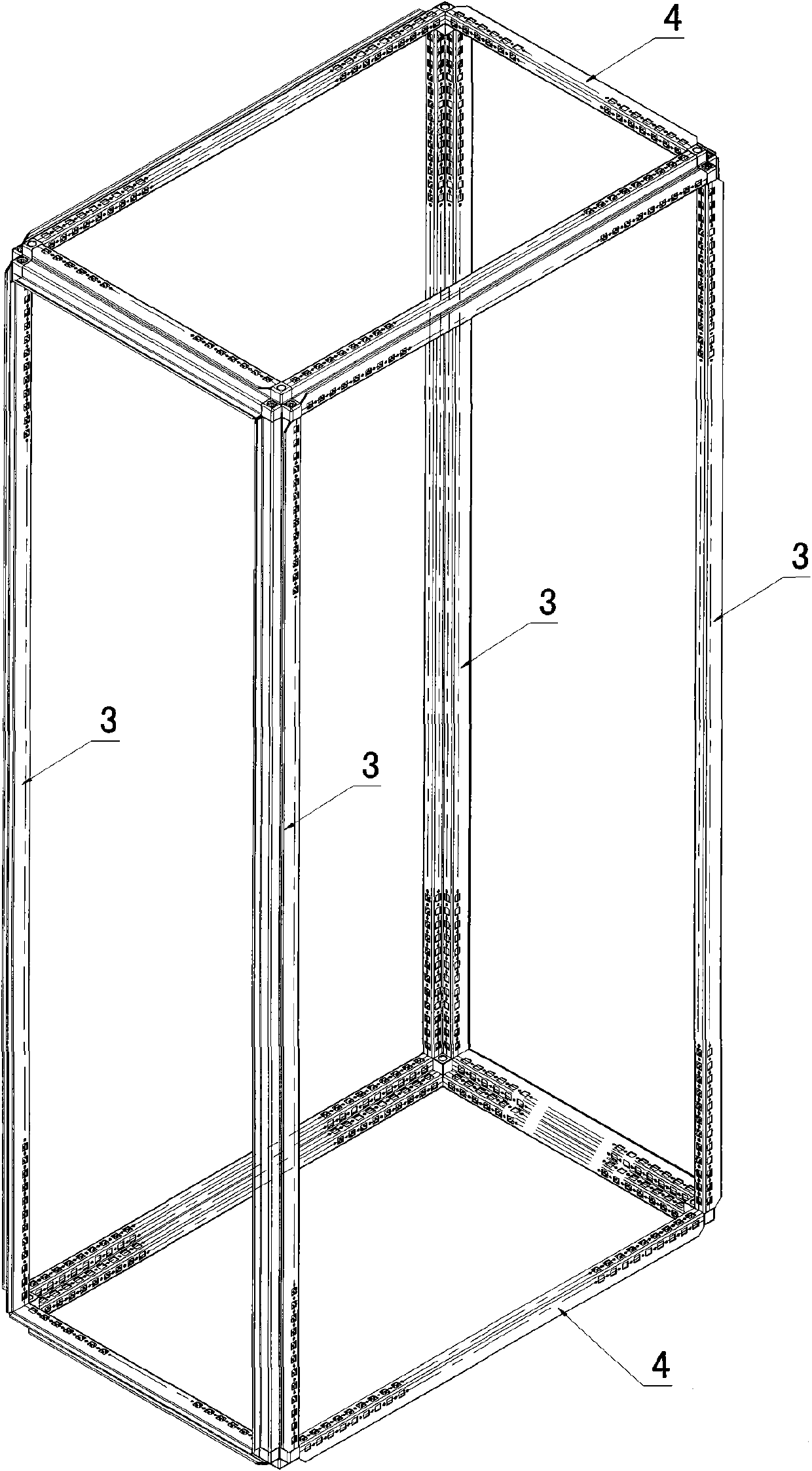

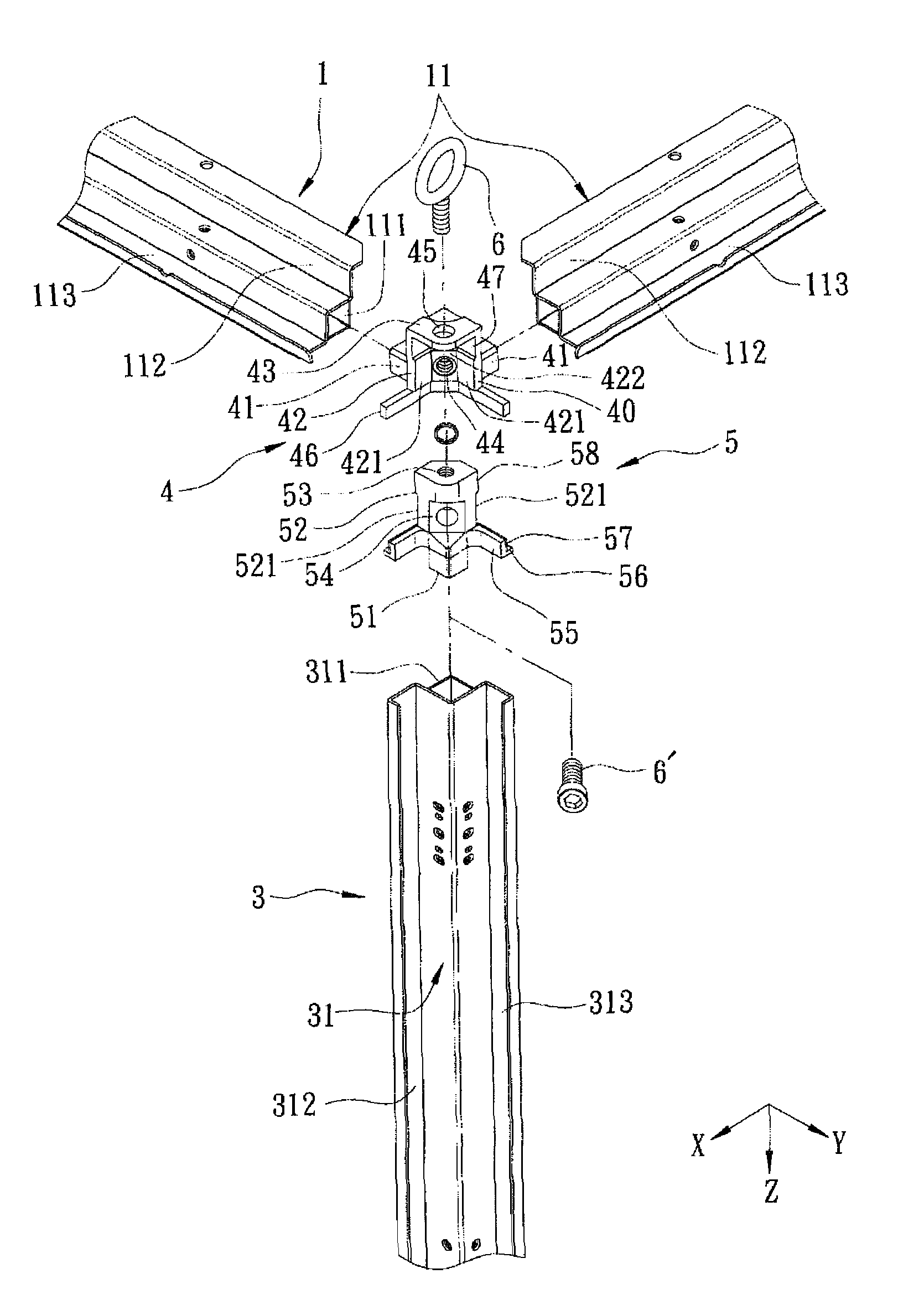

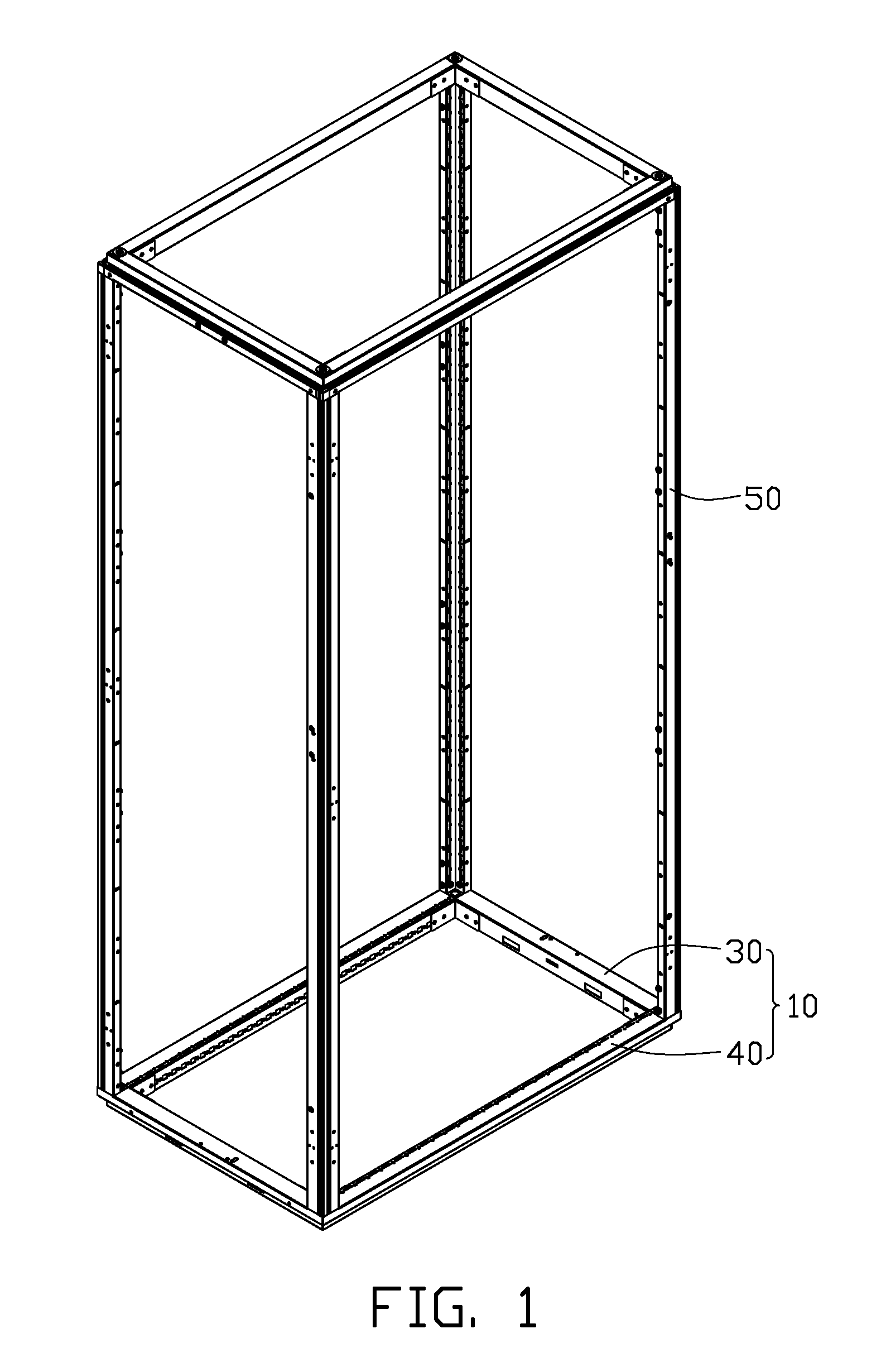

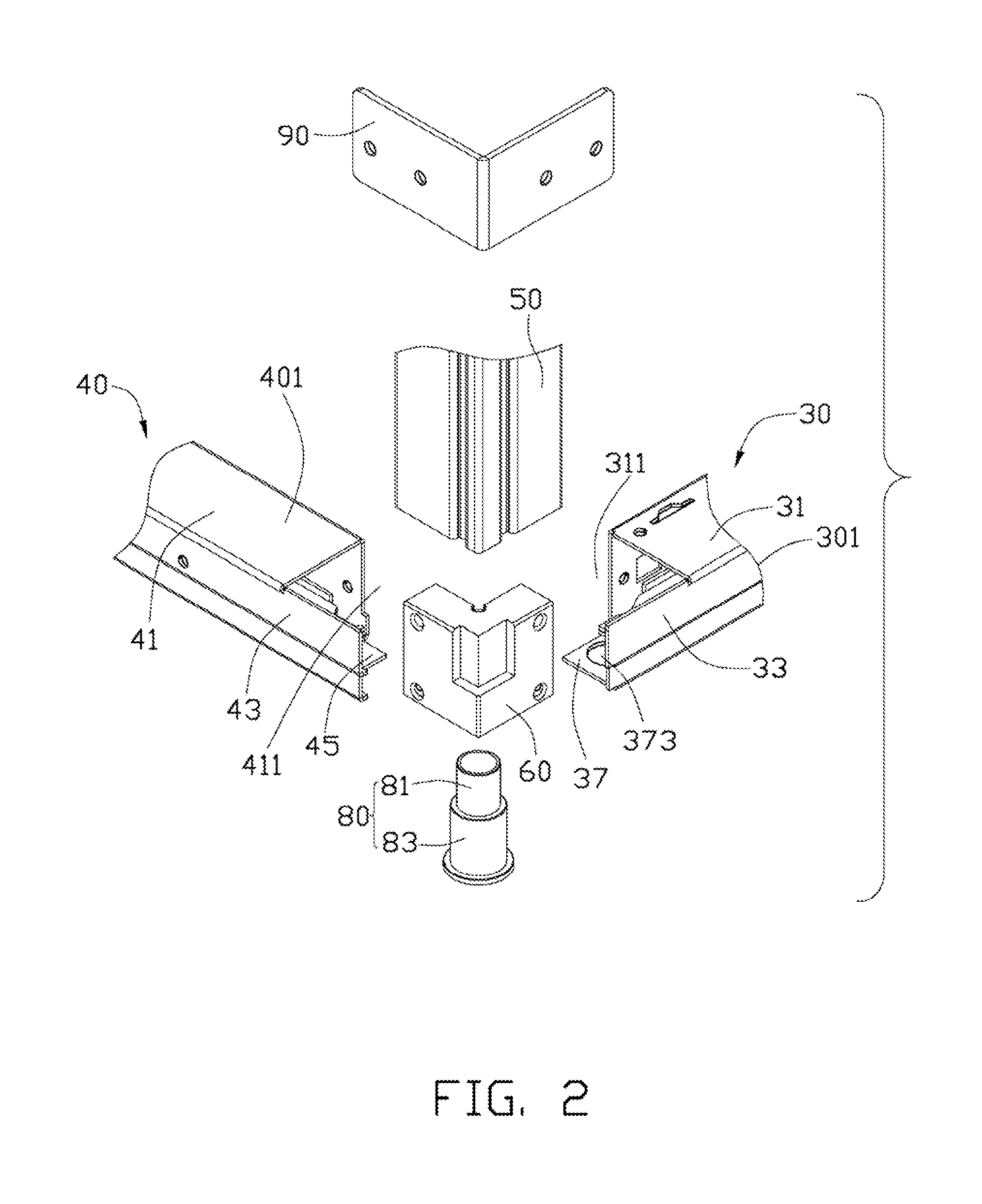

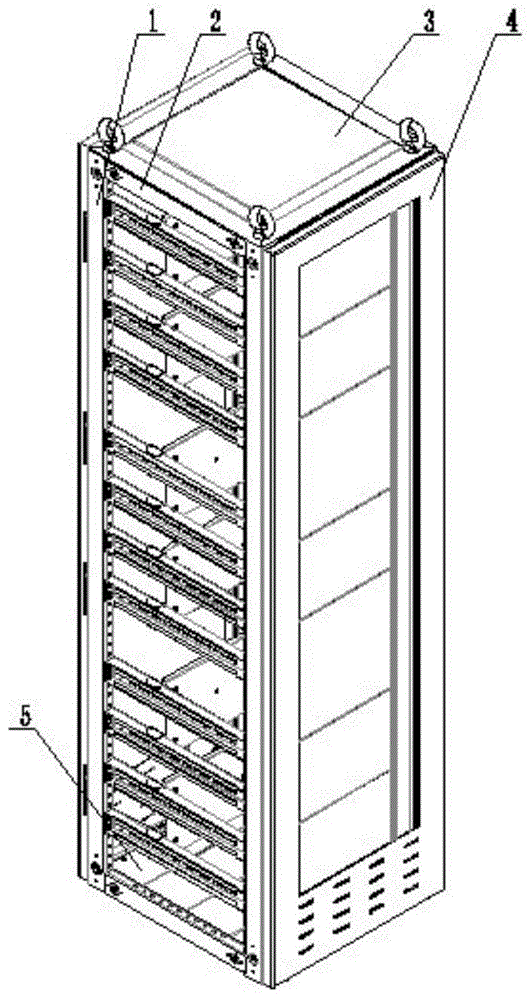

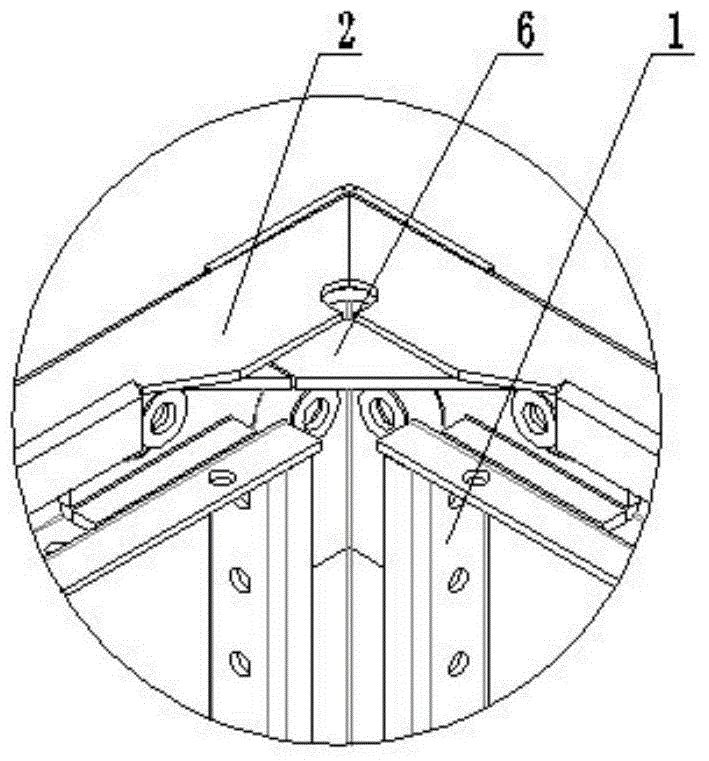

Cabinet framework convenient for assembly and assembly method thereof

ActiveCN101577398ASimple structureReasonable structureRack/frame constructionSubstation/switching arrangement frameworksCarrying capacitySoftware engineering

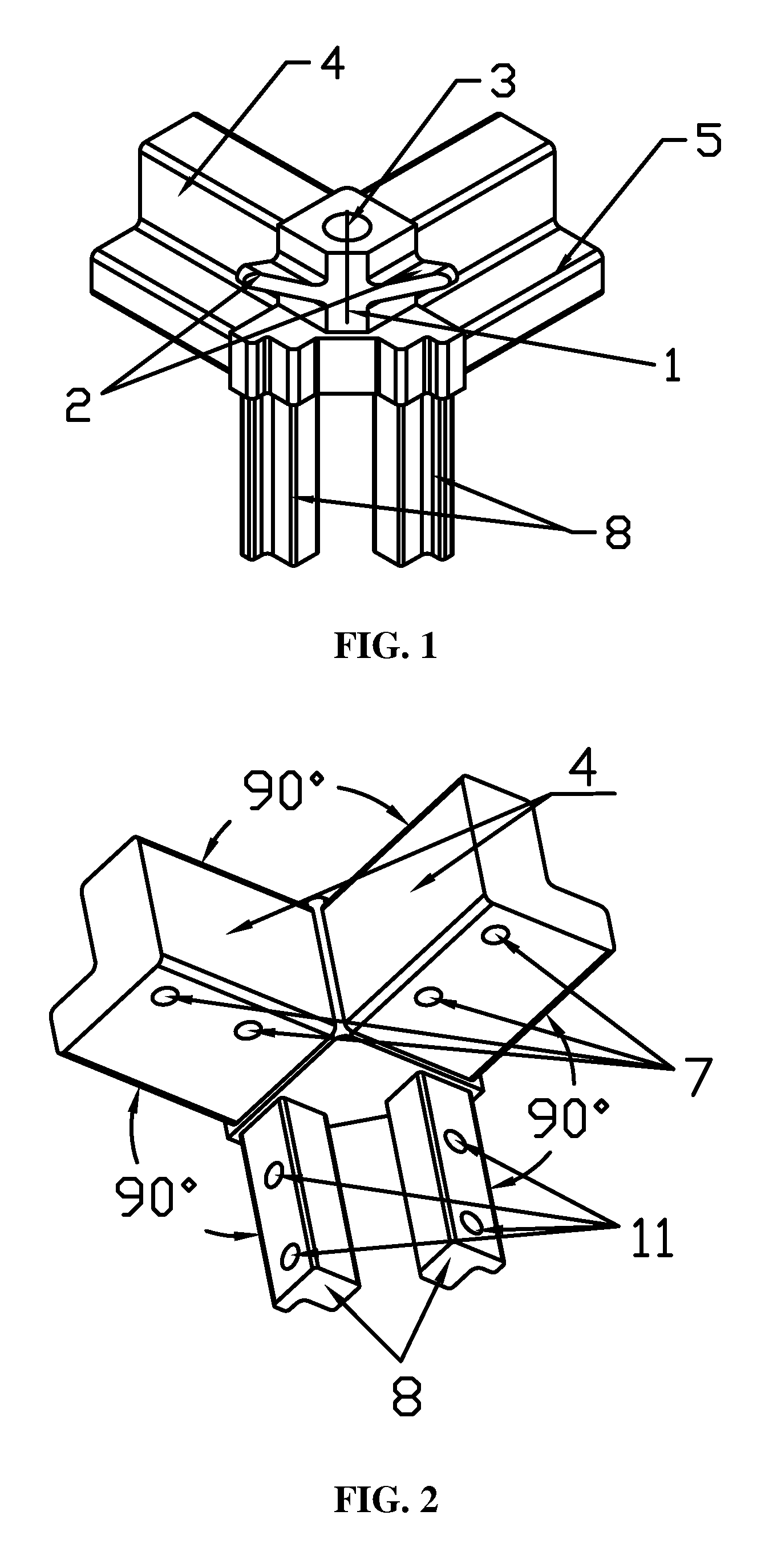

A cabinet framework convenient for assembly comprises an upper framework and a lower framework which are formed by four corner connecting pieces and four horizontal framework rods respectively as well as four column framework rods connected between the four corners of the upper framework and the lower framework. The invention is characterized in that the framework also comprises sixteen prismatic connecting rods used for assembly connection between the column framework rod and the corner connecting pieces at the four corners of the upper framework and the lower framework, symmetrical lug boss or step counter bore is arranged on the corner connecting pieces; and the horizontal framework rod and the column framework rod are profiles with the section like '*', and the square hole cavity at the two ends of the profile can be fitly connected with the lug boss on the corner connecting piece in an embedding way. The cabinet framework convenient for assembly is simple and reasonable in structure, the framework formed by assembling the corner connecting pieces and the prismatic connecting rods is stable in structure and is high in carrying capacity, and flexibility of cabinet framework assembly, fixing assembling piece and interior installation space is strong as each framework rod forming the framework is provided with a plurality of assembly planes, thus being favorable to change of specification and type of products.

