Hot air circulation system for I-phase drying air distribution of SCR (selective catalytic reduction) denitrated catalyst

A denitrification catalyst and circulation system technology, applied in the field of air purification equipment vent structure, can solve the problems of fast catalyst drying speed, slow drying speed, cracking of dried products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

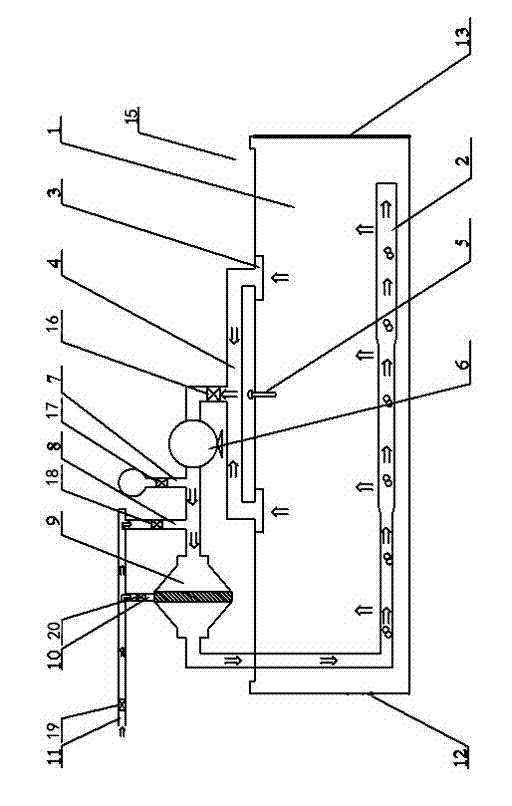

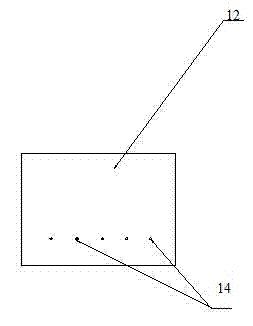

[0019] See figure 1 , figure 2 , which includes a drying chamber 15, a heat exchanger 9, and a circulating fan 6. The drying chamber includes two end walls, side walls, and a cavity 1 surrounded by both end walls and side walls. The hot air duct 2 is arranged in the cavity 1 One of the two end walls is an openable drying chamber door 13 , the other end has a through hole 14 under the end wall 12 , and the inside of the hole 14 communicates with the cavity 12 . The small holes 14 are specifically circular small holes; the small holes 14 are horizontally arranged in a single row; the hot air duct 2 is located below the cavity 1, and hot air outlets are evenly arranged on the hot air duct 2, and the upper ends of the cavity 1 Each is provided with return air outlet 3, and return air outlet 3 is connected with return air duct 4, and return air duct 4, heat exchanger 6, circulation blower 6 are positioned at the outside of drying chamber 15, and the outlet of return air duct 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com