Composite wound thermoplastic glass-reinforced-plastic pipe and production method thereof

A thermoplastic and composite technology, used in rigid pipes, pipes, machinery and equipment, etc., can solve the problems of high hoop tensile strength and low axial tensile strength, and achieve high hoop tensile strength and high production efficiency. , the effect of high axial tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

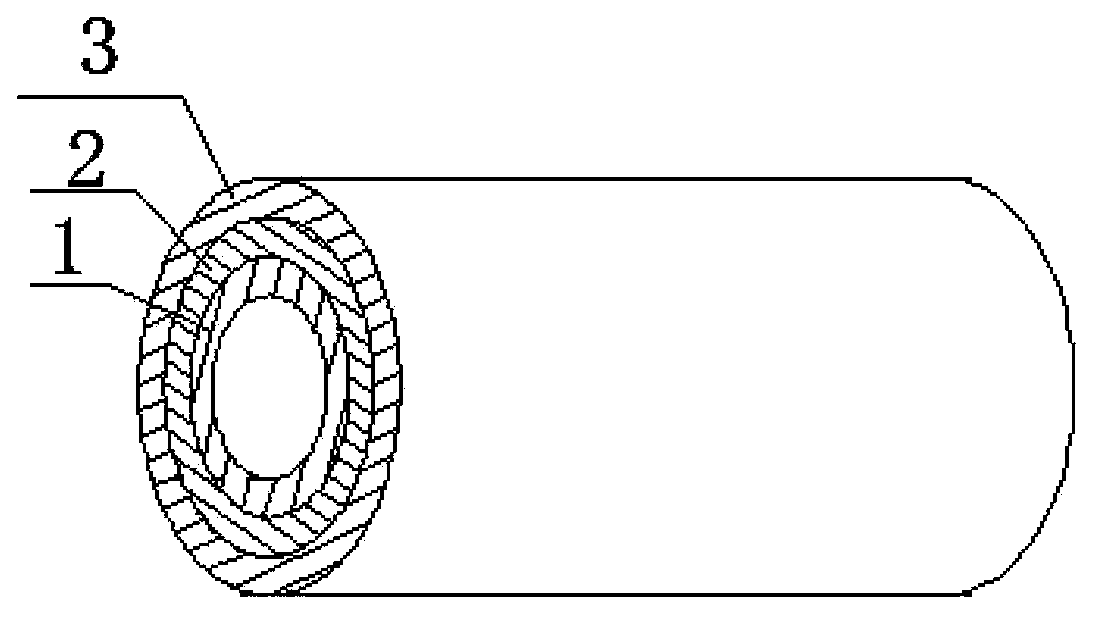

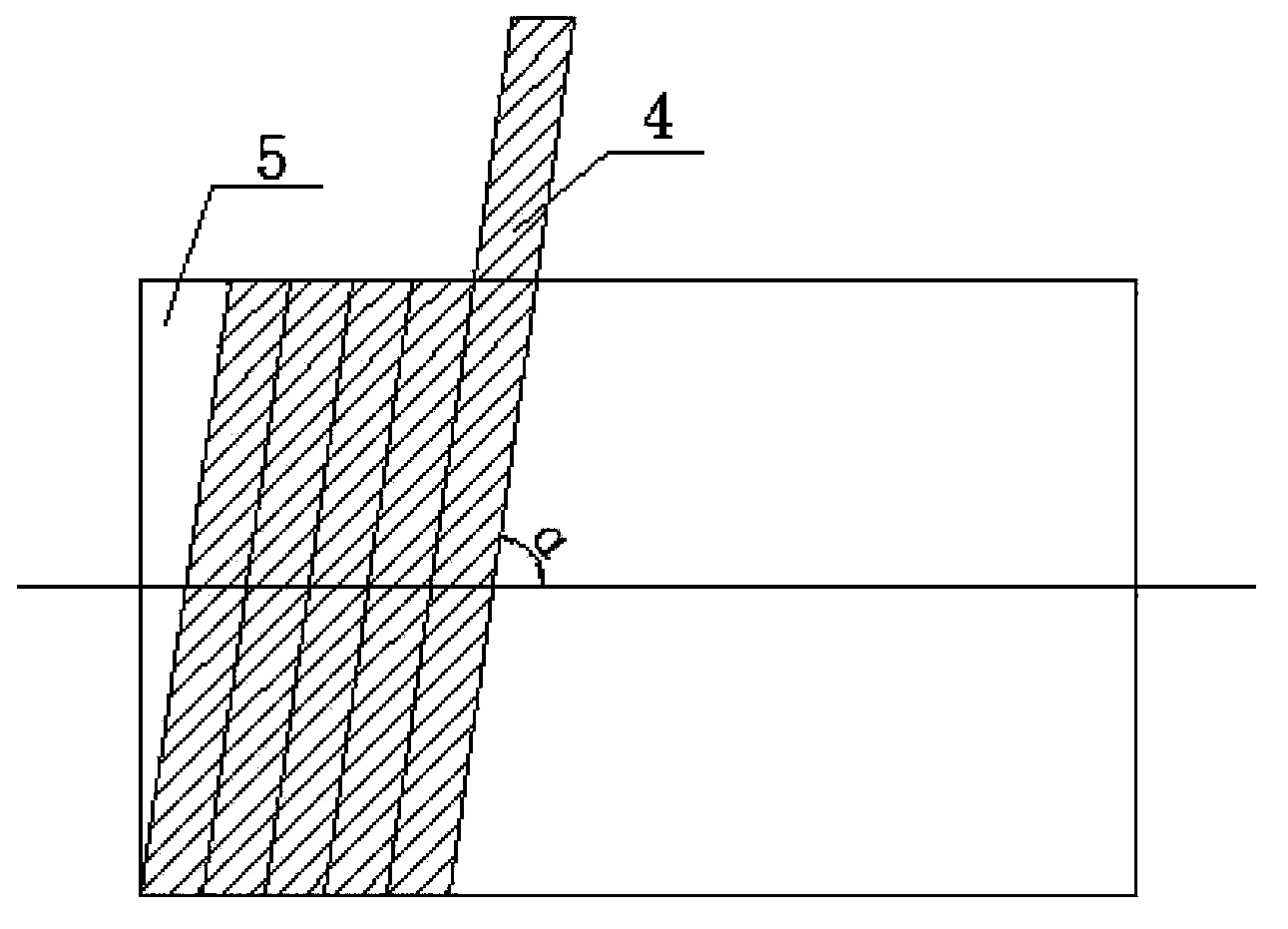

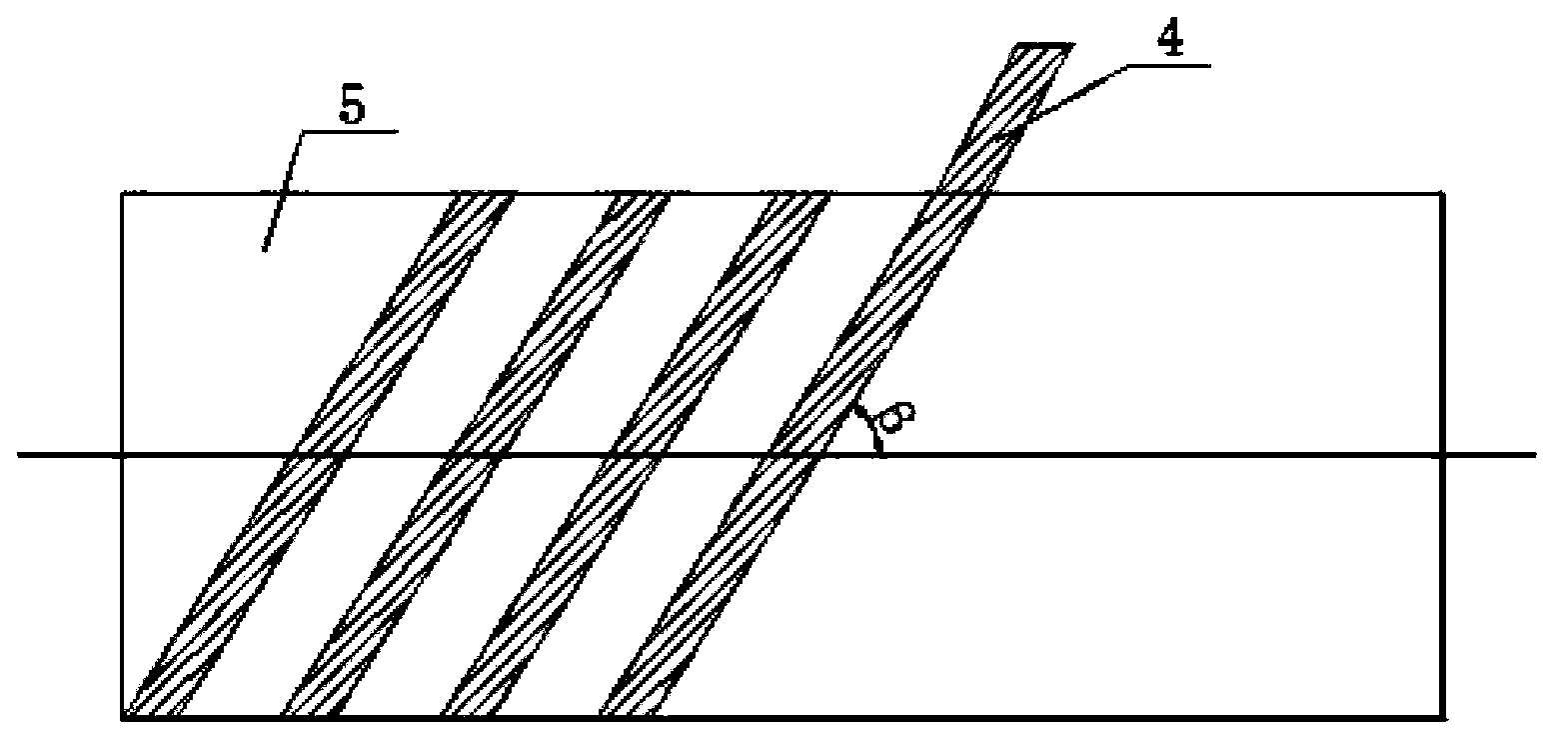

[0031] Such as figure 1 As shown, the composite wound thermoplastic fiberglass pipe consists of an inner layer 1, an intermediate layer 2 and an outer layer 3. The bandwidth of the continuous glass fiber reinforced thermoplastic resin prepreg tape 4 is 41mm, the continuous glass fiber reinforced thermoplastic resin prepreg tape 4 is continuous glass fiber reinforced thermoplastic polypropylene, the glass fiber content is 55%, the thickness of the prepreg tape is 0.2mm, and the winding The diameter of mandrel mold 5 is 150mm. Wrap the inner layer 1 first, such as figure 2 As shown, the circumferential winding angle α is 85°, the prepreg tape is melted after being