Owner:SHENZHEN YEEFU PRECISION MACHINERY

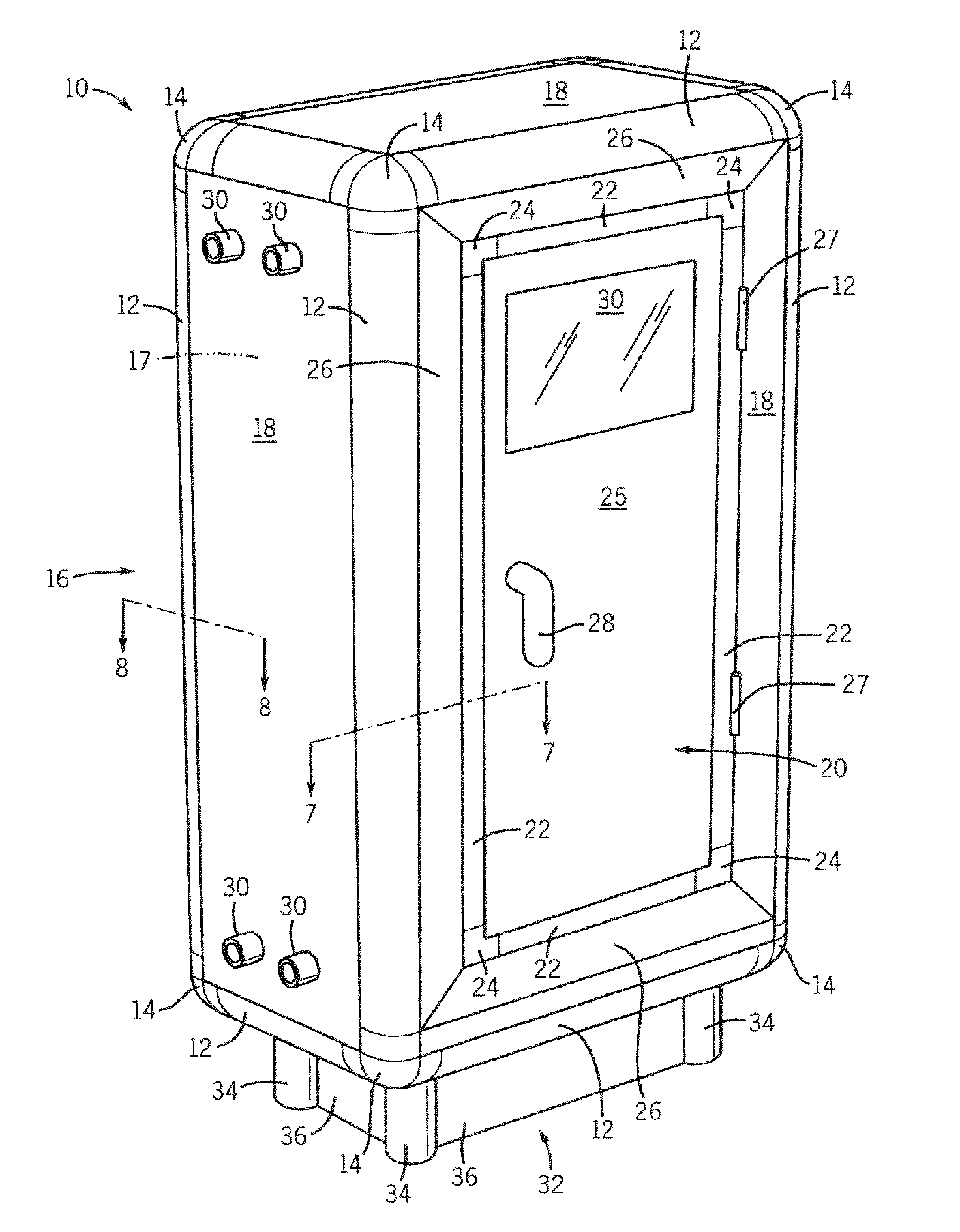

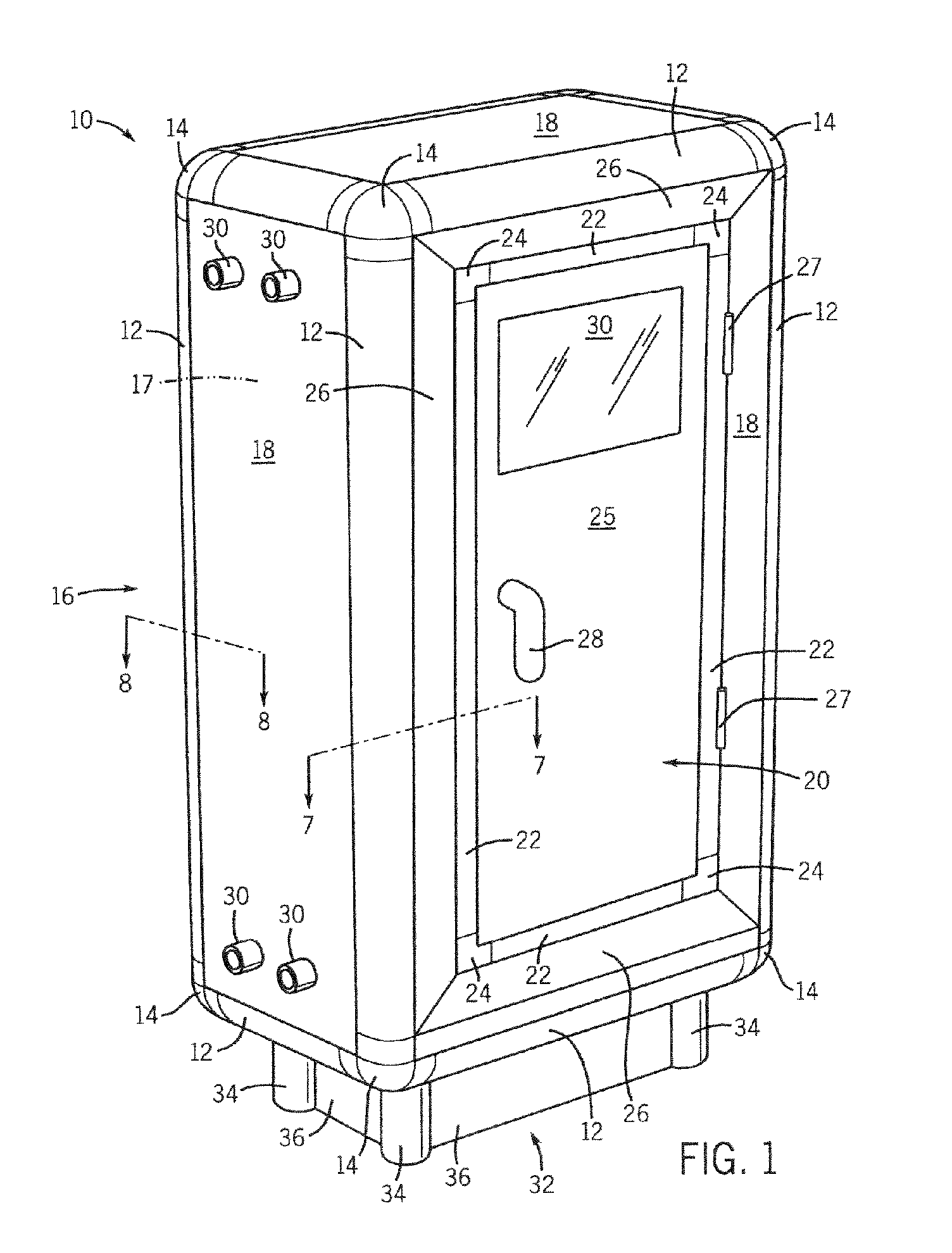

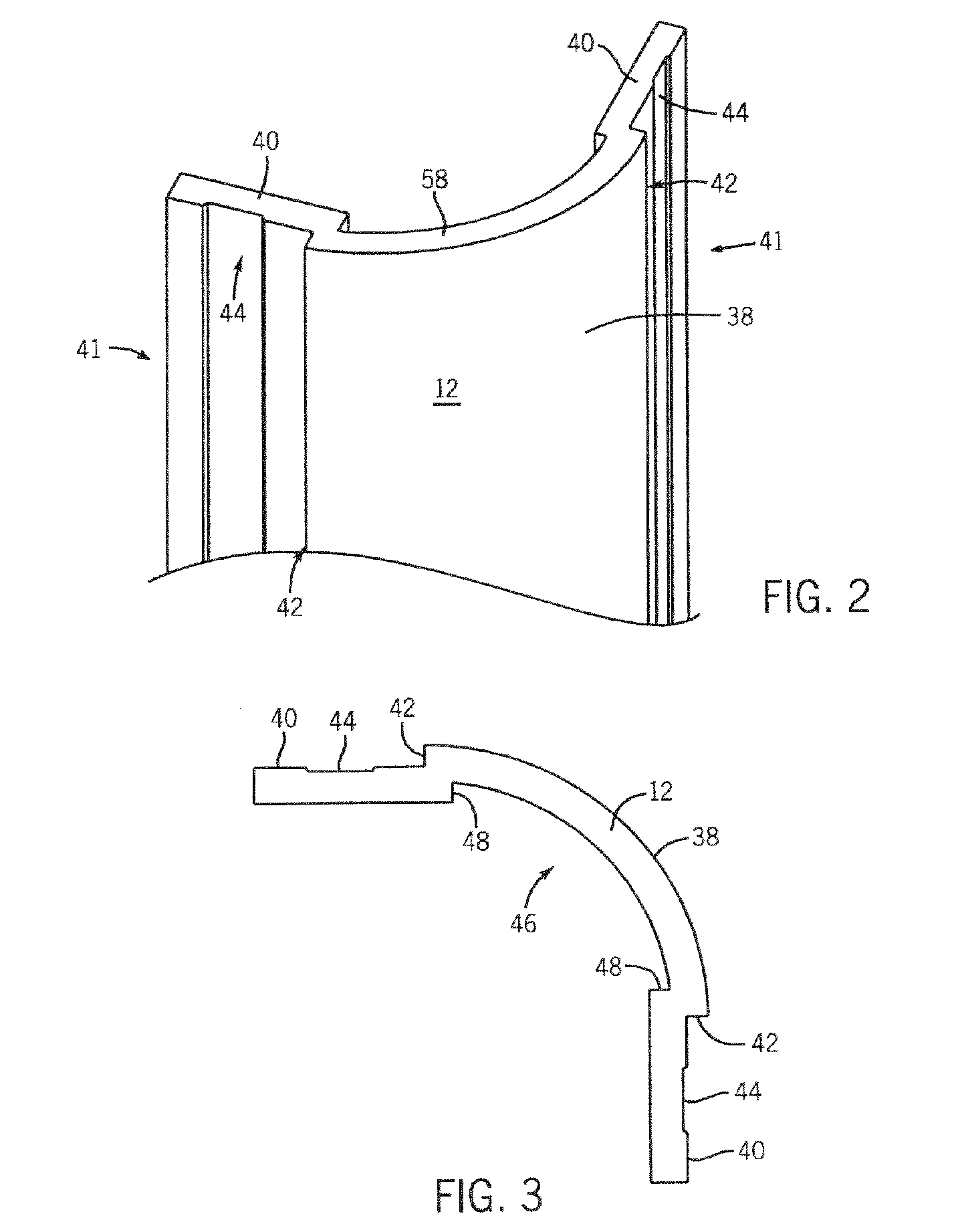

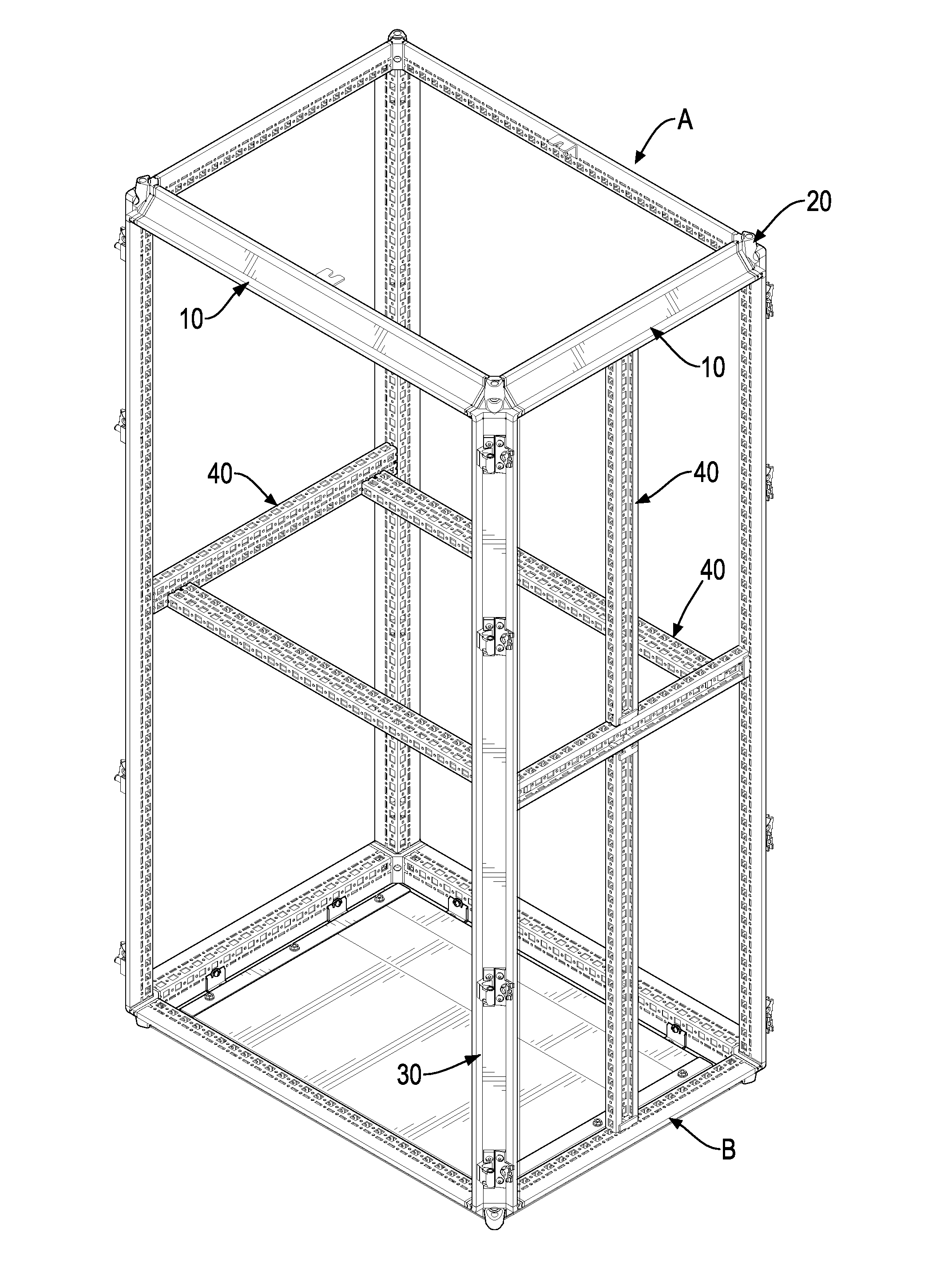

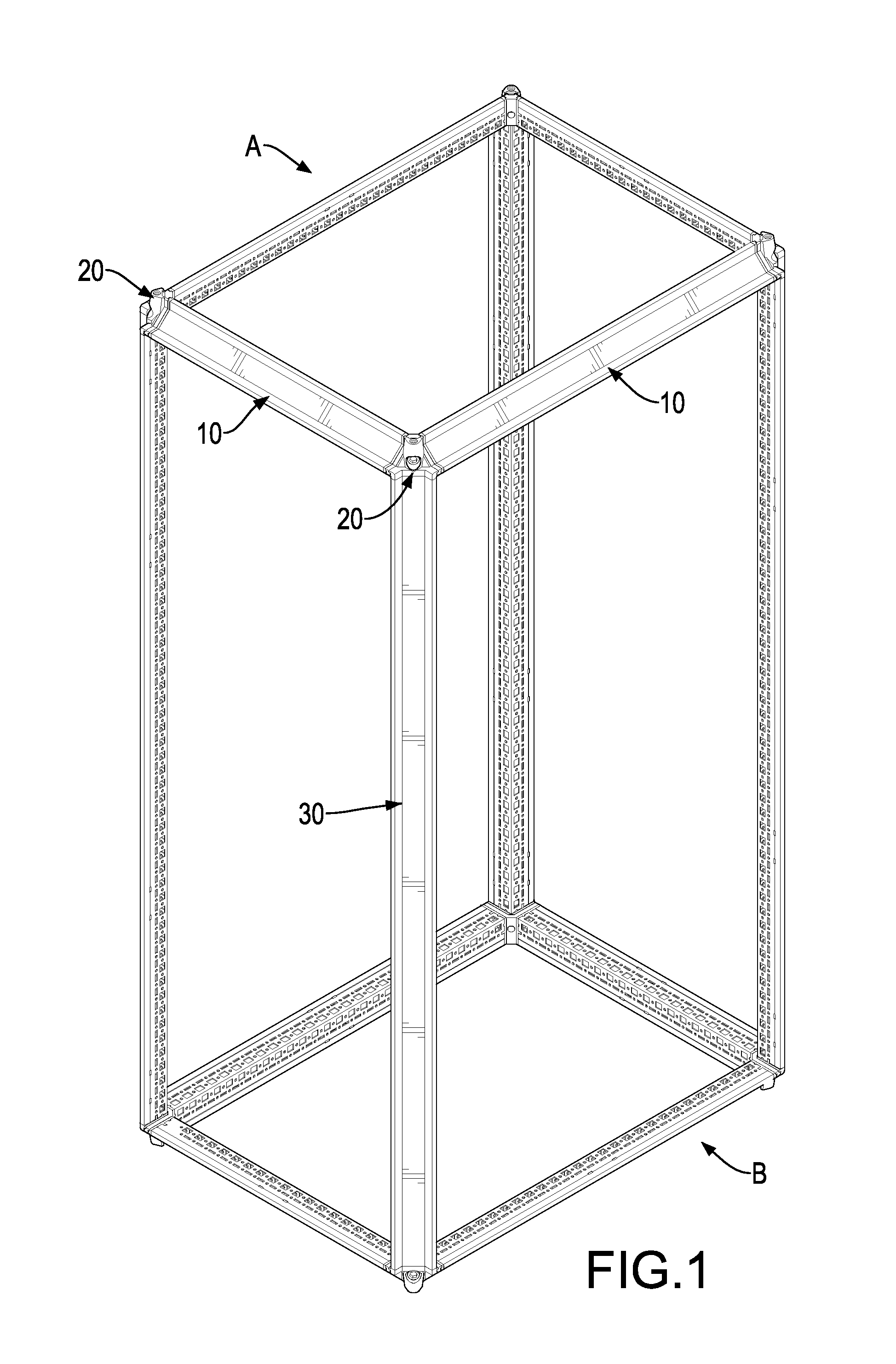

Modular enclosure system

A modular enclosure system and method for forming an enclosure are disclosed. The enclosure system includes a plurality of interchangeable edge rails constructed to engage a plurality of interchangeable corner connectors. The interchangeable edge rails include a flange constructed to engage and secure a plurality of panel sections to the enclosure thereby quickly and efficiently forming a desired volume enclosure.

