Mettalic structure improvement for manufacturing electrical cabinets

A metal structure, electrical cabinet technology, applied in the direction of rack/frame structure, substation/switchgear frame, application, etc., can solve transportation and storage difficulties, does not provide satisfactory rigidity or mechanical stability, increases manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

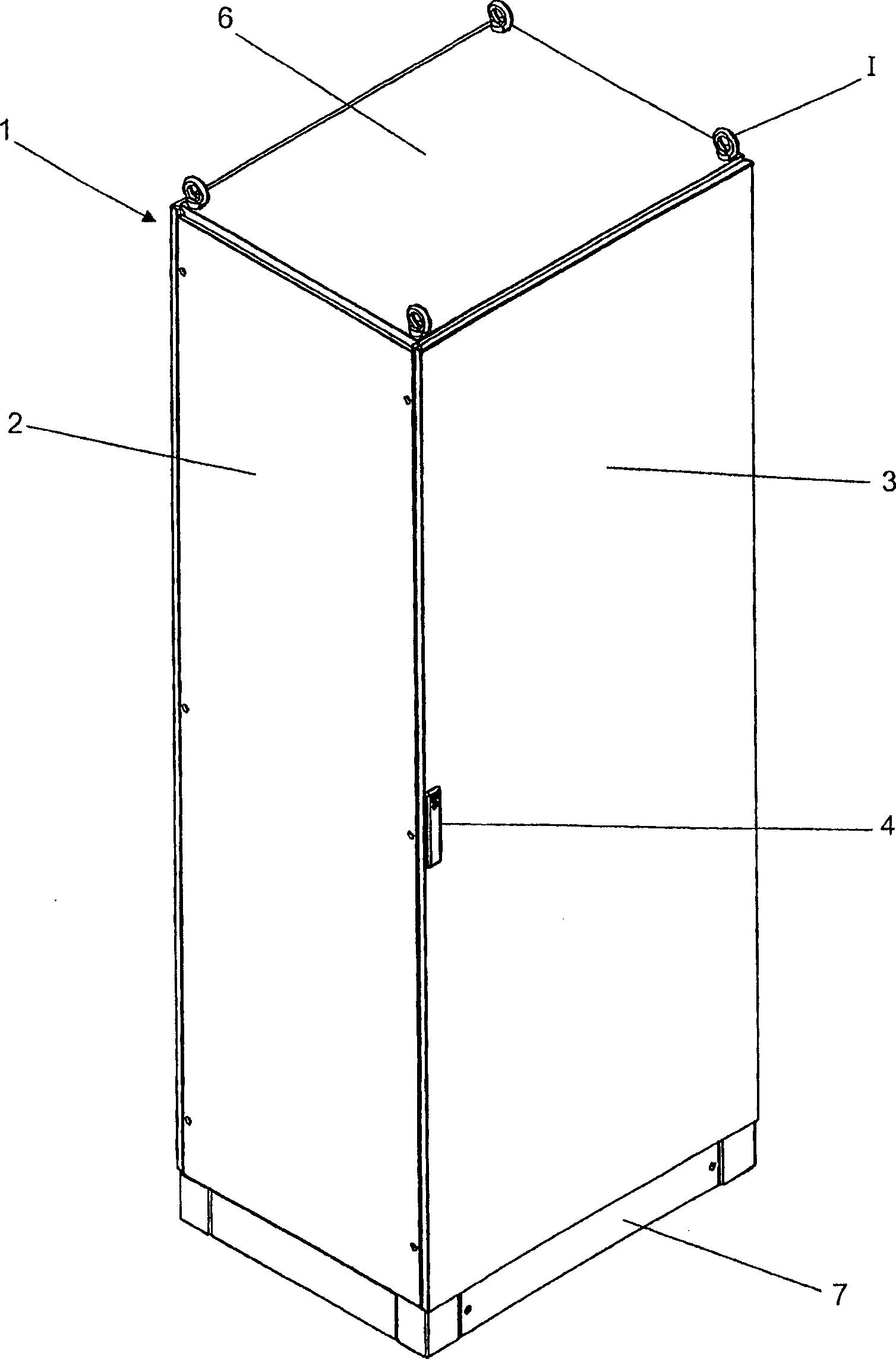

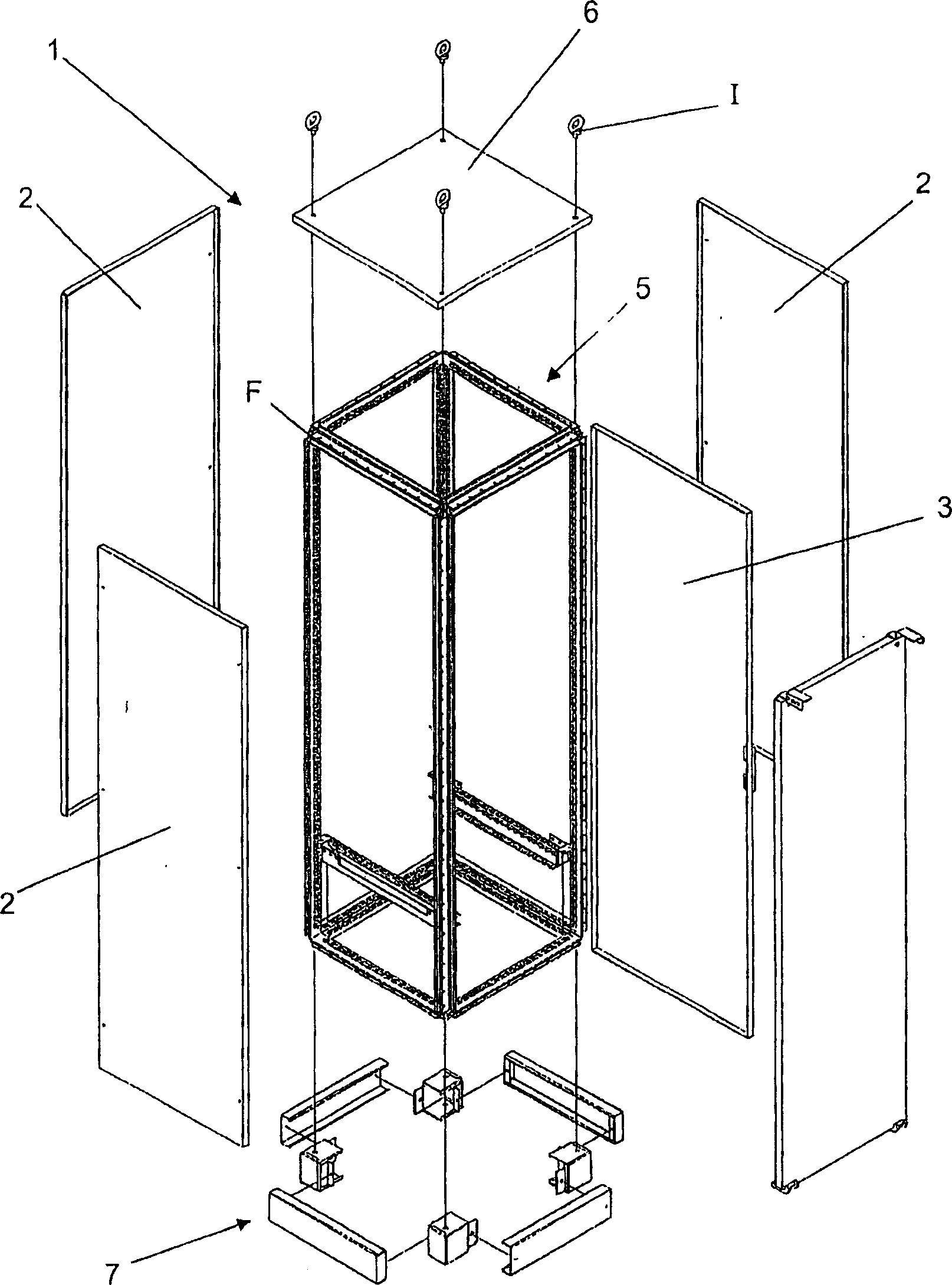

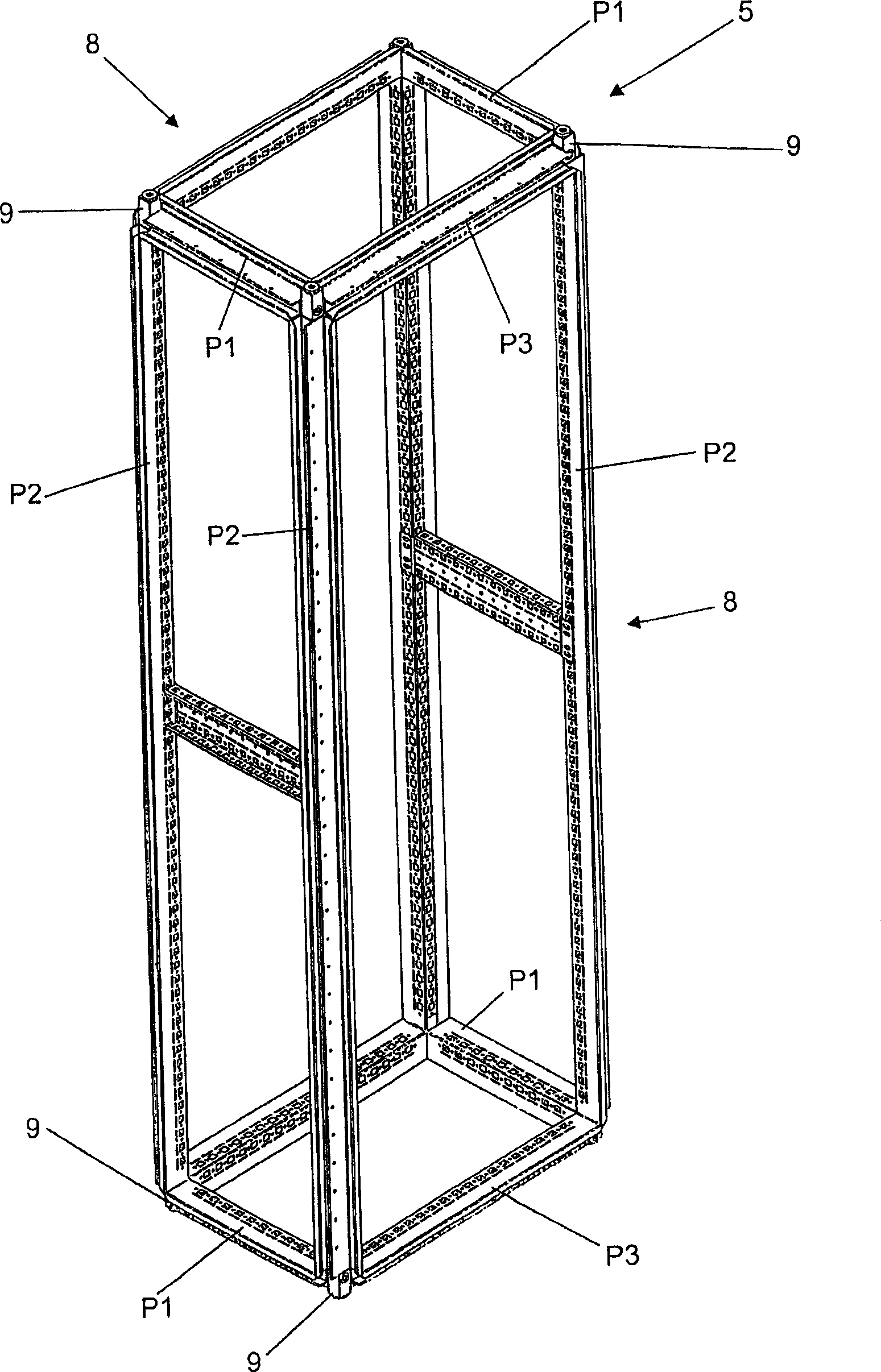

[0049] In accordance with these figures and their details, this modification to metal structures has been especially developed for installations usually such as figure 1 and 2 Cabinet or switchboard (1) shown in , where only one type of instance can be seen, which can be either indoors or outdoors, but in both cases the same Shown in the form of a metal box with closed sides (2) which also includes one or more swing doors (3) with locks (4). Such enclosures, including doors, are usually manufactured from very thin sheet metal. In this way, as figure 2 As shown in , all switchboards have an internal metal cross-section structure (5) through which it can be seen that, as the name of the structure itself suggests, this structure forms the The supporting device of the part of the outer wall formed, and it also constitutes the support and assembly means of the door, its various hinges and other accessories, such as: the upper shell (6) and the lower shell with the base (7) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com