Earthquake-resistant cabinet

An anti-seismic cabinet, integrated technology, applied in the direction of anti-seismic equipment, rack/frame structure, substation/switchgear frame, etc., to achieve high precision, solve special requirements for seismic resistance, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

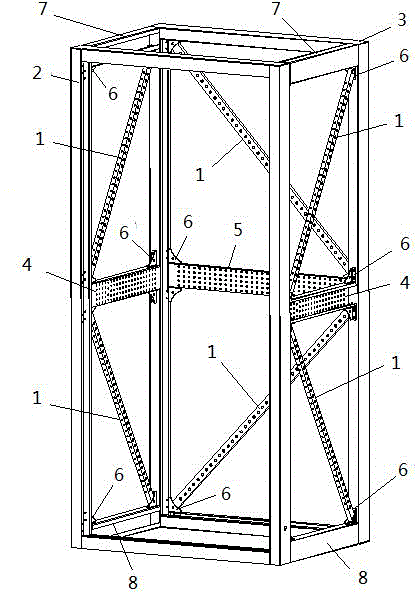

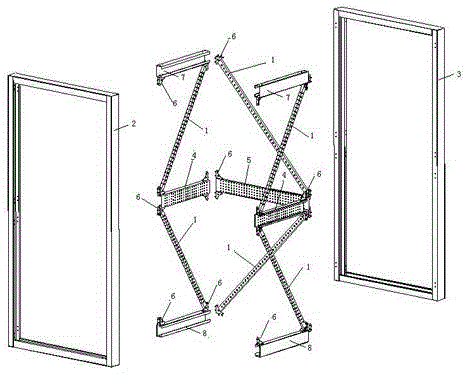

[0028] Such as figure 1 as well as figure 2 As shown, the present embodiment provides a kind of anti-seismic cabinet, which is a cuboid frame. The front and rear sides of the cuboid frame include a front frame 2 and a rear frame 3, and the middle part of the rear frame 3 is provided with a rear beam 5; The first side and the second side of the cuboid frame are respectively provided with an upper beam 7 and a lower beam 8, which are used to weld the front frame 2 and the rear frame 3 to form a cabinet body; the middle part of the first side and the second side The middle part is provided with side beams 4; the first side and the second side are divided into two rectangles by the side beams 4, and the rear frame is divided into two rectangles by the rear beams, each An angle iron 6 is provided at each of the four corners of the rectangle, and a reinforcement beam 1 is provided at each diagonal position of the rectangle to divide the rectangular structure into stable triangular...

Embodiment 2

[0040] Such as Figure 6 As shown, this embodiment provides an anti-seismic cabinet in the field of nuclear power, including a cuboid frame, each of the four corners of the rectangle of the cuboid frame is provided with an angle iron, and at least two of the side walls of the cuboid frame Reinforcing beams are arranged in the diagonal direction to divide the rectangular structure into stable triangular structures.

[0041] In this embodiment, the cuboid frame and the angle iron are connected and fixed by riveting, welding or a combination of riveting and welding, and the reinforcing beam and the angle iron are fixed by welding, screw and nut connection or welding and screw and nut Combined way to connect and fix.

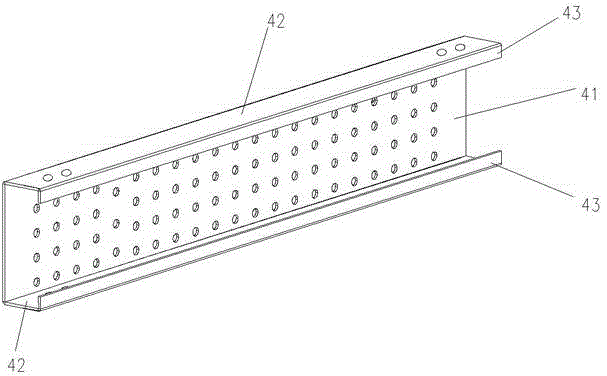

[0042] In this embodiment, the reinforcing beam is provided with several small holes to reduce weight.

[0043] In summary, compared with the prior art, the entire frame of the present invention is fixed by riveting and welding, and there are reinforcing beams on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com