Modular enclosure system

a modular enclosure and enclosure technology, applied in the field of enclosure assemblies, can solve the problems of requiring either, significant time and labor to modify a common enclosure, and substantial increase in the cost of a special-order enclosur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

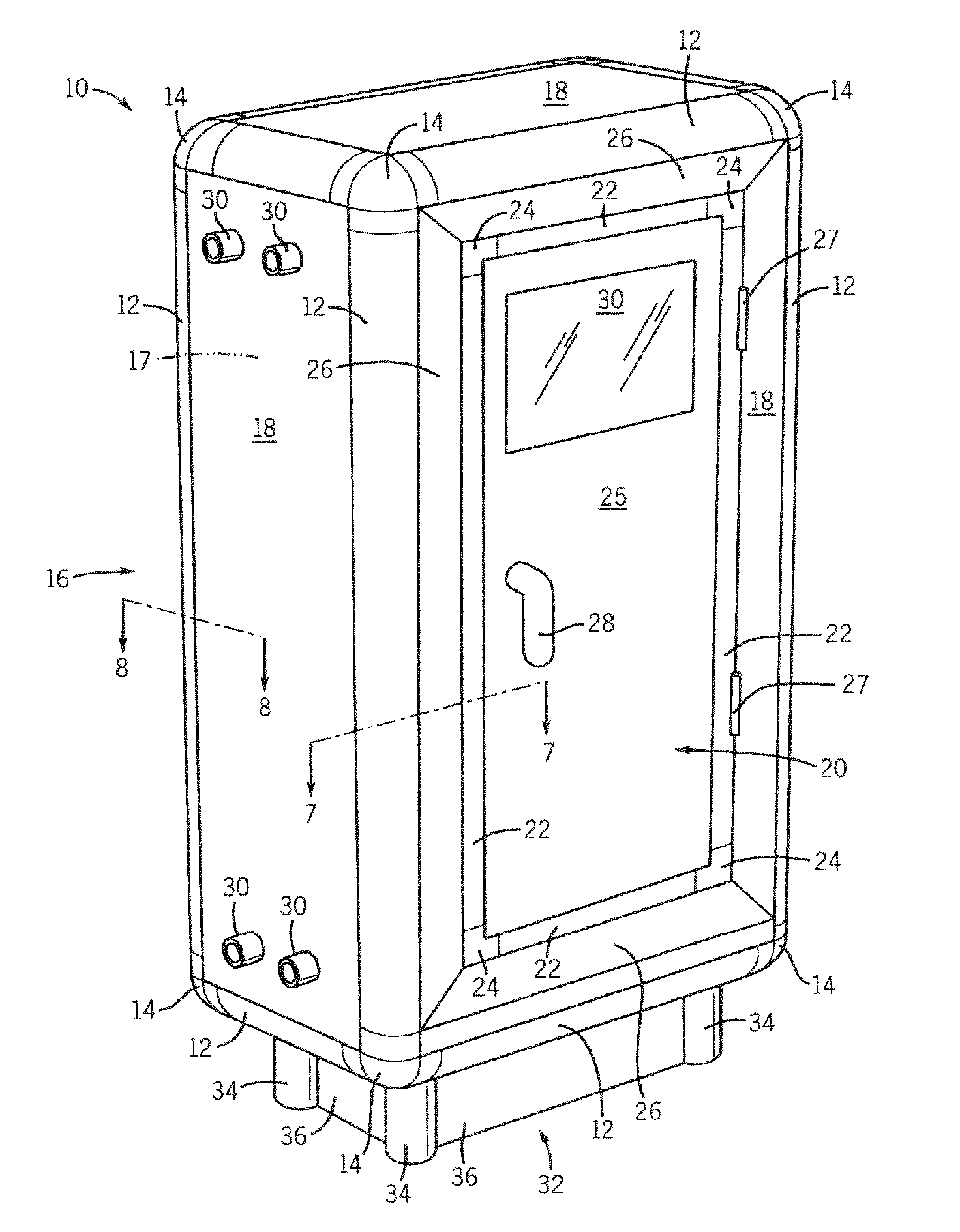

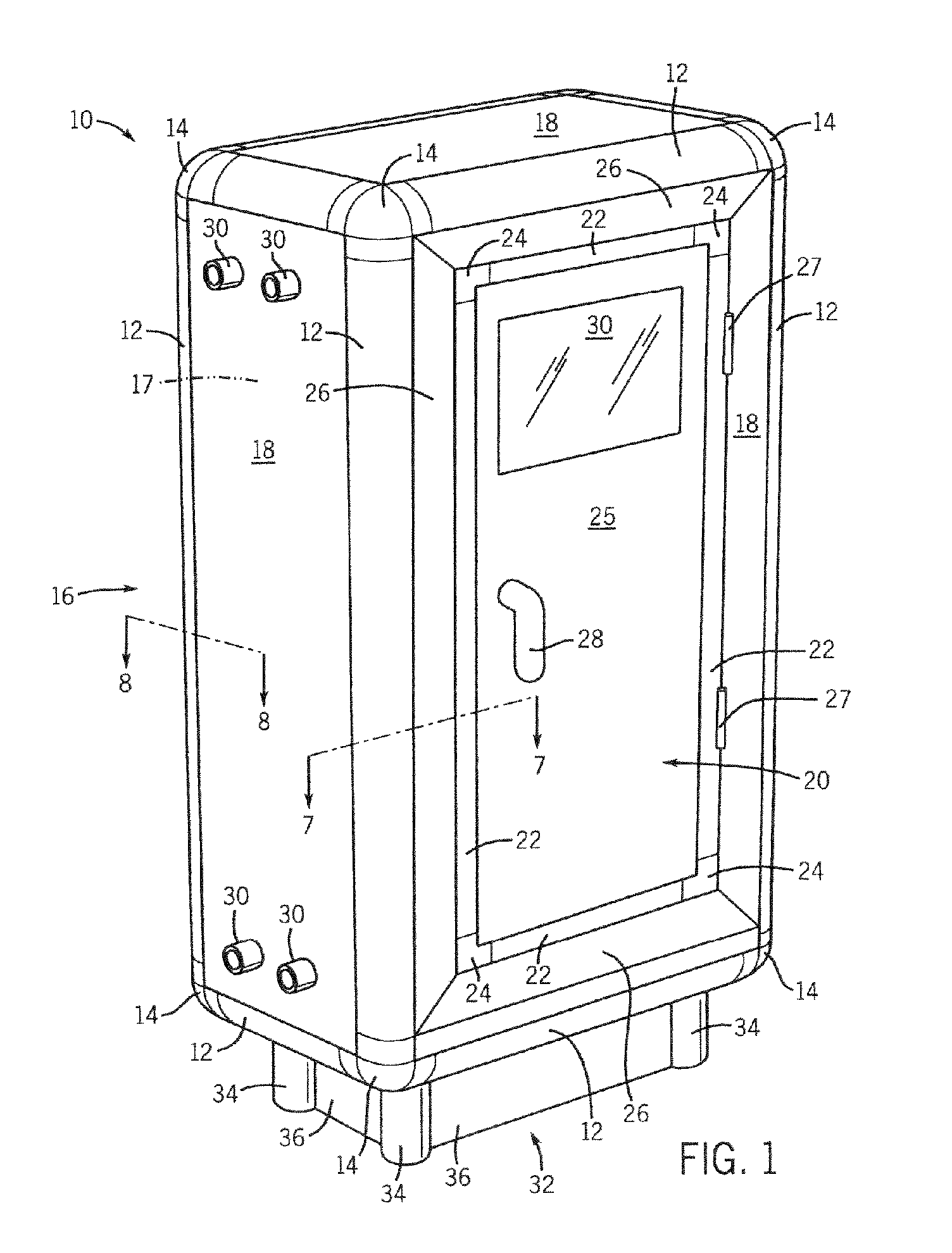

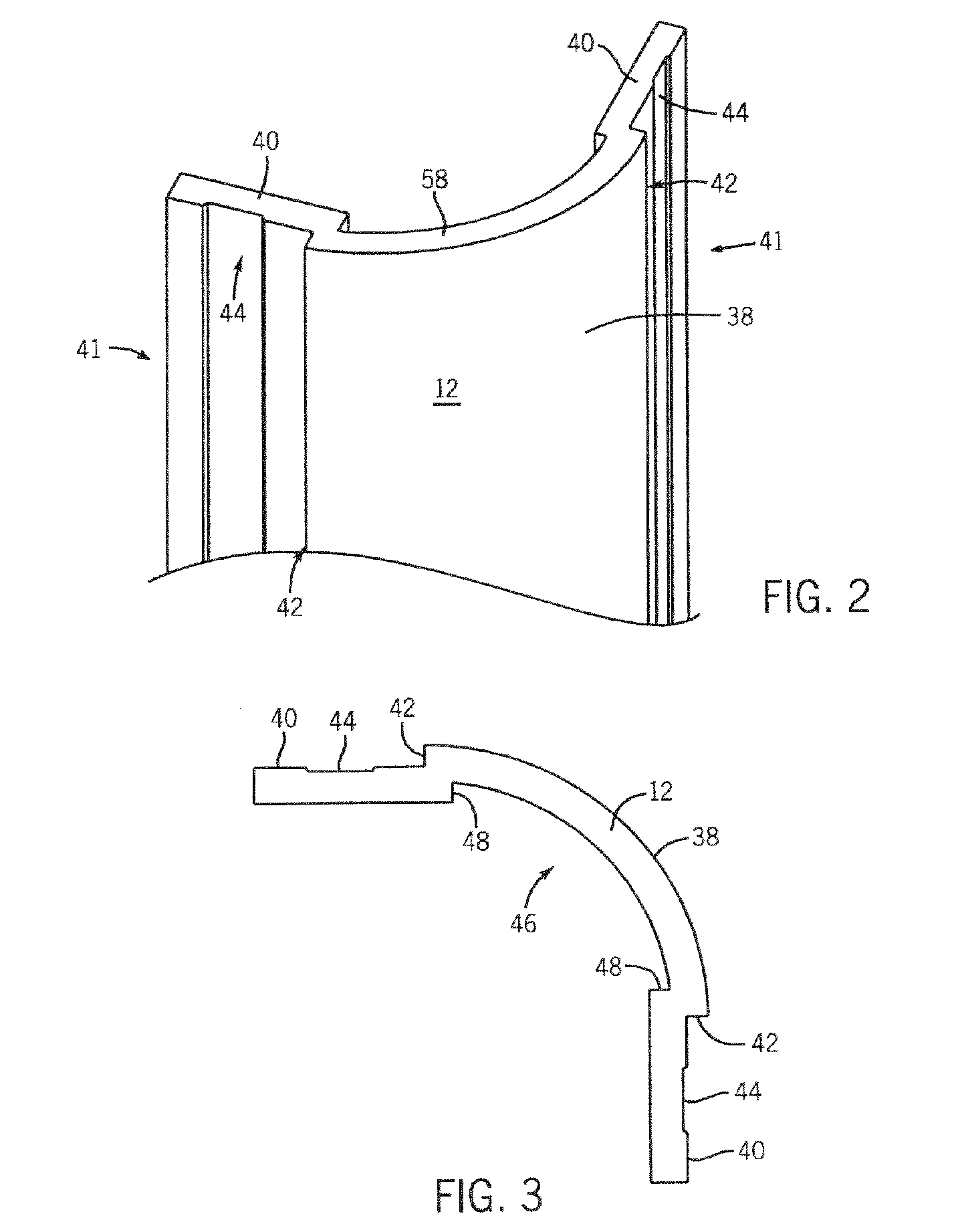

[0022]FIG. 1 shows an enclosure assembly 10 according to the present invention. The enclosure assembly 10 includes a plurality of edge rails 12 and a plurality of corner connectors 14 connected thereto. Edge rails 12 and corner connectors 14 are constructed to be interchangeable with each edge rail 12 and corner connector 14, respectively. Each corner connector 14 engages a plurality of the edge rails 12 such that the plurality of edge rails 12 and plurality of corner connectors 14 cooperate to form a frame assembly 16. A plurality of side panels 18 are connected to frame assembly 16 and enclose a cavity 17 therein. Enclosure assembly 10 includes a door assembly 20 that includes a plurality of door edge channels 22, a plurality of door corner connectors 24, a door panel 25, and a plurality of jam sections 26. Door assembly 20 is pivotably or removeably connected to enclosure assembly 10 by a hinge 27 or the like. A handle 28 provides a user of enclosure assembly 10 with selective ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com