Method for expanding tobacco shred and equipment for the method

A technology for expanding shredded tobacco and equipment, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems affecting the quality and taste of expanded shredded tobacco, affecting the use of expanded shredded tobacco, and increasing the energy consumption of the heating system, so as to achieve increased toughness and reduced The effect of crushing and increasing the filament rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

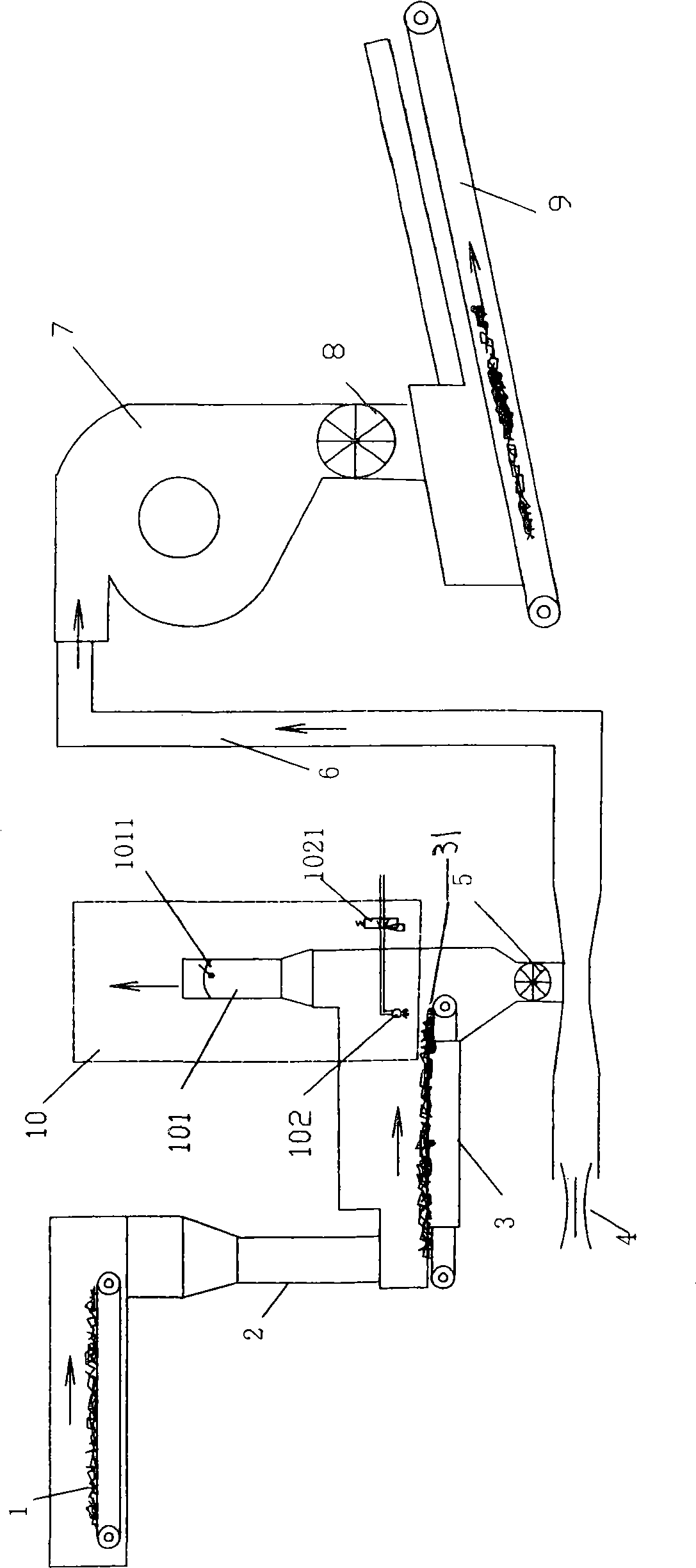

[0033] A method for expanding shredded tobacco, characterized in that it comprises the following steps:

[0034] ①Impregnation: Use CO2 liquid to impregnate shredded tobacco with a certain amount of moisture to form dry ice shredded tobacco 1;

[0035] ② Loosening: Loosen dry ice shredded tobacco 1 once to reduce lumps.

[0036] ③Storage: Buffer the material and keep it in the state of dry ice shredded tobacco.

[0037] ④Secondary loosening: Secondary loosening is performed on the cut dry ice tobacco 1 to further reduce lumps.

