Flexible robotic arm and system assembly

A technology for flexible manipulators and arms, applied in the field of flexible manipulators, can solve the problems of shape deformation, affecting the accuracy of linkage of the arm, and changes in the positive pressure between the arm joint rod and the center block, and achieves a reduction in the number of types and linkage accuracy. High and easy to industrialize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

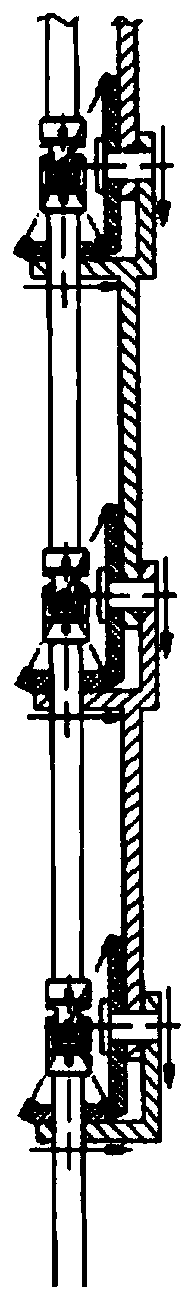

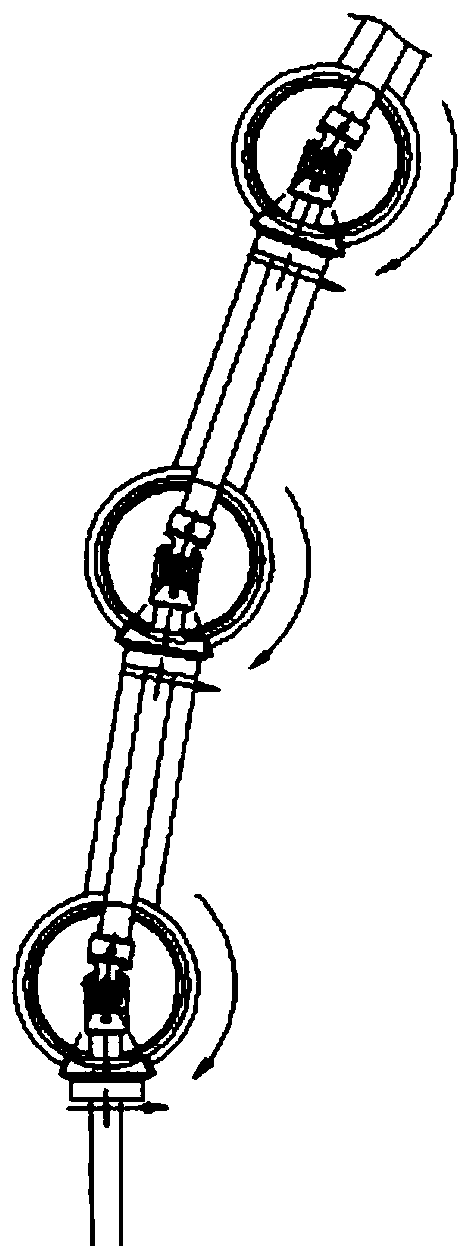

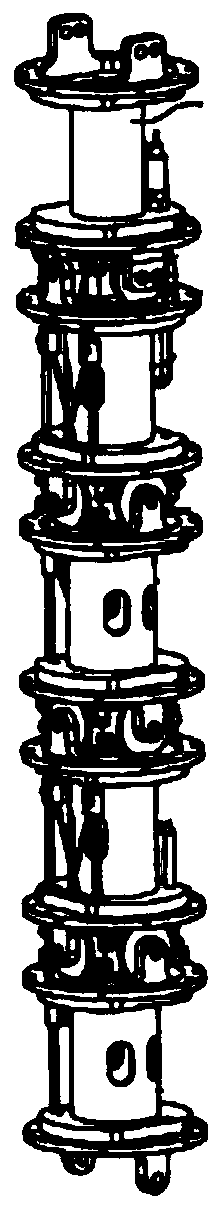

[0039] The flexible arm in the following embodiments of the present invention mainly includes multi-section arm joint sections and corresponding linkage ropes, and also includes a central block. The arm joint sections are connected with the central block through a rotating connection mechanism to form a unit of the arm main body. units form the main body of the boom. The main body of the boom, linkage rope and its linkage are introduced respectively below.

[0040] 1. The main body of the boom

[0041] Such as Figure 4a , 4b As shown, after the two side lugs of the arm joint section 11 are connected to the central block 21, the pin shafts 312, 314 are respectively pressed in from the ears on both sides of the arm joint section to realize the relative rotation between the joint section and the central block. Wherein pin shaft is made up of two sections, and one section is that cylindrical surface and central block form rotary hinge. The other section is a "D-shaped" struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com