Construction method for eliminating concrete shrinkage cracks of steel plate and concrete combined shear wall by preheating steel plate

A technology of combining shear walls and shrinkage cracks, which can be used in construction, building construction, and building materials processing. It can solve problems such as concrete cracking, and achieve the effects of easy operation, improved heating efficiency and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

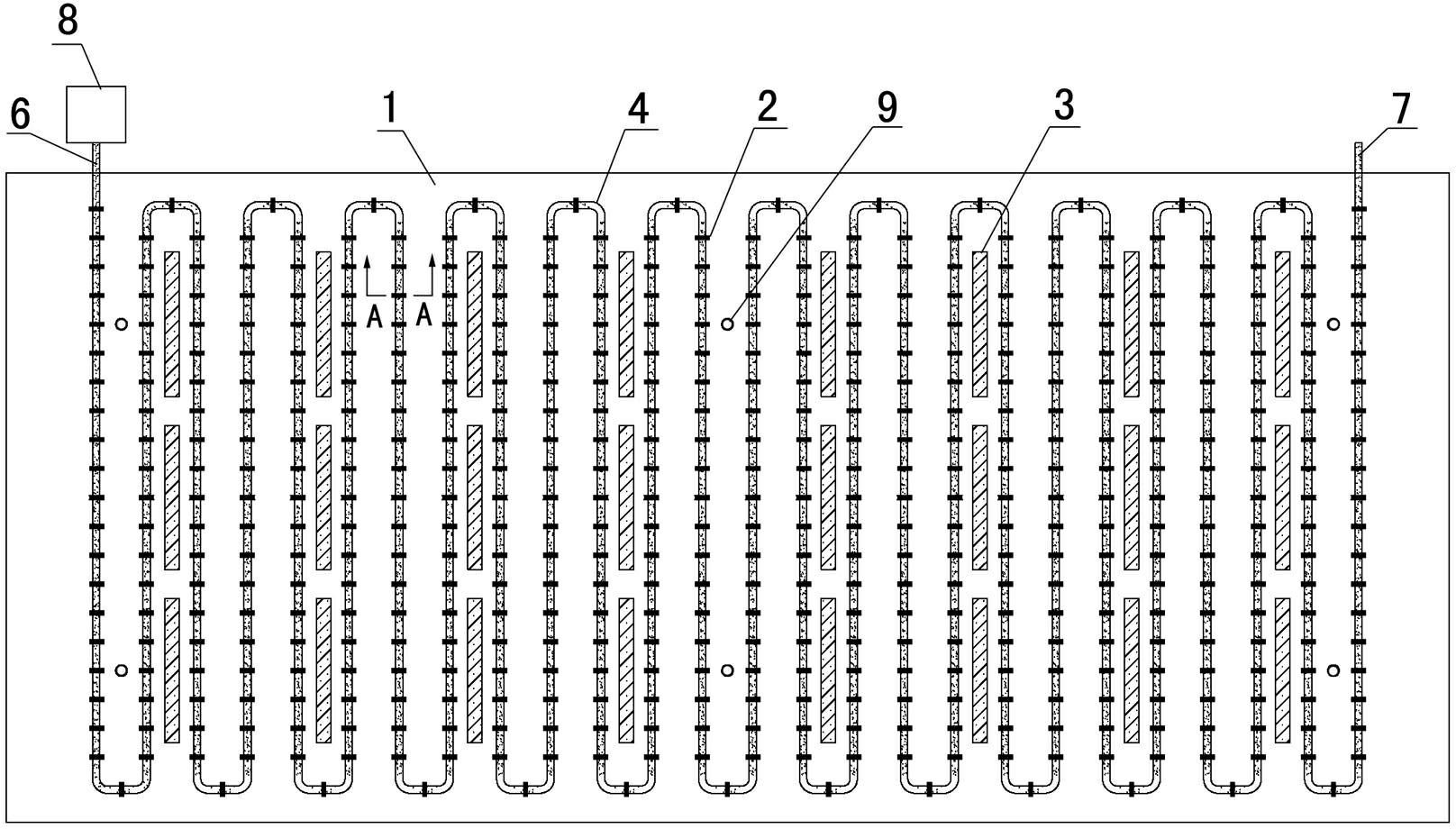

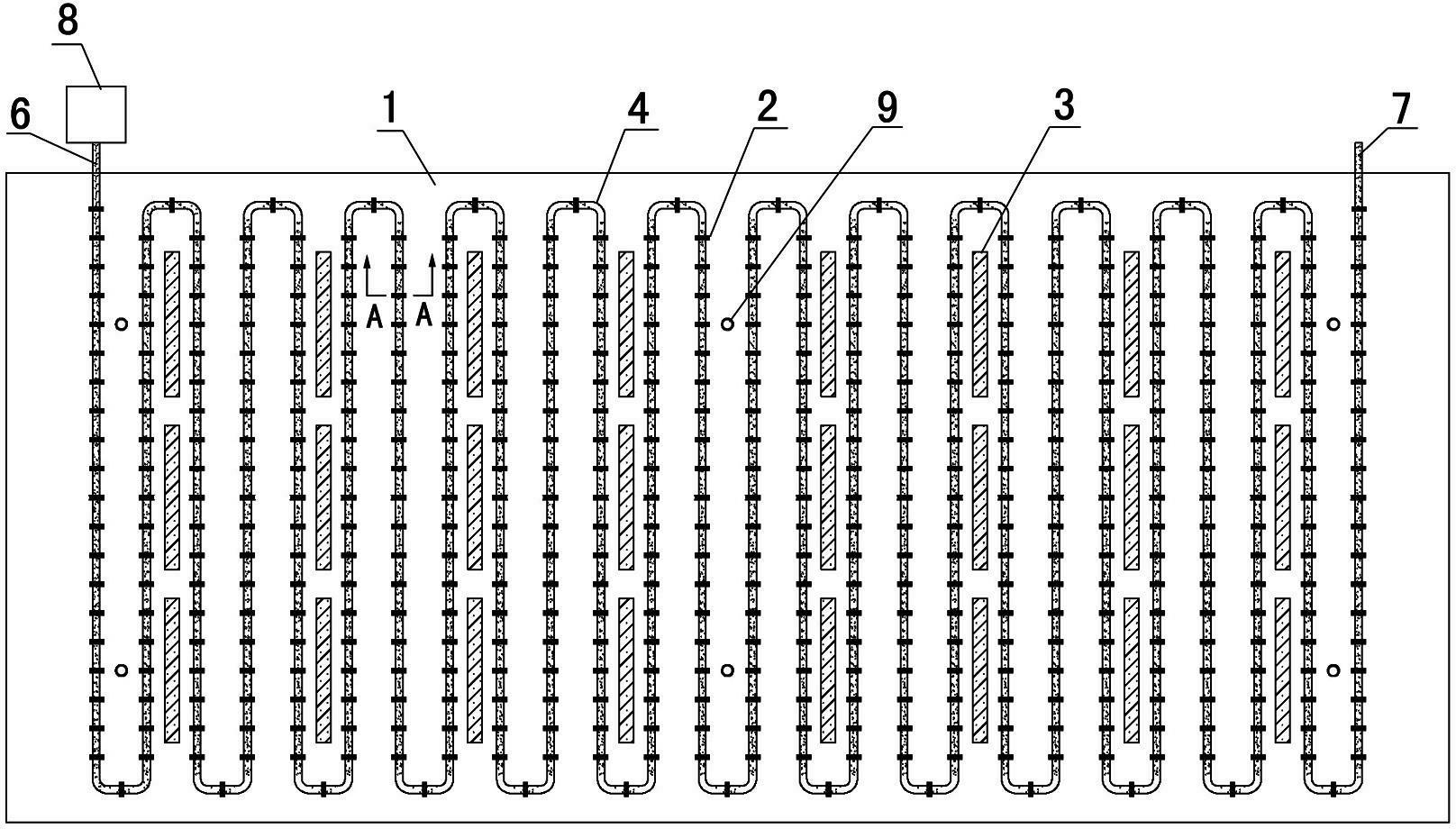

[0018] Examples see figure 1 , figure 2 As shown, this steel plate-concrete composite shear wall preheats the steel plate to eliminate the concrete shrinkage crack construction method, and its construction steps are as follows.

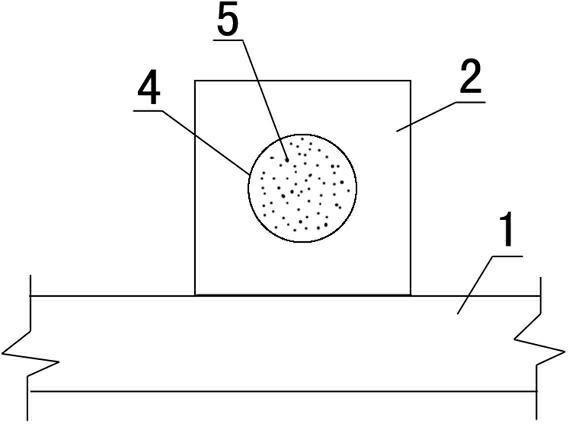

[0019] Step 1. Before the construction of the steel plate-concrete composite shear wall of the building, the thermal conduction coil 4 is laid on the shear wall steel plate 1, and the heat conduction coil 4 is provided with an inlet end 6 and an outlet end 7; The pipe diameter and distribution distance of the heat conduction coil 4 are determined based on conditions such as the cross-sectional area of the steel plate-concrete composite shear wall, the thickness of the shear wall steel plate 1, and the strength grade of the concrete in the steel plate-concrete composite shear wall. .

[0020] Step 2. After the on-site installation of the shear wall steel plate 1 is completed, first use the heat transfer medium injection system 8 to inject the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com