[0038] 5. Quantitative feeding, the dry ice shredded tobacco 1 impregnated through the expansion medium is sent into the blowing device 10 evenly by quantitative feeding equipment such as metering tube 2 and electronic scale or conveyor belt 3;

[0039] ⑥Pre-expansion and impurity removal and air extraction: the dry ice shredded tobacco 1 impregnated with the expansion medium enters the blowing device 10, and in this embodiment, the shredded tobacco ...

Embodiment 2

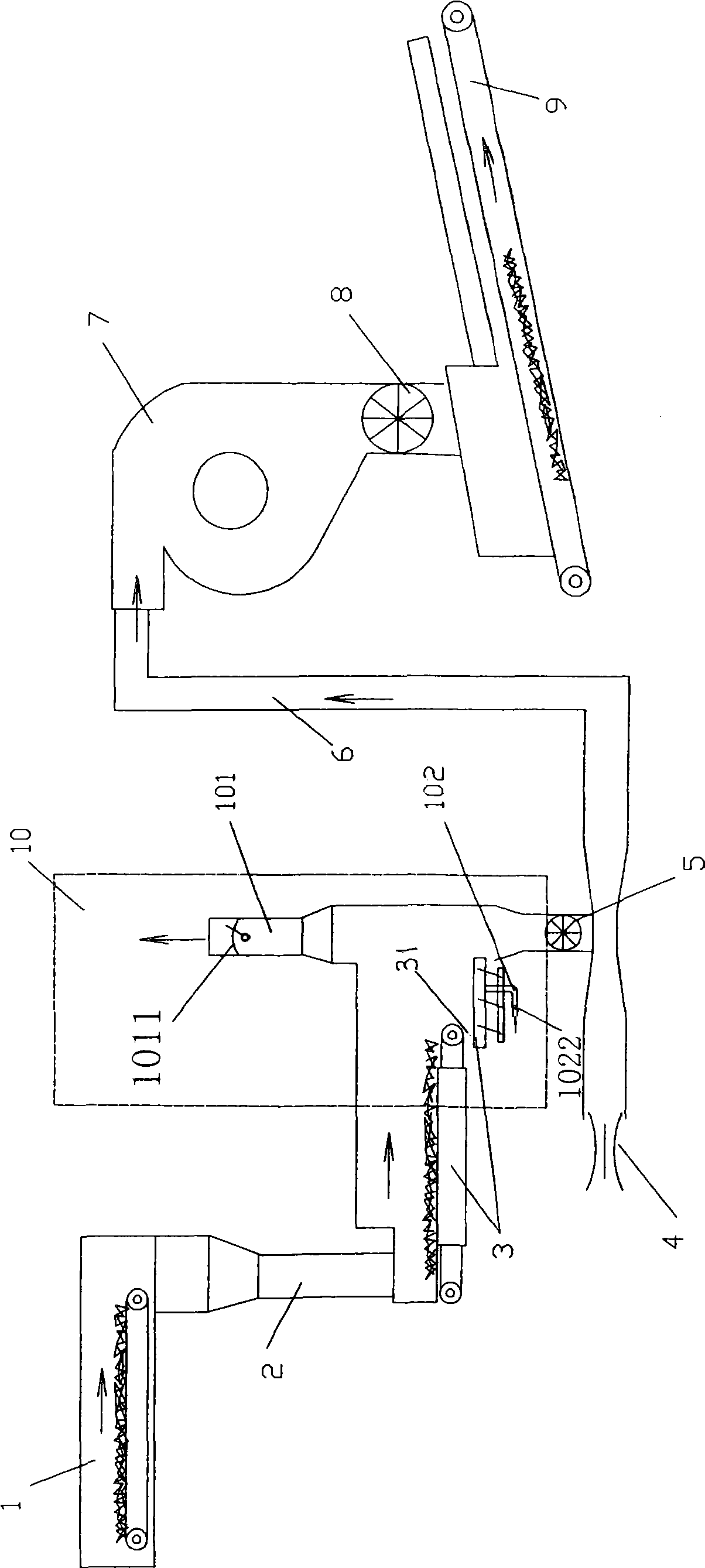

[0046] The differences between this embodiment and the first implementation are as follows:

