Profiled frame of a frame structure for an electrical enclosure or a distribution cabinet

A technology of special-shaped parts and distribution boxes, applied in the frame, electrical components of substation/switchgear, board/panel/desk of substation/switchgear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

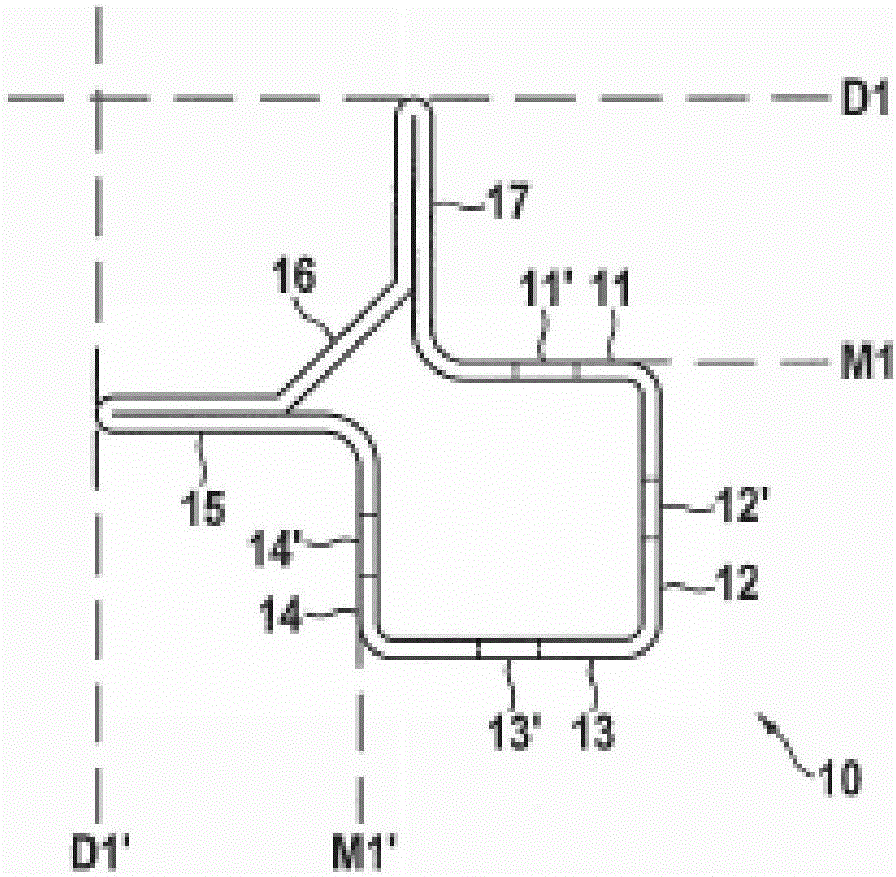

[0042] figure 1 A sectional view of a first embodiment of a frame profile 10 according to the invention is shown, which can be used in a frame for a switchgear or distribution box. The frame profile 10 can form the vertical profile and / or the horizontal profile of the machine frame and consist of a plurality of profile sections 11 , 12 , 13 , 14 , 15 , 16 , 17 that transition into each other, so that A closed hollow profile is formed. The profile sections 11 , 12 , 13 , 14 in this case substantially surround a cavity section with a square cross section, wherein the profile sections 11 and 14 transition into a profile region extending perpendicular thereto. In sections 17 and 15 , the profile sections 17 and 15 are folded back onto themselves and are connected to each other on the other hand via profile section 16 . The free end regions of the profile sections 15 and 17 in this case form the outer limit of the machine frame, which is established by the frame profile 10 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com