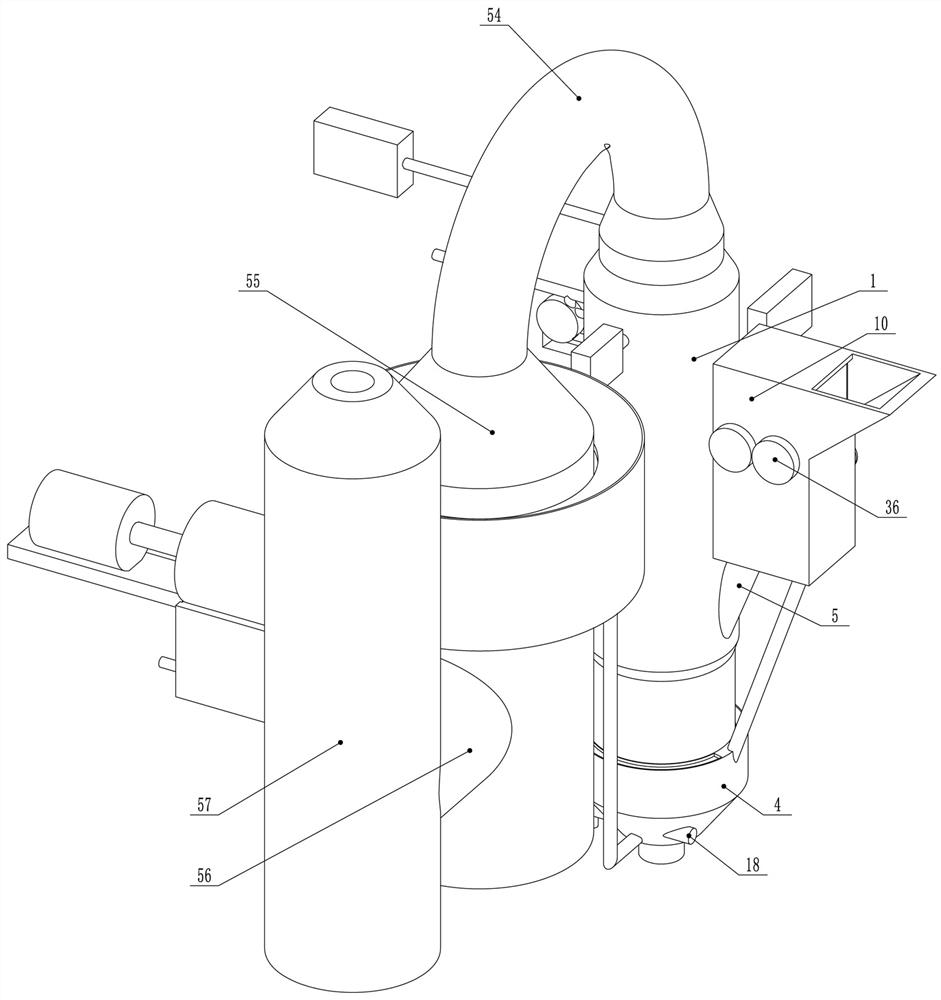

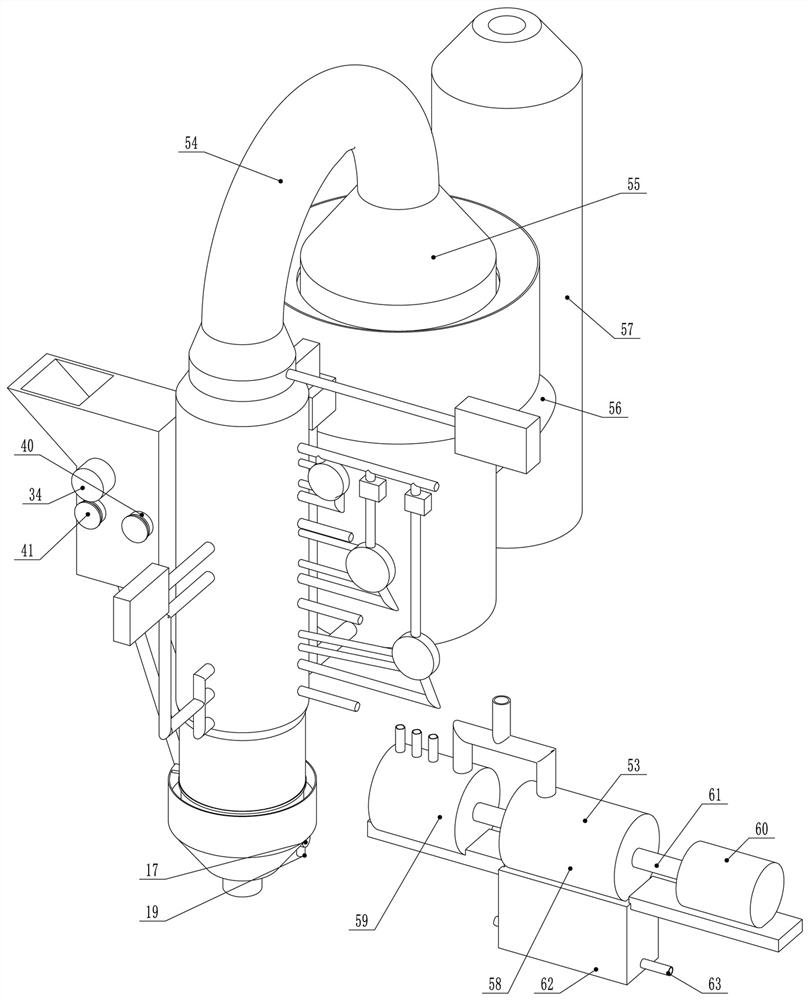

Fixed bed continuous upper suction gasification furnace power generation system for waste disposal

A technology of a power generation system and a fixed bed, which is applied in the field of gasifiers, can solve the problems of not being able to meet people's needs, not being able to fully use heat, and not being able to discharge large and massive residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

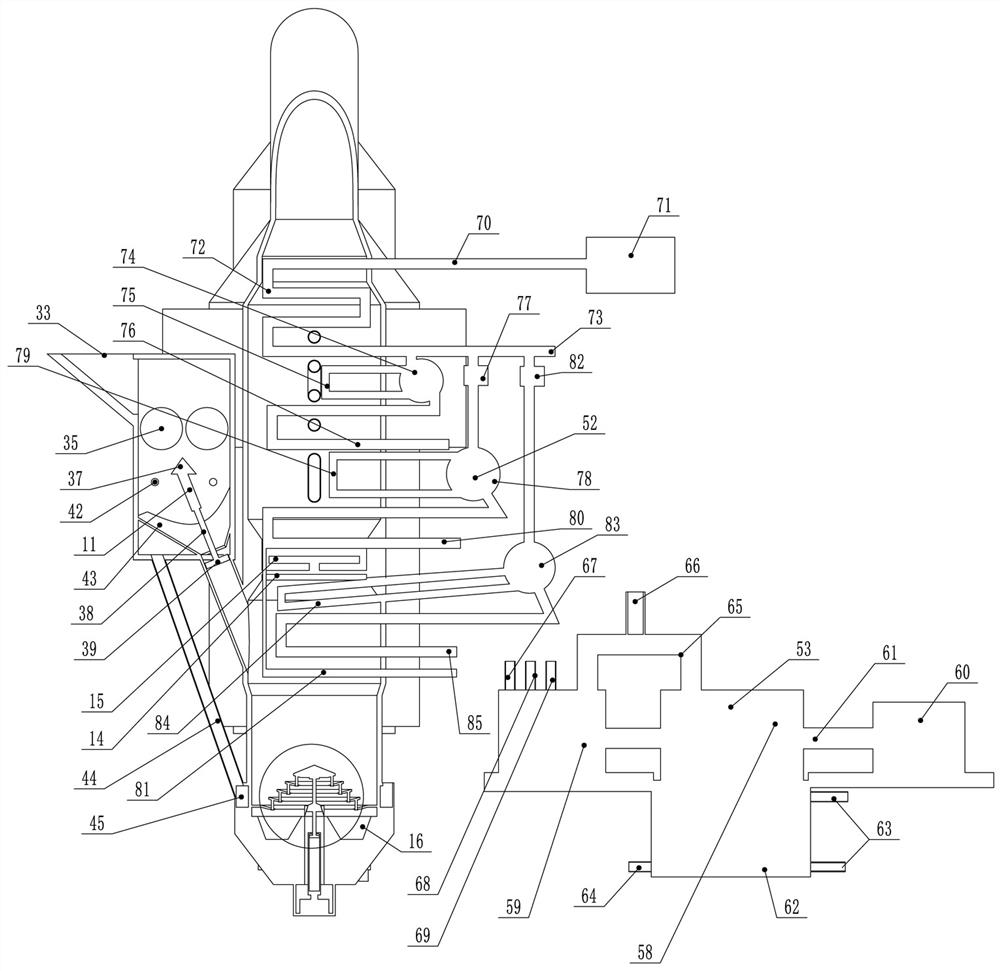

[0059] Example 1, a fixed-bed continuous up-suction gasifier power generation system for waste treatment. When in use, waste to be treated is added to the interior of the feed bin 10, and then the crushing motor 34 is operated, and the The waste is crushed, and the iron products in the waste are collected by the magnetic bar 42, and then the electric push rod 38 is reciprocated, so that the waste is added to the inside of the feeding pipe 5, and the material goes along the feeding pipe 5. The material pipe 5 enters the inside of the furnace body 1, and the waste entering the furnace body 1 forms a combustion layer at the bottom of the furnace body 1, and forms an oxide layer, a thermal contact layer and a drying layer successively above the combustion layer. The water vapor, volatile gas and combustible mixed gas produced by the cracking of garbage in the pyrolysis layer generated during drying are collectively referred to as flue gas and the air inside the dispersion pipe 51 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com