Long wind pipe uniform wind sending and returning method and device thereof

A long wind and uniform technology, applied in the direction of pipeline layout, heating method, space heating and ventilation, etc., can solve the problem of affecting the working quality of the building environmental control system and air conditioning and ventilation system, high material input and processing costs of long air ducts, Unable to achieve uniform air supply and return air, etc., to achieve valuable market application prospects, scientific and reasonable device structure, and obvious advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

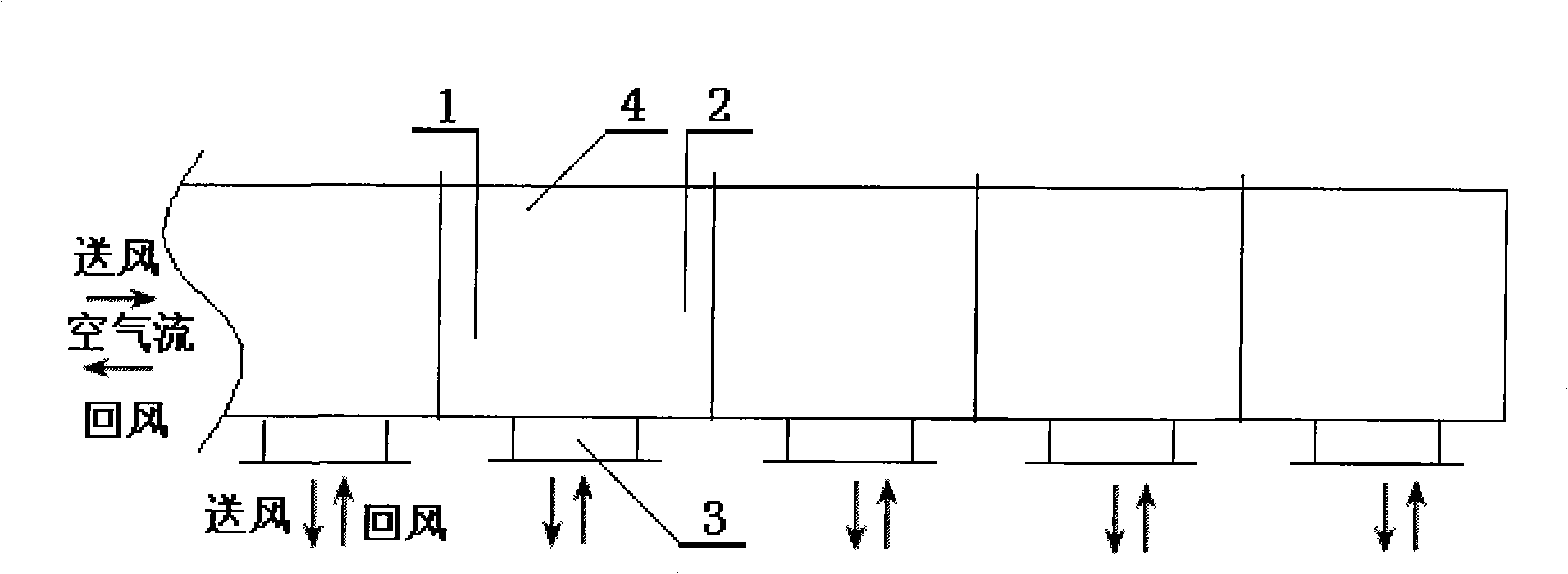

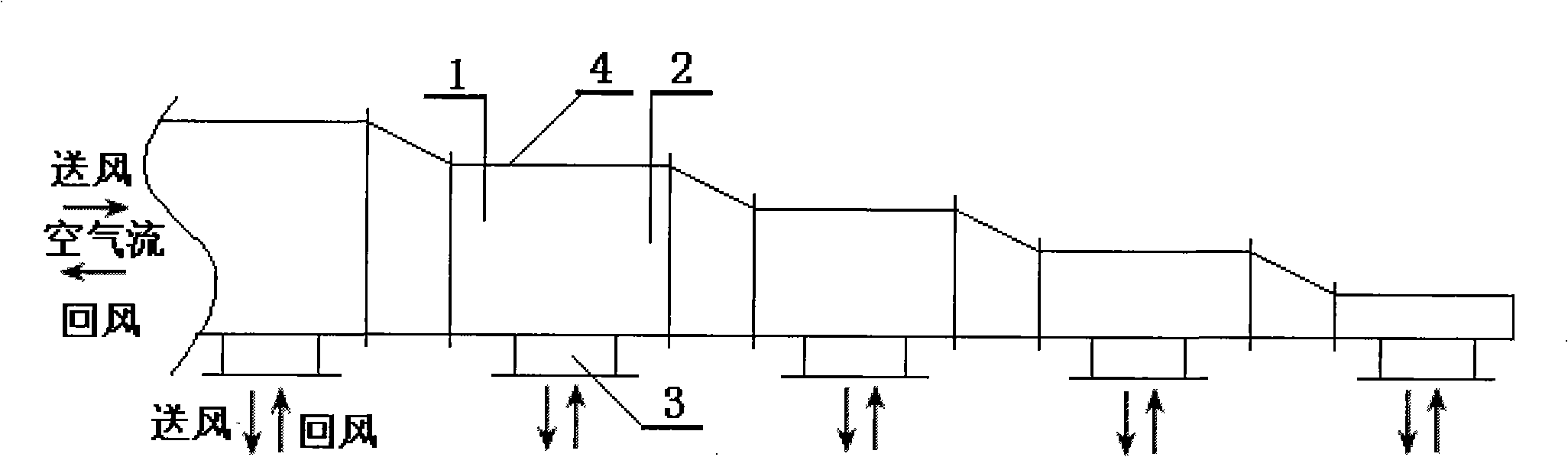

[0028] Embodiment 1 shunt adjustment type

[0029] exist Figure 5 with Image 6 In the present invention, the main body of the device for evenly sending and returning air through the long air duct is composed of a long air duct and a bypass branch pipe. The valve bodies of the three ventilation valves 4 are connected, and the valve bodies are composed of interconnected main air pipes 1 and straight-through branch pipe interfaces 2. The feature is that the three ventilation valves 4 are served by energy-saving air volume diversion three-way regulating valves 6, so The above-mentioned long air pipe is composed of a group of several valve body cross-sectional area sizes that are gradually reduced according to the ratio of the rated air flow volume of each stage. The main body of the regulating diversion type energy-saving air volume diversion three-way regulating valve 6 is composed of a main air pipe 1, a straight-through branch pipe interface 2 and a bypass branch pipe inter...

Embodiment 2

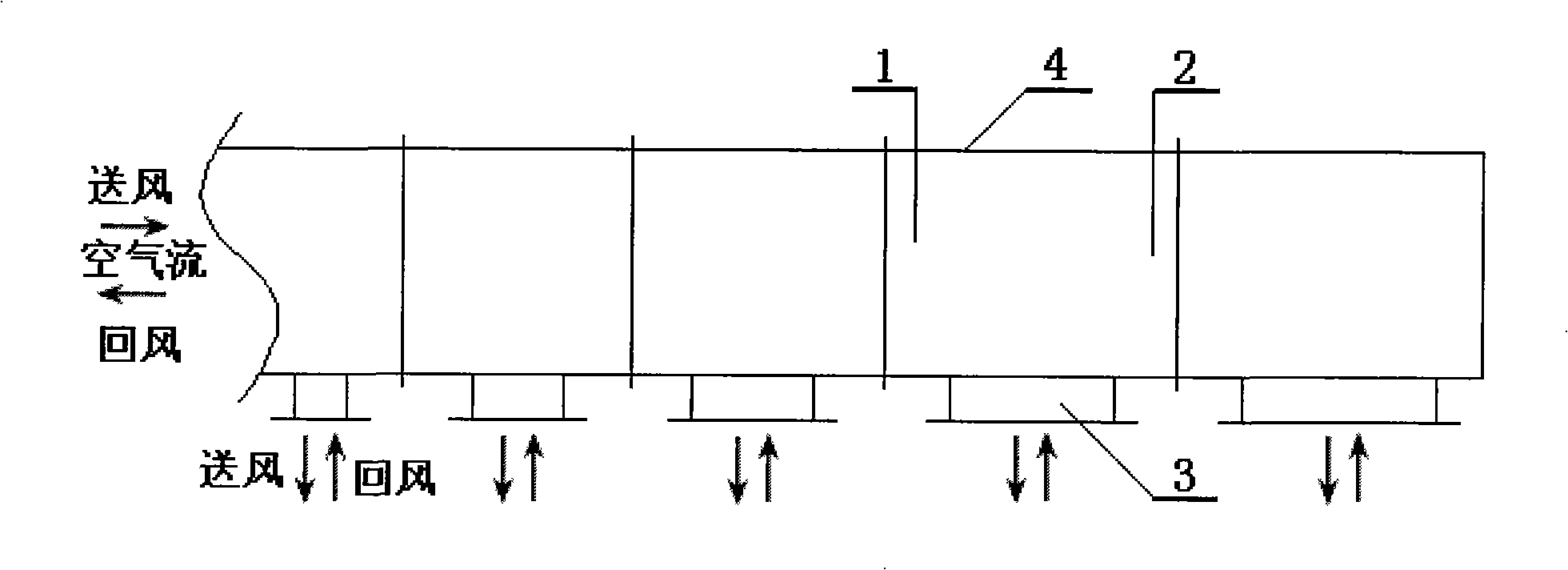

[0031] Embodiment 2 shunt rated type

