Electrical system enclosures

a technology of electrical system and enclosure, applied in the field of enclosure, can solve problems such as problems such as the problem of transporting such enclosures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]As described above, conventional electrical system enclosures may be problematic in that transportation is cumbersome due to the conventional, fully-assembled welded manner of assembly. However, exemplary embodiments of the present invention provide a solution which significantly reduces a volume required for transport while maintaining an appropriate level of ingress protection as compared to conventional welded enclosures.

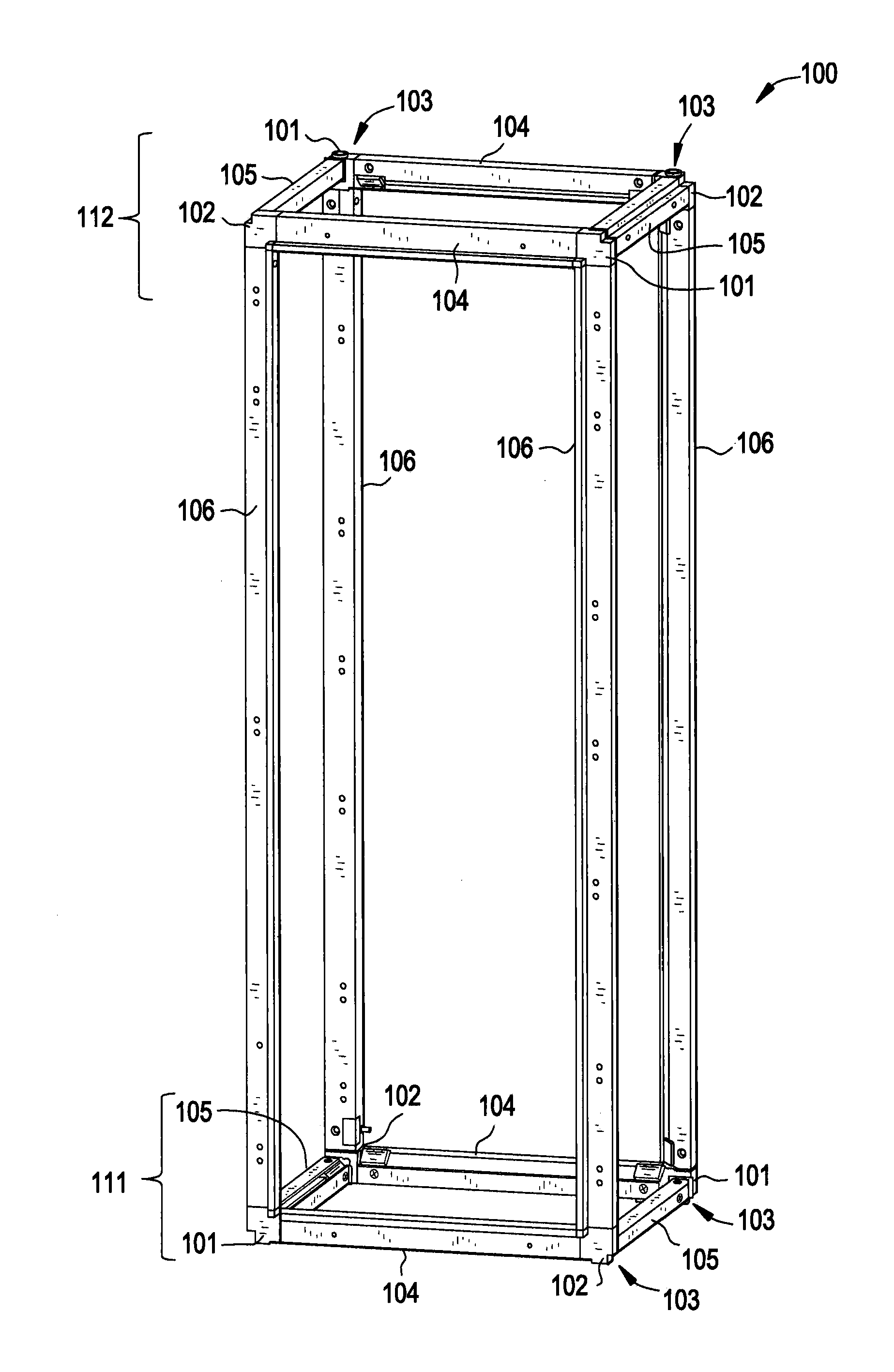

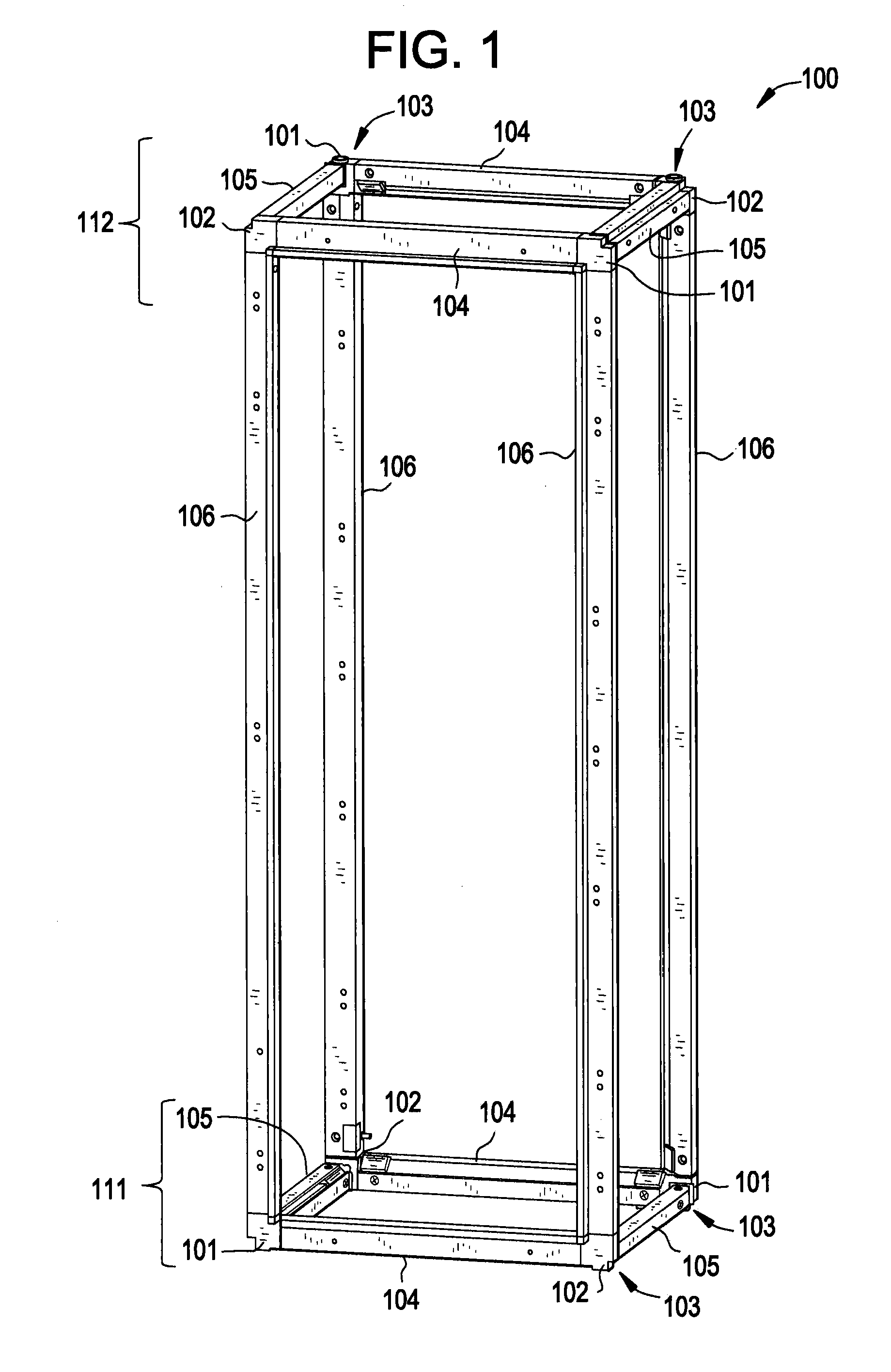

[0044]Turning to FIG. 1, a perspective view of a supportive frame of an electrical system enclosure is provided. As illustrated, the frame 100 includes four corner support structures 101 (e.g., a first set of corner support structures), four corner support structures 102 (e.g., a second set of corner support structures), eight gasket assemblies 103, four horizontal framing support members 104, four horizontal framing support members 105, and four vertical framing support members 106. As shown, the corner support structures 101 and 102 engage proximate frami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com