Fabrication method of seamless rear projection spherical screen and device thereof

A production method and a production device technology, which are applied in projection devices, optics, instruments, etc., can solve problems that affect the projection effect, high requirements for technology and equipment, and affect the appearance of products, so as to achieve automatic stress relief, product quality assurance, good projection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

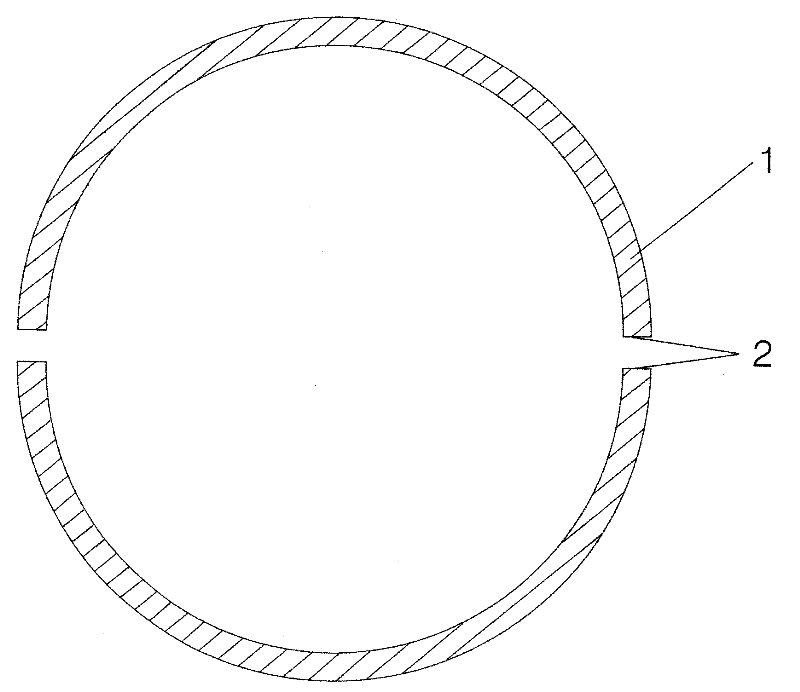

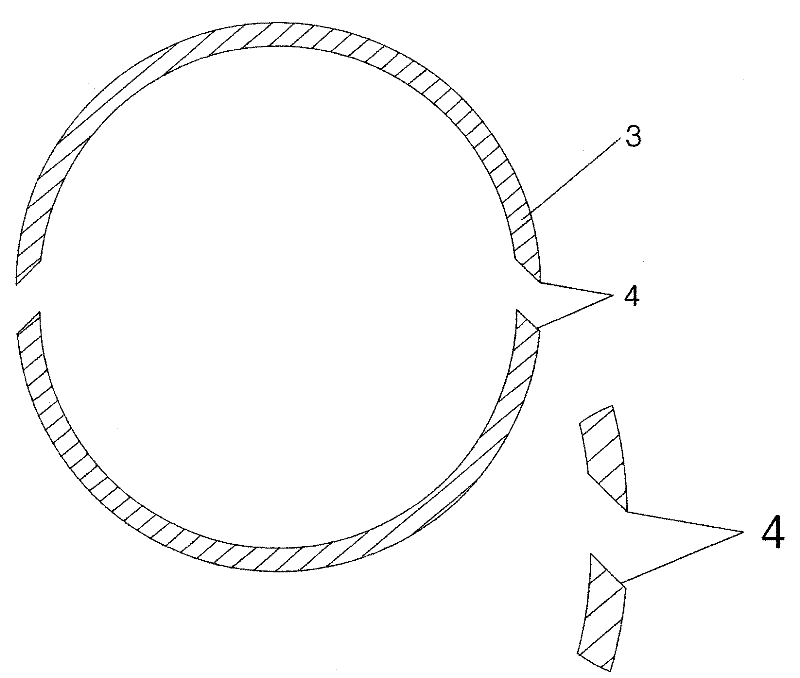

[0035] Embodiment 1, epoxy resin seamless rear projection ball screen

[0036] a, Prepare reactive two-component transparent resin system A, choose transparent epoxy resin system, 5931A / B from Wuxi Resin Factory.

