Antibacterial water inlet pipe and processing technology thereof

A processing technology, water inlet pipe technology, applied in coating and other directions, can solve the problems of PPR water pipes not having antibacterial properties, affecting the service life of PPR water pipes, bacteria breeding and fouling, etc., to increase anti-aging ability, inhibit R water pipe damage, increase Antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

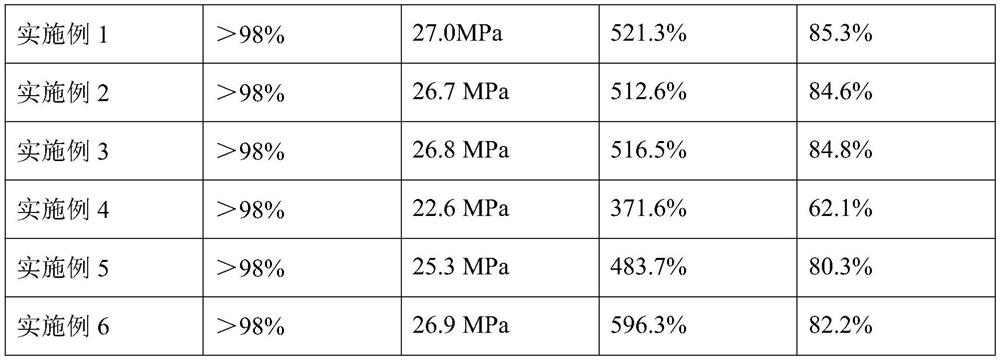

Embodiment 1

[0027] Step 1: Preparation of raw materials: (1) Ultrasonic dispersion of titanium dioxide nanoparticles in ethanol solution, adding vinyl silane coupling agent, acid to adjust pH=5.3, stirring evenly; set temperature at 70°C, react for 6 hours to obtain ethylene base titanium dioxide; disperse it in DMF, add 2,2'-azobis(2-amidinopropane) dihydrochloride and cysteamine hydrochloride in sequence, and set the temperature at 70°C to react for 24 hour, cool, add 1M sodium hydroxide solution, wash, filter and dry to obtain cysteamine / titanium dioxide; mix it with maleic anhydride-modified polypropylene at a mass ratio of 1:1, and reflux in toluene solution for 24 , obtain polypropylene / cysteamine / titanium dioxide. (2) Wash and dry the grape seed meal, grind and sieve; use ethanol with a concentration of 30%, at a solid-liquid ratio of 1:25, set the temperature at 40°C for ultrasonic extraction for 55 minutes, and the ultrasonic frequency is 45KHz; solid-liquid separation, Freeze-d...

Embodiment 2

[0032]Step 1: Preparation of raw materials: (1) Ultrasonic dispersion of titanium dioxide nanoparticles in ethanol solution, adding vinyl silane coupling agent, adjusting the pH to 5.2 with acid, stirring evenly; setting the temperature at 72°C, and reacting for 4 hours to obtain ethylene base titanium dioxide; disperse it in DMF, add 2,2'-azobis(2-amidinopropane) dihydrochloride and cysteamine hydrochloride in sequence, and set the temperature at 68°C to react for 20 hour, cooling, adding 1M sodium hydroxide solution, washing, filtering and drying to obtain cysteamine / titanium dioxide; mix it with maleic anhydride-modified polypropylene at a mass ratio of 1:1, and reflux in toluene solution for 20 hours to obtain polypropylene / cysteamine / titanium dioxide. (2) Wash and dry the grape seed meal, grind and sieve; use ethanol with a concentration of 30%, at a solid-liquid ratio of 1:22, set the temperature at 42°C for ultrasonic extraction for 50-60 minutes, and the ultrasonic fre...

Embodiment 3

[0037] Step 1: Preparation of raw materials: (1) Ultrasonic dispersion of titanium dioxide nanoparticles in ethanol solution, adding vinyl silane coupling agent, acid to adjust pH = 5.6, stirring evenly; set the temperature at 78 ° C, react for 8 hours to obtain ethylene base titanium dioxide; disperse it in DMF, add 2,2'-azobis(2-amidinopropane) dihydrochloride and cysteamine hydrochloride in sequence, and set the temperature at 75°C to react for 24 hour, cool, add 1M sodium hydroxide solution, wash, filter and dry to obtain cysteamine / titanium dioxide; mix it with maleic anhydride-modified polypropylene at a mass ratio of 1:1, and reflux in toluene solution for 24 hours to obtain polypropylene / cysteamine / titanium dioxide. (2) Wash and dry the grape seed meal, grind and sieve; use ethanol with a concentration of 30%, at a solid-to-liquid ratio of 1:25, set a temperature of 45°C for ultrasonic extraction for 60 minutes, and an ultrasonic frequency of 45KHz; solid-liquid separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com