[0047] 1. Steps of a method for expanding shredded tobacco 6. In pre-expansion and impurity removal and air extraction: the temperature of the airflow during blowing is normal temperature; the dry ice shredded tobacco 1 impregnated with the expansion medium is located above the blowing pipe 101 of the blowing device 10; the blowing pipe 101 When under the dry ice shredded tobacco 1, it is better to have a slightly suspended state of the dry ice shredded tobacco 1. In the present embodiment, the air velocity discharged from the blowing pipe is 10 m / s;

[0048]2. The blowing device 10 is installed at the lower part of the outlet 31 of the conveying device at the front end of the feed air lock 5 of the sublimator 6. In this embodiment, the blowing pipe 102 of the blowing device 10 is located below the outlet 31 of the conveyor belt 3 of the conveying device. The air blowing pipe 102 is p...

Embodiment 3

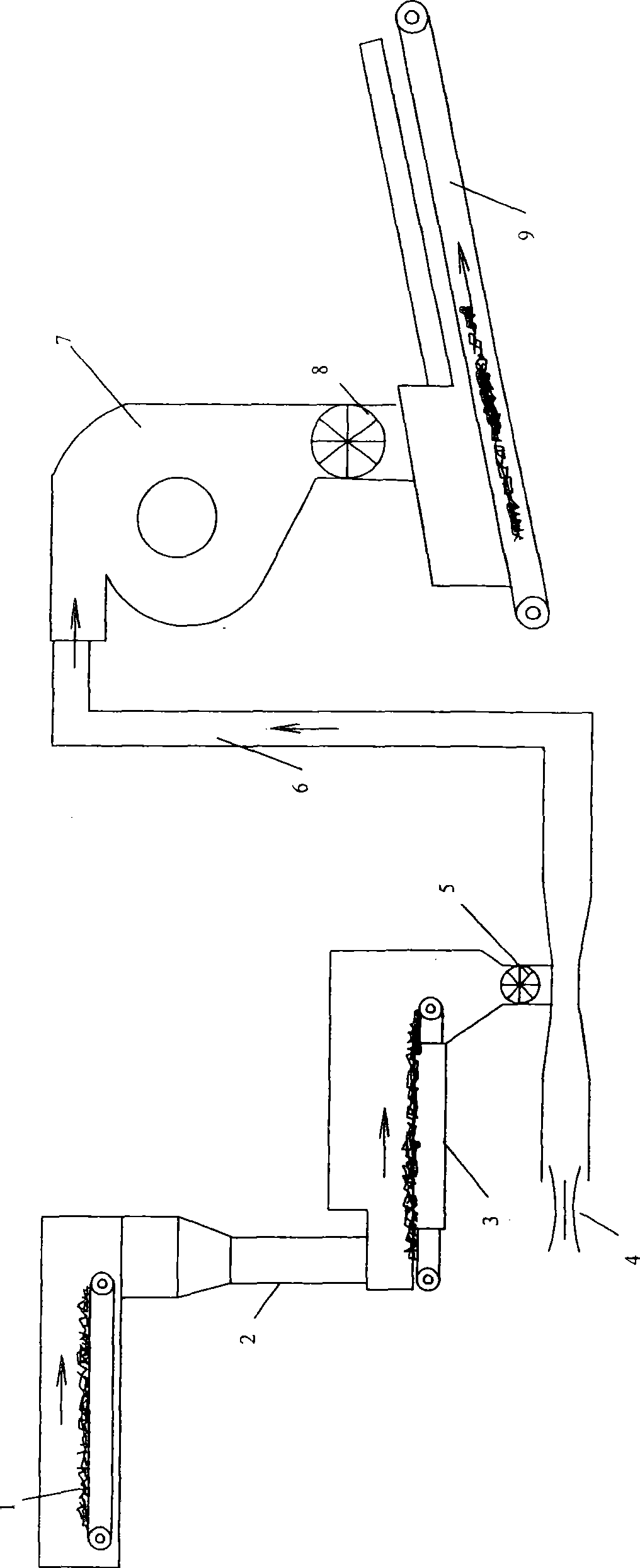

[0051] The differences between this embodiment and the first implementation are as follows:

[0052] 1. Steps of a method for expanding shredded tobacco ⑥ During pre-expansion and impurity removal and air extraction: the temperature of the airflow during blowing is 200°C; the airflow velocity discharged from the blowing pipe is 10 m / s;

[0053] 2. The airflow velocity discharged from the blowing pipe 102 on the blowing device 10 is 10 m / s.

[0054] The rest are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com