Owner:NOHL

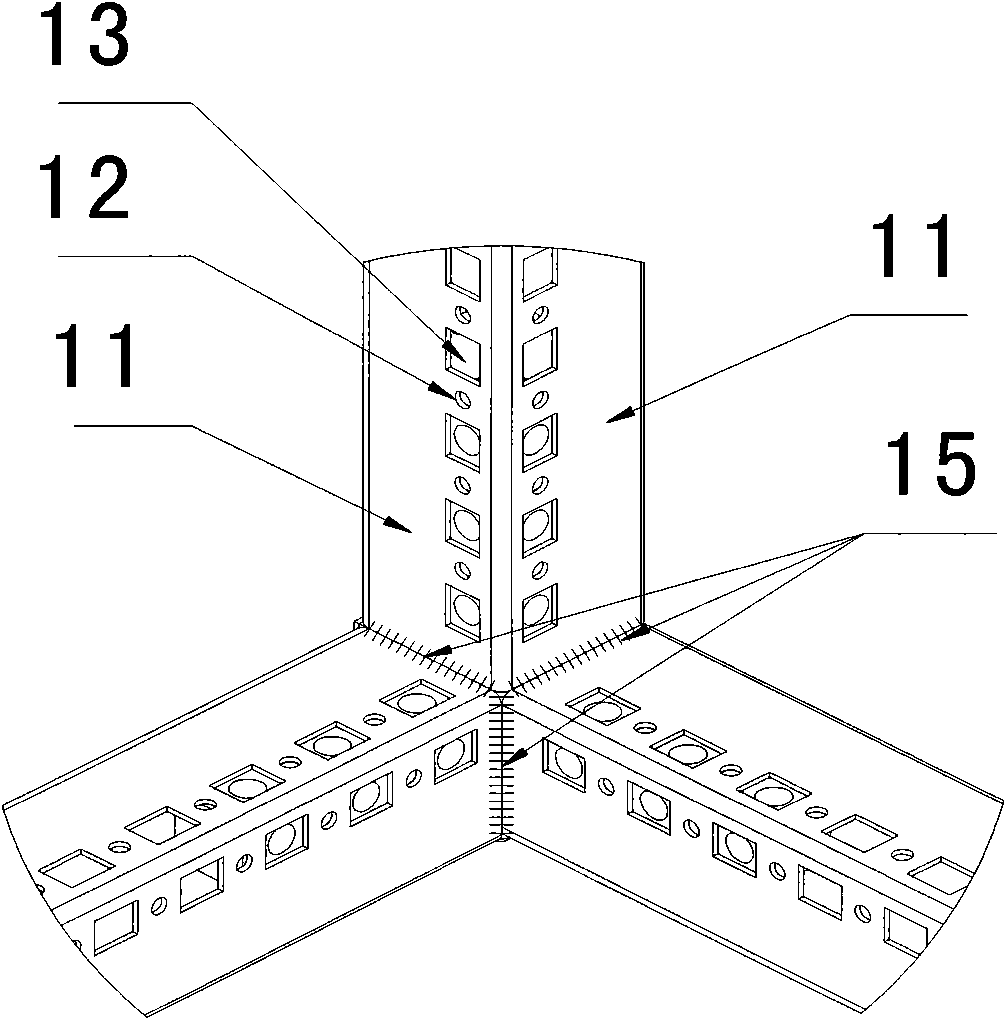

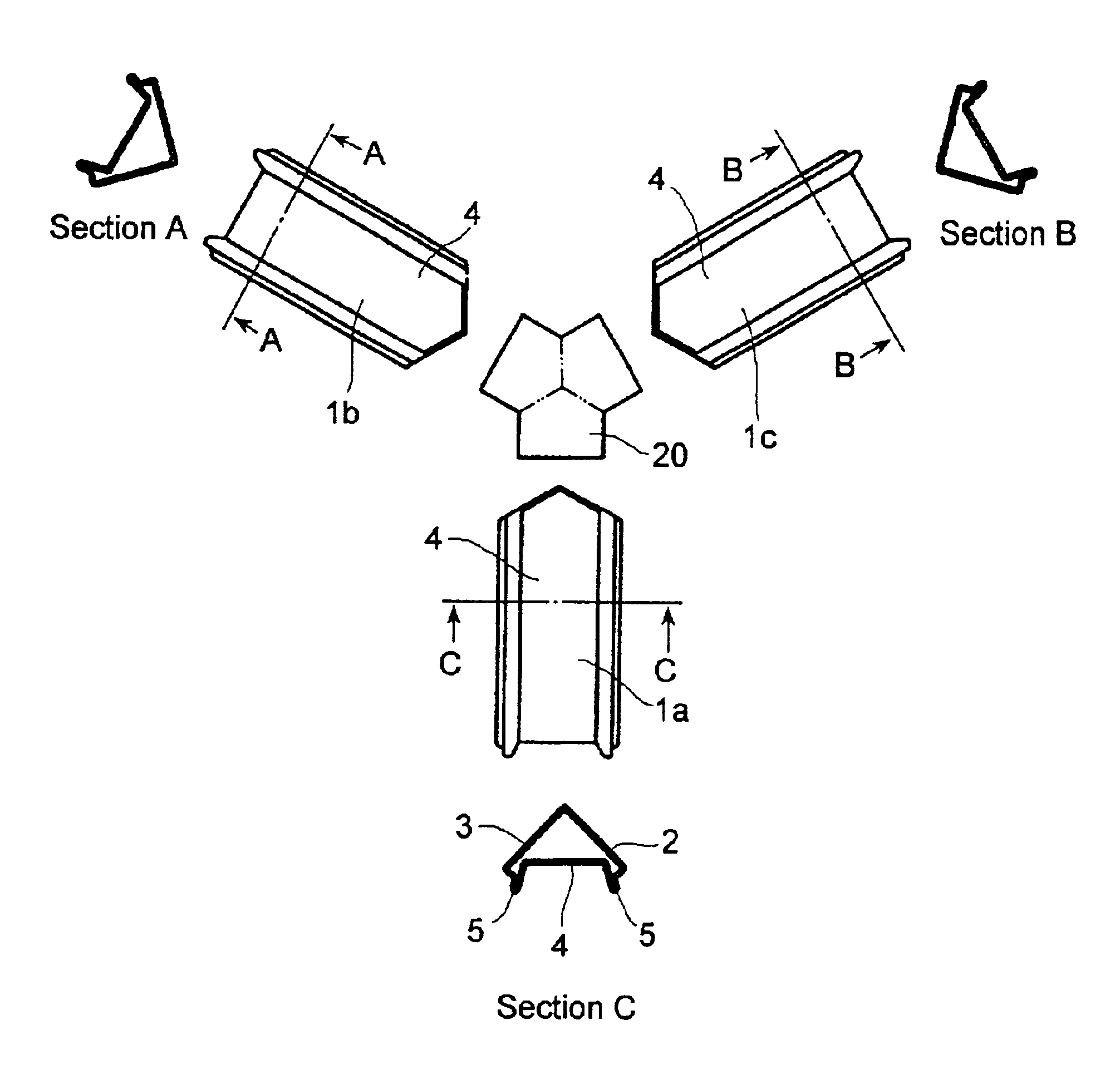

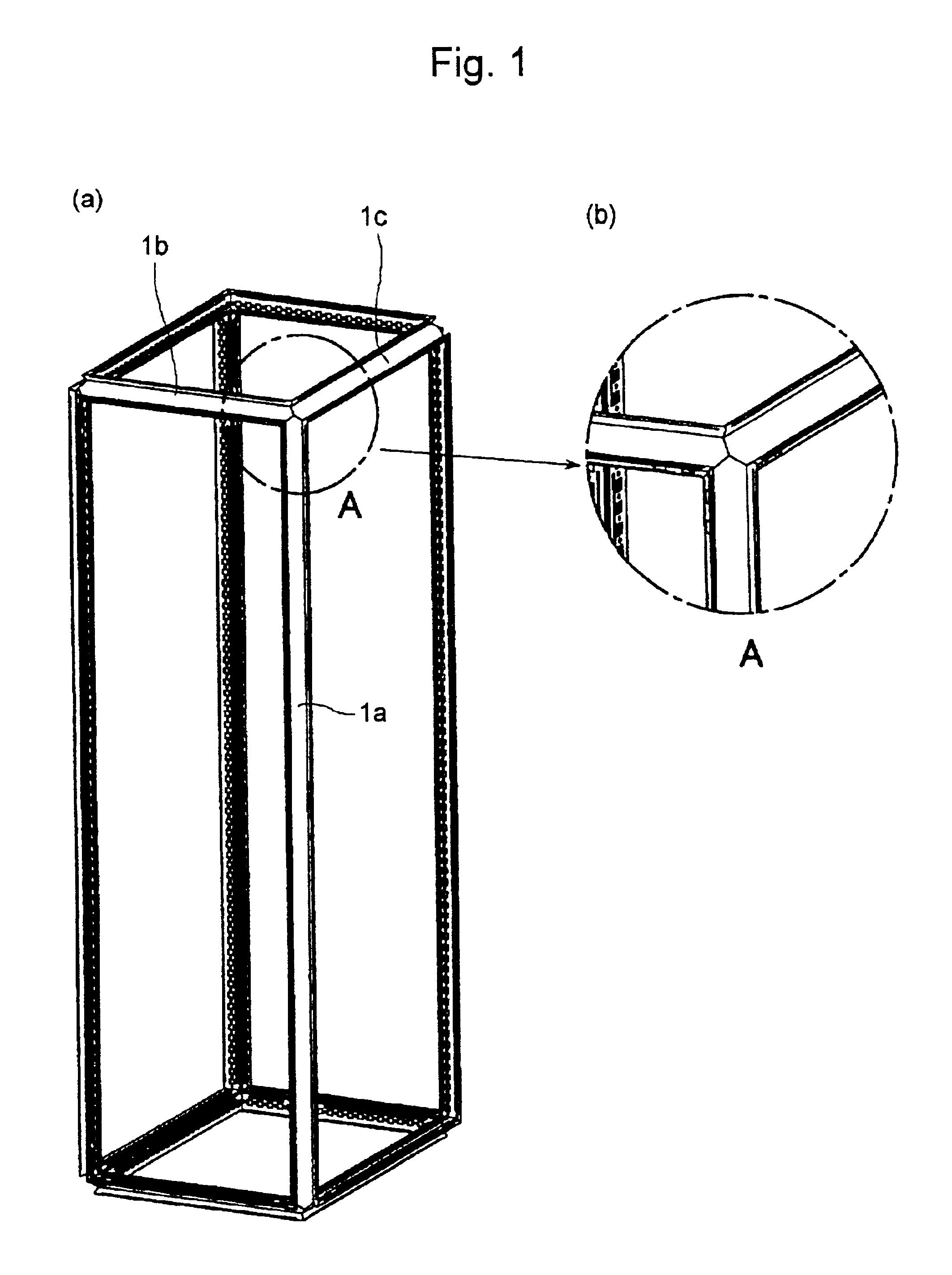

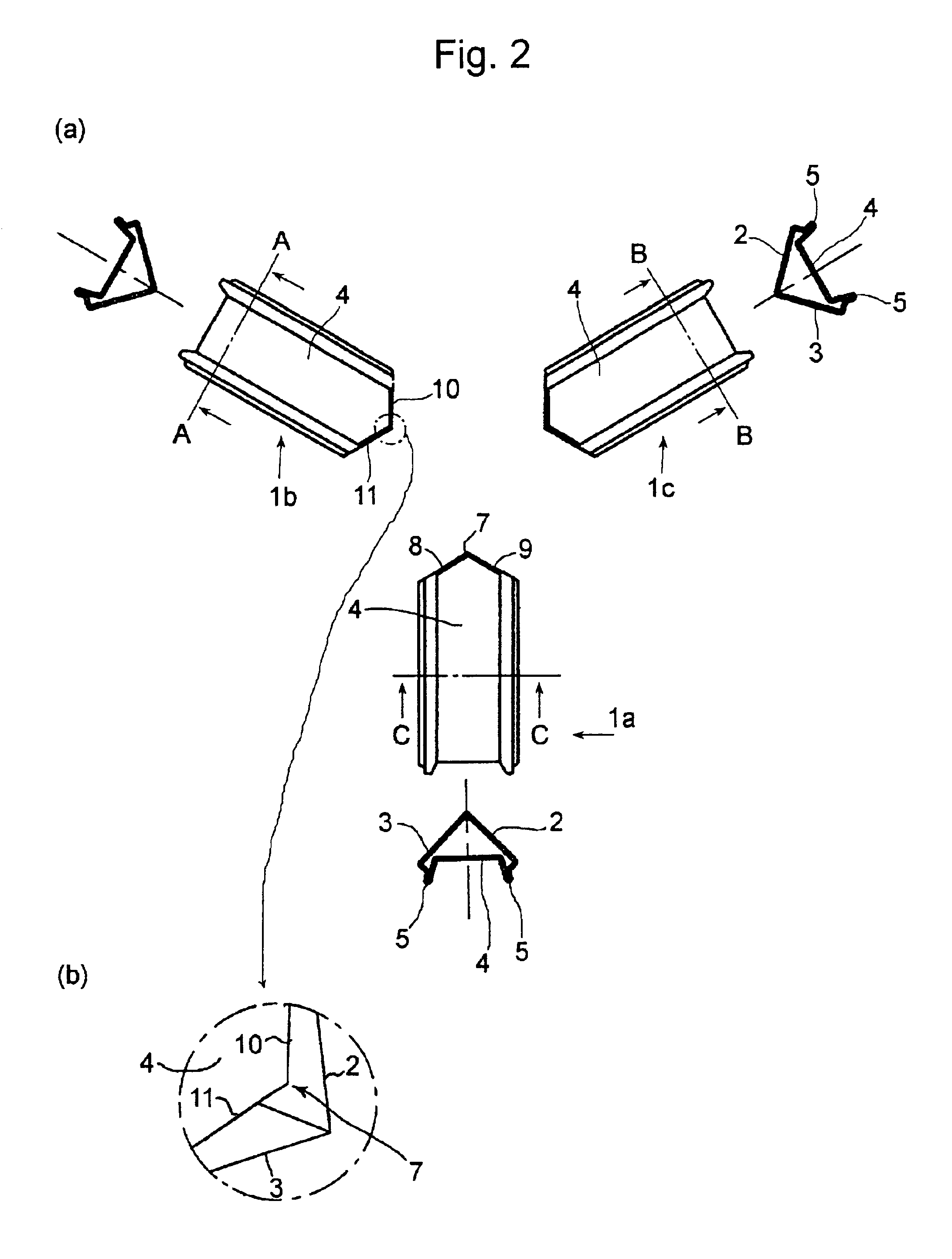

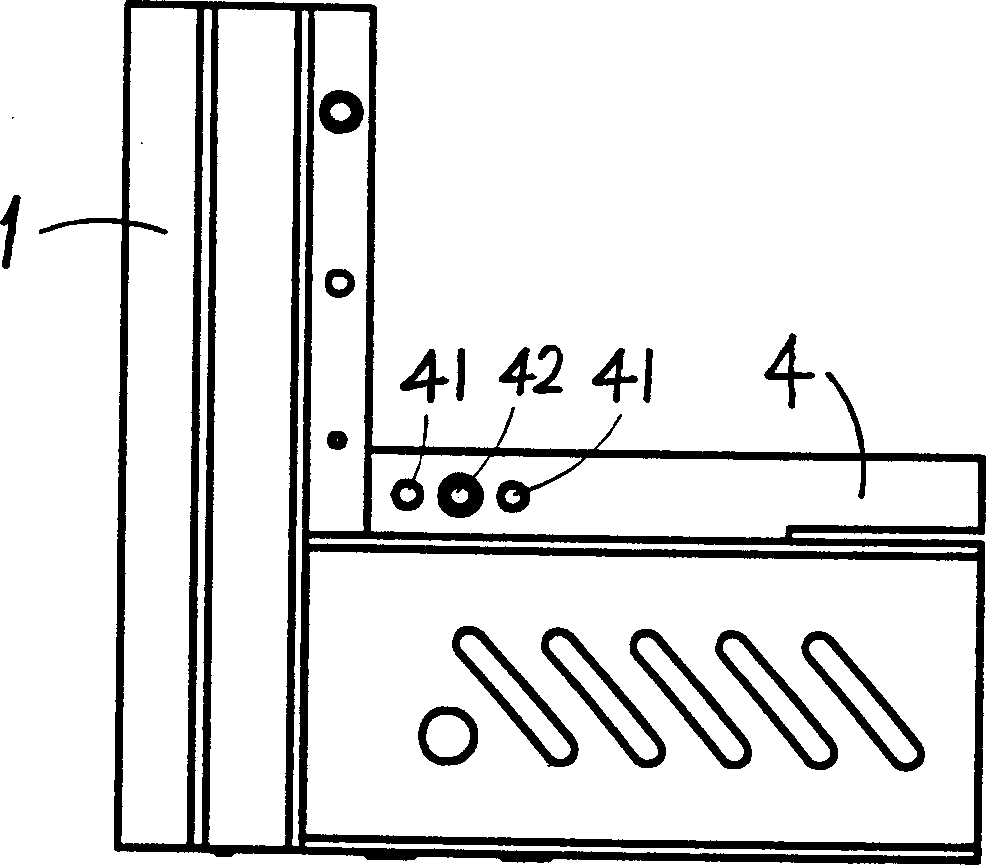

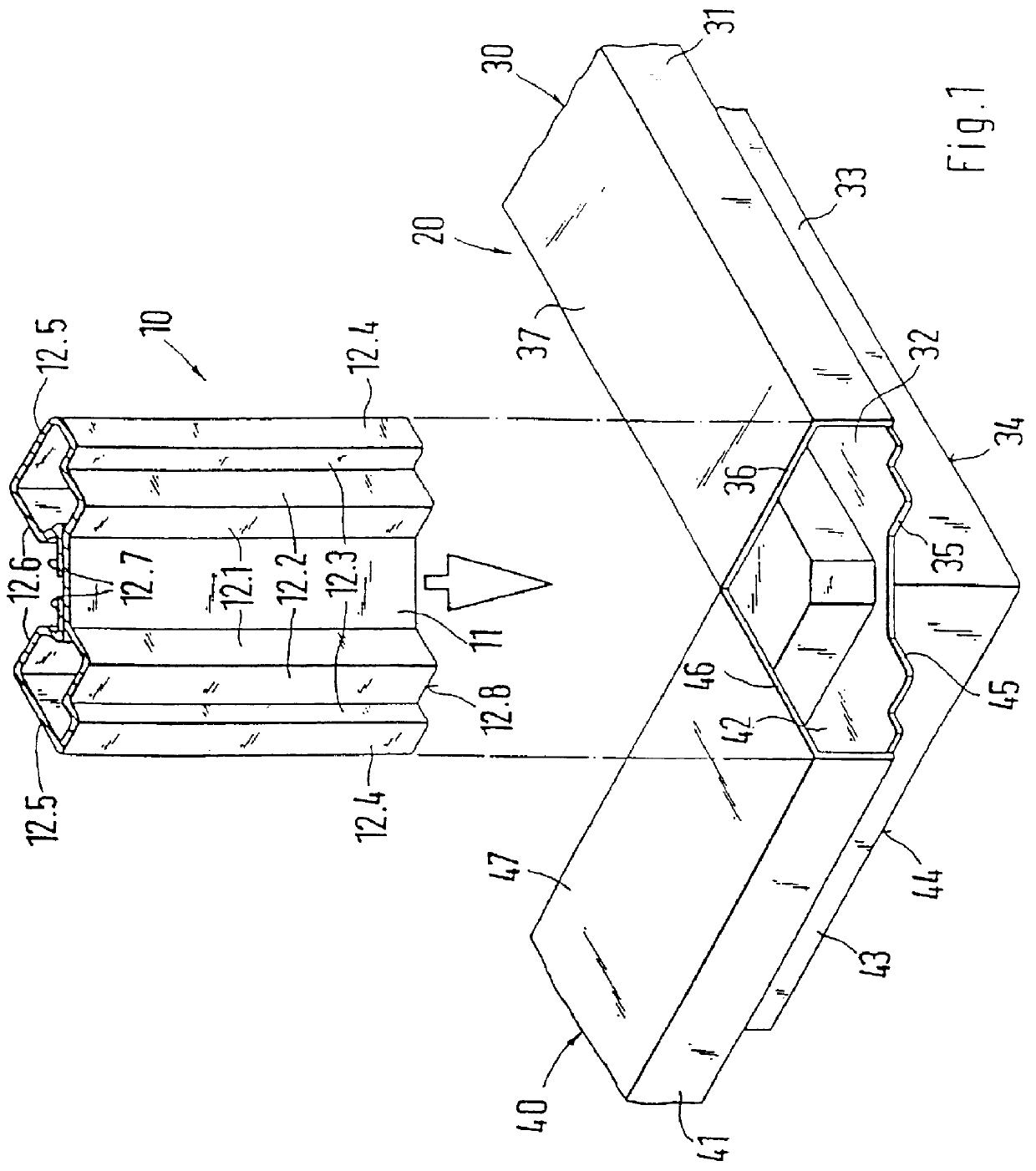

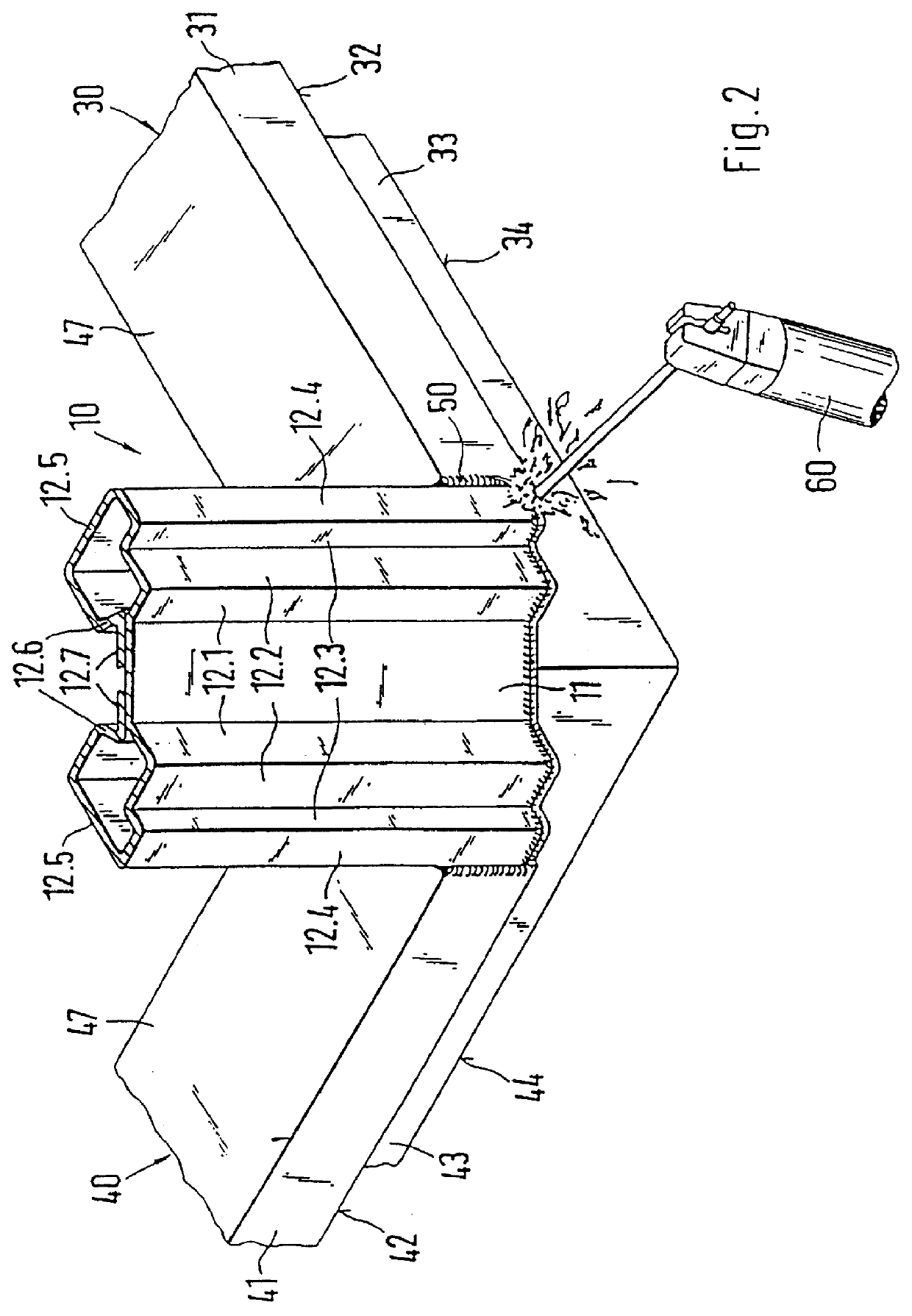

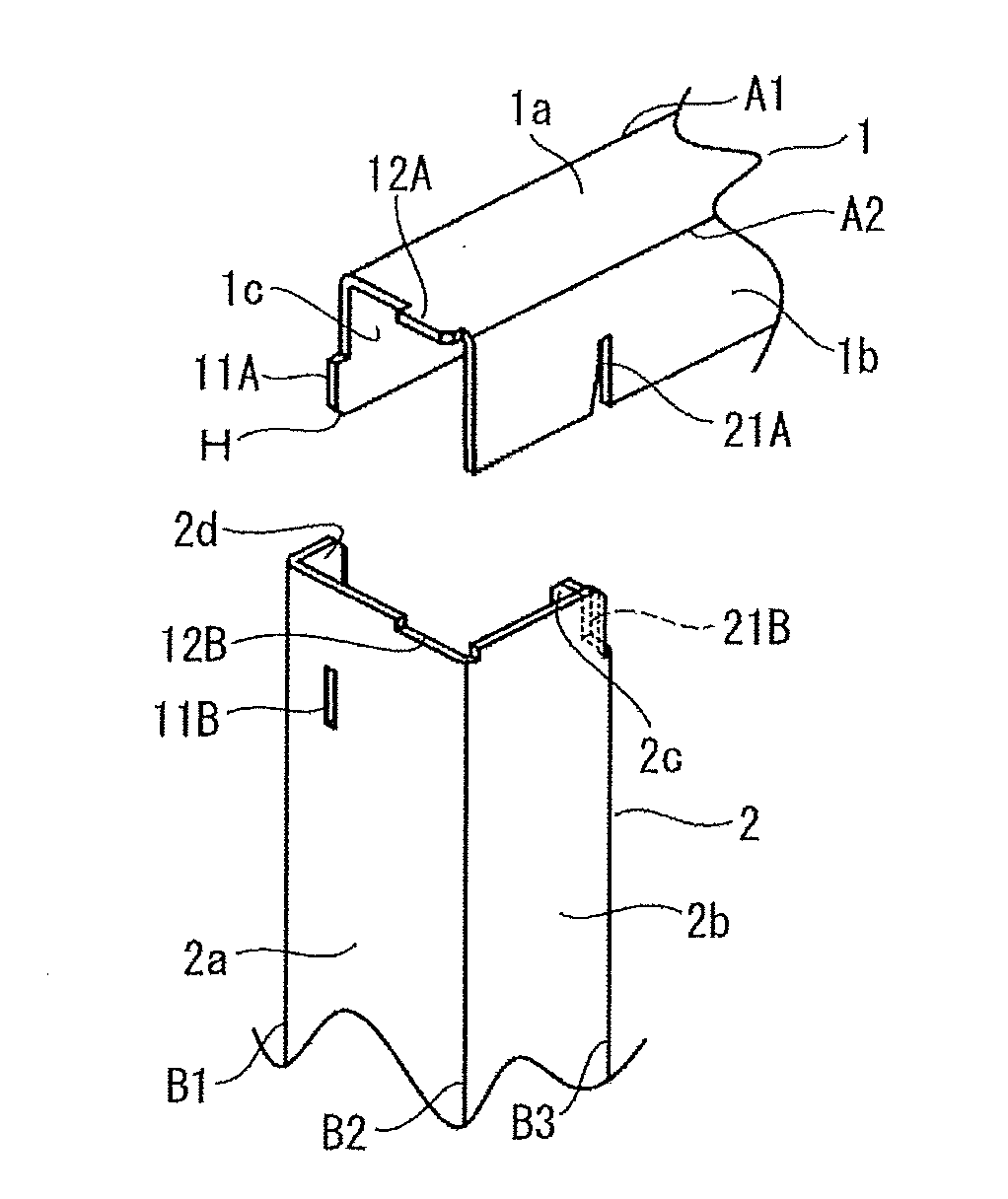

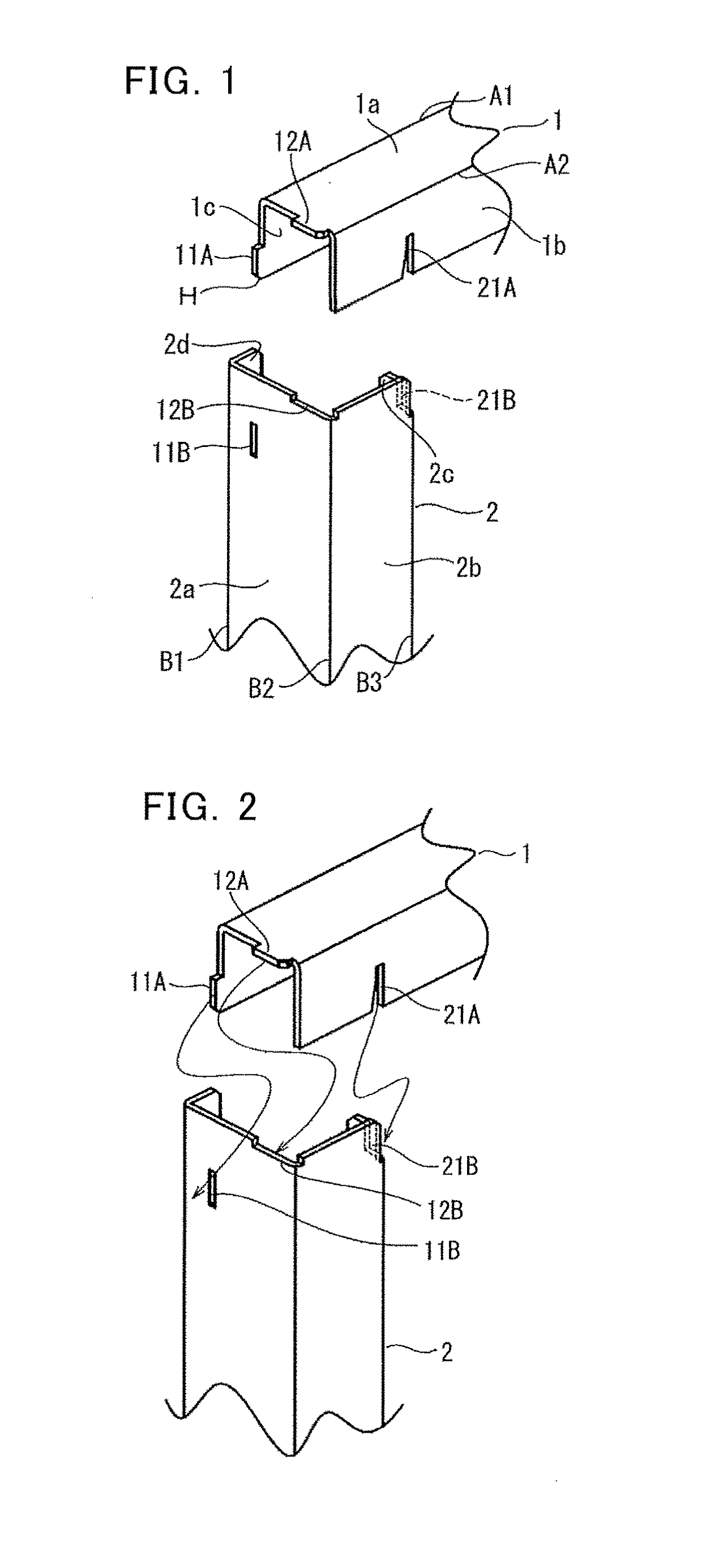

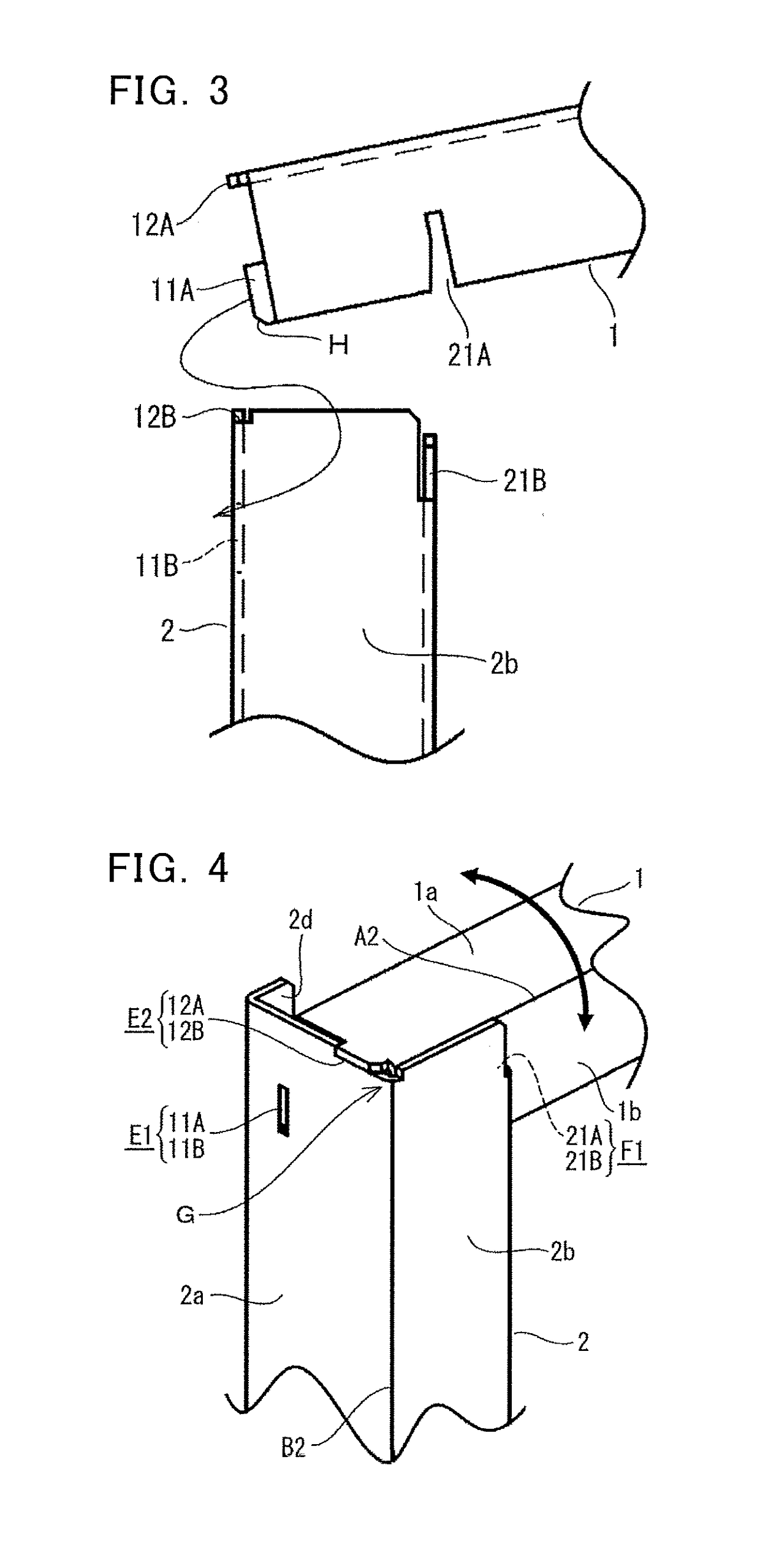

Frame for electrical and electronic equipment housing cabinets and a frame joining structure

InactiveUS6965075B2Low costReducing locationCeilingsSecuring devicesEngineeringUltimate tensile strength

A frame joining structure for electrical and electronic equipment housing cabinets, in which ends of frames are simplified in shape to dispense with complex cutting and which possesses excellent strength and waterproof property. Ends of outer side surfaces (4) of three mutually orthogonal frames (1a, 1b, 1c), which constitute a framework of a cabinet, are cut at two planes of ±45° relative to a plane defined by other two frames to be point-shaped. These ends are joined together directly or through a corner member (20) having the same configuration as that of the ends to constitute a firm corner portion.

Owner:NITTO KOGYO KK

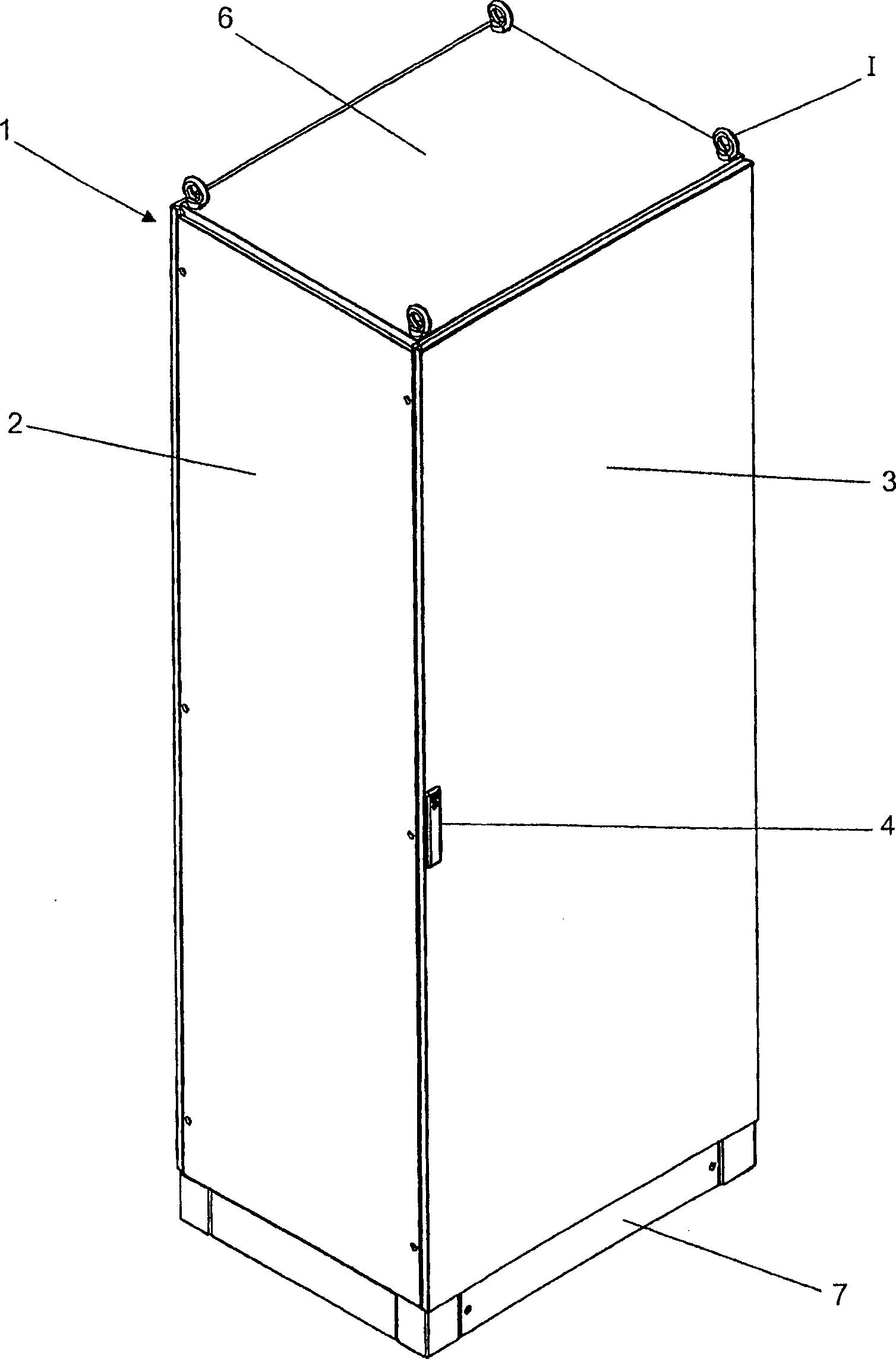

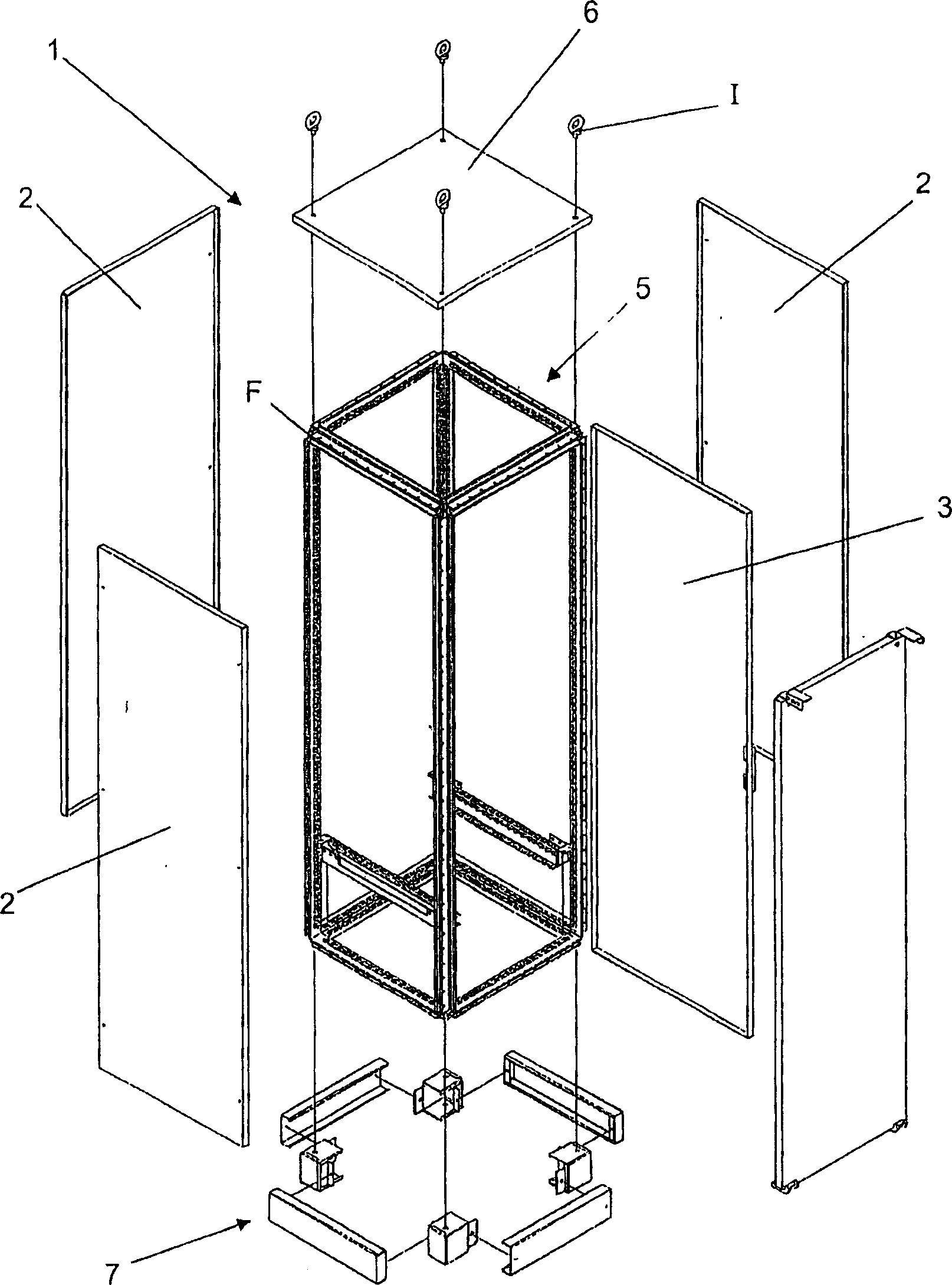

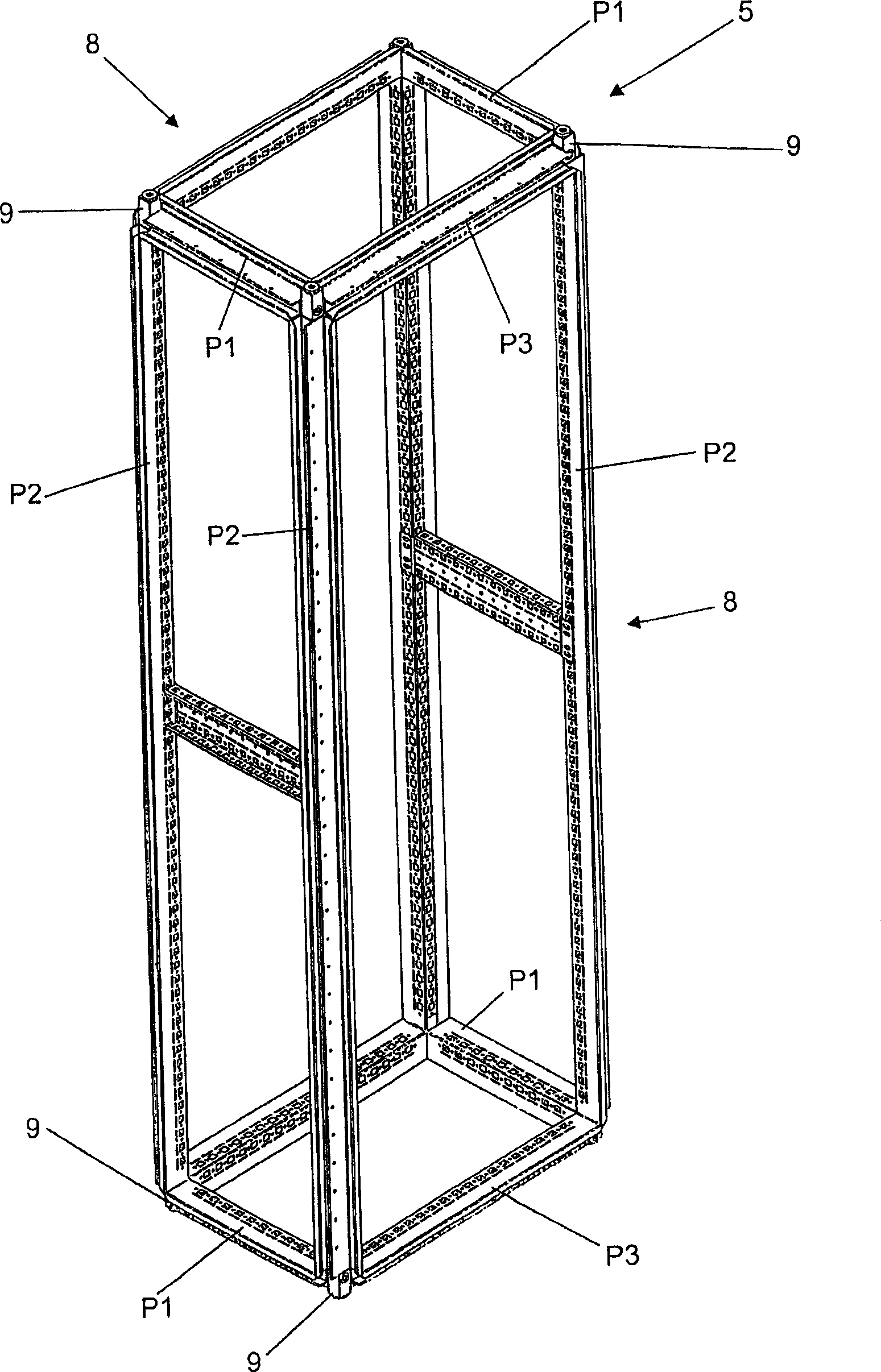

Mettalic structure improvement for manufacturing electrical cabinets

InactiveCN1879272AEasy to manufactureLow costSubstation/switching arrangement casingsRack/frame constructionEngineeringMechanical engineering

Improvement to the metallic structure for manufacturing electrical panels / cabinets, enclosing a structure of metallic cross sections (5), with the means for supporting the parts making up the external walls from folded sheets, as well as constituting the means for supporting and mounting the doors with its respective hinges, the upper (6) and lower enclosure with the base (7) and other electrical and electronic inside of the cabinet components.The said structure (5) can be presented semi-assembled, where four of its uprights or four of its cross sections (P1) are completely free whilst all the other cross sections are rigidly integrated into two equal rectangular frames (8) which form the two opposite sides of the said structure (5) and therefore at the corner point of the junction of each rectangular frame (8) there is a complementary device (9) cooperating for the interlinking at 90 DEG between two adjacent cross sections (P2) and (P3) of each frame (8), as also this selfsame device presents the means so that the extremities of the other cross sections (P1) may be coupled between the corners of the rectangular frames (8), thus forming the structure (5).

