Heat dissipation housing assembly for electric motor and manufacturing method

A manufacturing method and casing technology, which are applied in the directions of electric components, electrical components, and motor generators, etc., can solve the problems of difficulty in meeting the requirements of explosion-proof electric motors, inability to meet the strength requirements of electric motors, and unsatisfactory economic benefits, so as to speed up the production response. The effect of speed, reduction of inventory types, and shortening of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

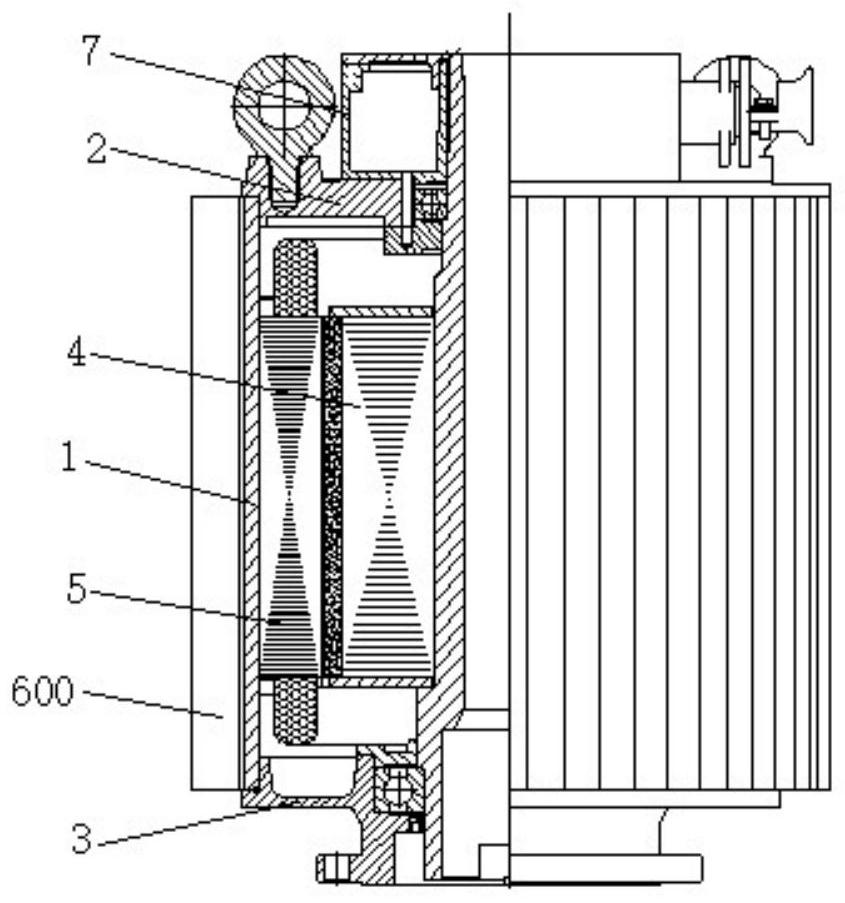

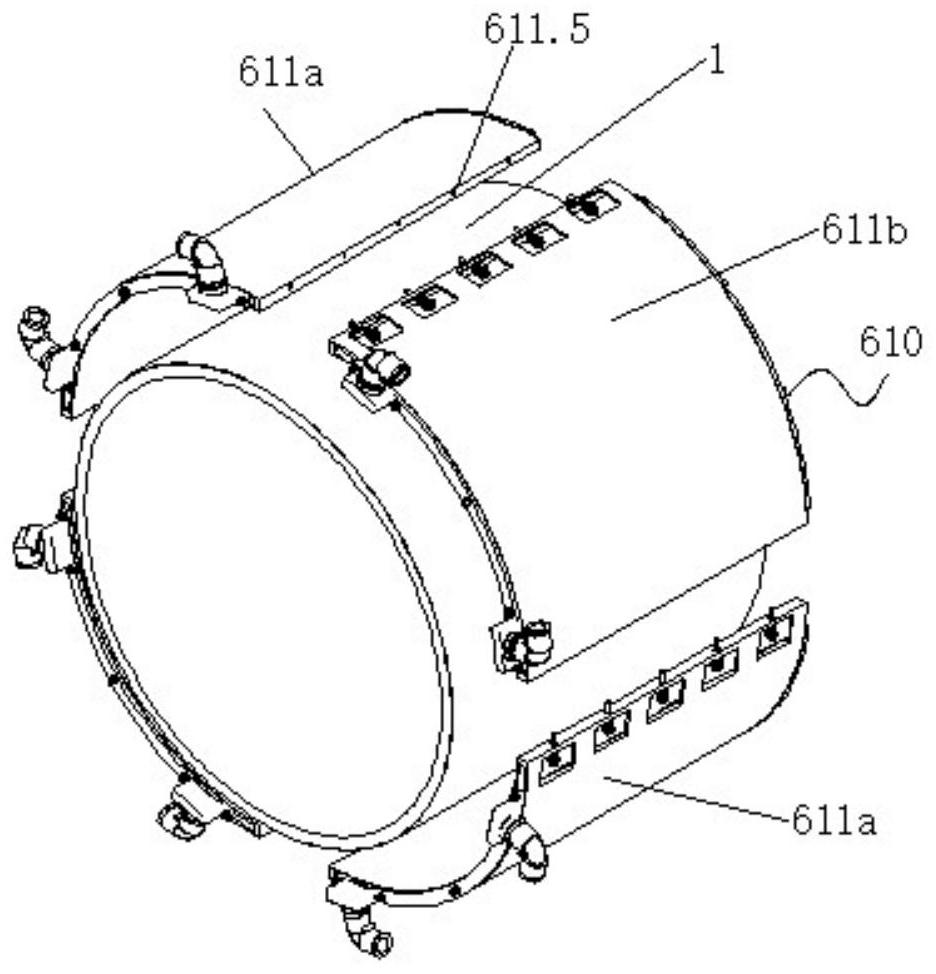

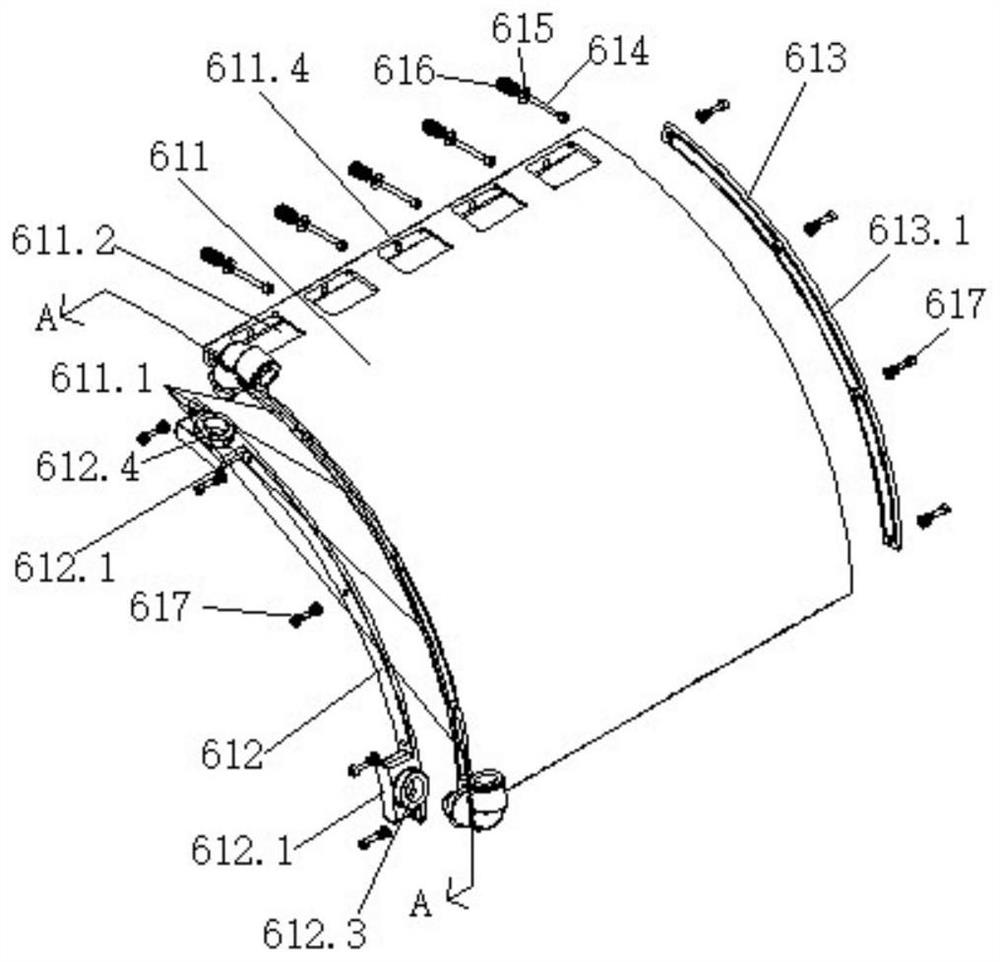

[0060] This embodiment provides a method for manufacturing a heat dissipation casing assembly for a motor. The heat dissipation module adopts a liquid cooling heat dissipation module 610 (such as Figure 2-Figure 3 shown).

[0061] such as 1 and figure 2 As shown, the housing 1 used for the motor in this embodiment is a housing with a cavity for housing the internal components of the motor, which is cut from a hollow elongated steel pipe section. In the actual production process, according to actual needs, a section of pipe