Cabinet framework convenient for assembly and assembly method thereof

A frame and cabinet technology, which is applied to the cabinet frame and its assembly field that is easy to assemble, can solve the problems of high cost, large deformation, high transportation and storage costs, and achieve the effects of improved bending strength, large bearing capacity and strong flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

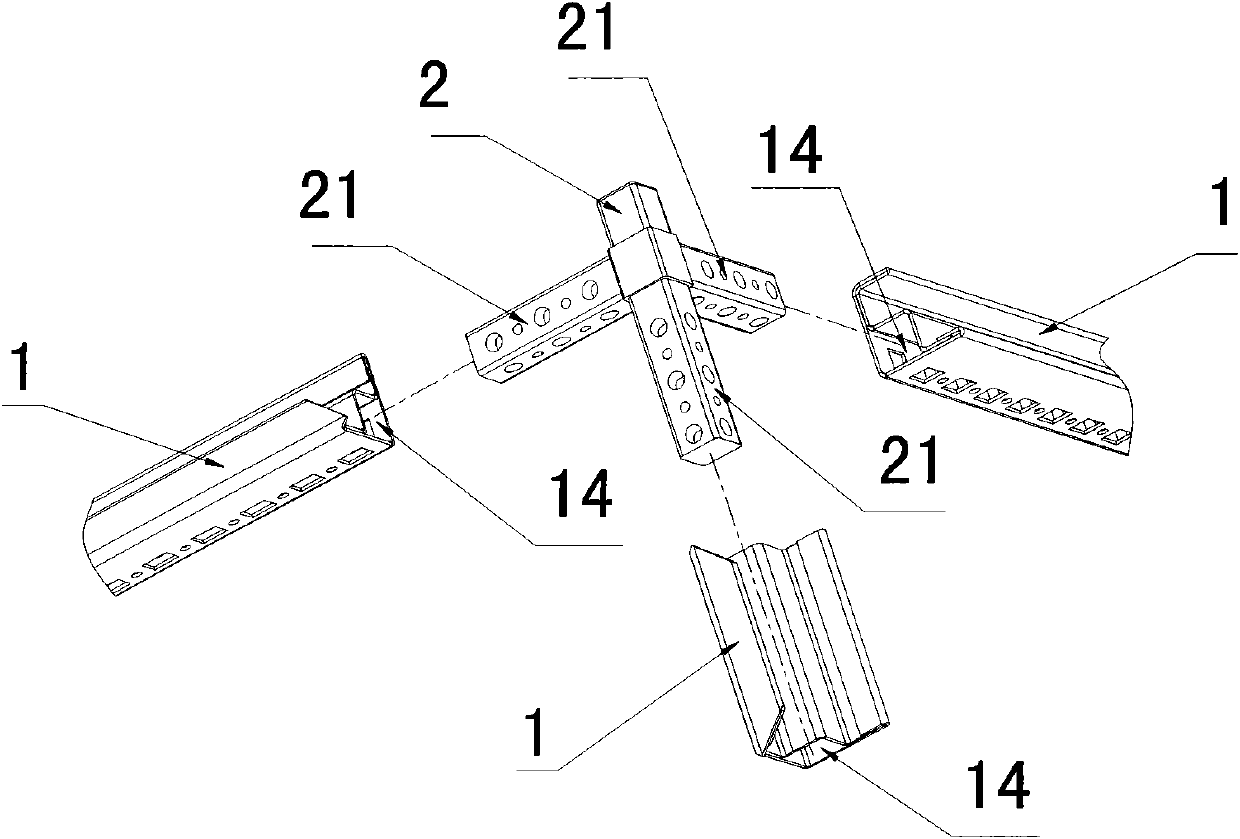

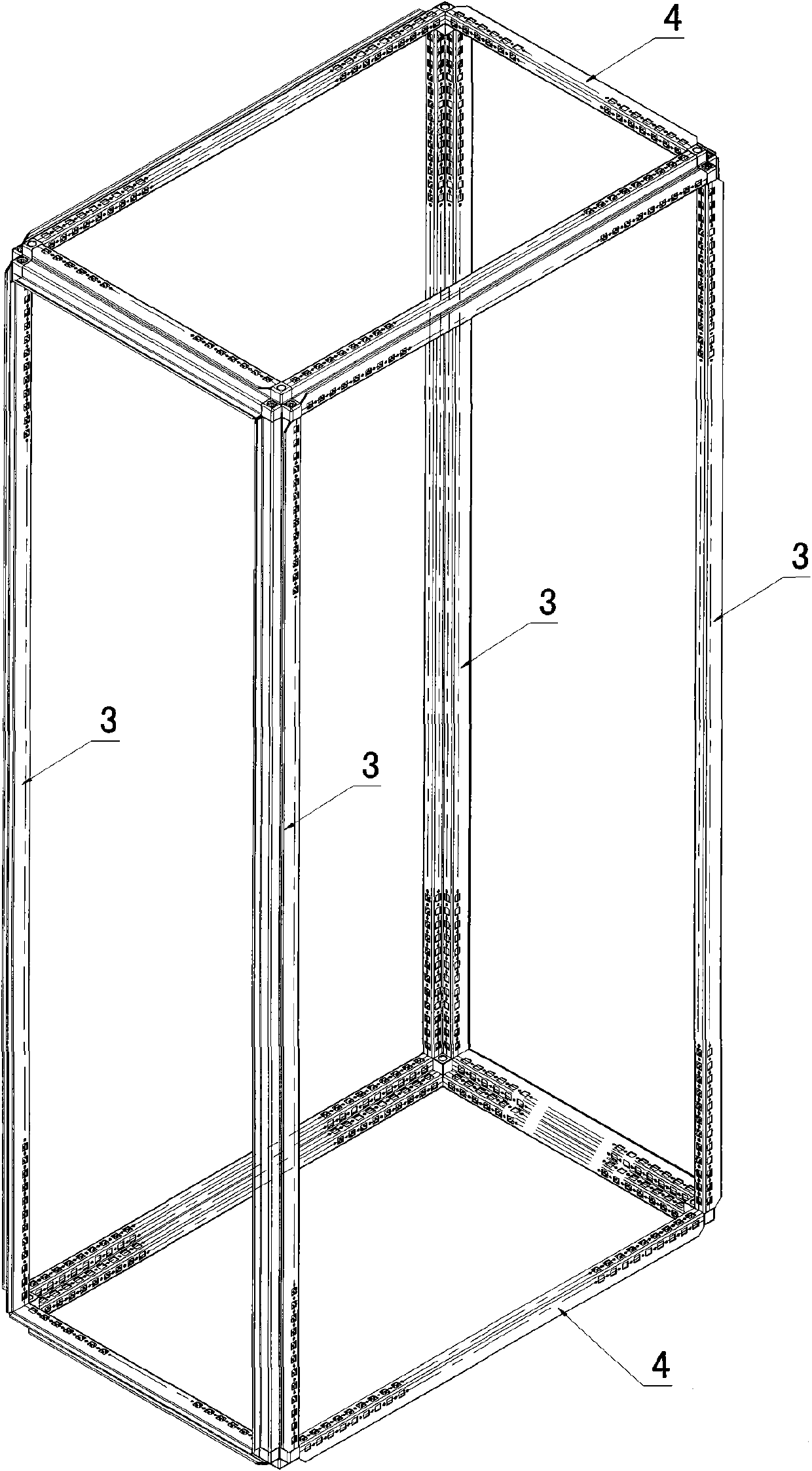

[0045] Example: such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the cabinet frame for easy assembly includes: four vertical column frame rods 3 , an upper frame 4 and a lower frame 4 with the same structure, eight corner connectors 5 and sixteen prismatic coupling rods 6 .