Owner:梅尔基塞代克・弗朗西斯基尼

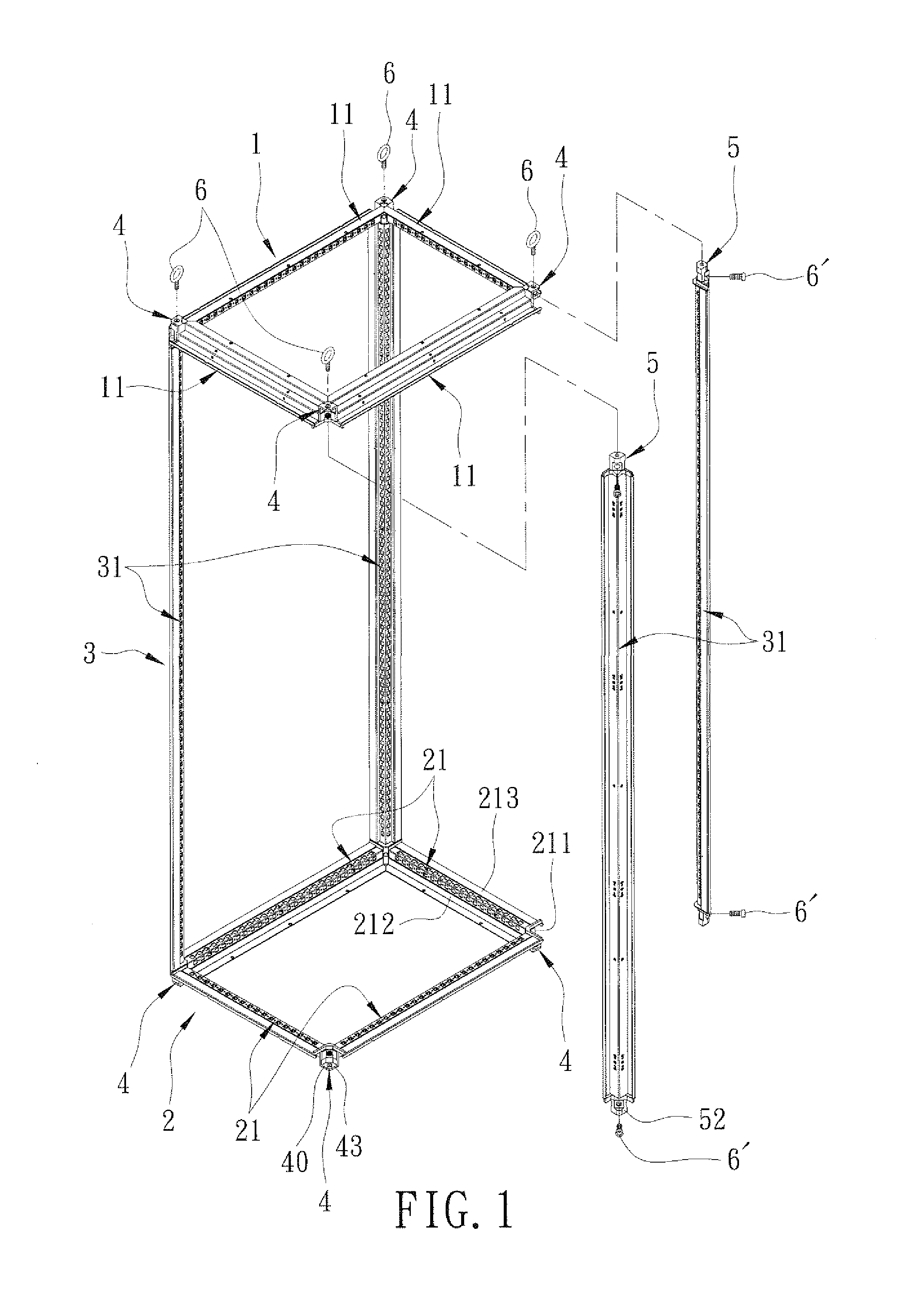

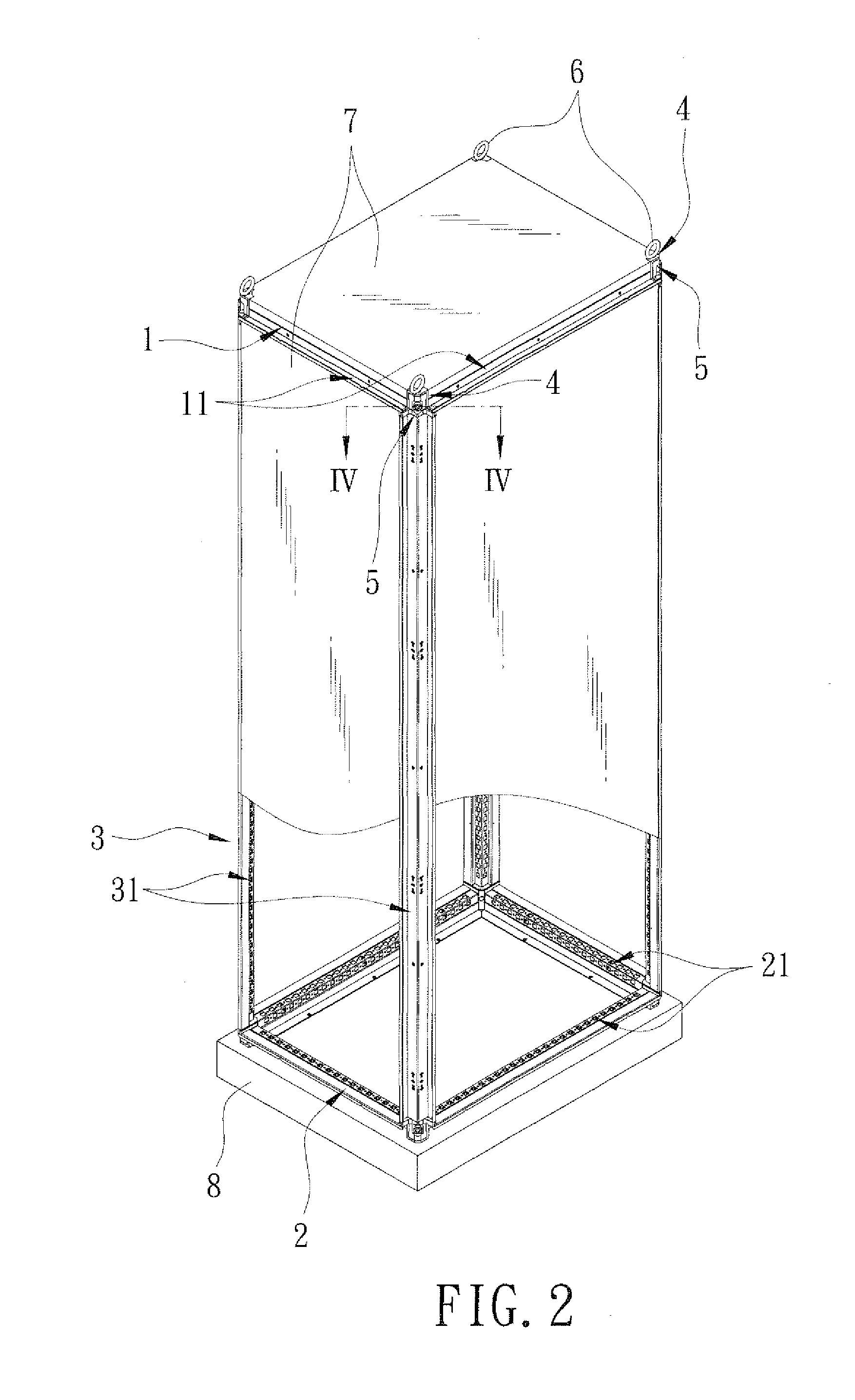

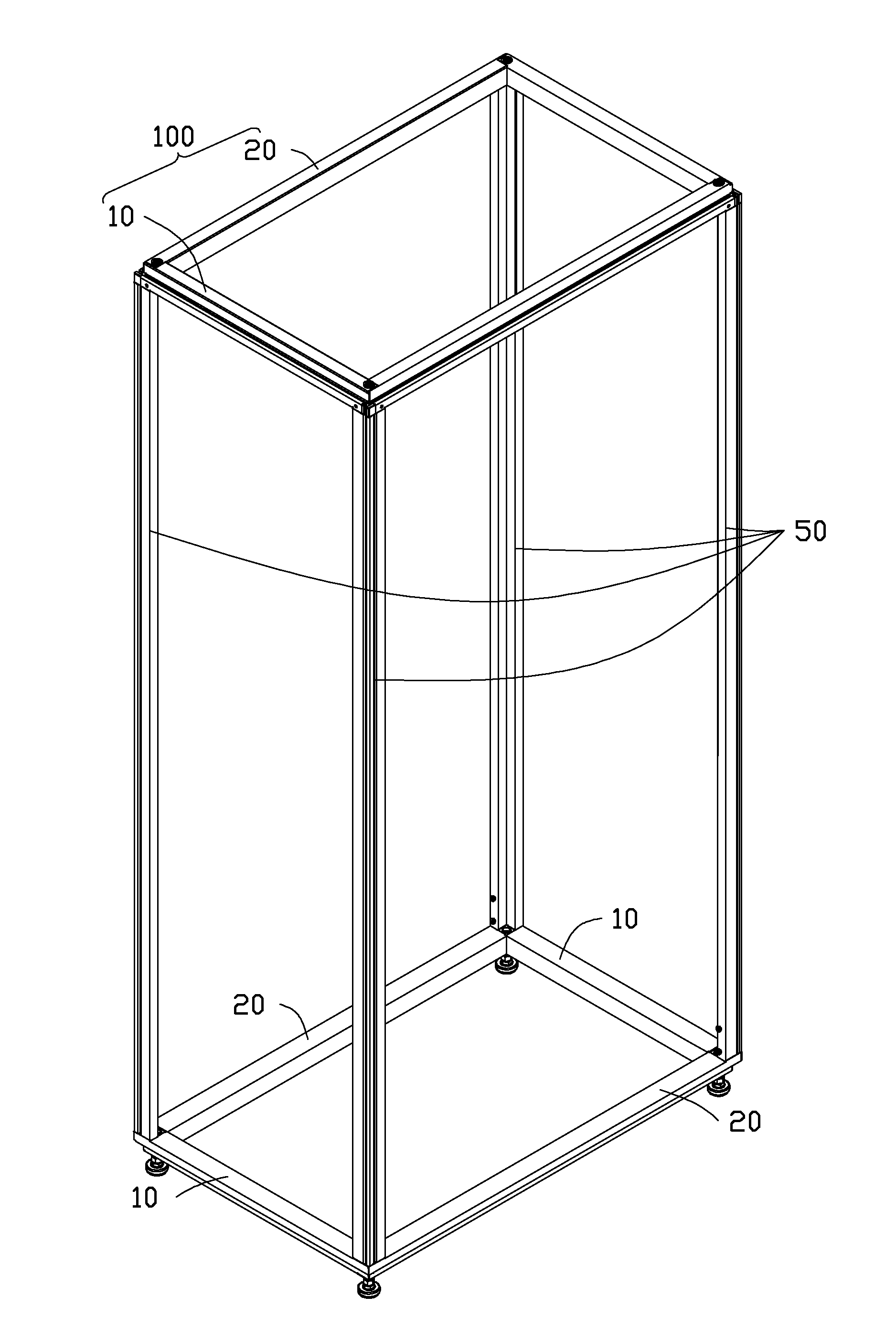

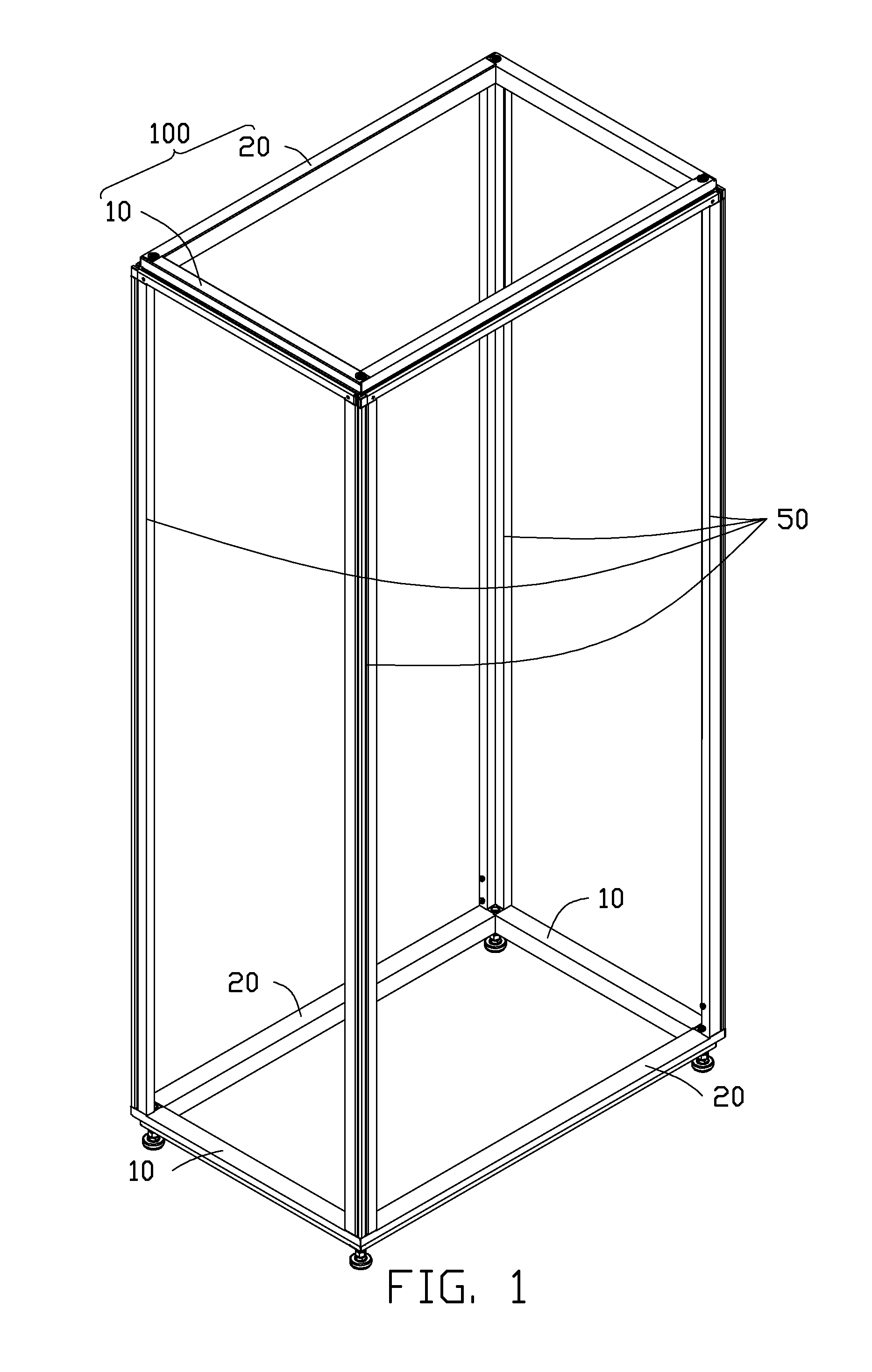

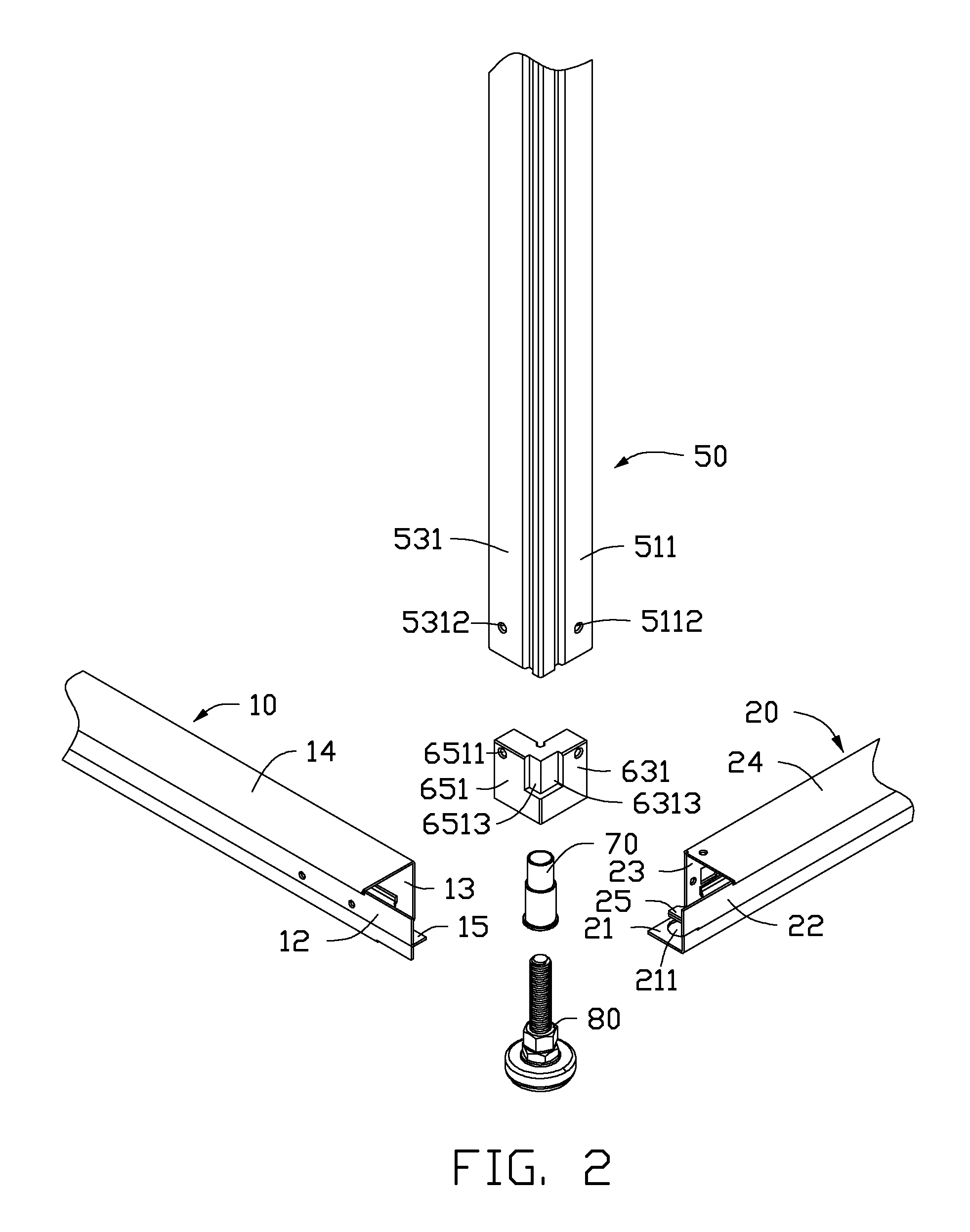

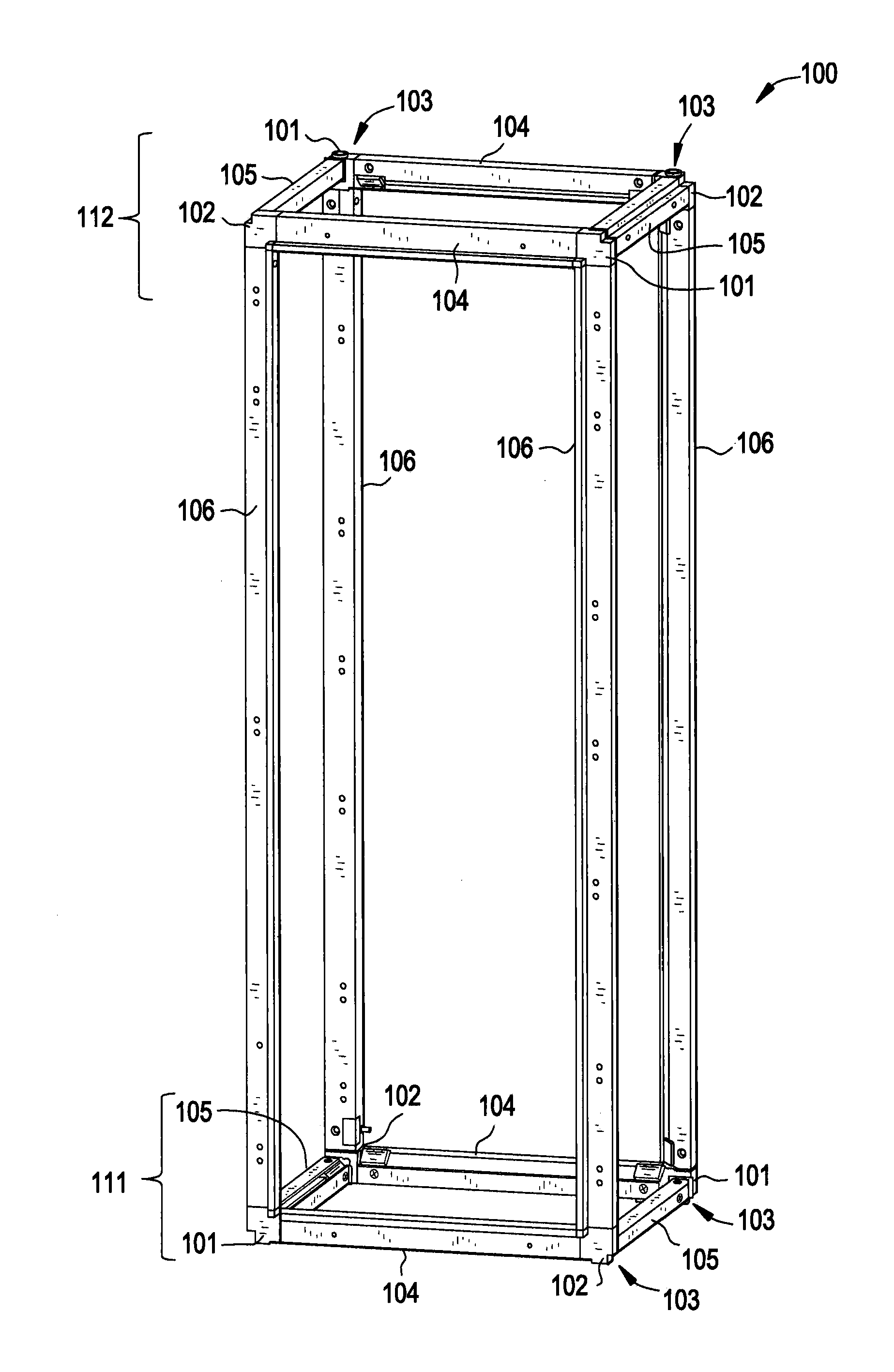

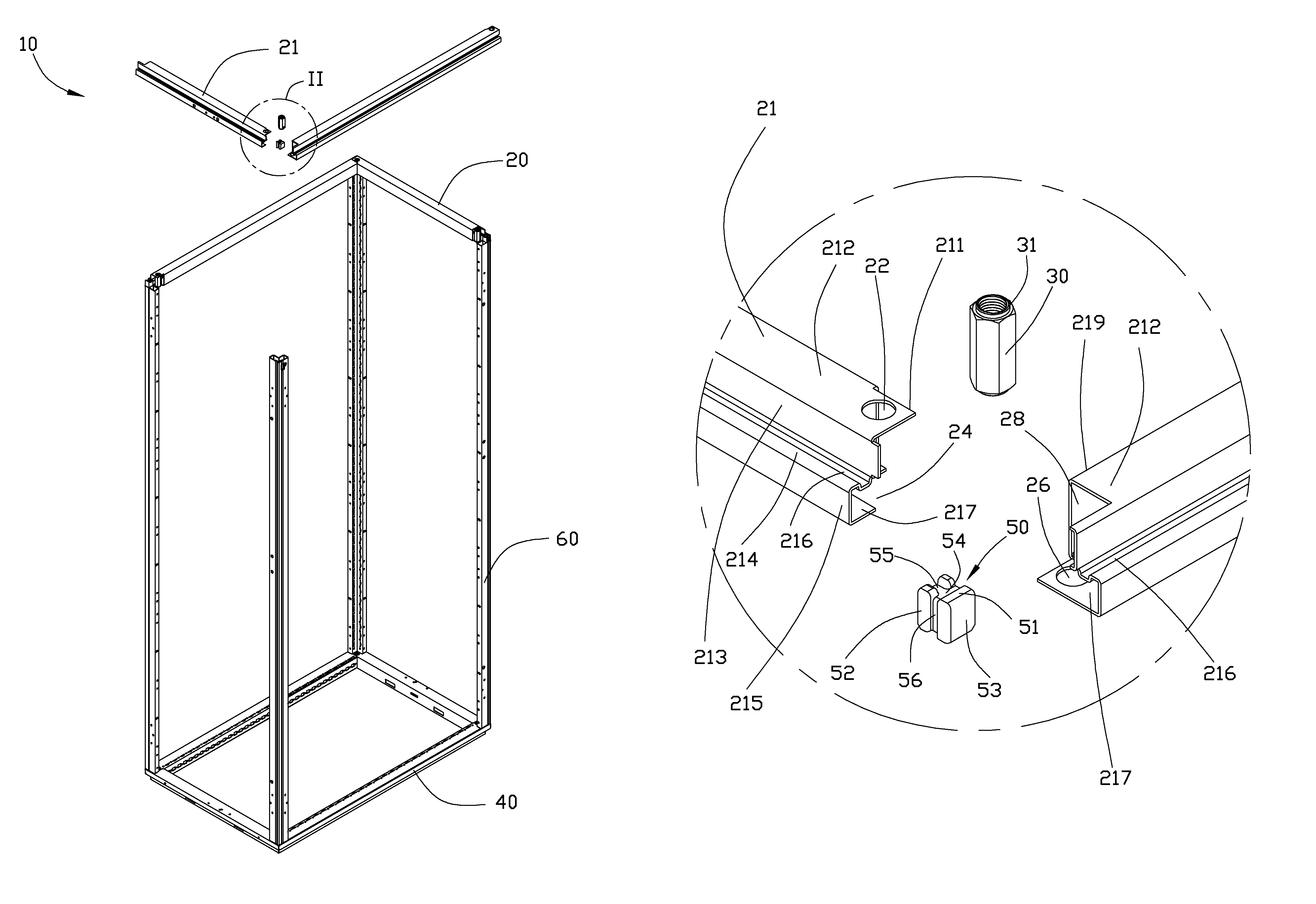

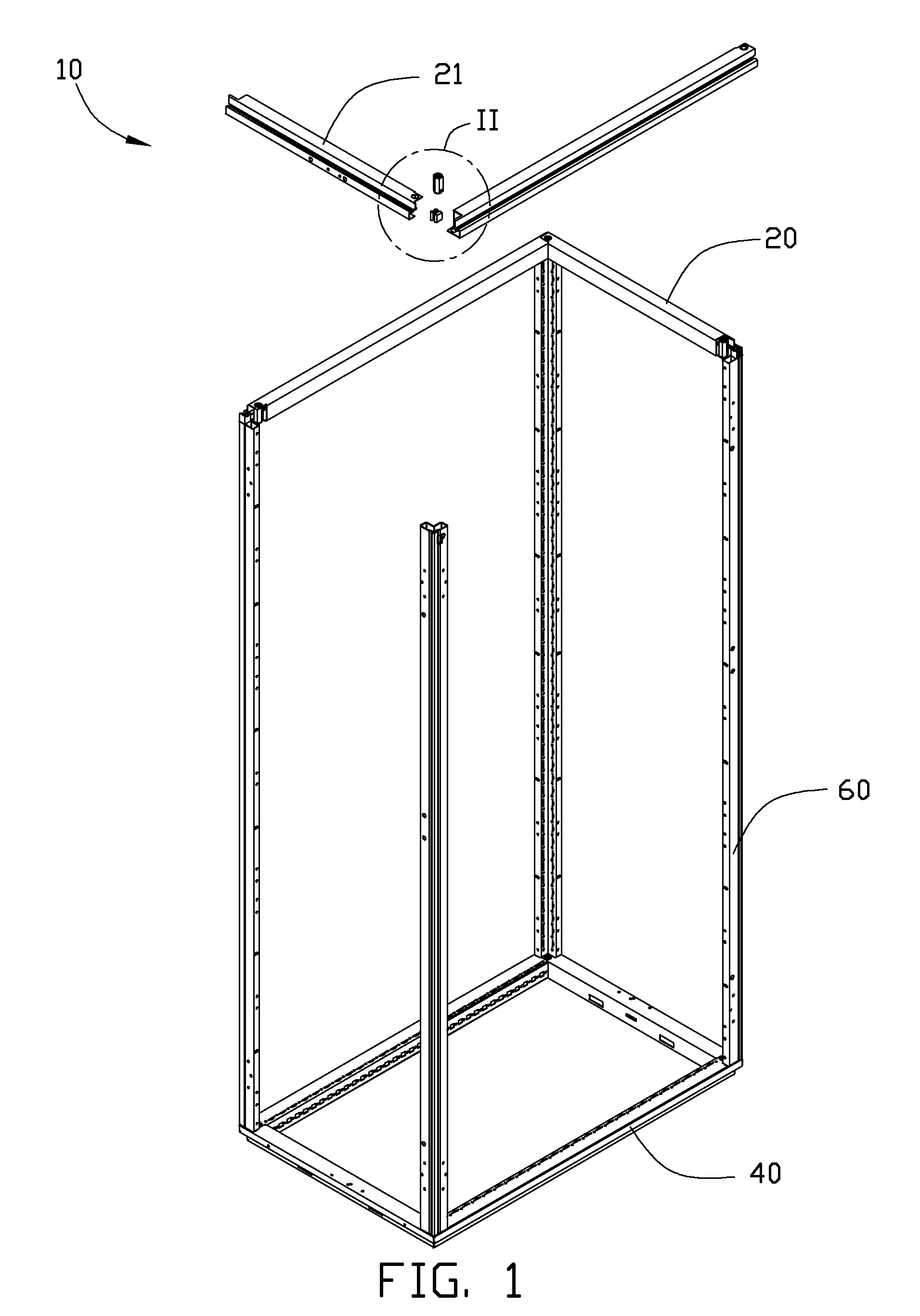

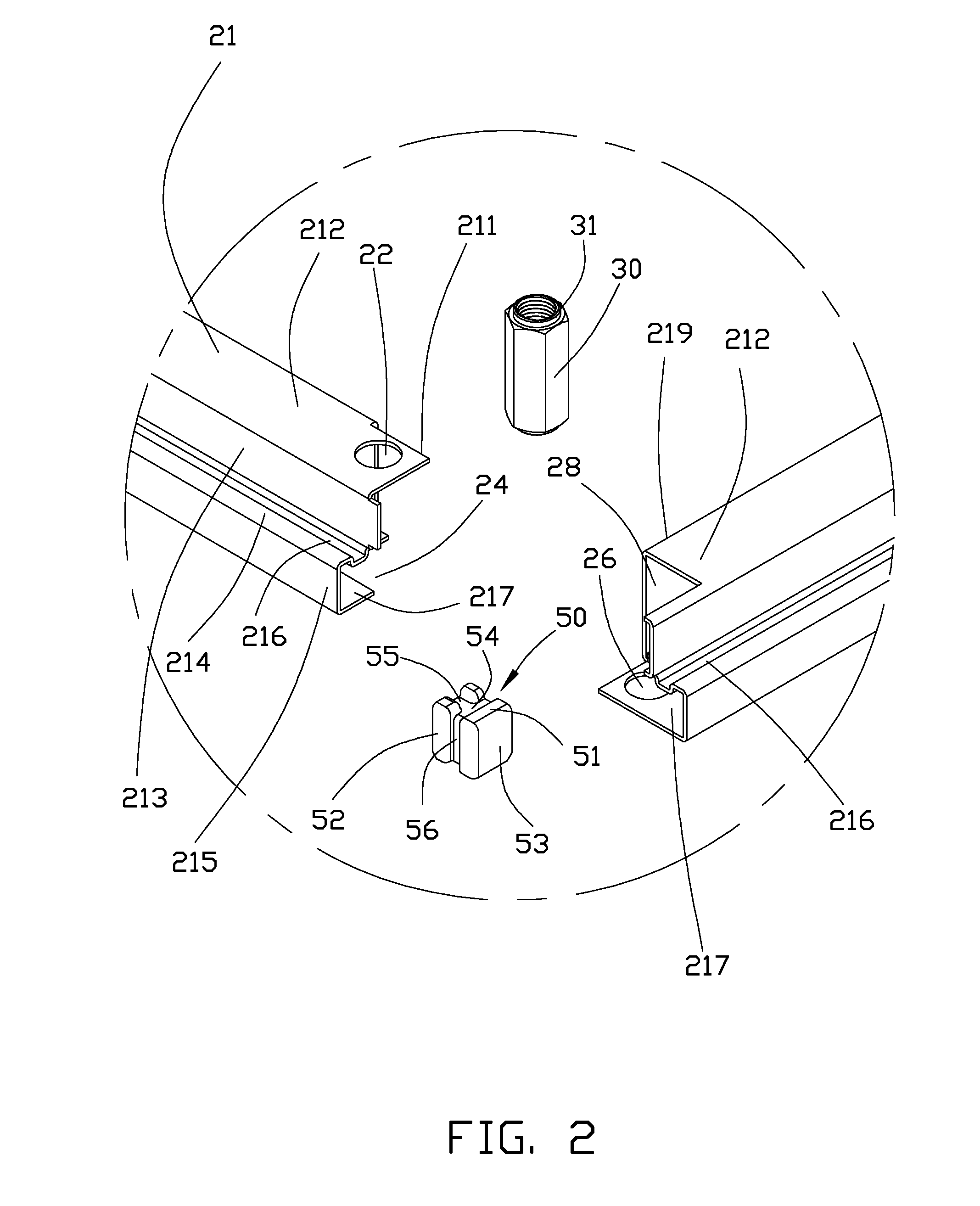

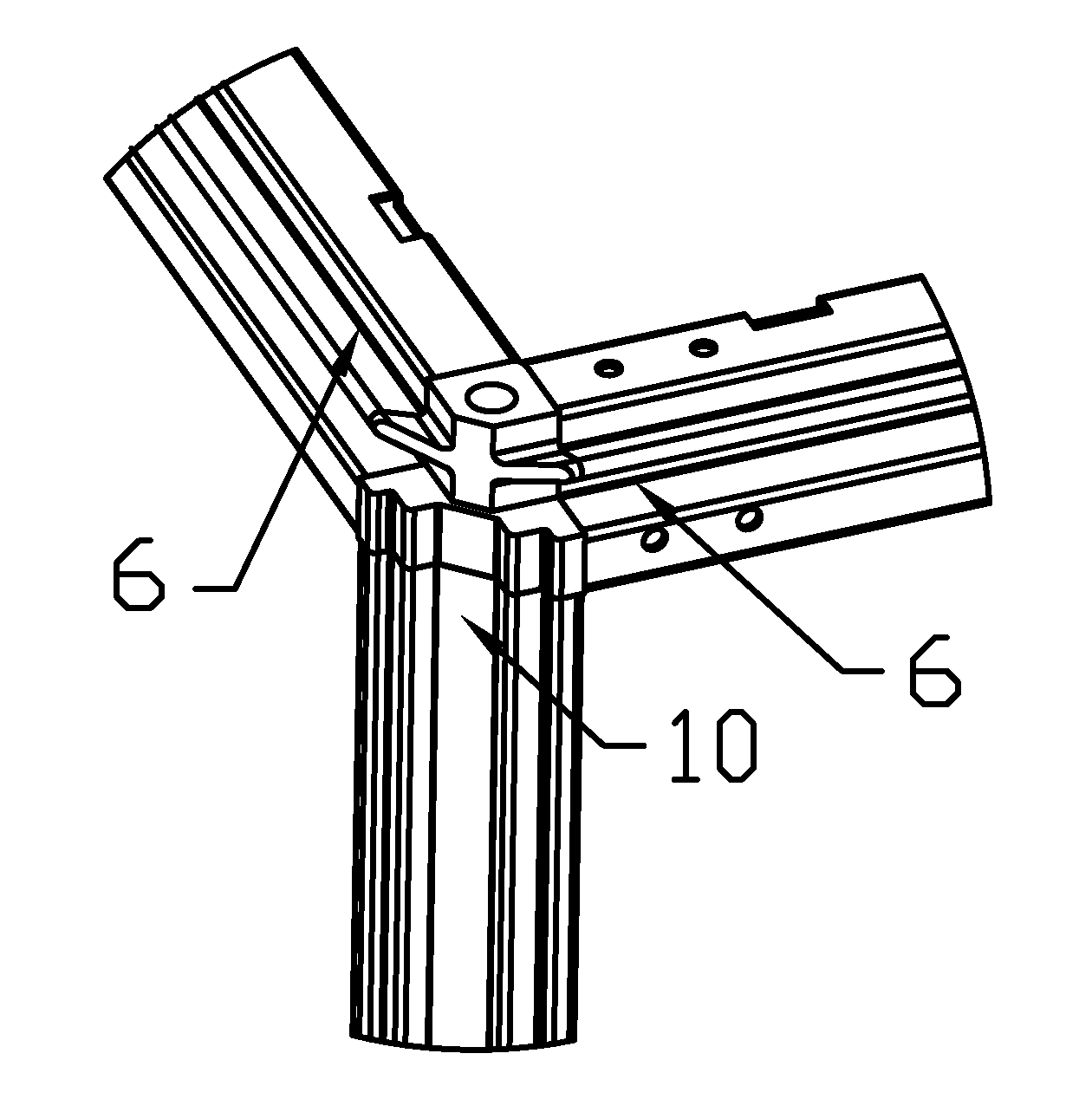

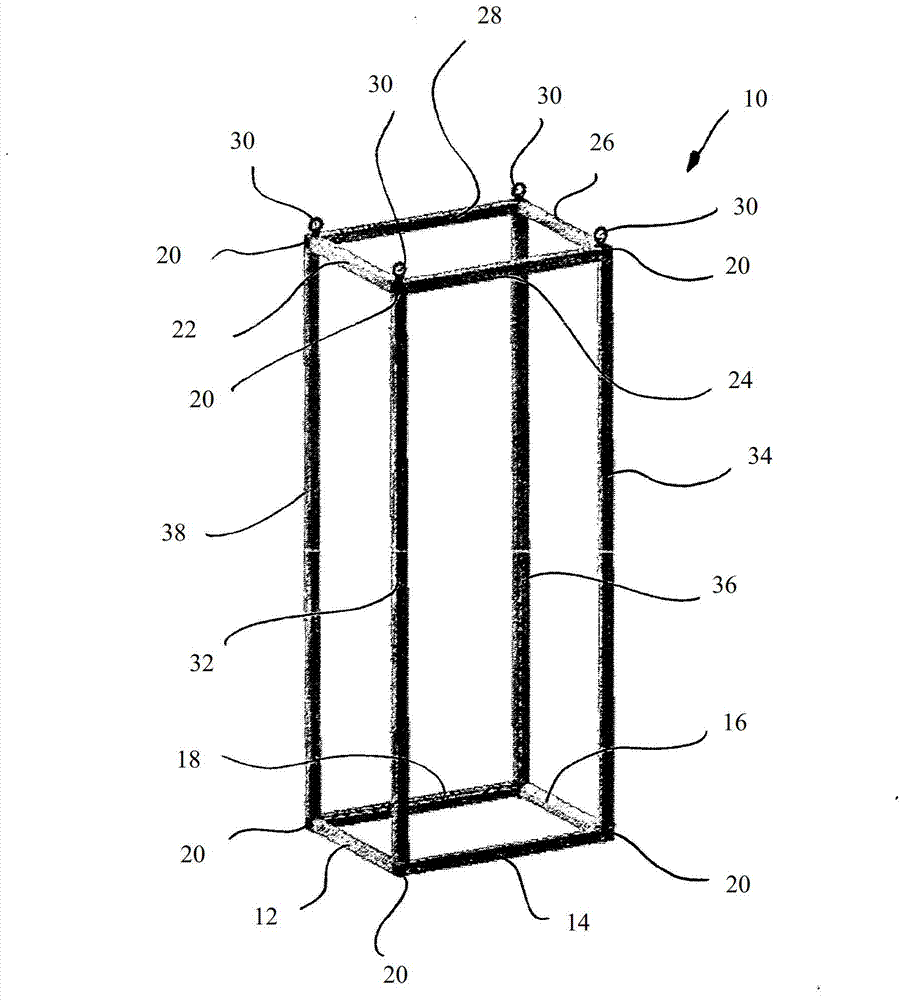

Frame assembly

InactiveUS8196758B2Easy to assembleImprove structural strengthKitchen equipmentMetal-working hand toolsEngineering

A frame assembly includes upper and lower frame units, four vertical frame rods, four pairs of top and bottom female connectors, eight male connectors, and first and second bolts. Each frame unit includes four rectangularly-arranged horizontal frame rods. Each female connector interconnects an adjacent pair of the horizontal frame rods, and includes two horizontal tenons engaging respectively the adjacent pair of the horizontal frame rods. The male connectors are connected respectively to opposite ends of the vertical frame rods. Each male connector includes a vertical tenon engaging a respective one of the opposite ends of the vertical frame rods, and an engaging block mating with a respective one of the female connectors. The first and second bolts are for securing releasably and respectively the female connectors to the male connectors.

Owner:LEE YUNG YU

Assembling type rack frame structure

InactiveCN1450297AEasy to shipDoes not affect normal useElongated constructional elementsDismountable cabinetsMetal sheetEngineering