heated at 140°C, bonded to the surface of the winding mandrel 5, wound to the right end of the winding mandrel 5, and then wound to the left, the winding angle is different change, laying layers in sequence to form an inner layer 1 with a thickness of 2 mm. Next wind the middle layer 2, such as image 3 As shown, ...

Embodiment 2

[0032] Such as figure 1 As shown, the composite wound thermoplastic fiberglass pipe consists of an inner layer 1, an intermediate layer 2 and an outer layer 3. The continuous glass fiber reinforced thermoplastic resin prepreg tape 4 has a bandwidth of 40 mm, the continuous glass fiber reinforced thermoplastic resin prepreg tape 4 is continuous glass fiber reinforced thermoplastic polypropylene, the glass fiber content is 75%, and the thickness of the prepreg tape is 0.1 mm. The diameter of mandrel mold 5 is 50mm. Wrap the inner layer 1 first, such as figure 2 As shown, the circumferential winding angle α is 75°, the prepreg tape is melted after being heated at 130°C, bonded to the surface of the winding mandrel 5, wound to the right end of the winding mandrel 5, and then wound to the left, the winding angle is different Lay layers sequentially to form an inner layer 1 with a thickness of 0.1 mm. Next wind the middle layer 2, such as image 3 As shown, the helical winding ...

Embodiment 3

[0034] Such as figure 1 As shown, the composite wound thermoplastic fiberglass pipe consists of an inner layer 1, an intermediate layer 2 and an outer layer 3. The bandwidth of the continuous glass fiber reinforced thermoplastic resin prepreg tape 4 is 22mm, the continuous glass fiber reinforced thermoplastic resin prepreg tape 4 is continuous glass fiber reinforced thermoplastic polypropylene, the glass fiber content is 60%, the thickness of the prepreg tape is 0.25mm, and the winding The diameter of mandrel mold 5 is 200mm. Wrap the inner layer 1 first, such as figure 2 As shown, the circumferential winding angle α is 88°, the prepreg tape is melted after being heated at 150°C, bonded to the surface of the winding mandrel 5, wound to the right end of the winding mandrel 5, and then wound to the left, the winding angle is different Lay layers in turn to form an inner layer 1 with a thickness of 5 mm. Next wind the middle layer 2, such as image 3As shown, the helical win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Inner diameter range | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com