Preparation method of high-strength graphene expandable polystyrene board

A technology of expandable polystyrene and polystyrene particles, which is applied in the field of packaging materials, can solve the problems of high viscosity, easy to form kettle, dispersion difference, and high cost, and achieves expansion of application fields, stable polymerization process, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of high-strength graphene expandable polystyrene plate is characterized in that, comprises the following steps:

[0030] A, Graphene, sodium alkylsulfate, sodium alkylsulfonate and styrene are mixed homogeneously to prepare modified graphene pre-dispersion liquid, wherein graphene, sodium alkylsulfonate and sodium alkylsulfate and styrene The weight percentage is 0.1~1wt%, 0.05~0.1% and 0.01~0.1%;

[0031] B, preparation of oil-based mixed solution: the modified graphene pre-dispersion obtained in step A is moved into a stirring tank added with an oil-based dispersant and stirred evenly to obtain an oil-based mixed solution, the weight percentage of the oil-based dispersant and styrene is 0.1%;

[0032] C, preparation of graphene polystyrene particles by suspension polymerization:

[0033] C1. Add deionized water and dispersant to the reaction kettle and stir for 15-45 minutes, then slowly add the oil-based mixture obtained in step B to th...

Embodiment 1

[0047] A kind of preparation method of high-strength graphene expandable polystyrene plate is characterized in that, comprises the following steps:

[0048] A, 0.5kg graphene, 0.025kg alkyl sodium sulphate, 0.005kg alkyl sulfonate and 500kg styrene are mixed homogeneously, make modified graphene predispersion;

[0049] B, preparation of oil-based mixed solution: move the modified graphene pre-dispersion obtained in step A into a stirring tank added with polyvinyl alcohol and stir to obtain an oil-based mixed solution;

[0050] C, preparation of graphene polystyrene particles by suspension polymerization:

[0051] C1. Add 1500kg of deionized water and 0.5kg of active calcium carbonate into the reaction kettle and stir for 15-45 minutes, then slowly add the oil-based mixture obtained in step B into the reaction kettle, and check the dispersion of the mixture until it can be dissolved in water. Disperse into small oil droplets, then start to heat up, add 0.5kgPE800, 1.5kg bis(4-...

Embodiment 2

[0057] A kind of preparation method of high-strength graphene expandable polystyrene plate is characterized in that, comprises the following steps:

[0058] A, 2.5kg graphene, 0.035kg alkyl sodium sulphate, 0.015kg alkyl sulfonate and 500kg styrene are mixed homogeneously, make modified graphene predispersion;

[0059] B, preparation of oil-based mixed solution: move the modified graphene pre-dispersion obtained in step A into a stirring tank added with polyvinyl alcohol and stir to obtain an oil-based mixed solution;

[0060] C, preparation of graphene polystyrene particles by suspension polymerization:

[0061] C1. Add 1000kg of deionized water, 1.2kg of calcium phosphate and 0.01kg of sodium dodecylbenzenesulfonate into the reaction kettle and stir for 15-45min, then slowly add the oil-based mixture obtained in step B into the reaction kettle, Check the dispersion of the mixed liquid until it can be dispersed into small oil droplets in water, then start to heat up, and add...