The present invention relates to a machine cabinet frame structure, in particular, it relates to a frame assembled by using upper and lower base seats and four corner upright columns, and the structure of every frame corner is made up by adopting corner upright column, corner connecting blocks, corner inner fastening blocks and base seat and directing, positioning, mounting and fixing the above-mentioned four metal sheet members. The above-mentioned metal members having good university and interchangibility, so that said invention can assemble various rectangular machine cabinets with different sizes.

Owner:上海惠亚电子有限公司

Device Support

InactiveUS20090175678A1Simpler and faster assemblyIncrease stiffnessCandle holdersLighting support devicesEngineeringMechanical engineering

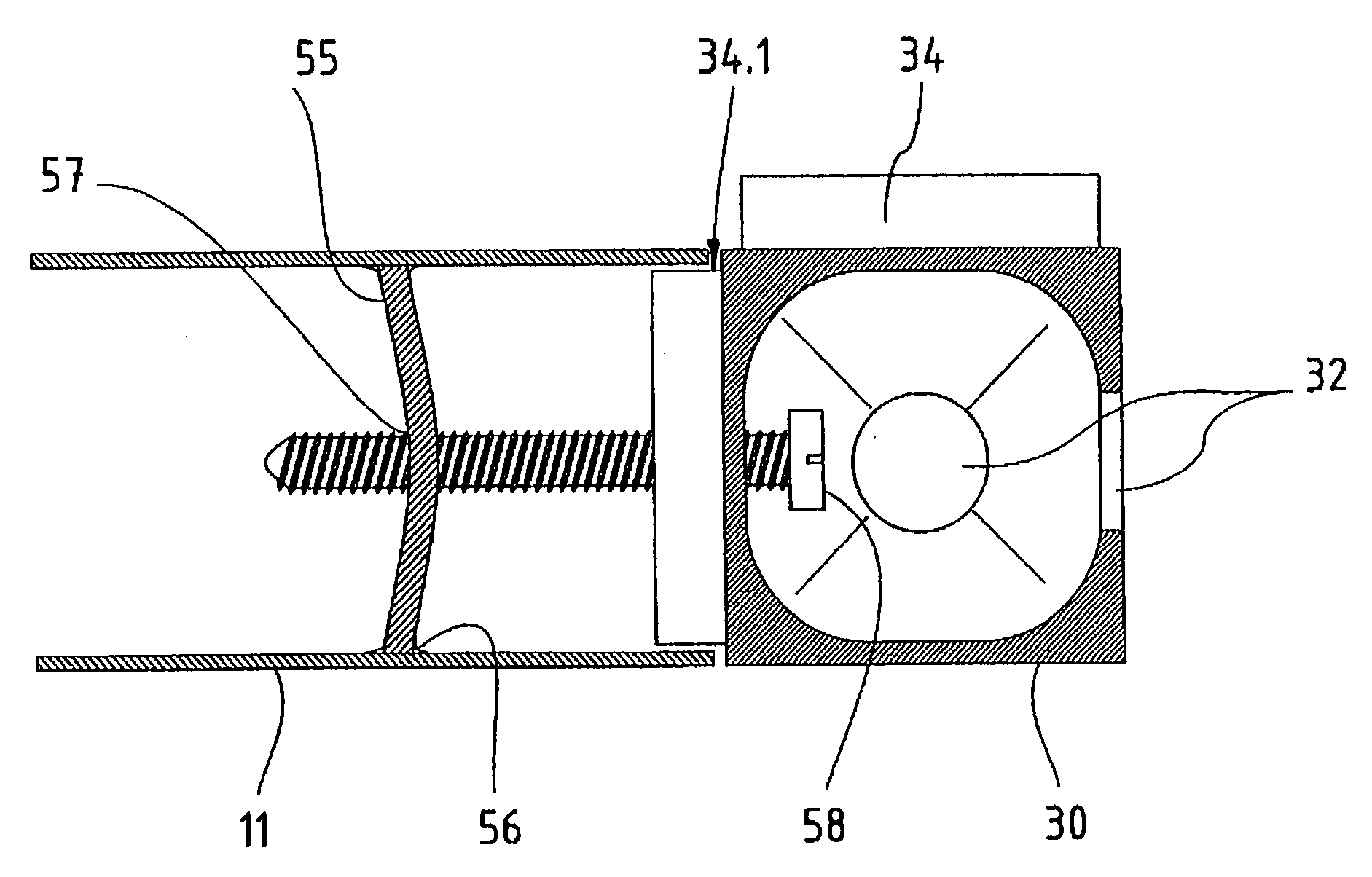

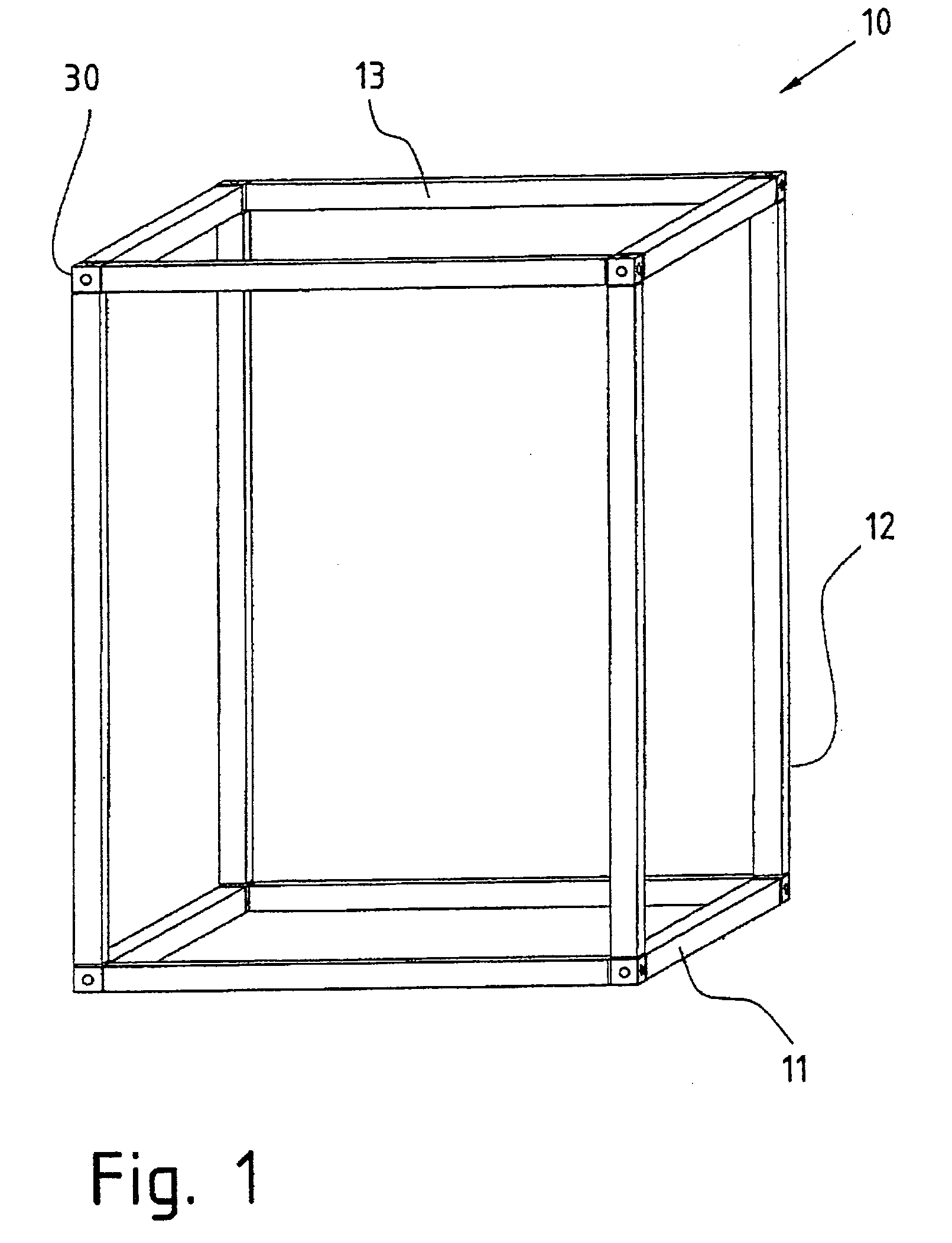

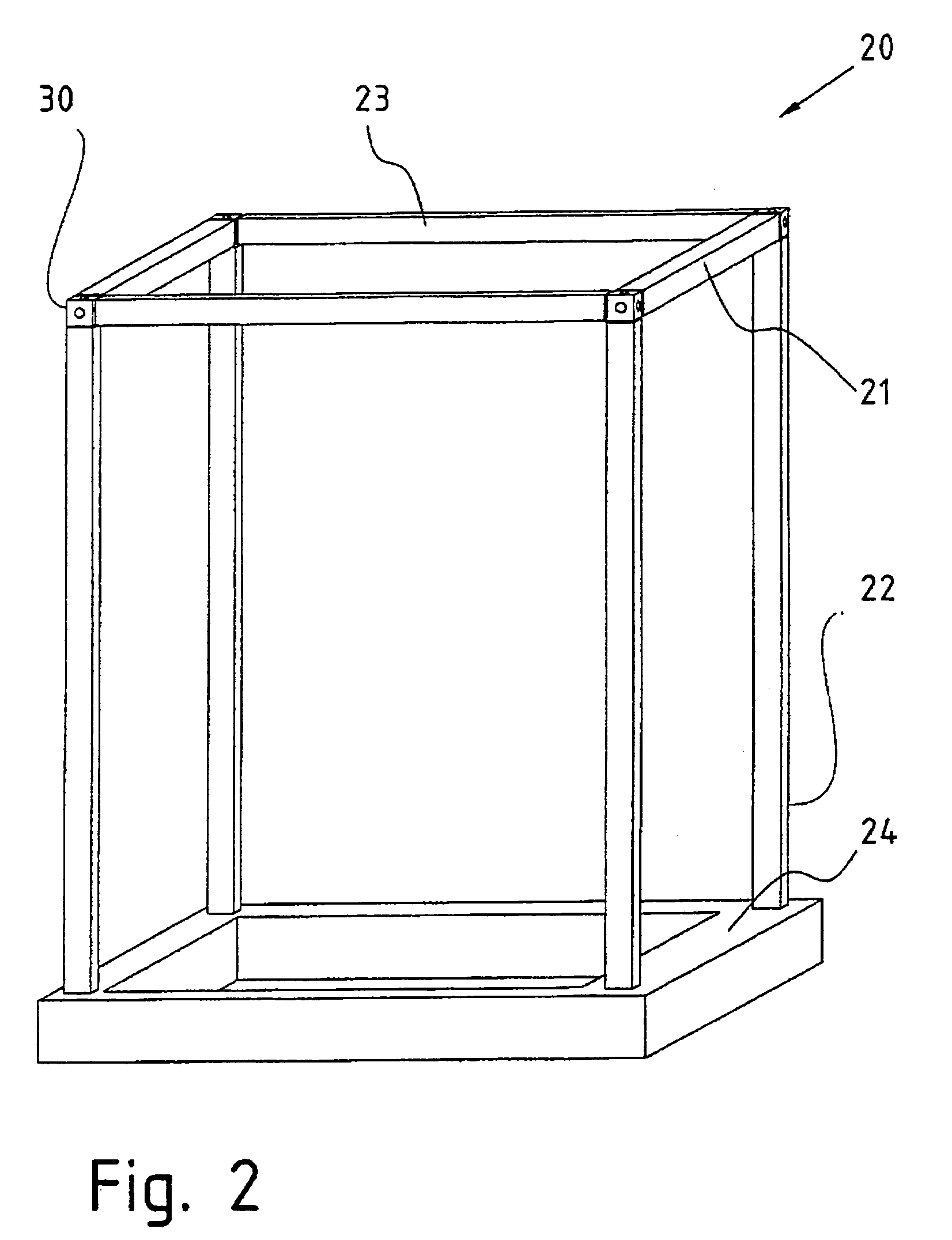

A device support comprises a cabinet frame that is formed by metal hollow profiles (11) and that has at least in one of its corners a parallelepiped corner connector element (30) connected to at least one of the hollow profiles (11) by means of a screw. At least one outside face of the corner connector element (30) is configured as a securing face which has a guiding shoulder (34) with at least two parallel outer edges (34.1), resting on inner peripheral surfaces of the hollow profile (11). The hollow profiles (11) have a closed cross-section. A throughbore runs from every securing face for receiving the screw shank and continues, starting from a support shoulder in the interior of the corner connection element (30), along a passage recess (32) which extends to an outside face of the corner connector element opposite the securing face.

