Rack particularly for equipment cabinet

A frame and instrument cabinet technology, which is applied to the frame of the substation/switchgear, the layout details of the substation/switch, electrical components, etc., can solve the problem of the frame's laborious transportation, and achieve the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

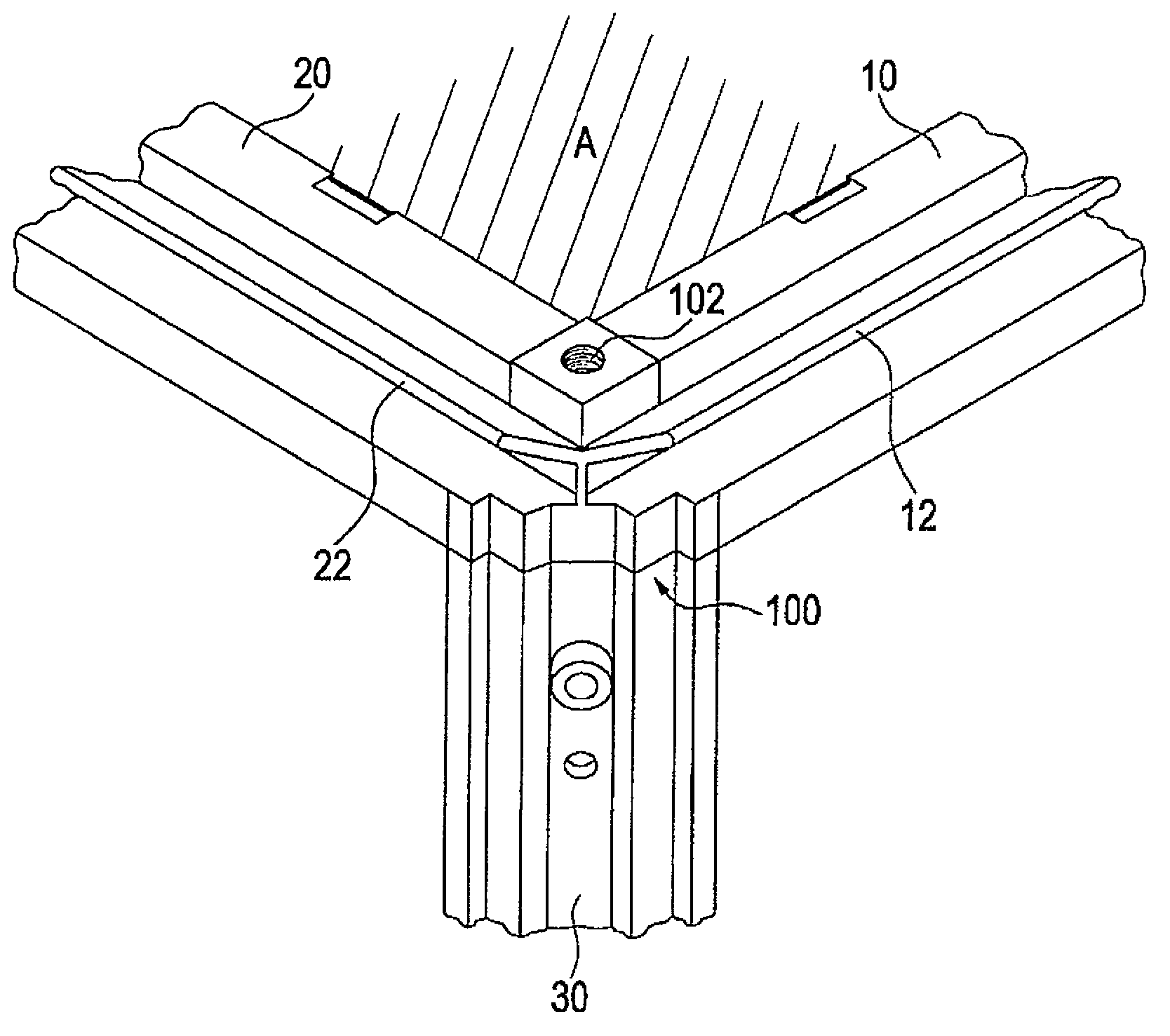

[0023] figure 1 Schematic representation of a corner of a frame according to the invention, which is particularly conceivable for use in switchgear cabinets.

