Energy-saving fresh air system for clean room

A technology of fresh air system and clean room, which is applied in the field of energy-saving fresh air system for clean room, can solve the problems of unreasonable design in the early stage, increase of capital consumption and high cost of clean room fresh air system operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

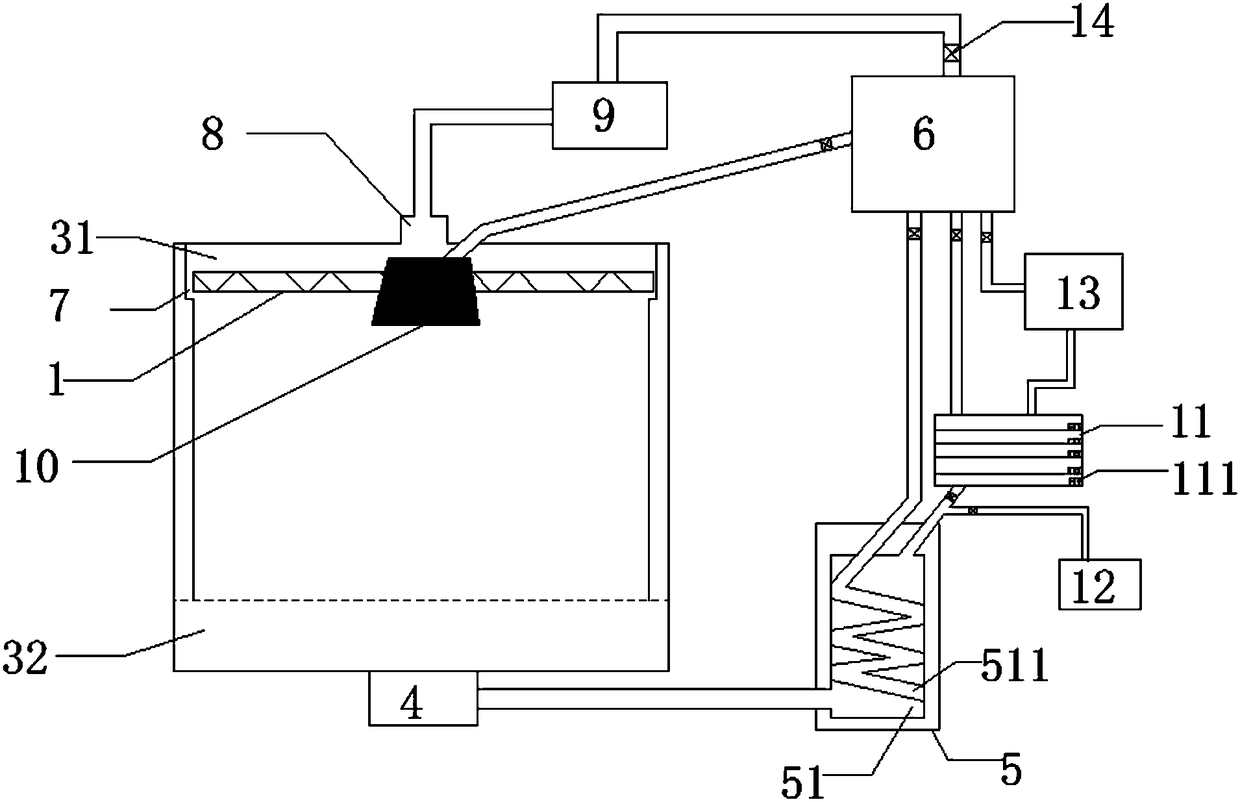

[0019] An energy-saving fresh air system for a clean room, comprising: a top plate 1 and an air-leakage bottom plate 2 are respectively installed under the top wall and above the bottom wall of the clean room; 2 and the bottom wall form the return air main passage 32, the side wall of the clean room around the top plate 1 is provided with a return air outlet 7 and the return air outlet 7 communicates with the return air secondary passage 31, and the center of the clean room bottom wall is connected to the return air main passage 32 connected return air unit 4 sucks the gas with high dust content at the bottom of the clean room through the air leakage bottom plate 2 into the return air main channel 32. The heat exchange channel 51 is provided with a spiral heat exchange tube 511, and the spiral heat exchange tube 511 accounts for 4 / 5 of the cross-sectional area of the heat exchange channel 51, and the inlet end of the heat exchange channel 51 is connected to the air outlet of ...

specific Embodiment 2

[0024] An energy-saving fresh air system for a clean room, comprising: a top plate 1 and an air-leakage bottom plate 2 are respectively installed under the top wall and above the bottom wall of the clean room; 2 and the bottom wall form the return air main passage 32, the side wall of the clean room around the top plate 1 is provided with a return air outlet 7 and the return air outlet 7 communicates with the return air secondary passage 31, and the center of the clean room bottom wall is connected to the return air main passage 32 connected return air unit 4 sucks the gas with high dust content at the bottom of the clean room through the air leakage bottom plate 2 into the return air main channel 32. The heat exchange channel 51 is provided with a spiral heat exchange tube 511, the spiral heat exchange tube 511 accounts for 2 / 3 of the cross-sectional area of the heat exchange channel 51, and the inlet end of the heat exchange channel 51 is connected to the air outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com