[0032] exist Figure 7 with Figure 8 In the present invention, the main body of the device for evenly sending and returning air through the long air pipe is composed of the long air pipe and the bypass branch pipe connection 3, the long air pipe is formed by connecting the valve bodies of several three ventilation valves 4, and the valve bodies are interconnected The main air duct 1 and the straight branch pipe interface 2 are characterized in that the three ventilation valves 4 are served by rated split-type improved three-ventilation valves 23, and several rated split-type improved three-ventilated valves are set on the long air duct. The cross-sectional size of the valve body of the ventilation valve 23 is reduced step by step according to the ratio of the rated split air volume of each stage. On the inner surface of the main air duct 1 of the valve 4, one end is connected to the bypass branch pipe interface 3, the cross-sectional a...

Embodiment 3

[0034] Embodiment 3 Shunt Complementary

[0035] exist Figure 9 In the present invention, the main body of the device for evenly sending and returning air to the long air pipe is composed of the long air pipe and the bypass branch pipe interface 3, the long air pipe is composed of several valve bodies connected by three ventilation valves 4, and the valve body is composed of interconnected The main air pipe 1 and the straight branch pipe interface 2 are composed of the three-way ventilation valve 4, which is composed of a combination of an improved three-way ventilation valve 23 of an adjustable split type and a rated split type energy-saving air volume diversion three-way regulating valve 6, wherein: the said The rated split-type improved three-way ventilation valve 23 is set at several stages in the first half of the long air pipe, and the adjustable split-type energy-saving air volume split three-way regulating valve 6 is set at several stages in the second half of the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com