High-tension steel with excellent weldability and plastic deformation ability

A cold forming and steel technology, applied in the direction of building elements, slender elements, etc., can solve the problems of high yield ratio and inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

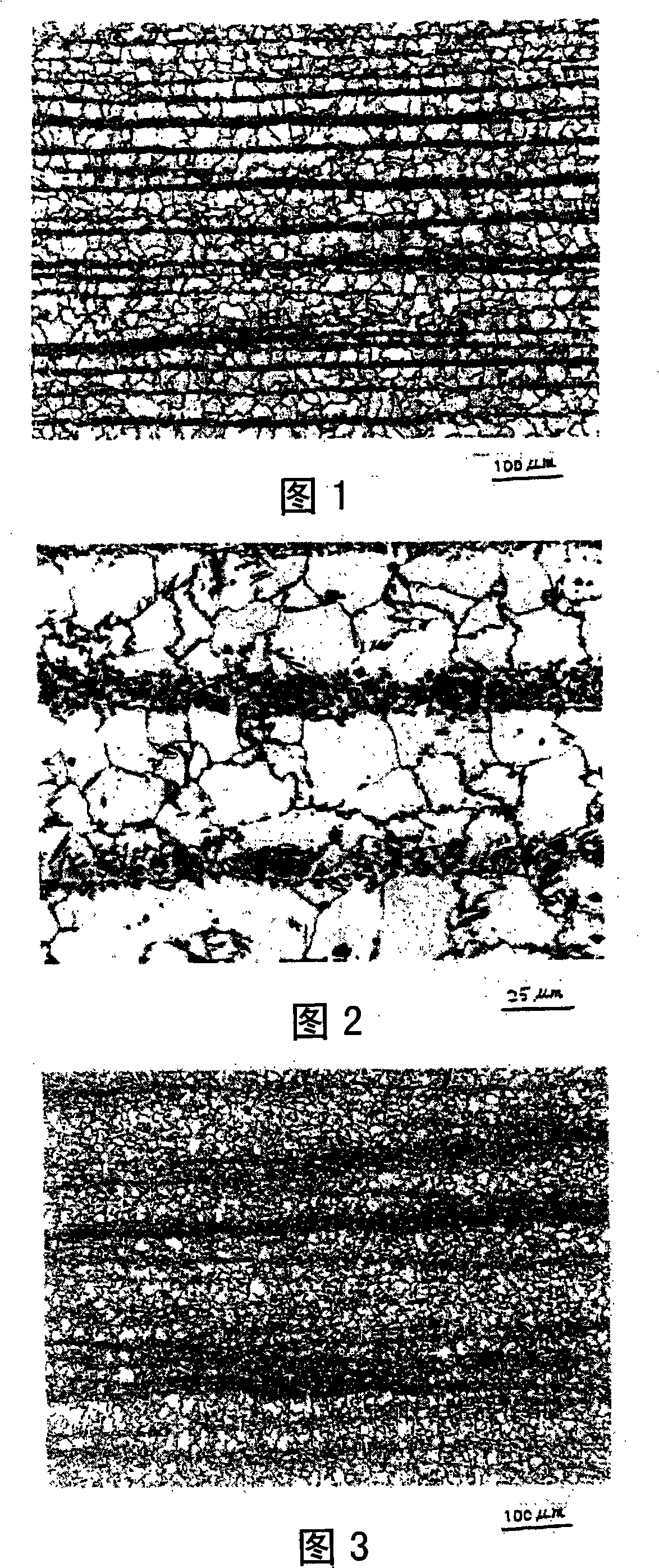

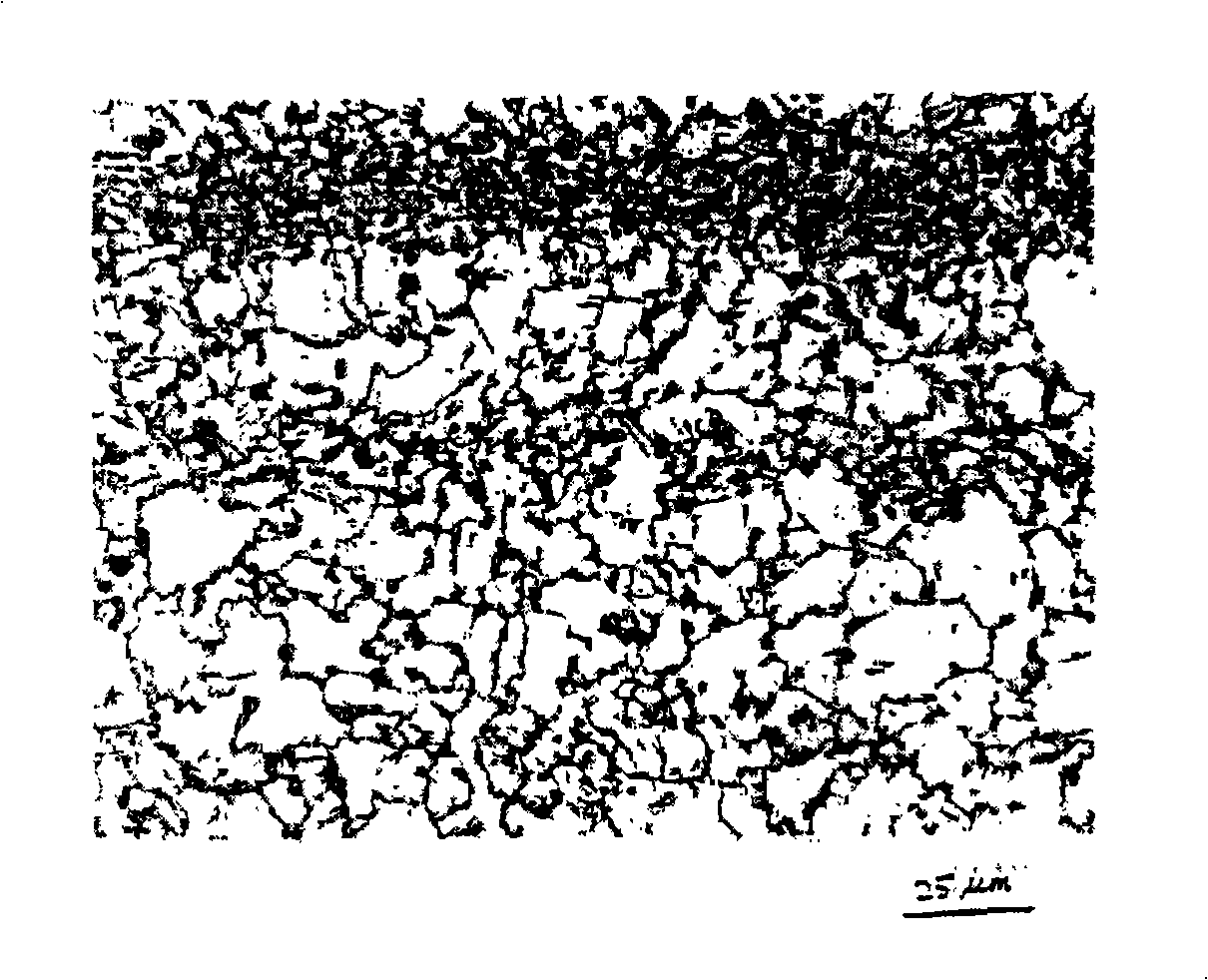

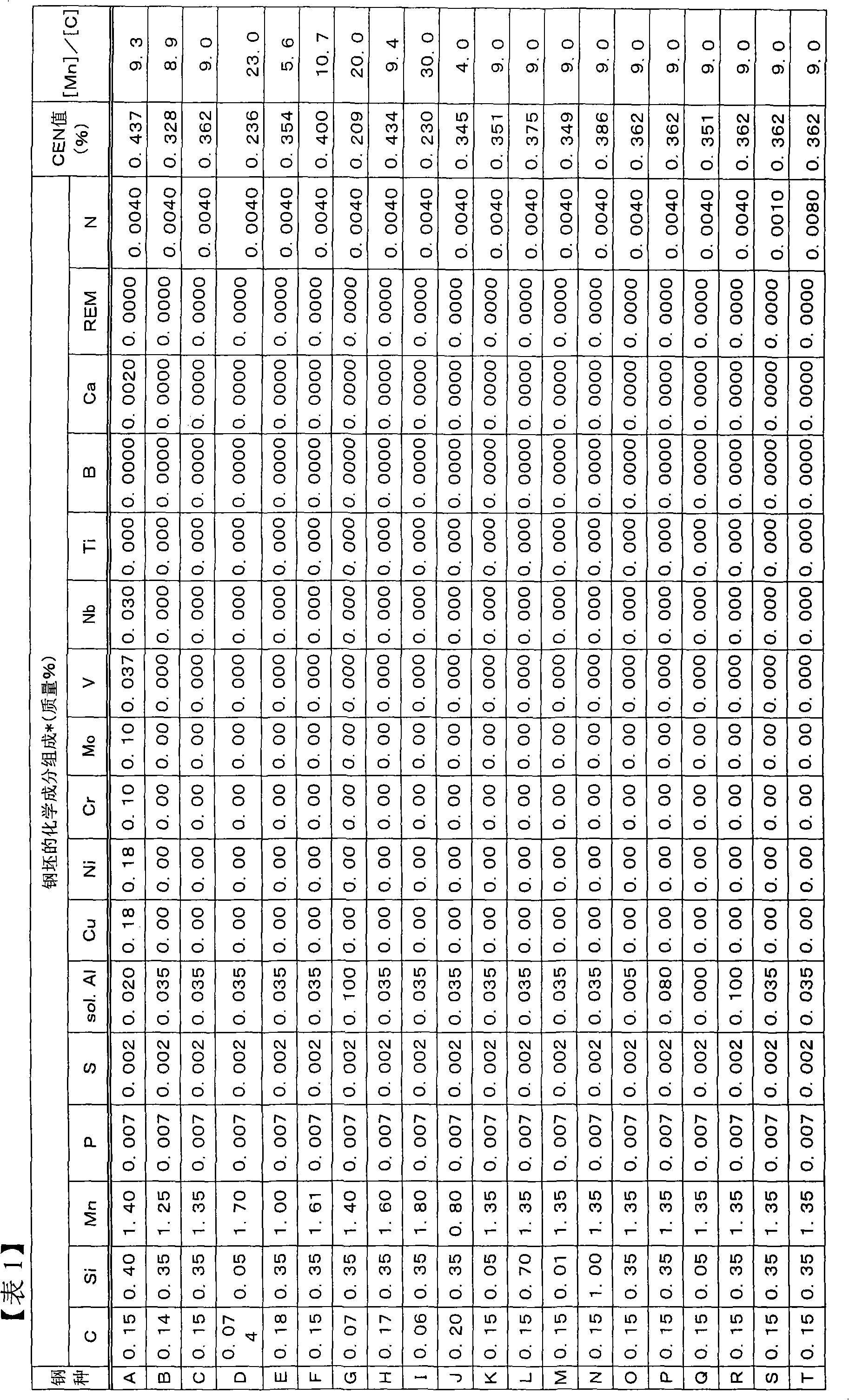

[0092] Steels with the chemical compositions shown in Tables 1 and 2 below were smelted according to common smelting methods to form steel slabs, and then any one of the treatments (types 1 to 5) shown below was performed to manufacture steel sheets. In addition, Tables 1 and 2 also show the value of CEN and the value of [Mn] / [C] defined by the above formula (1). The production conditions at this time are shown in Tables 3 and 4 below.