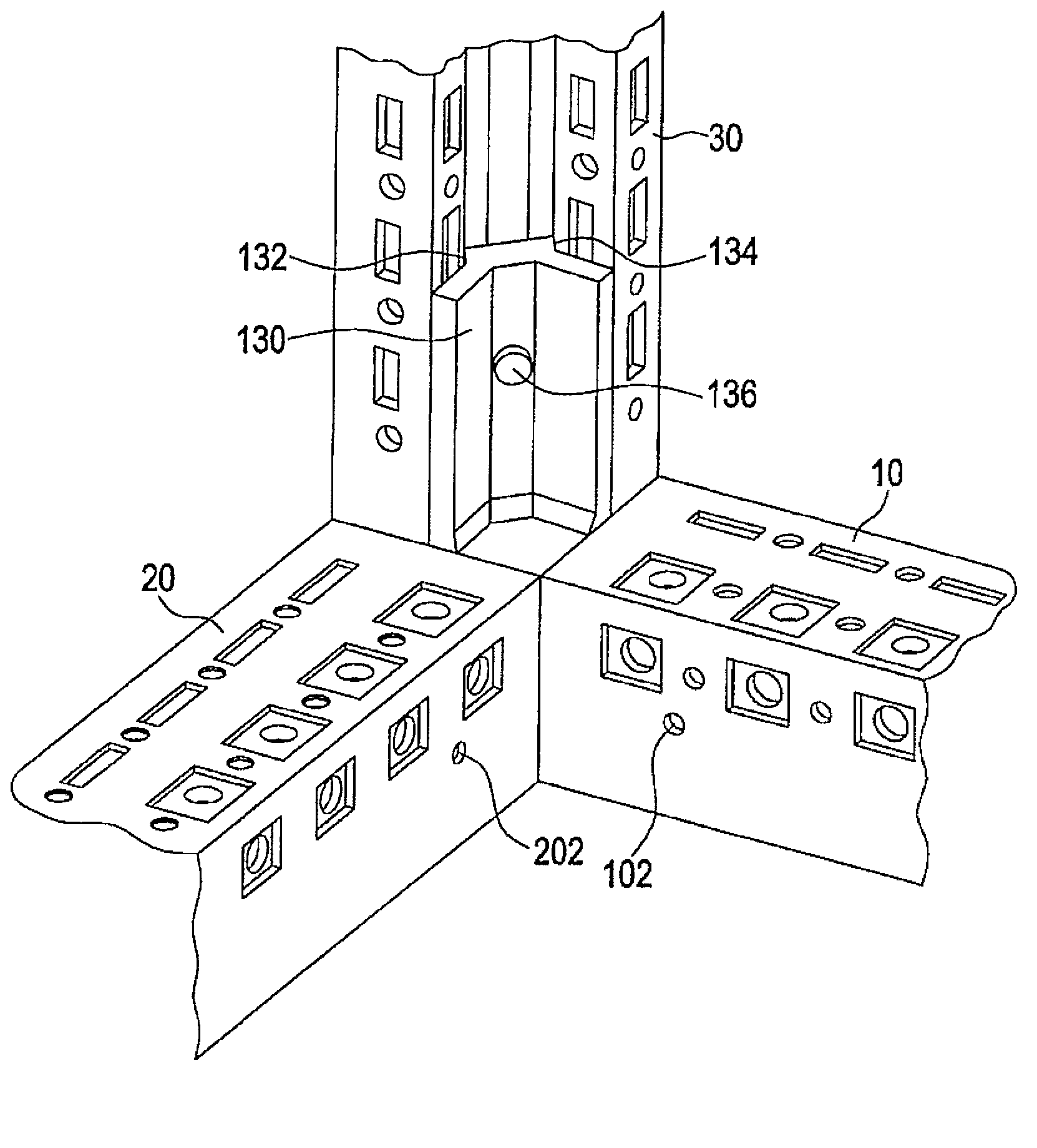

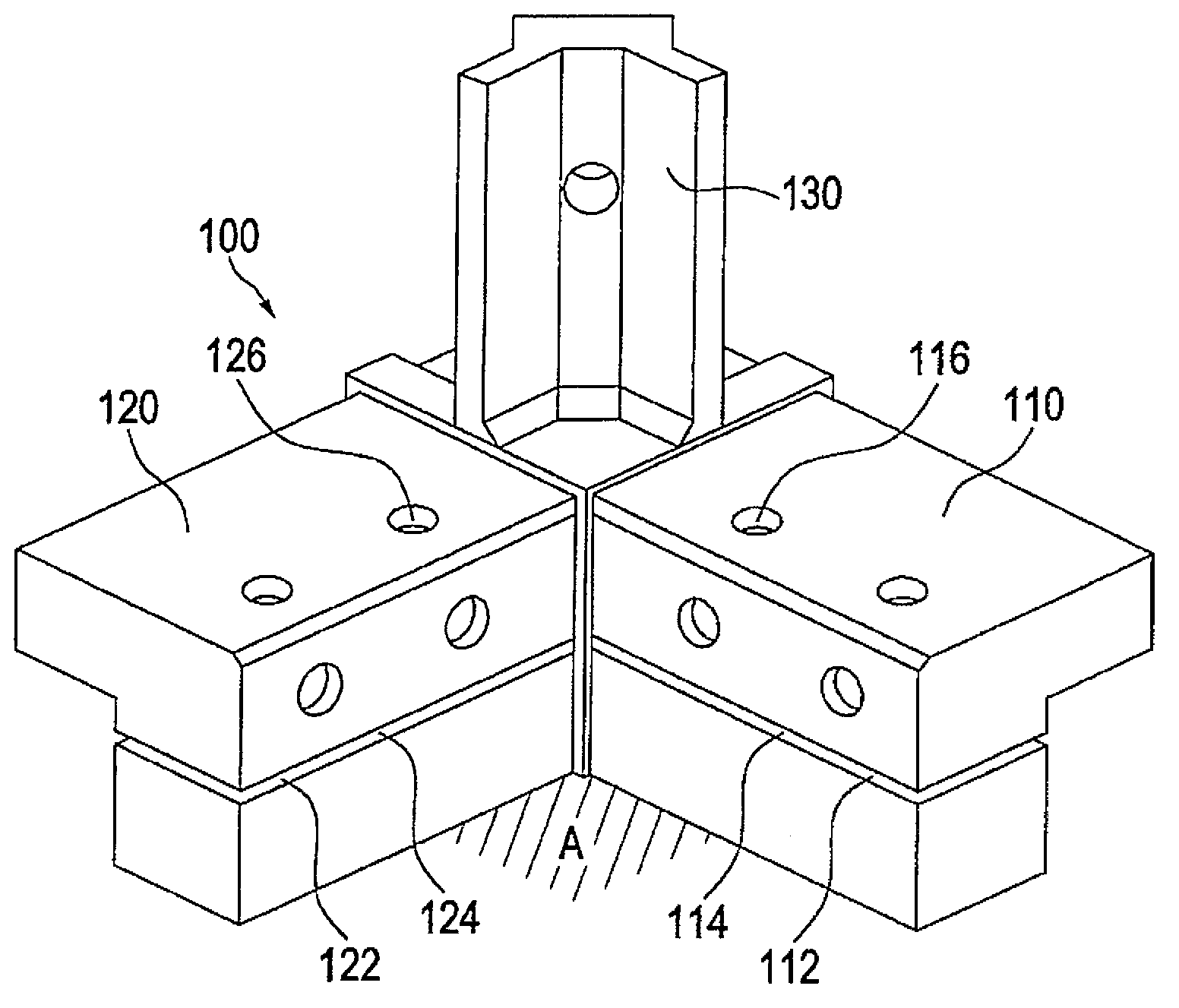

[0024] The frame according to the invention consists of profiles 10, 20, 30 which are passed through image 3 The corner connector 100 shown in detail in the connection. Here, two profiles adjacent to each other define a reference plane, which in the description of the invention is only used to clarify the spatial relationship of the components and has nothing to do with the physical mounting plane of the frame. In particular, the profile 10 extending in the transverse direction and the profile 20 extending in the depth direction define the reference plane A. As shown in FIG.

[0025] Each profile 10, 20, 30 is plugged into and fixed on the corresponding plug-in piece of the corner connector 100 which will be described later. The corner connector 100 has threaded holes 102 in its exposed corner regions not covered by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com