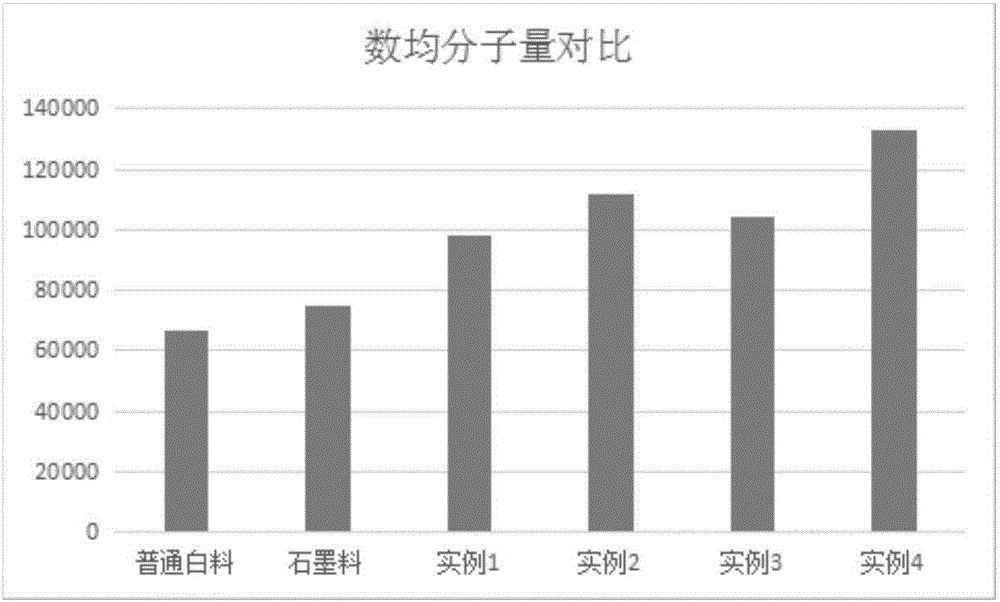

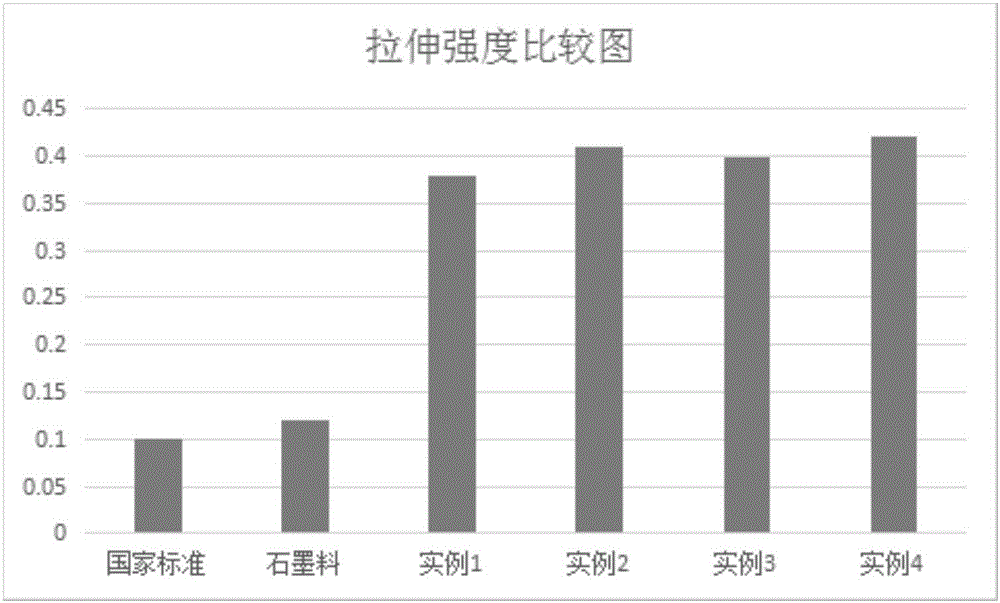

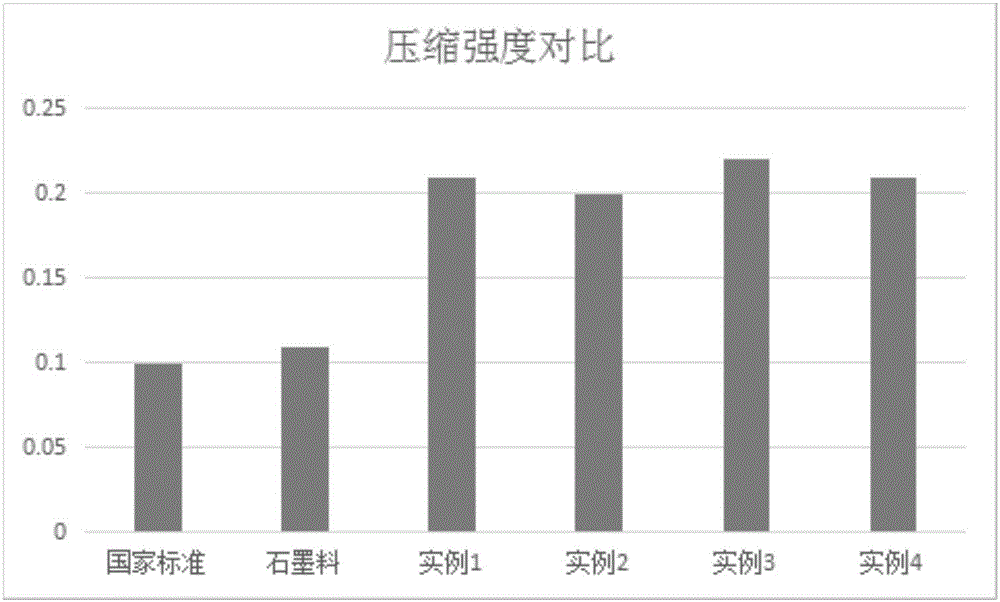

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com