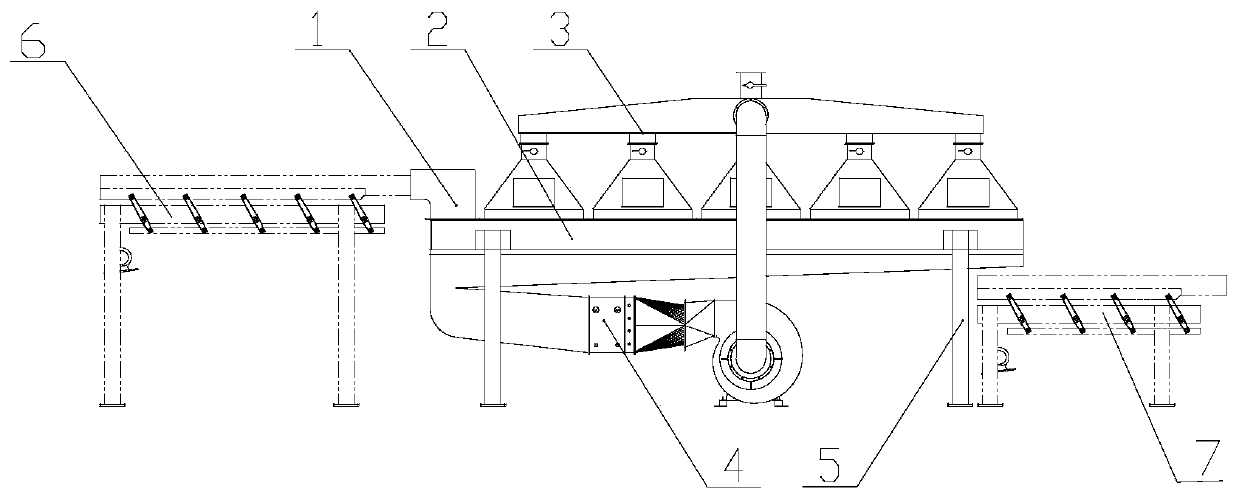

Tobacco heating and humidifying device

A heating, humidifying and equipment technology, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of affecting the inherent quality and taste of materials, unevenness of moisture regain of materials, affecting the process indicators of production lines, etc., and achieves reduction of processing strength and disassembly The effect of easy maintenance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