body can be cut from a long steel pipe to be used as the housing 1 of the motor. Through such an operation, the problem of making multiple molds when producing motors of different lengths can be avoided, thereby reducing the production cost of making molds.

[0062] And as figure 2 As shown, the radiator 600 of this embodiment is ring-shaped and arranged on the outer surface of the housing 1. The radiator 600 is formed by splicing two or more arc-shape...

Embodiment 2

[0092] This embodiment provides a method for manufacturing a heat dissipation casing assembly for a motor. The difference from Embodiment 1 is that the radiator of this embodiment is an air-cooled radiator.

[0093] like Image 6 As shown, the heat sink 600 of this embodiment is formed by splicing a plurality of air-cooled heat dissipation modules 620 with fins in pairs, and when spliced, adjacent heat dissipation modules are connected by an elastic connection structure. When multiple motor housings 1 with different diameters need to be matched, the diameter of the annular body surrounded by the radiator can be adjusted by increasing or decreasing the number of heat dissipation modules 620 in the radiator.

[0094] like Image 6 As shown, the air-cooled heat dissipation module 620 includes an arc-shaped arc-shaped plate 621 extruded from aluminum, radially outwardly protruding cooling fins 622 arranged on the outer wall of the arc-shaped plate 621, and arranged on the arc-sha...

Embodiment 3

[0102] This embodiment provides a heat dissipation casing assembly for a motor, such as figure 2 , Image 6 As shown, the cooling case assembly of the present embodiment includes:

[0103] It has a housing 1 for housing the cavity of the internal components of the motor;

[0104] A plurality of arc-shaped heat dissipation modules arranged on the outer periphery of the casing, the plurality of heat dissipation modules can be assembled to form a radiator that surrounds the exterior of the casing and can dissipate heat from the casing;

[0105] An elastic connection structure for connecting two adjacent heat dissipation modules among the plurality of arc-shaped heat dissipation modules, so that the heat sink can automatically adapt to the thermal expansion and contraction of the motor housing.

[0106] Wherein, the housing 1 can be formed by cutting the strip-shaped steel pipes described in the above embodiments, or can be made by other methods, such as casting.

[0107] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com