[0093] (processing steps)

[0094] Type 1: After performing controlled rolling (CR), normalizing (N) was performed (test No. 1 described later). The normalizing (N) here is from Ac 1 Air cooling at temperatures above the phase transition point.

[0095] Type 2: Accelerated cooling was performed after controlled rolling (test No. 2 described later).

[0096] Type 3: Controlled rolling (CR), followed by normalizing (N), followed by quenching (Q') at the dual-phase temperature (test No. 3 described later).

[0097] Type 4: After controlled r...

Embodiment 2

[0140] Steels with the chemical compositions shown in Tables 9 and 10 below were smelted according to common smelting methods to form steel slabs, and then any one of the treatments (types 1 to 5) shown below was performed to manufacture steel sheets. In addition, Tables 1 and 2 also show the value of CEN and the value of [Mn] / [C] defined by the above formula (1). The manufacturing conditions at this time are shown in Tables 11 and 12 below.

[0141] (processing steps)

[0142] Type 1: Normalizing (N) was performed after controlled rolling (CR) (test No. 44 described later). The normalizing (N) here is from Ac 1 Air cooling at temperatures above the phase transition point.

[0143] Type 2: After controlled rolling, accelerated cooling was performed (Test No. 45 described later).

[0144] Type 3: Controlled rolling (CR), followed by normalizing (N), followed by quenching (Q') at the dual-phase temperature (test No. 46 described later).

[0145] Type 4: After controlled rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com