[0037] b, preparation of optical projection layer reaction system B

[0038] In the formula of A, add the following ratio of optical functional components

[0039] Transparent epoxy resin system A 100 parts

[0040] Polysiloxane pellets (particle size 50-400nm) 0.5 parts

[0041] Carbon-free black pigment (particle size 5-100 nanometers) 0.1 parts

[0042] Titanium dioxide (particle size 5-50 nanometers) 0.1 parts

[0043] c, making a spherical mold with a smooth inner surface

[0044] Two hemispheres with a diameter of 1 meter are made of metal, and they are docked at the equator. There are fixed screws that can be opened and closed at the butt joints. The inner surface of the sphere is smooth, and there is no unevenness at the joint of the two halves.

[004...

Embodiment 2

[0049] Example 2, polyurethane seamless rear projection ball screen - light black

[0050] a, Prepare reactive two-component transparent resin system A, choose transparent polyurethane resin system, Guangzhou Ruisheng Chemical RS-3012A / B transparent polyurethane.

[0051] b, preparation of optical projection layer reaction system B

[0052] In the formula of A, add the following ratio of optical functional components

[0053] Transparent polyurethane system A 100 parts

[0054] Polysiloxane pellets (particle size 50-400nm) 2 parts

[0055] Carbon-free black pigment (particle size 5-100 nanometers) 1 part

[0056] Titanium dioxide (particle size 5-50 nanometers) 0.2 part

[0057] c, d together with embodiment

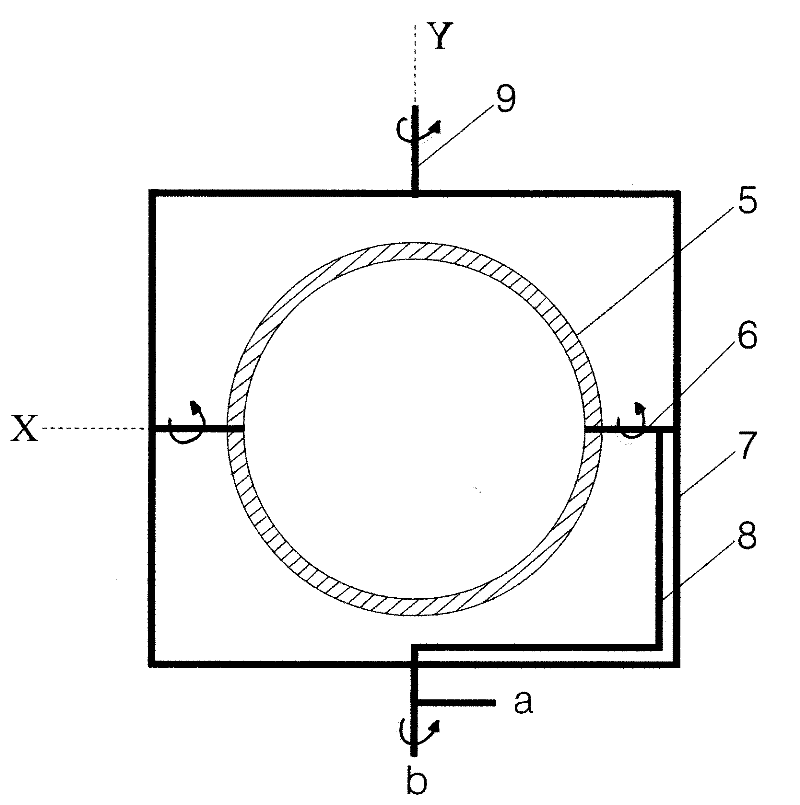

[0058] e. The mold is fixed on a biaxial rotary molding machine, inject 19Kg of material A, and carry out biaxial rotation, so that the liquid resin is centrifugally diluted on the inner wall, uniformly, and undergoes a chemical reaction, and the mold is heated to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com