Auxiliary Tooling for Cylindrical Roller Bearing Inspection

A technology of cylindrical roller bearings and auxiliary tooling, which is applied in the direction of mechanical bearing testing, measuring devices, and testing of mechanical components, and can solve the problems of high processing costs and low adaptability of supporting tooling, so as to reduce processing costs and types The effect of quantity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

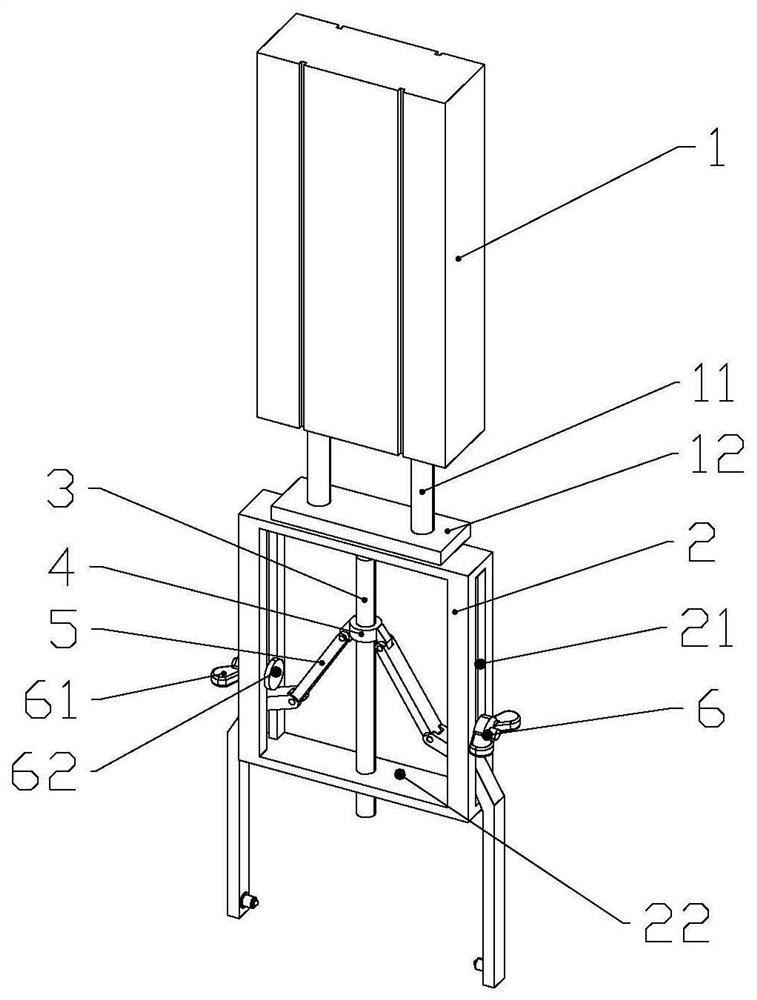

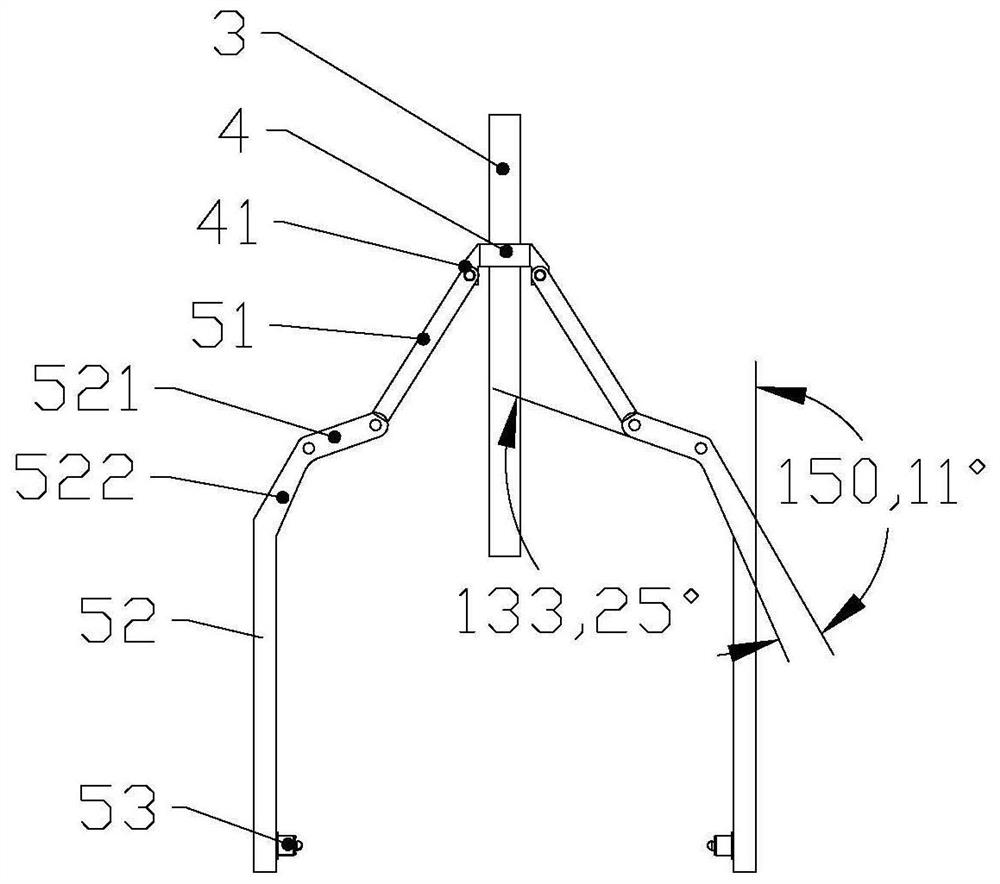

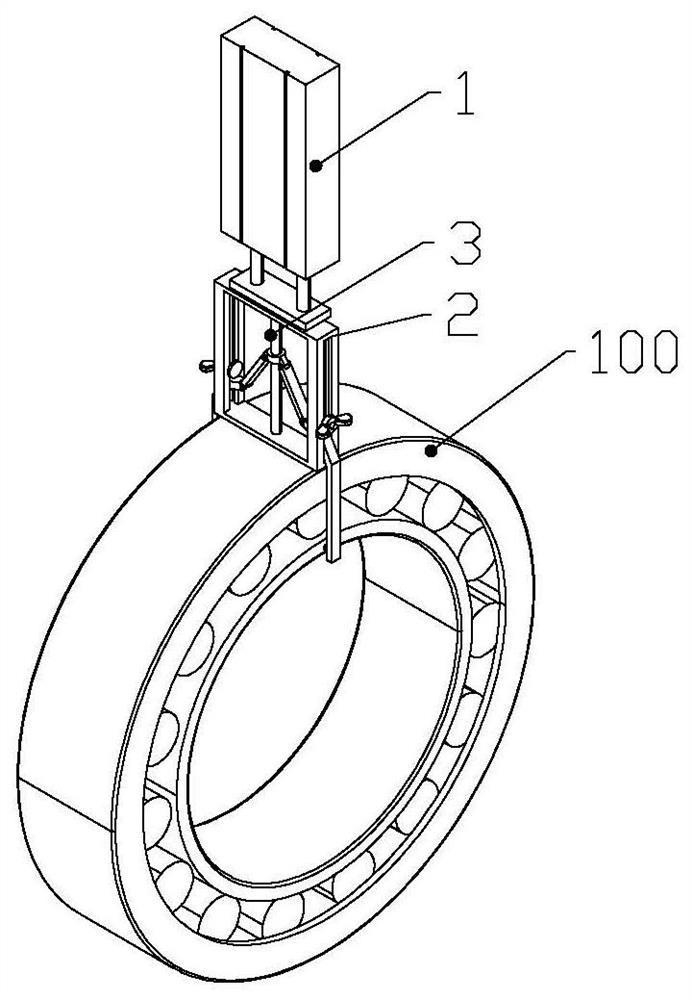

[0030] Embodiment 1 This embodiment provides a cylindrical roller bearing detection auxiliary tool, including a loading mechanism, a main frame body 2, a threaded rod 3 and a swing clamping assembly 5, wherein the swing clamping assembly 5 includes a pair of symmetrical connections and threads The connecting rod 51 and the fixed claw 52 on the rod 3. Such as figure 1 As shown, in the present embodiment, the loading mechanism adopts the cylinder 1, and the cylinder 1 is provided with an air chamber and a piston that displaces following the volume change of the air chamber, and at least two parallel piston rods 11 are connected to the piston. In this embodiment, , There are two piston rods 11. One end of the piston rod 11 is fixedly connected to the piston, and the other end of the piston rod 11 is connected to a top plate 12 , and is detachably and fixedly connected to the top of the main frame body 2 through the top plate 12 . to combine Figure 5 As shown, the main frame b...

Embodiment 2

[0035] Embodiment 2 The difference between this embodiment and Embodiment 1 is that: the bending rod is an arc-shaped bending structure, and the arc angle corresponding to the arc-shaped bending structure is 133-136°. Compared with the double-short straight rod structure in Embodiment 1, the structure of this embodiment may be easier to process, and there are relatively few swing bumps during the swinging process of the fixed claw 52, but its controllability is lower than that in Embodiment 1. double straight rod structure.

Embodiment 3

[0036] Embodiment 3 The difference between this embodiment and Embodiment 1 is that in this embodiment, the straight rod includes a rod one and a rod two, wherein the rod one and the rod two are detachably and fixedly connected, such as threaded connection, clamping or socket. One end of the first rod is hinged with the connecting rod 51, and the other end is fixedly connected with the second rod, and the other end of the second rod is used as the bottom end of the straight rod, on which the fixed head 532 described in the first embodiment is arranged.

[0037] In summary, the present invention provides a simple structure and strong versatility to limit the axial displacement of the bearing inner ring 101 of the cylindrical roller bearing without inner ring rib by clamping on both sides, effectively avoiding the The situation that the bearing inner ring 101 disengages occurs. Through the control of the loading mechanism, the running stability of the bearing inner ring 101 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com