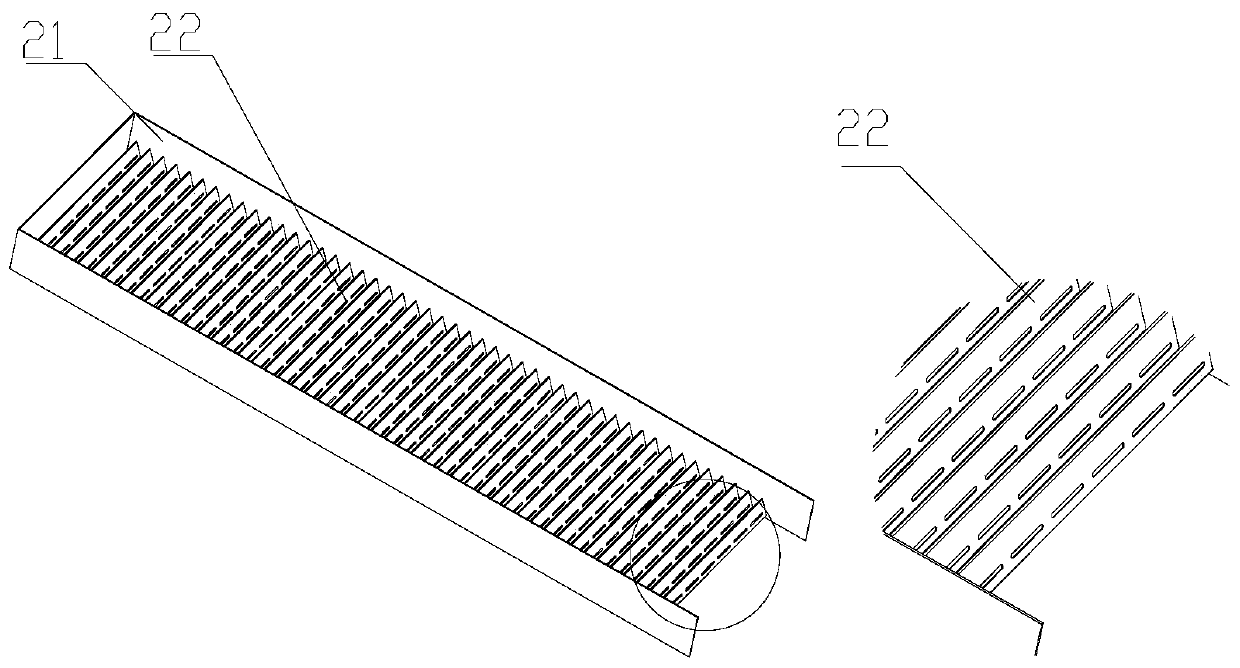

[0032] Such as figure 2 with Figure 5 As shown, the chute 2 in this embodiment includes a chute enclosure 21 and a trough bottom 22 , and the chute bottom 22 is uniformly provided with air outlets. Preferably, the bottom plate 22 of the trough is a louver type or a V-shaped plate type, and long holes or round holes are uniformly arranged on the slope of the material traveling direction, and the high-humidity hot air enters the chute 2 through the holes, and the material is blown by the circulating wind. Moving up and down toward the discharge end, the shredded tobacco is heated and humidified. During the progress of the material, the temperature and humidity gradually increase, and it is transported from the discharge port to the next equipment. The chute 2 can be adjusted to form an angle of -15° to +15° with the horizontal plane as required, so as to control the conveying speed of the material to ensure the heating and humidifying efficiency, and also avoid the problem o...

Embodiment 2

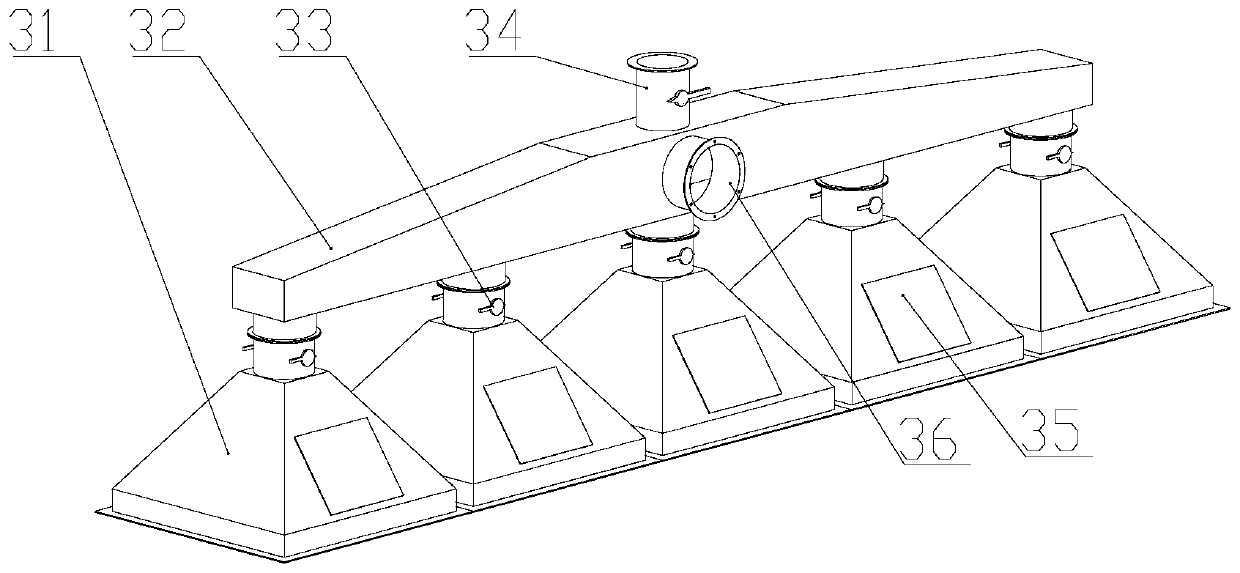

[0035] Such as image 3 As shown, the moisture removal system 3 described in this embodiment includes: a moisture collecting cover 31, a moisture collecting cavity pipe 32, a damper 33, a moisture discharging pipe 34, a maintenance window 35, and a circulating air outlet 36, which are integrally sealed and connected to the chute 2 In the upper part, the circulating air outlet 36 is the circulating air outlet of the hot air system 4. The hot and humid moisture enters the moisture collecting cavity tube 32 through the moisture collecting cover 31. When the moisture concentration is too high, the damper 33 is opened to discharge part of the moisture and enter the air at the same time, and new air Enter the hot air system again through the circulating air outlet.

[0036]Specifically, the moisture-collecting cover 31 is generally provided with n (n≥1), and there is no gap between the moisture-collecting cover 31, which can reduce the overall height of the system to ensure the nega...

Embodiment 3

[0038] Such as Figure 4 As shown, the hot air system 4 includes: a hot air pipe 41, a heat exchanger 42, a humidifier 43, a fan 44, a circulating air pipe 45, a hot air box 46, the circulating air pipe 45 is sealed and connected with the circulating air outlet 36, and the moisture removal system 3 Most of the collected moisture enters the fan 44 through the circulating air pipe 45 for recovery, and the humidity and temperature of the gas are increased through the humidifier 43 and the heat exchanger 42 to form high-temperature and high-humidity hot air and enter the hot air box 46 through the hot air pipe 41. Control it within the range of 20-150°C according to the needs, and the water vapor will act on the material from the gap on the chute 2. Since the air outlet of the trough bottom plate 22 faces the discharge end, the material is blown by high-temperature, high-humidity hot air in a state of ups and downs to the outlet. Move in one direction, and constantly change the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com