Owner:BSW ANLAGENBAU

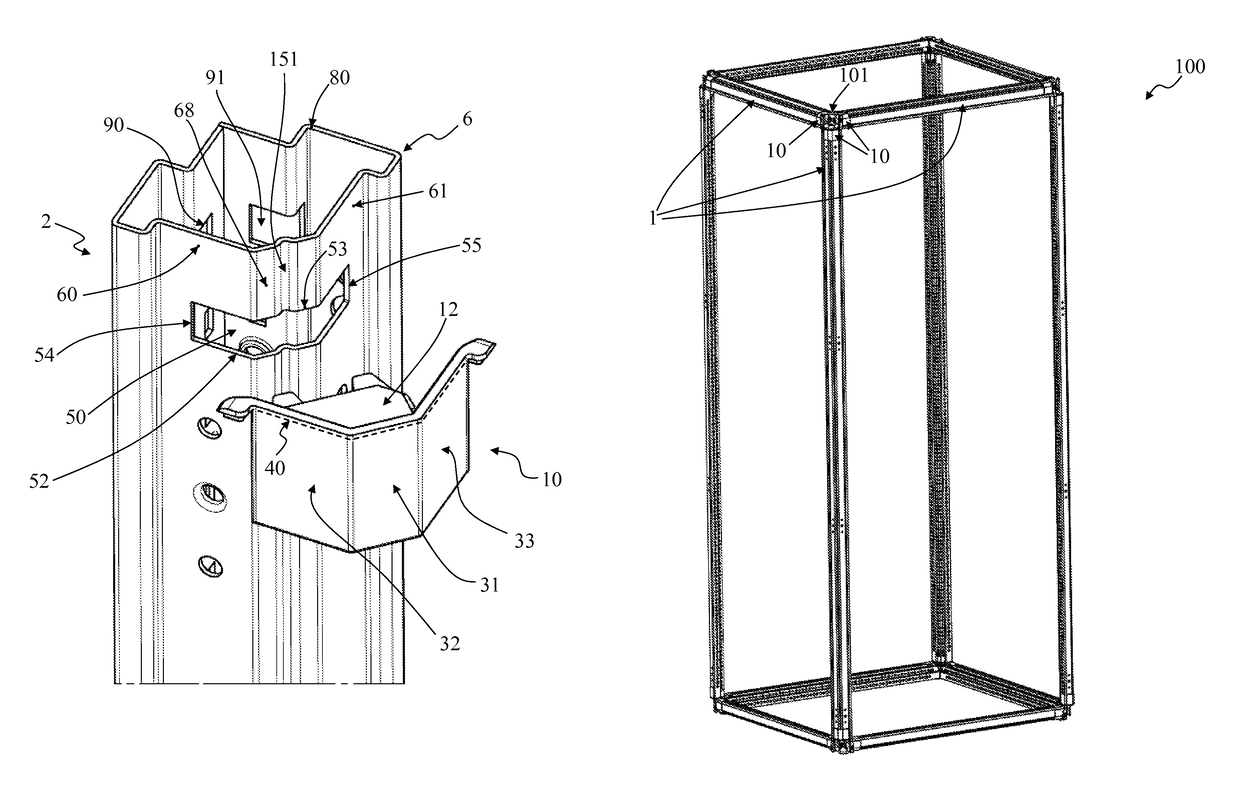

Rack particularly for equipment cabinet

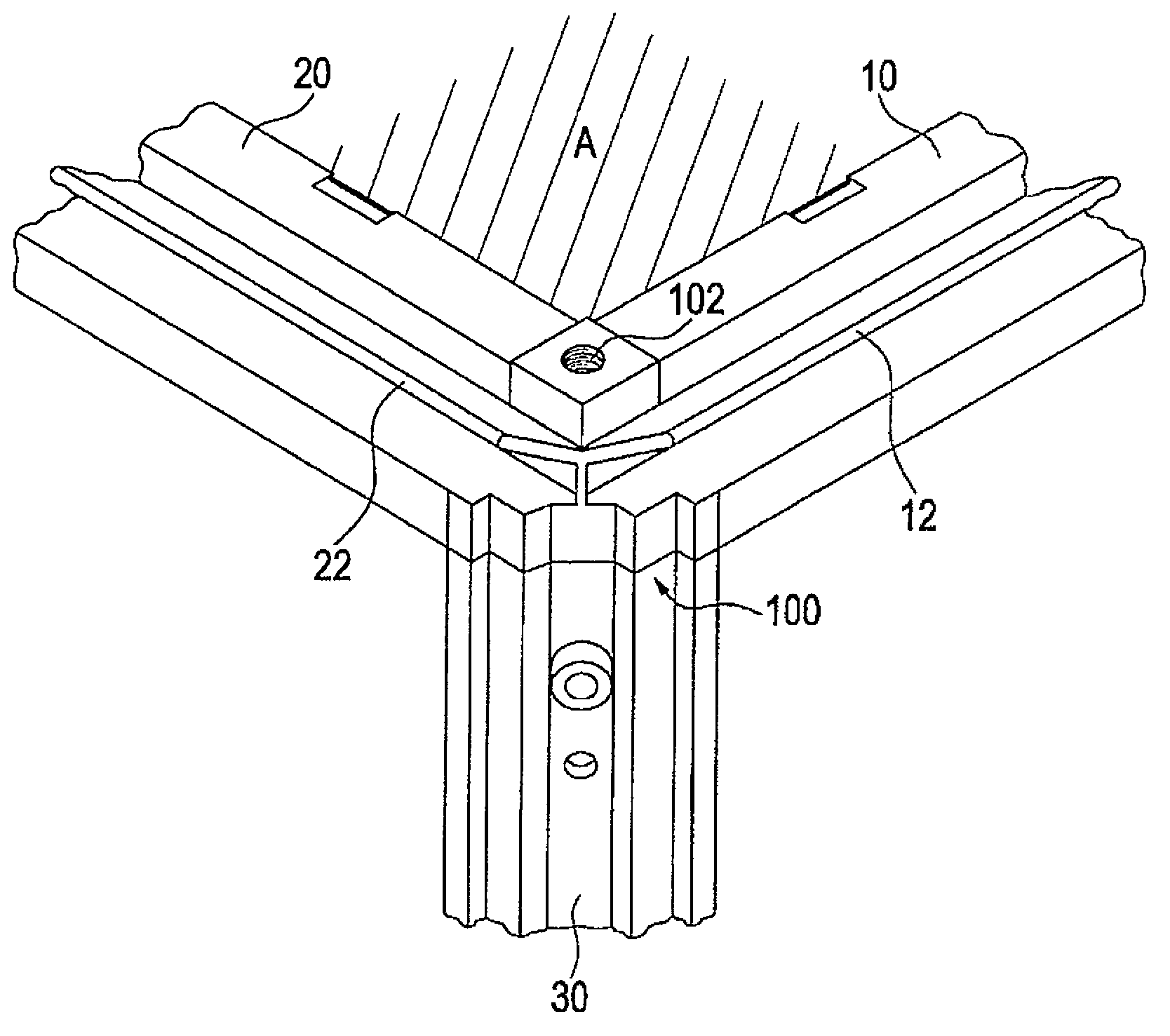

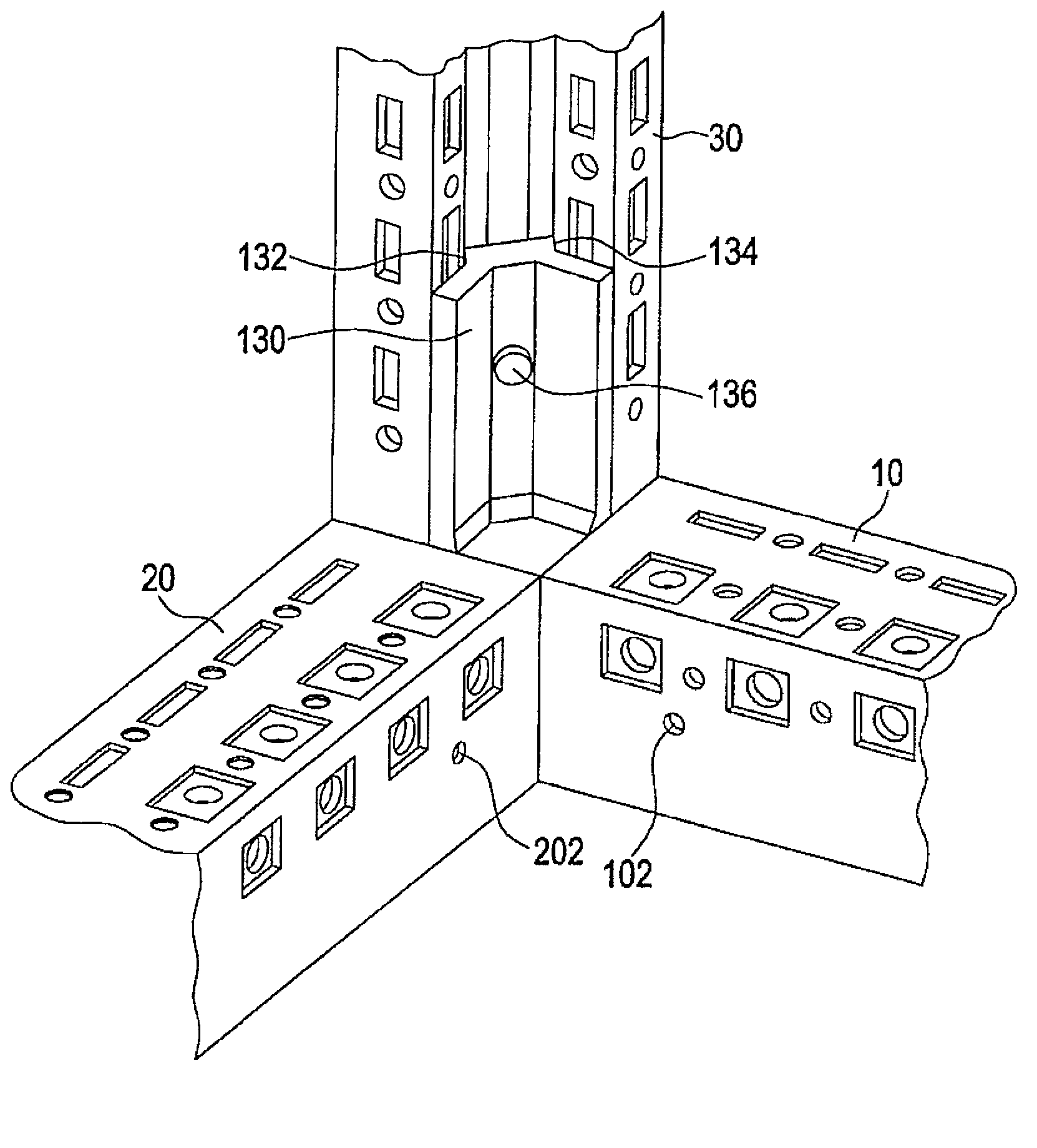

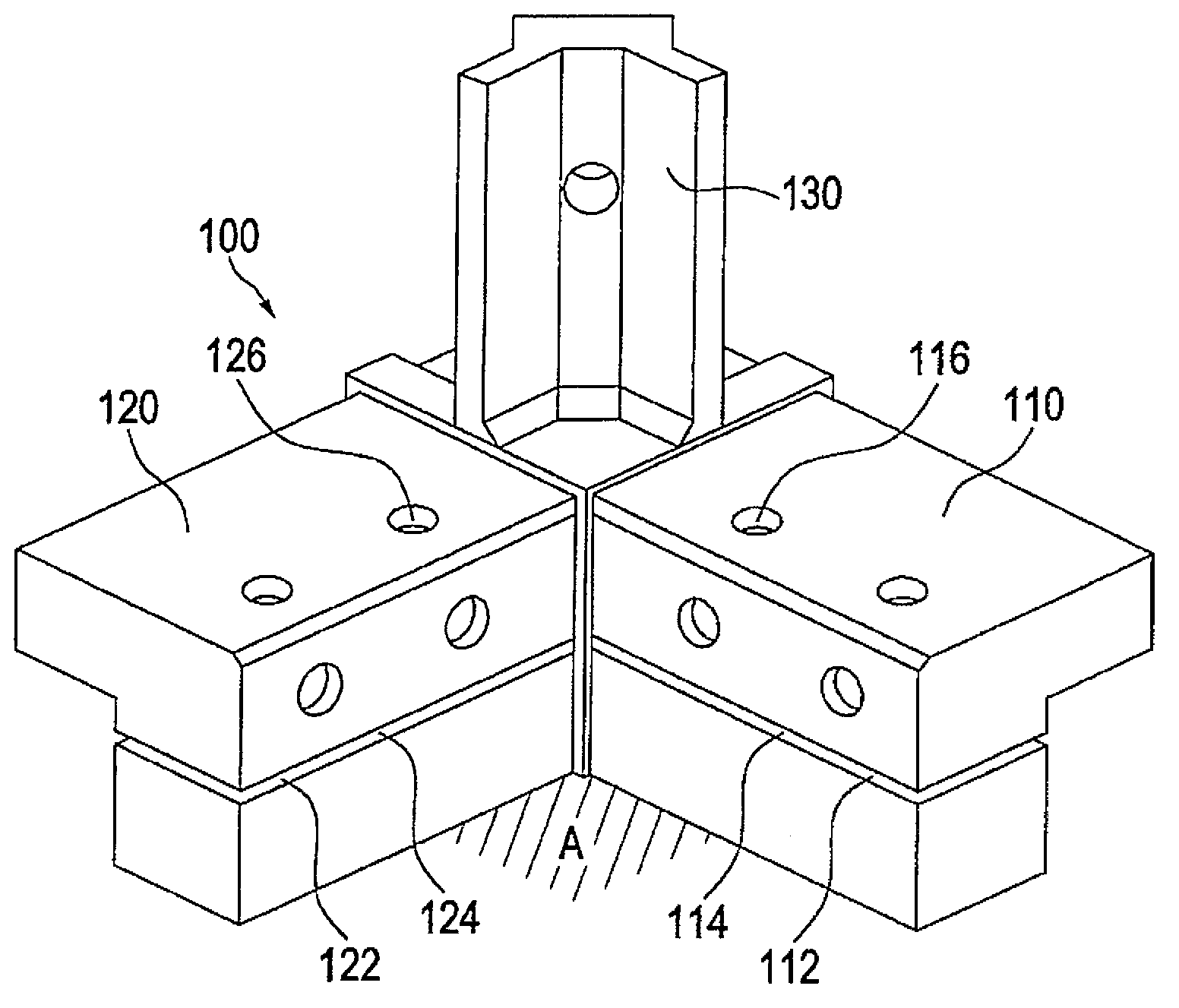

ActiveCN103227421AFirmly connectedConnector connection is simpleSubstation/switching arrangement frameworksEngineeringShape matching

The invention relates to a rack, particularly for equipment cabinets, which comprise section bars (10, 20, 30 ) extending in the transverse direction, in the depth direction and / or in the vertical direction, wherein, two adjacent section bars (10, 20) determine a reference plane (A), and the section bar is connected by a corner connector (100) with plug connectors, and each section bar is covered and fixed on the plug connecters, and at least one plug (110, 120) has an open slot (112, 122) continuously extended and parallel to the relative reference plane, and section bar relative to the plug has pores (102, 202) in the area of the plug connector at the height of the groove, and a fixing plug crosses the pore and is parallel to the reference plane, and pores sink into the groove with force and / or in shape matching type; the corner connector (100) has a plug connector (130), and the plug connector comprises side concaves (132, 134) which are mutually opposite for jointing dovetail joint outline of the vertically extending profile (30) with force and / or in shape matching type.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Switching cabinet with a rack

InactiveUS6164737ASimple designSubstation/switching arrangement casingsFurniture partsEngineeringSwitchgear

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

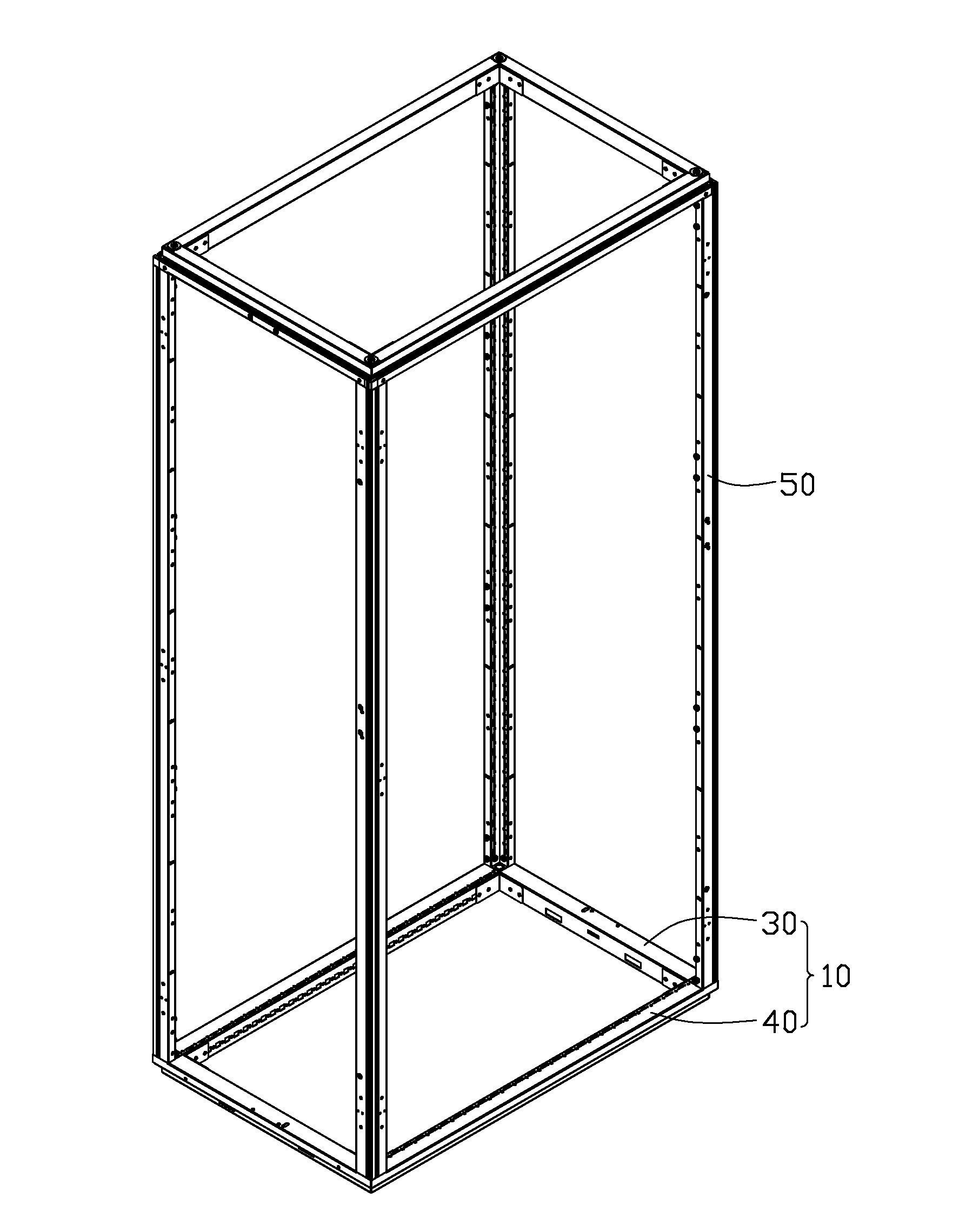

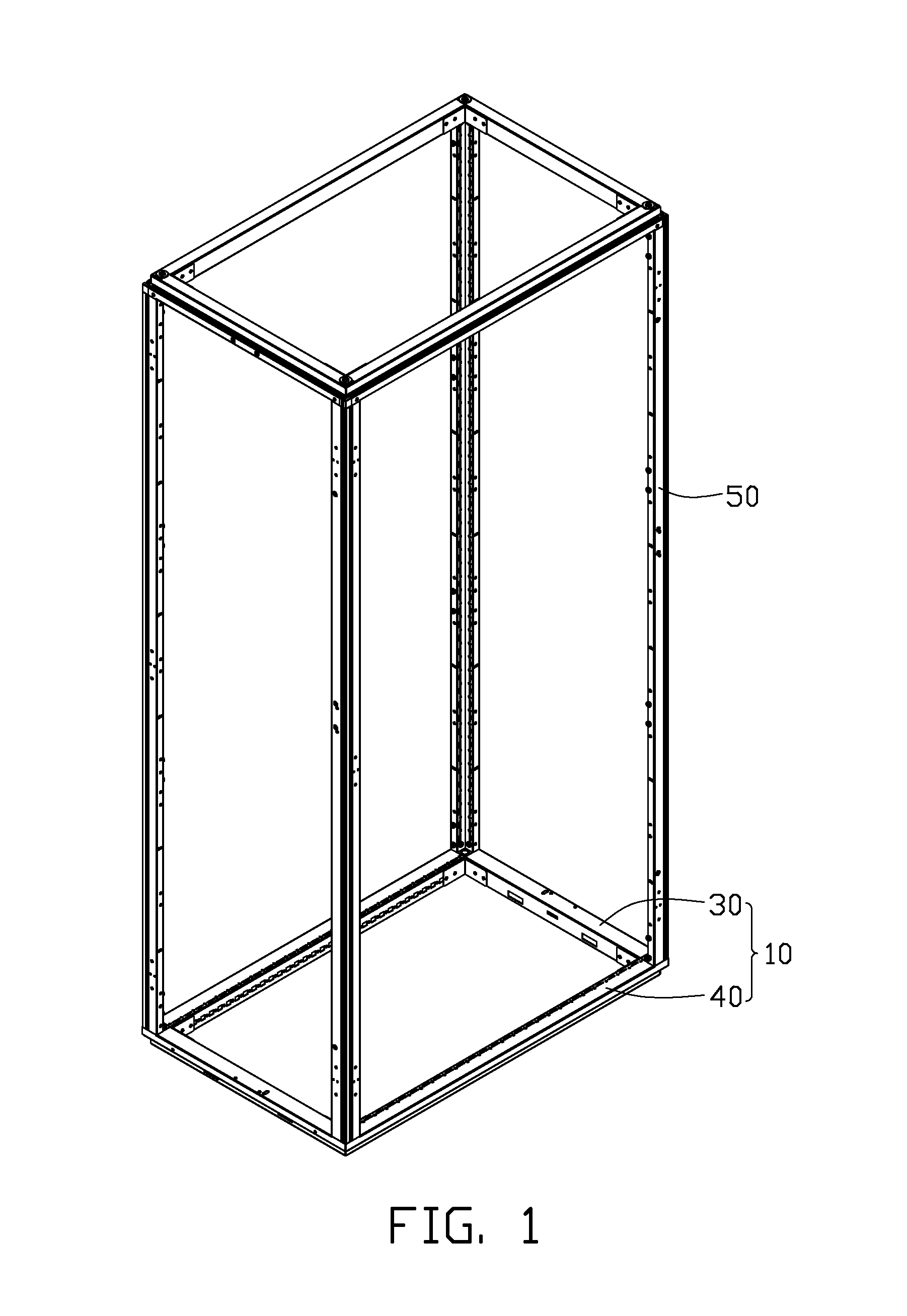

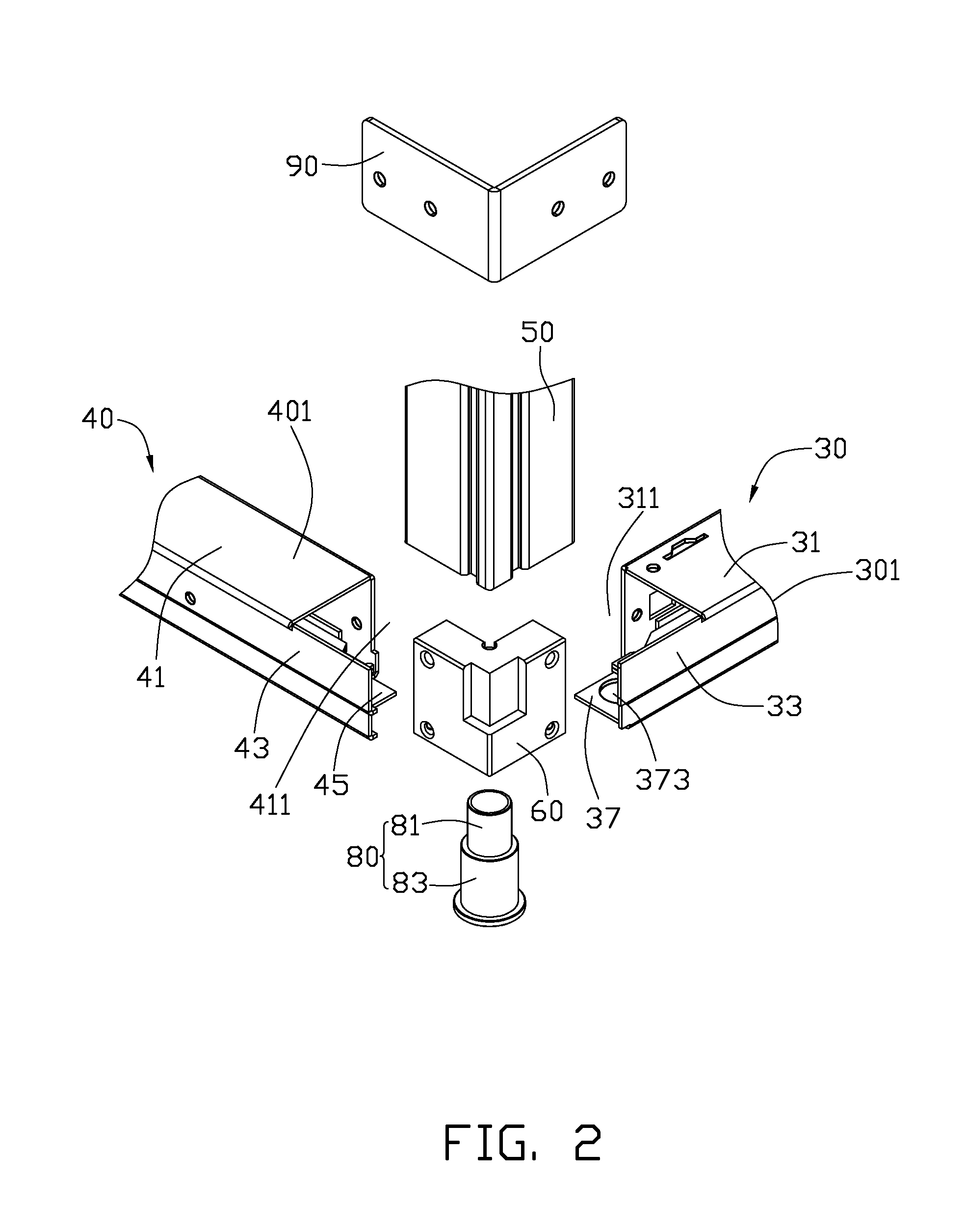

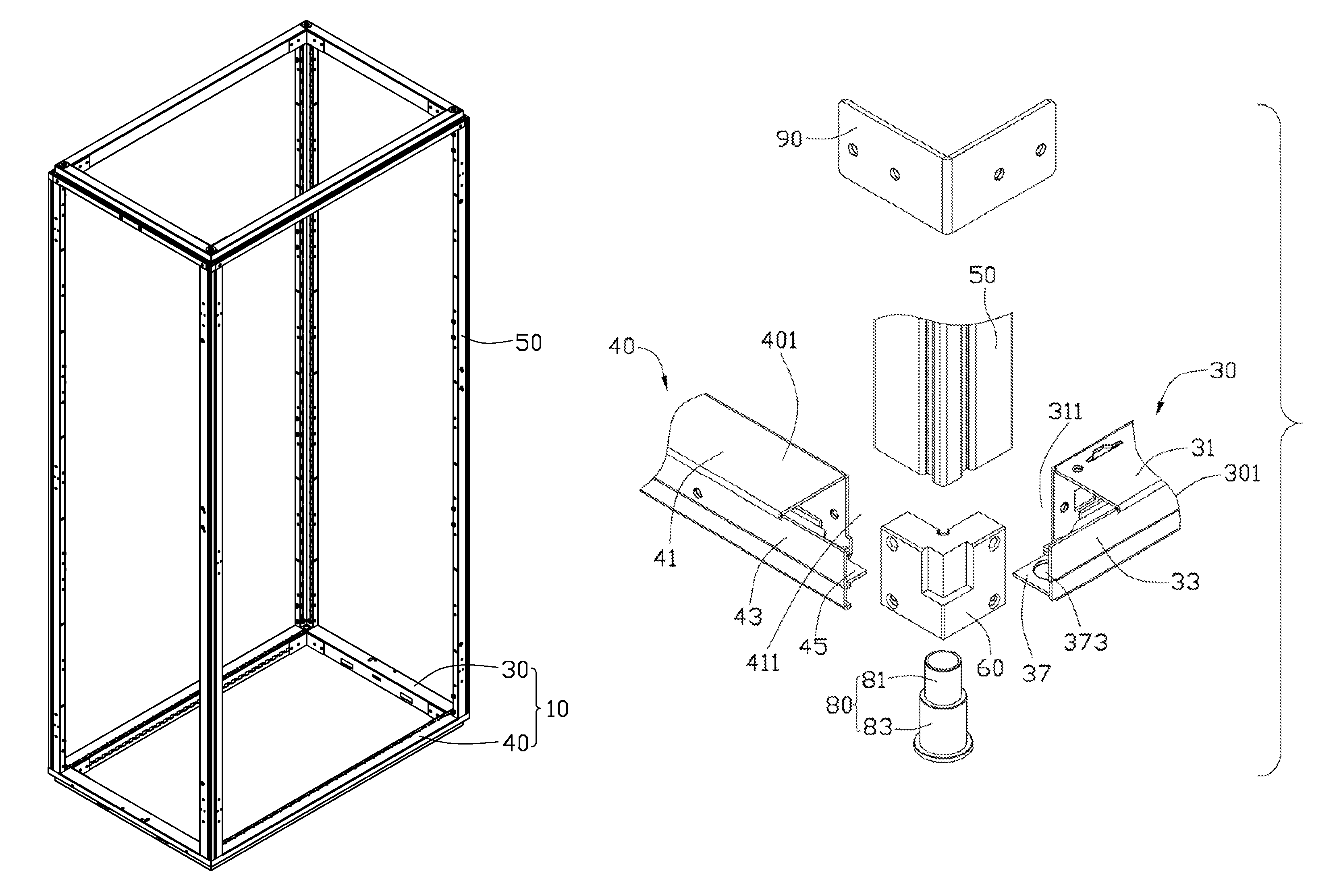

Rack frame assembly

A rack frame assembly includes a first frame pole, a second frame pole, a linking member, linking post, and a support pole. A first frame pole includes a first support wall and a first through hole. The second frame pole includes a second support wall. The second frame pole is assembled with the first frame pole with the first support wall and the second support wall is located on the same plane. The linking member is located on the first support wall and the second support wall. The linking member includes a second through hole in alignment with the first through hole, and an insert portion. The linking post is located in the first through hole and the second through hole to secure the linking member to the first frame pole. The support pole includes an insert hole with the insert portion located therein.

Owner:CLOUD NETWORK TECH SINGAPORE PTE LTD

Rack frame assembly

A rack frame assembly includes a first frame pole, a second frame pole, a linking member, linking post, and a support pole. A first frame pole includes a first support wall and a first through hole. The second frame pole includes a second support wall. The second frame pole is assembled with the first frame pole with the first support wall and the second support wall located on the same plane. The linking member is located on the first support wall and the second support wall. The linking member includes a second through hole in alignment with the first through hole, and an insert portion. The linking post is located in the first through hole and the second through hole to secure the linking member to the first frame pole. The support pole includes an insert hole with the insert portion located therein.

Owner:CLOUD NETWORK TECH SINGAPORE PTE LTD

Electrical system enclosures

A frame for an enclosure includes a first set of corner support structures. Each corner support structure of the first set of corner support structures includes a main body, a first protrusion arranged to extend from the main body, a second protrusion arranged to extend from the main body and substantially orthogonal to the first protrusion, and a third protrusion arranged to extend from the main body and substantially orthogonal to both the first protrusion and the second protrusion. The frame further includes a second set of corner support structures having mirror image symmetry about a plane of symmetry of an opposing corner support structure of the first set of corner support structures.

Owner:GENERAL ELECTRIC CO

Combined frame for an electromechanical box

Owner:TAIWAN ENCLOSURE SYST CO LTD

Rack for cabinet

Owner:CLOUD NETWORK TECH SINGAPORE PTE LTD

Three-way connector for cabinet frame

Owner:SHEN SUIZHANG

Switchgear cabinet including framework and covering members

InactiveUS6776464B2Improve hinge and closureImprove securityCasings/cabinets/drawers detailsSubstation/switching arrangement casingsCouplingDouble wall

A switchgear cabinet including rectangular frameworks of frame members, wherein, in the region of the outer corner edges, free spaces are formed for the accommodation of angled edges of the double-wall covering members, which are juxtaposed each other. At least one covering member is configured as a cabinet door, which has hinges on the framework, which is pivotally mounted with hinges and which is closable and openable by closure members on the framework. If the covering members and the cabinet doors have an interior wall and an exterior wall, the formed cavity extending at least partially over the free space of the associated vertical frame member, in the case of the cabinet doors, in the region of the covered free space, the cavity receives hinged members on the one vertical side and closure members on the opposite side. Counter-hinged members and counter-closure members are mounted on the framework, the coupling points of the hinged members and counter-hinged members being inside or outside the cavity of the cabinet door and the engagement points of the closure members and counter-closure members being in the cavity of the cabinet door, and thus precisely in the region of the hinging side and closure side of the cabinet door, safety against vandalism is improved.

