Preparation method of low-temperature and high-rate graphite anode material for power battery

A technology of graphite negative electrode and power battery, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low temperature lithium intercalation of graphite, low rate charging and discharging of power batteries, etc., and achieves small expansion, simple preparation method, and good cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

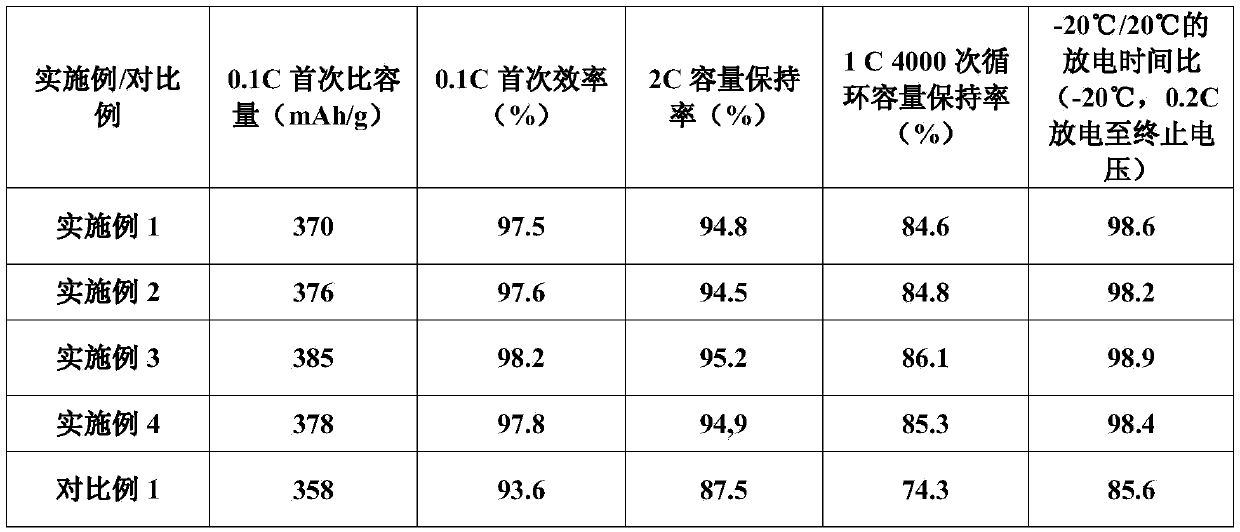

Embodiment 1

[0026] A method for preparing a low-temperature high-rate power battery graphite negative electrode material, comprising the following steps:

[0027] (1) Shaping and crushing

[0028] Add natural flake graphite into the pulverizer to carry out agitation ball mill, and use wet agitation mill for shaping; the wet agitation mill shaping process conditions include: using spherical zirconia with a diameter of 1-3mm as the grinding medium, using ammonium polyacrylate As a grinding aid, add natural flake graphite, grinding medium, grinding aid, and solvent into the ball mill together. The mass fraction of solvent in the whole system is 70%. %, spheroidal ink machine frequency: 30HZ, spheroidal ink time: 8h, the particle size of the prepared graphite is D50=2um. The natural flake graphite is spherical graphite with purity C≥99.5%, particle size D50=15um, and the solvent is distilled water and ethanol.

[0029] (2) intercalation micro-expansion

[0030] After mixing the graphite po...

Embodiment 2

[0037] A method for preparing a low-temperature high-rate power battery graphite negative electrode material, comprising the following steps:

[0038] (1) Shaping and crushing

[0039] Add natural flake graphite into the pulverizer to carry out agitation ball mill, and use wet agitation mill for shaping; the wet agitation mill shaping process conditions include: using spherical zirconia with a diameter of 1-3mm as the grinding medium, using ammonium polyacrylate Or sodium hexametaphosphate as a grinding aid, adding natural flake graphite, grinding media, grinding aids, and solvents into the ball mill together, the solvent mass fraction in the entire system is 90%, and the amount of grinding media and grinding aids is graphite mass 10 times, 0.1%, nodular ink machine frequency: 50HZ, nodular ink time: 4h, the particle size of the prepared graphite is D50=10um. The natural flake graphite is spherical graphite with a purity C≥99.5%, and a particle size D50=20um; the solvent is a...

Embodiment 3

[0048] A method for preparing a low-temperature high-rate power battery graphite negative electrode material, comprising the following steps:

[0049] (1) Shaping and crushing

[0050] Add natural flake graphite into the pulverizer to carry out agitation ball mill, and use wet agitation mill for shaping; the wet agitation mill shaping process conditions include: using spherical zirconia with a diameter of 1-3mm as the grinding medium, using ammonium polyacrylate Or sodium hexametaphosphate as a grinding aid, adding natural flake graphite, grinding media, grinding aids, and solvents into the ball mill together, the solvent mass fraction in the entire system is 80%, and the amount of grinding media and grinding aids is graphite mass 8 times, 0.3%, nodular ink machine frequency: 40HZ, nodular ink time: 6h, the particle size of the prepared graphite is D50=6um. The natural flake graphite is spherical graphite with purity C≥99.5%, particle size D50=18um, and the solvent is distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com