Synchronizer gear ring inner ring machining composite clamp

A synchronizer gear ring and fixture technology, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the workpiece cannot be guaranteed to meet the coaxiality, the dimensions between processes cannot be effectively connected, and the order scheduling is difficult to track, etc. problems, to achieve the effect of canceling intermediate work-in-process inventory, facilitating processing, and preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples.

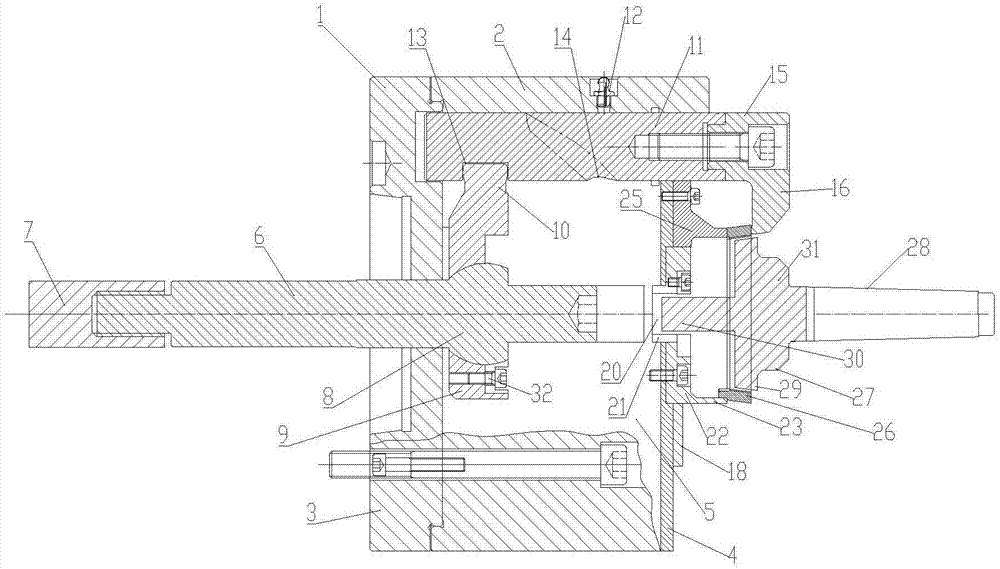

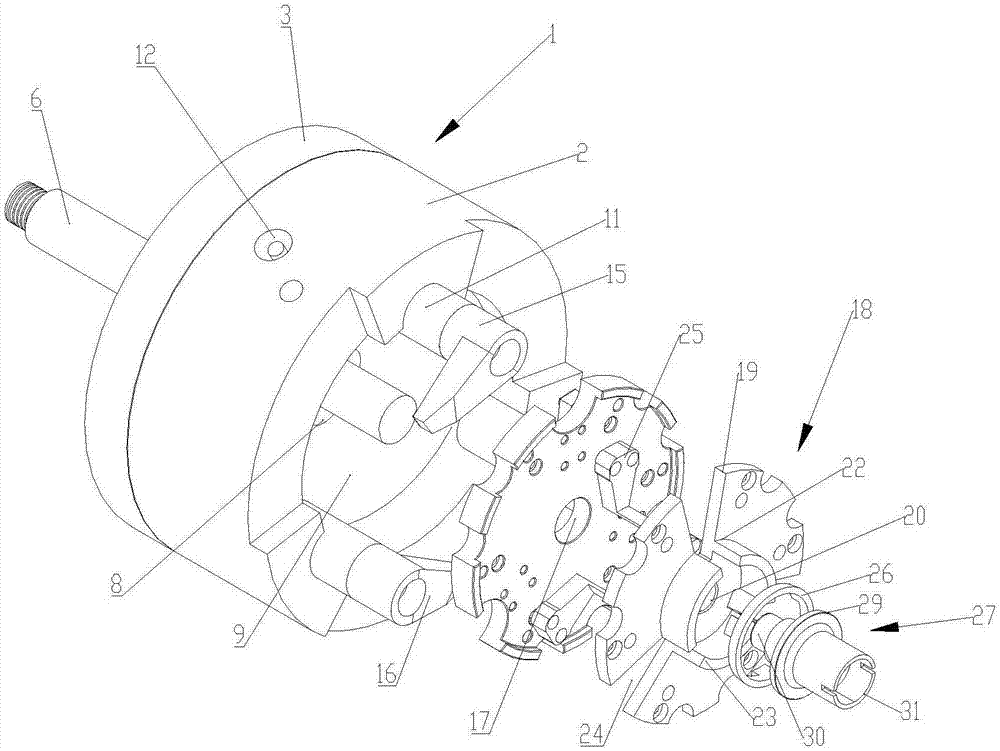

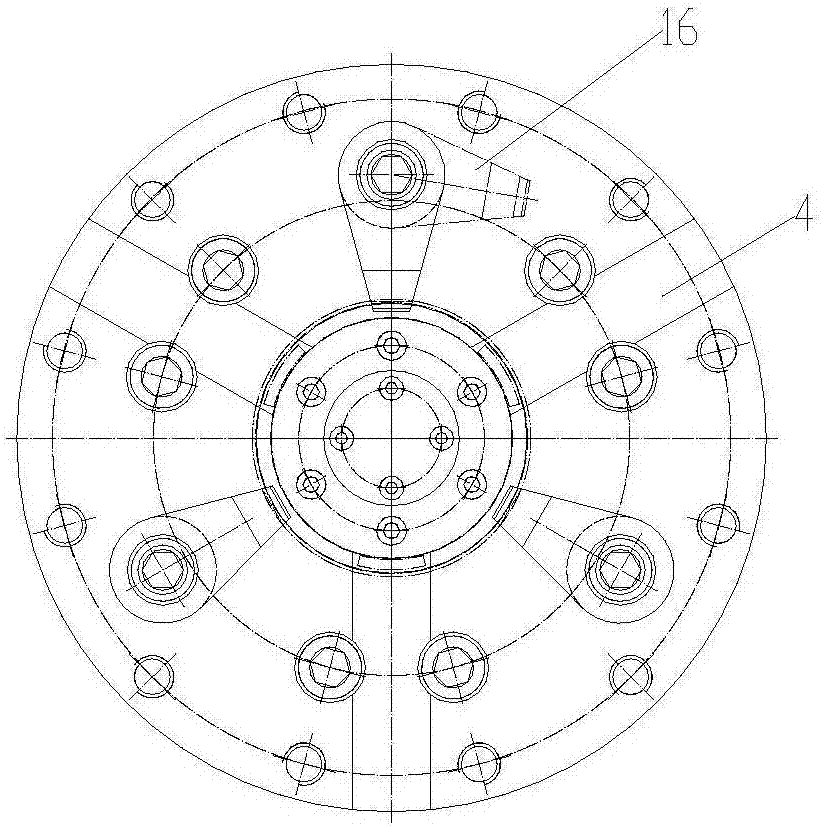

[0038] Such as Figure 1-Figure 7As shown, a compound fixture for processing the inner ring of the synchronizer gear ring includes a hollow chuck 1, and the hollow chuck 1 includes a chuck side wall 2, a chassis 3, and a connecting plate 4; the chassis 3 and the connecting plate 4 are respectively located on the side of the chuck The two ends of the cavity 5 formed around the wall 2; the outer surface of the chassis 3 is fixed to the machine tool, and the center part of the chassis 3 is horizontally penetrated with a chuck tie rod 6, and one end of the chuck tie rod 6 is connected to one end of the main shaft tie rod 7 through a nut, and the main shaft tie rod 7 is located outside the cavity 5, and the other end is connected with the machine tool; the middle part of the chuck rod 6 is connected with a floating ball post 8, which is a cylinder formed by the middle part of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com