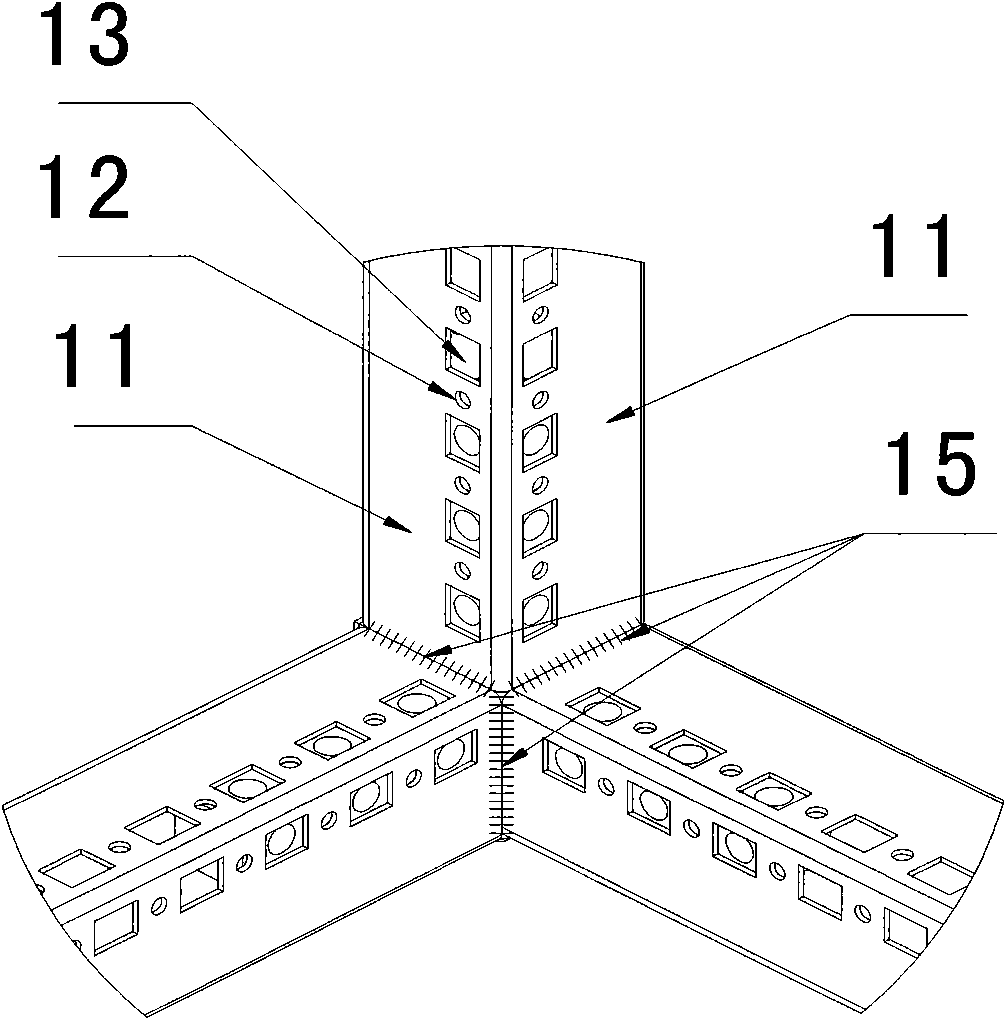

[0046] The corner connector 5 is as Figure 7 As shown, it is composed of three mutually perpendicular right-angled surfaces 53, 54, wherein the symmetrical two corners of the two right-angled surfaces 53 are provided with bosses 51 that can be embedded and connected by frame rods, and the other right-angled surface 54 is symmetrical. The two corners are provided with stepped counterbore holes 52 for the head of the connecting rod to be embedded and connected, and the center of the stepped counterbore holes 52 is provided with a bolt penetration hole 55 .

[0047] The column frame rod 3 such as Figure 4 As shown, is a cross-section For structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com