Owner:RITTAL RCS COMM SYST

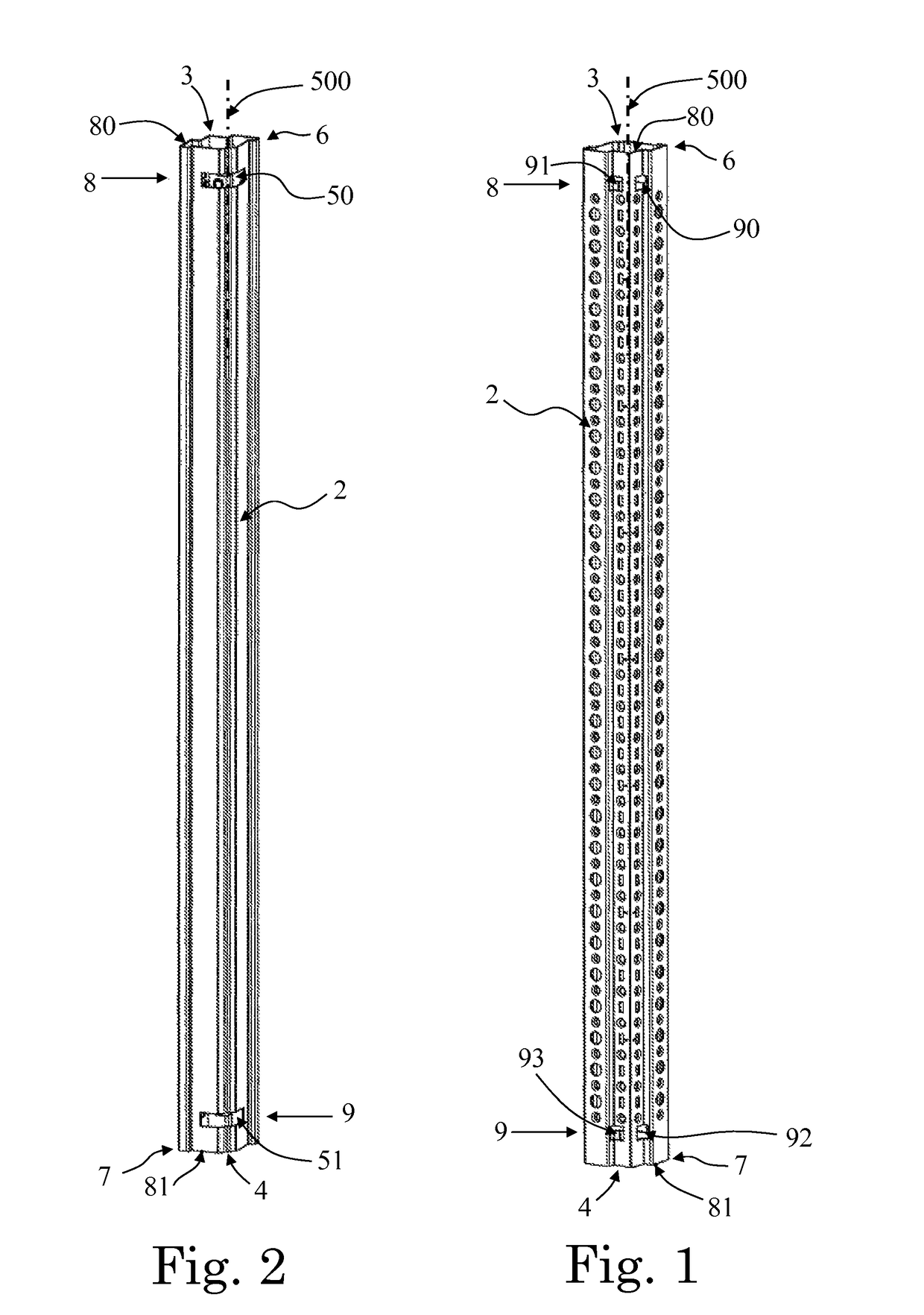

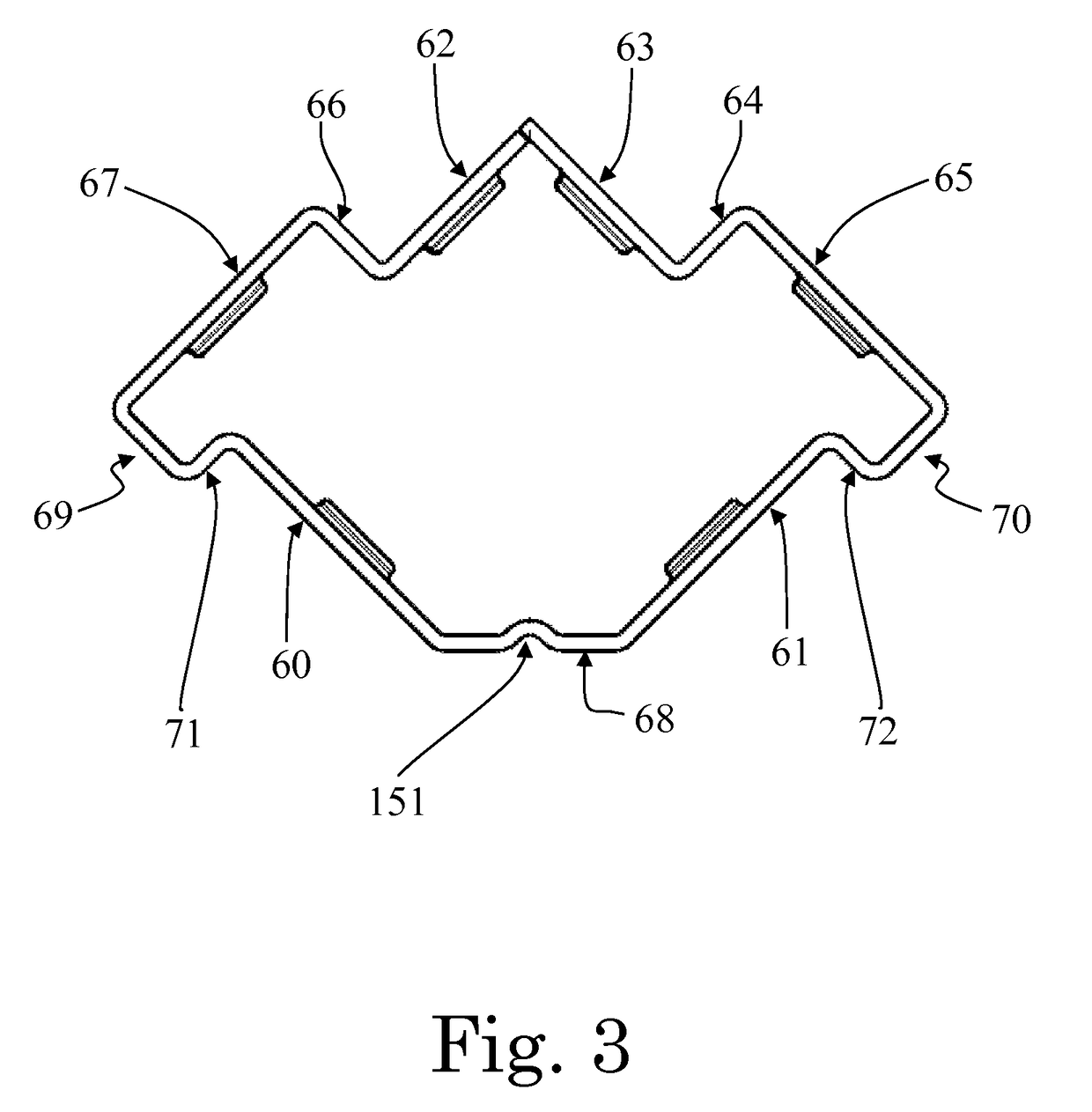

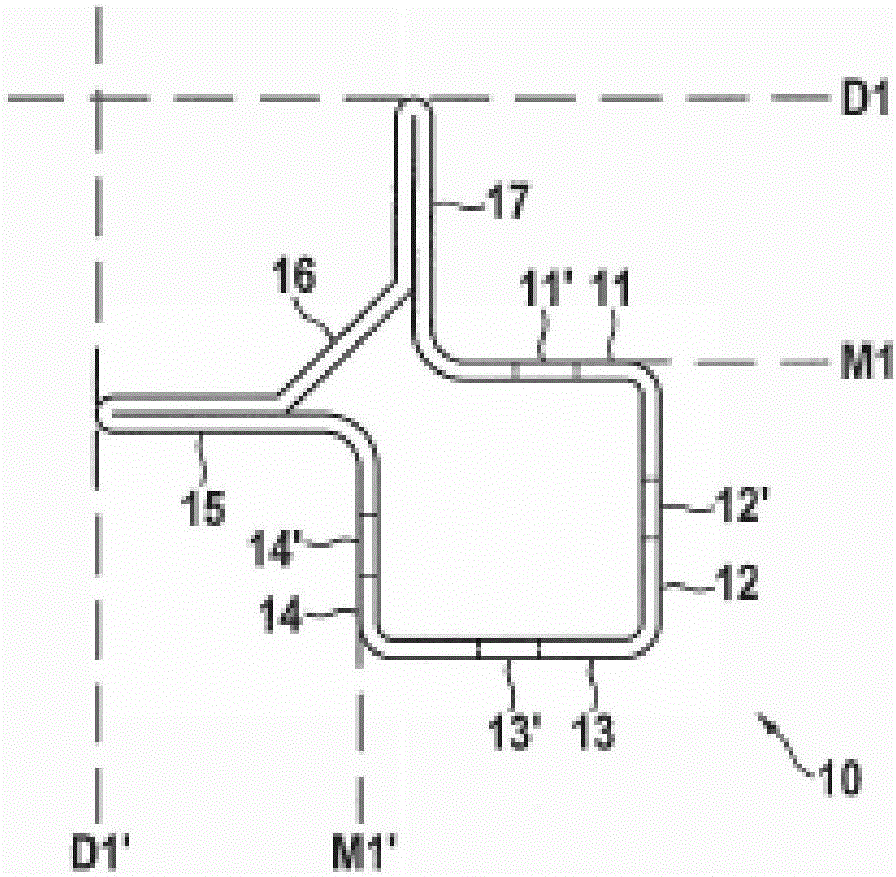

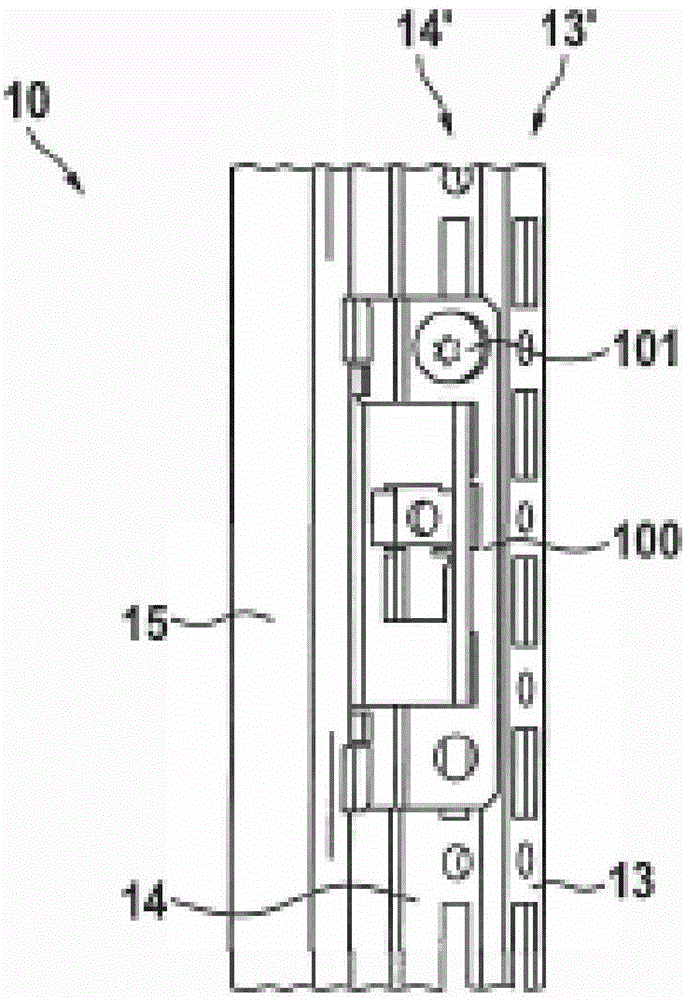

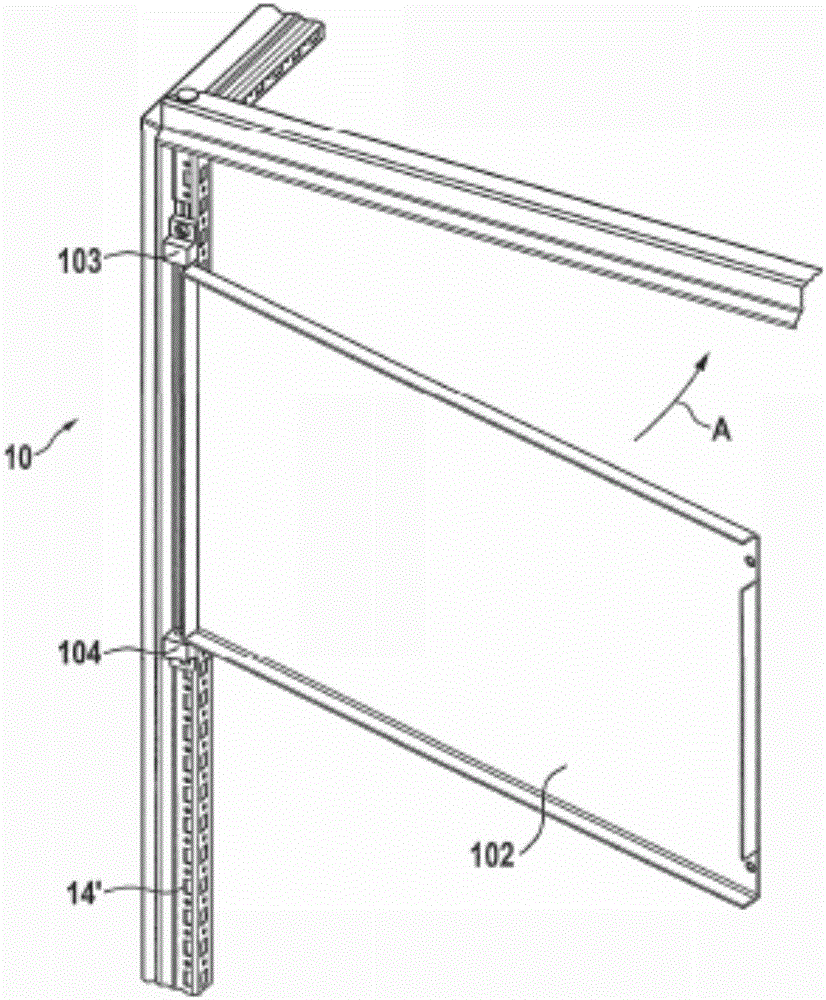

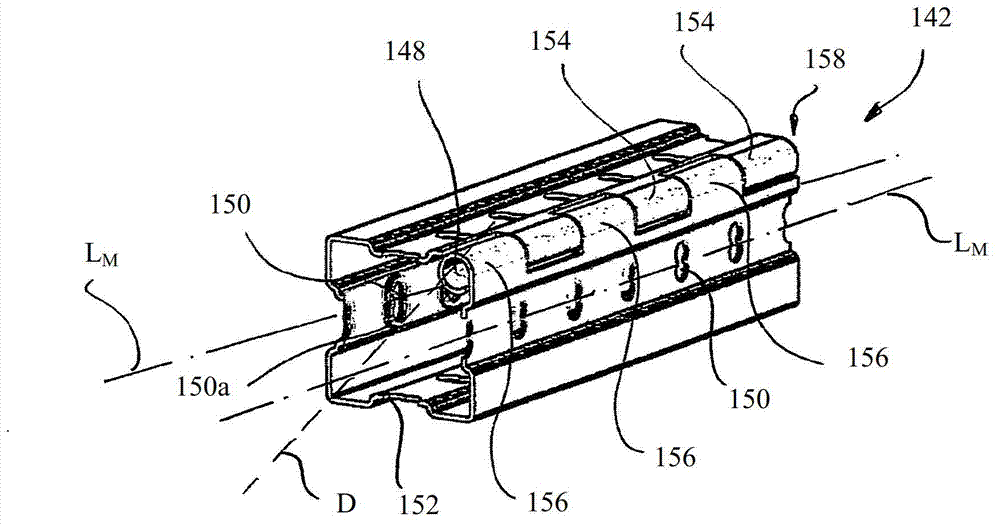

Profiled frame of a frame structure for an electrical enclosure or a distribution cabinet

ActiveCN106256058AGuaranteed installationDismountable cabinetsSubstation/switching arrangement boards/panels/desksEngineeringSwitchgear

The invention relates to a profiled frame of a frame structure for an electrical enclosure or a distribution cabinet. The framed profile forms a vertical and / or horizontal profiled section of the frame structure and consists of a plurality of profiled portions which at least partly transition into one another in order to form an opened or closed hollow profiled section. The profiled frame further has the following feathers that at least one first profiled portion(11, 14, 21, 24, 31, 34, 41, 44, 51, 53, 62) has a number of securing recesses (11, 14); wherein a first surface of the profiled portion defines an outer mounting plane (M1, M1, M2, M2, M3, M3, M4, M4, M5, M5, M6); a sealing plane (D1, D1, D2, D2, D3, D3, D4, D4, D5, D5, D6) for sealing the inner region of the frame structure is defined by at least one second profiled portion (15, 17, 25, 27, 35, 37, 45, 47, 55.1, 55.2, 57.1, 57.2, 61); the outer mounting plane (M1, M1, M2, M2, M3, M3, M4, M4, M5, M5, M6) is offset from the sealing plane (D1, D1, D2, D2, D3, D3, D4, D4, D5, D5, D6) towards the inner regions of the frame structure; and the securing recesses (11, 14) of the first profiled portion (11, 14, 21, 24, 31, 34, 41, 44, 51, 53, 62) are oriented away from the inner region of the frame structure.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

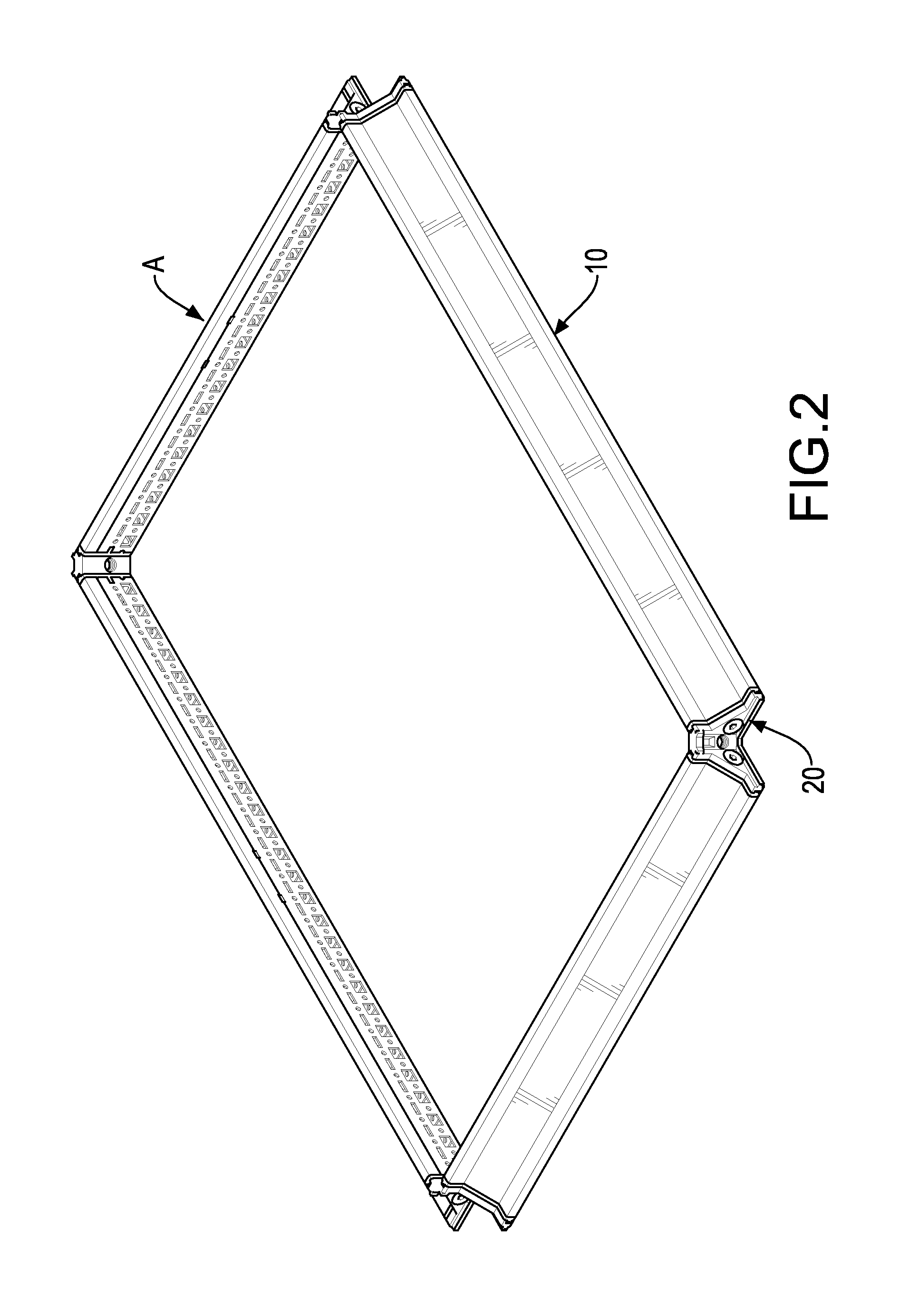

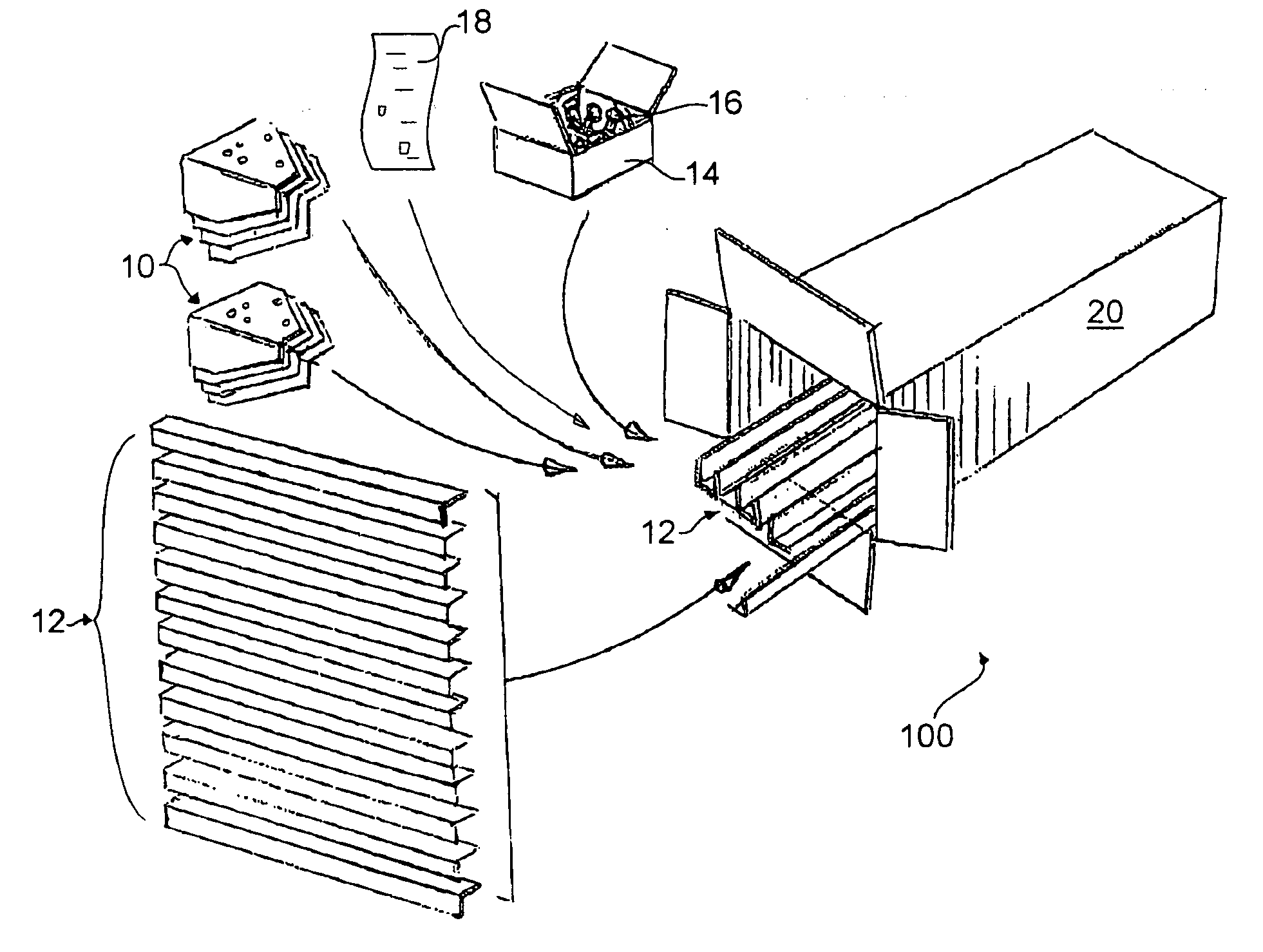

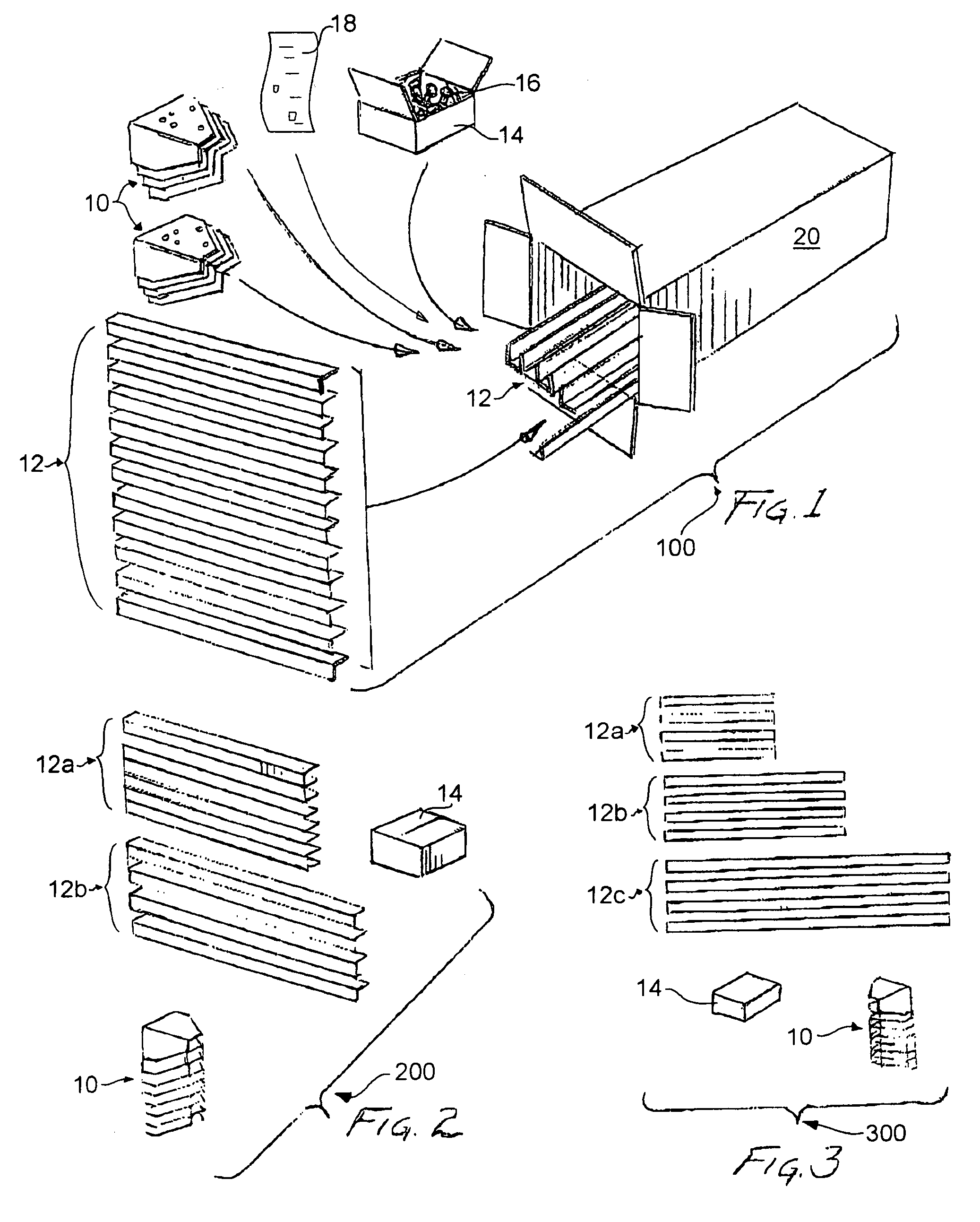

Frame kit and methods therefor

A frame kit comprises a plurality of improved corner connectors and a plurality of rail members both having a plurality of holes, a plurality of fasteners for coupling each one of the corner connectors to one end of three rail members of the plurality of rail members and at least one set of instructions located in at least one container suitable for constructing at least one frame assembly. The frame kit may also comprise at least one of a plurality of leveling feet, a plurality of casters adapted for coupling to a portion of at least one of the corner connectors, a plurality of rib members for strengthening at least one frame assembly and a plurality of accessory members adapted to couple to at least one of the plurality of rail members. A method for assembling the frame kit and constructing at least one frame assembly is also disclosed.

Owner:STAR CASE MFG CO +1

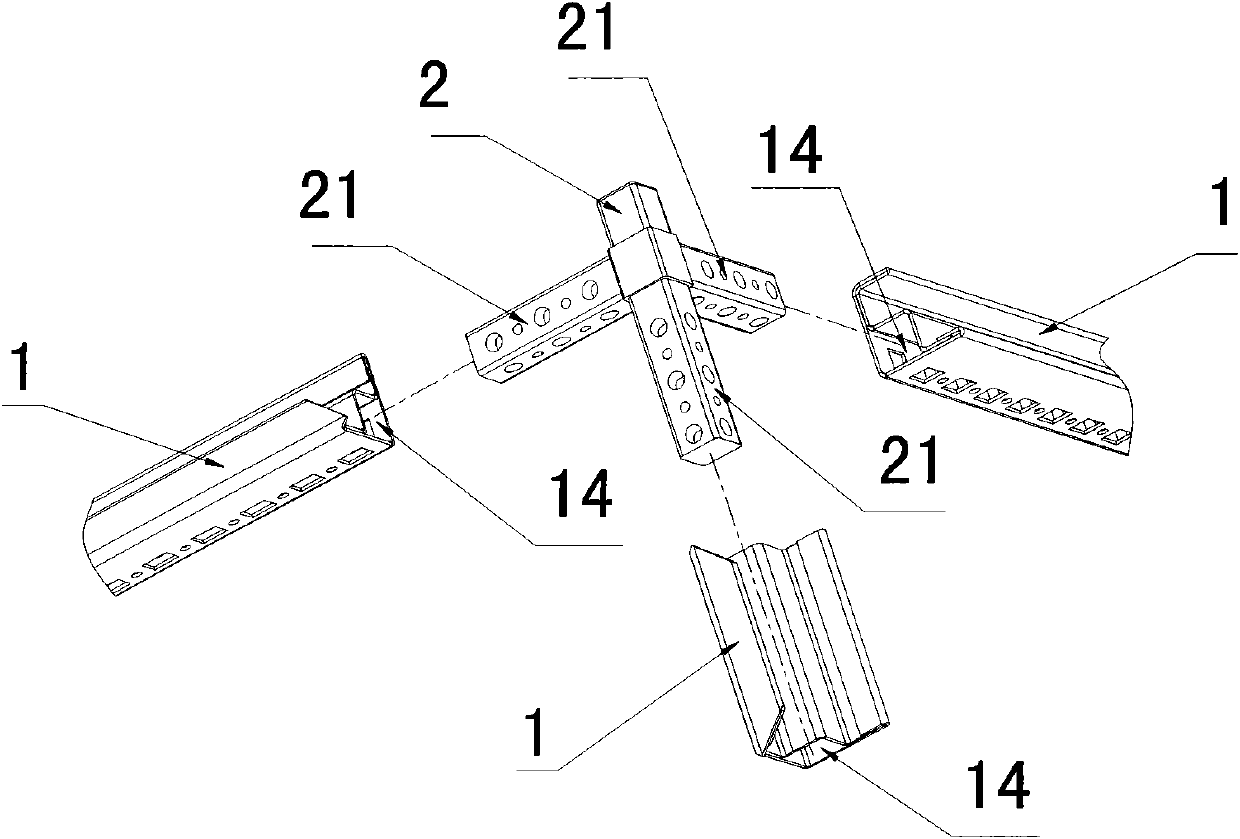

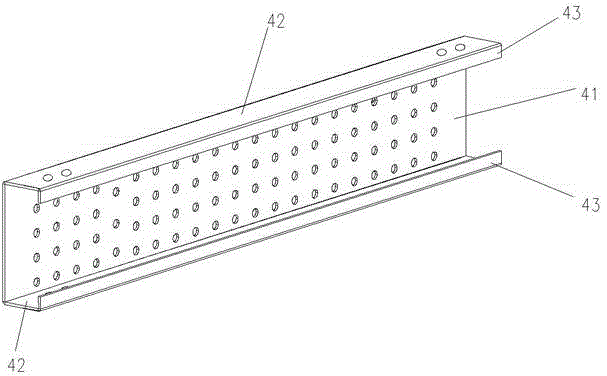

Switch cabinet body made of G sectional materials with 45-degree wing angles

ActiveCN104466709AFlexible and diverse assemblyImprove general performanceSubstation/switching arrangement casingsSubstation/switching arrangement frameworksEngineeringCounterbore

The invention relates to a switch cabinet body made of G sectional materials with 45-degree wing angles. A main body frame of the cabinet body is of a square frame type structure composed of four stand columns, four upper crossbeams and four lower crossbeams, the stand columns are made of enhanced open sectional materials, the crossbeams are made of the G sectional materials with the 45-degree wing angles, the openings of the sectional materials face inward, a metal plate three-way part is adopted for frame installation at the connection portion of each stand column and the corresponding crossbeams, and the stand columns and the crossbeams are fixed together through positioning and fixing of positioning holes and indenting counterbores of the metal plate three-way parts and the stand columns, positioning and fixing of positioning holes and indenting counterbores of the metal plate three-way parts and the crossbeams and positioning connection of stand column bayonets and the crossbeams. The cabinet body is assembled by applying the open sectional materials, the G sectional materials with the wing angles and the independently researched and developed metal plate three-way parts in a matched mode, the cabinet body can be assembled into multipurpose switch cabinets such as industrial control cabinets and power distribution cabinets through self-tapping bolts in a non-welding mode through positioning connection of auxiliary holes and the bayonets, and the switch cabinet body is suitable for being produced by enterprises which have metal plate processing capability and have bending equipment.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

Rack

InactiveCN103201917AReduces solder connectionsSubstation/switching arrangement frameworksEngineeringMechanical engineering

Owner:C E S CONTROL ENCLOSURE SYST

Frame assembly body and casing

InactiveUS20180066691A1Easy to assembleHigh strengthFurniture partsRack/frame constructionEngineeringMechanical engineering

A frame assembly body includes a connected section in which one ends of first and second frame materials, each of which has plural bent sections and plural surfaces, are joined perpendicularly. The connected section has: a projected piece locking section in which a slit-shaped fitting hole, a notch, or a recessed section formed in the second frame material is fitted to a projected piece provided in the first frame material; and a slit fitted section in which a slit-shaped notch formed in the second frame material is fitted to a fitting slit formed in a manner to notch the first frame material.

Owner:MITSUBISHI ELECTRIC CORP

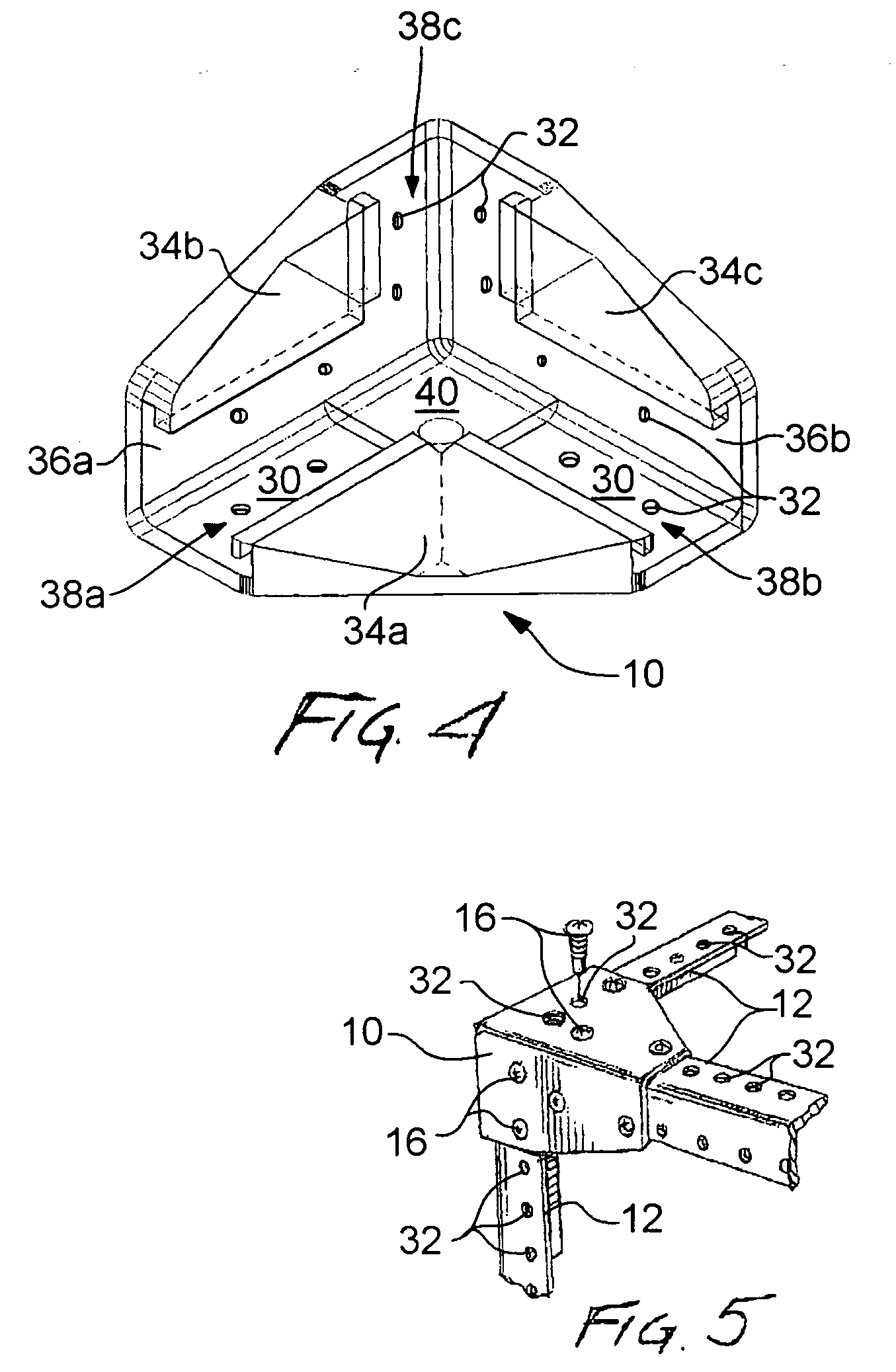

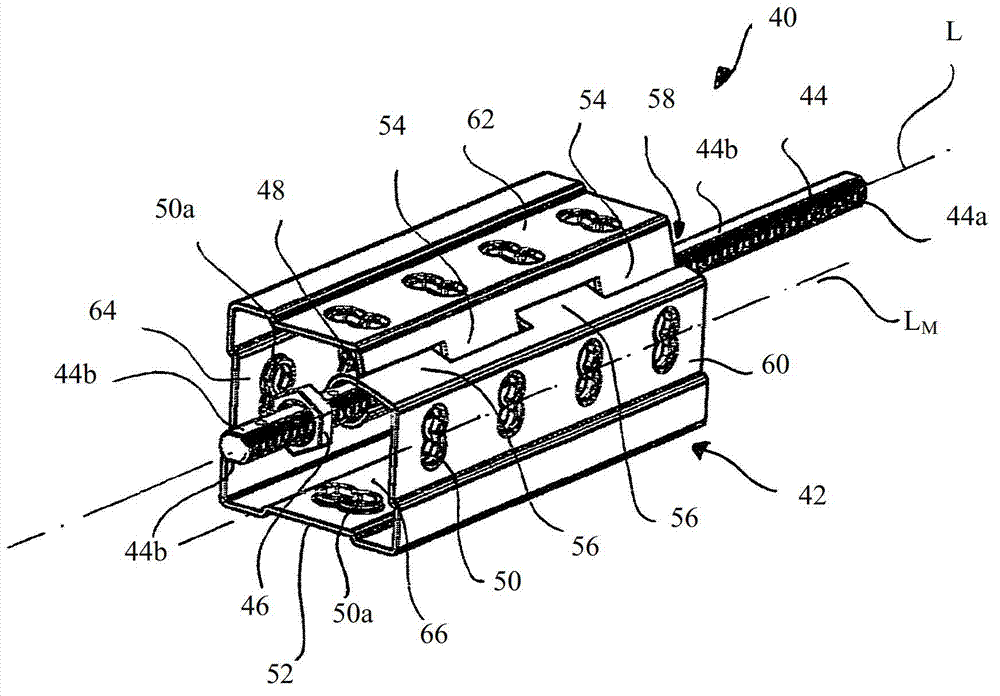

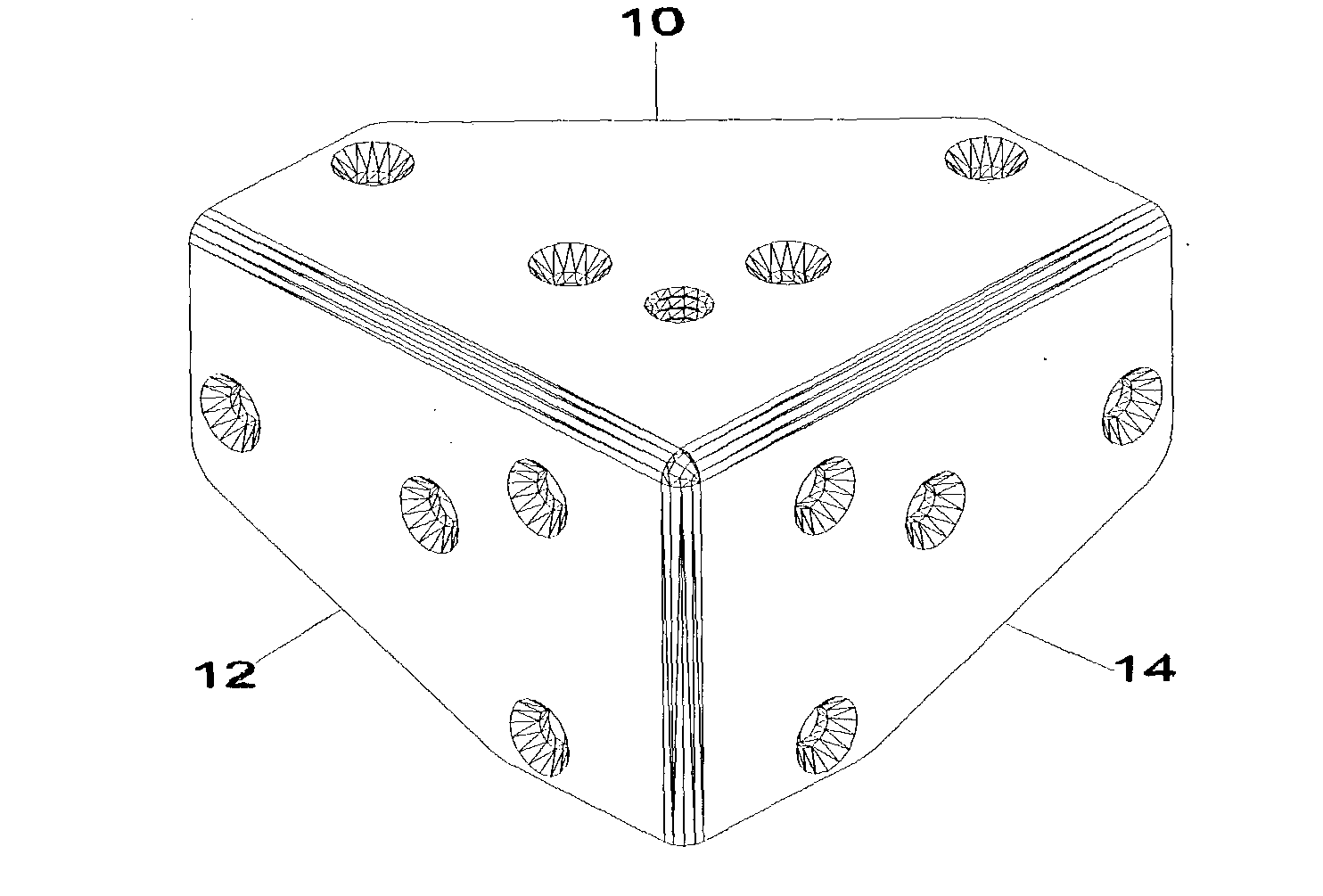

Connecting corner for knock down racks

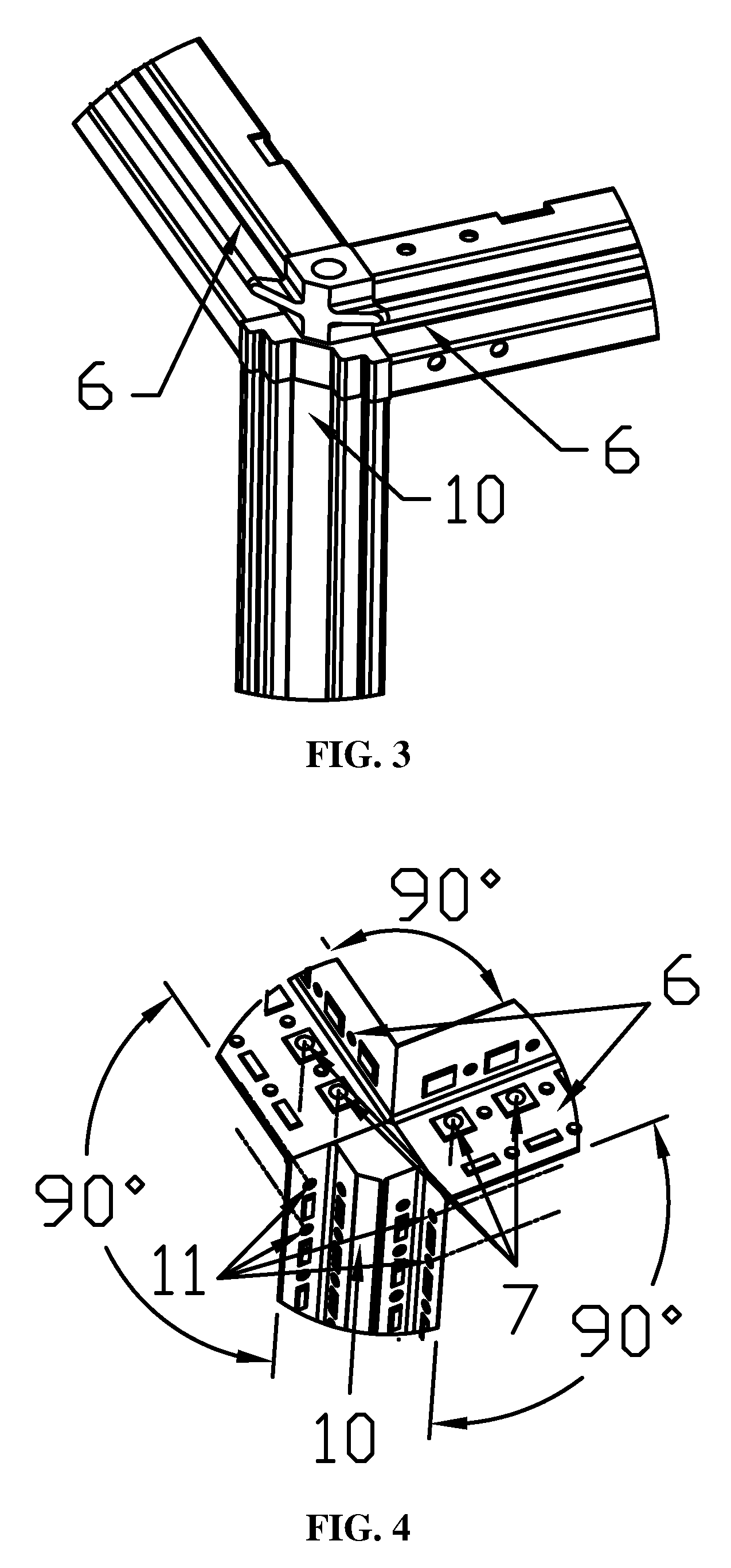

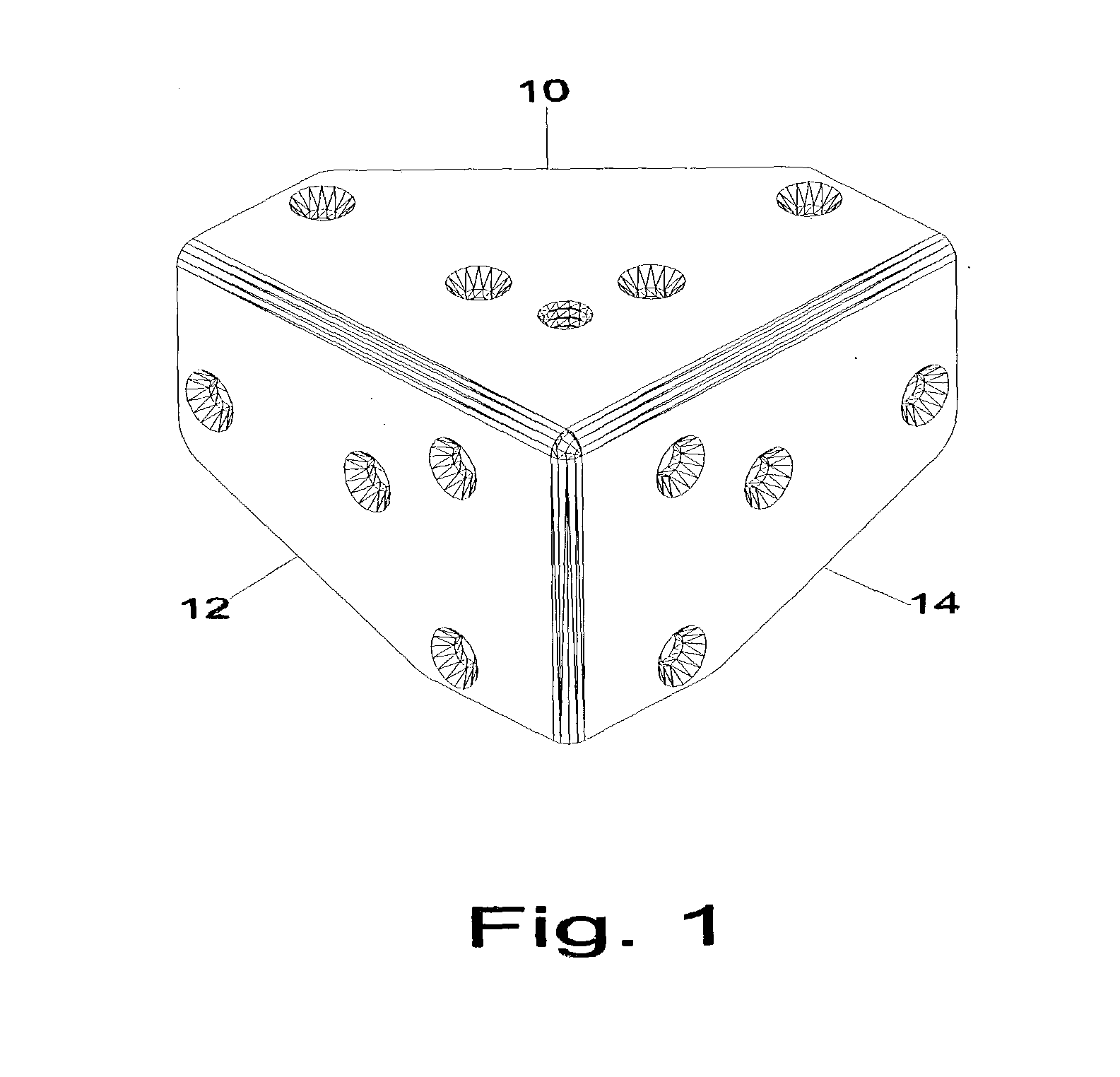

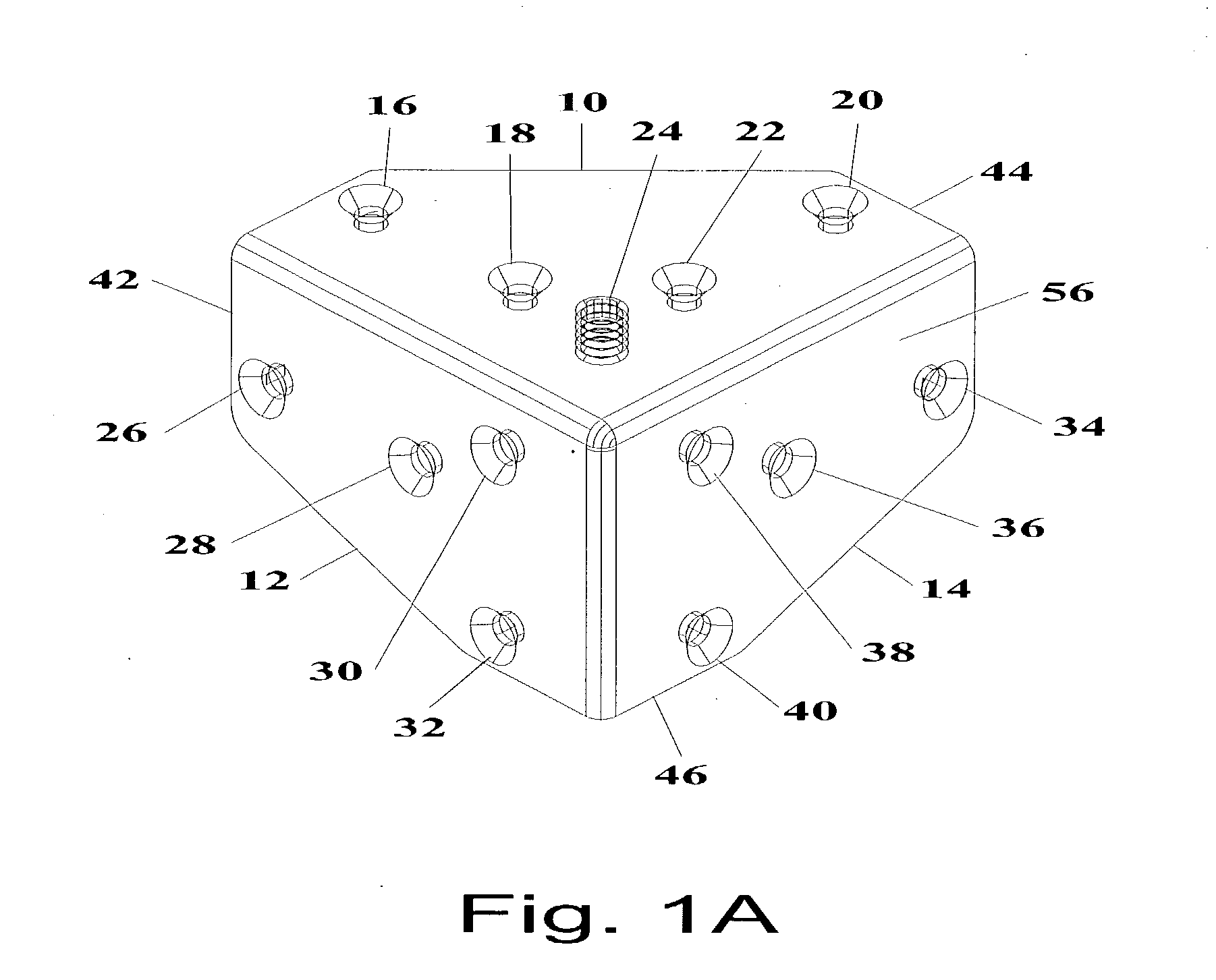

The invention pertains to a connecting corner used in assembling metal rack frame enclosures for housing a variety of equipment. A completely assembled rack frame consists of eight connecting corners, three sets of variable length rails (four identically sized rails per set), and ninety-six fasteners. The connecting corner is made of metal. The connecting corner has three legs; base (10), leg (12), and leg (14) with three inner slots; slot (42), slot (44), and slot (46). Each slot accepts two-legged metal rail (58), with industry standard, consistently repetitive hole pattern; hole (60), hole (62), hole (64), and marker (66). Each slot is supported by double-sided overlapping tapered reinforcing ribs; rib (50), rib (52), and rib (54). Rail stop embossment (48) prevents rails in slot (42), slot (44), and slot (46) from making contact with each other. There are four counter sunk holes in each leg of connecting corner. Corner base (10) includes hole (16), hole (18), hole (20), hole (22), and supplemental threaded hole (24). Corner leg (12) includes hole (26), hole (28), hole (30), and hole (32). Corner leg (14) includes hole (34), hole (36), hole (38), and hole (40). These holes match up, and align, with holes in metal rail (58), and fasteners are used to secure each rail in place thus forming a completely assembled rack frame.

Owner:ERWIN TOMA SUSAN +1

Earthquake-resistant cabinet

InactiveCN104901171AHigh precisionEasy to processAnti-seismic devicesRack/frame constructionEarthquake resistanceEngineering

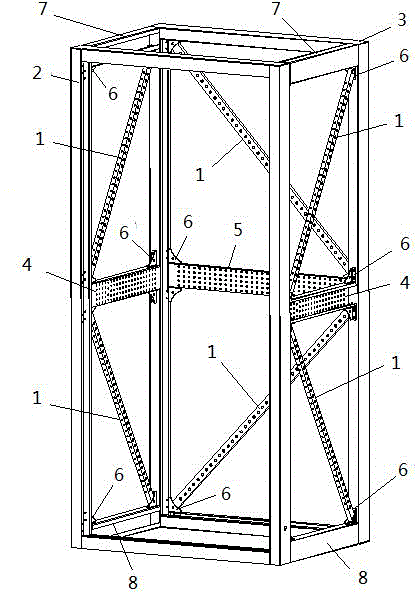

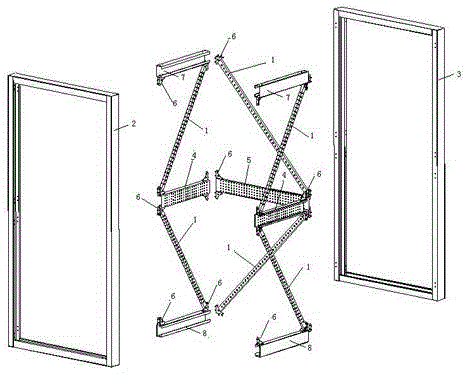

The present invention relates to an earthquake-resistant cabinet which is a rectangular frame. The front and back sides of the rectangular frame comprise a front frame and a back frame. The middle of the back frame is provided with a back cross beam. Upper and lower cross beams are arranged above and under the first side face and the second side face of the rectangular frame. The upper and lower cross beams and the front and back frames are integratedly welded to form a cabinet body. The middle of the first side face and the middle of the second side face are provided with side cross beams. The first side face and the second side face are cut by the side cross beams to be two rectangles. The back frame is cut by the back cross beam to be two rectangles. The four corners of each rectangle are provided with an angle iron. The diagonal position of each rectangle is provided with a reinforcing beam for dividing a rectangle structure into stable triangular structures. The earthquake-resistant cabinet has the advantages of high accuracy, easy processing and strong earthquake-resistant performance, and the special requirement for the earthquake-resistant performance of the cabinet by nuclear power and other special occasions is solved.

Owner:KEHUA DATA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com