Paper packaging warpage detector for machinery

A warpage and detector technology, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of slow manual detection and inaccurate detection, and achieve the effects of fast detection speed, high detection accuracy and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the implementation mode of specific detection packet cigarette label and stick cigarette label of the present invention is described in detail as follows:

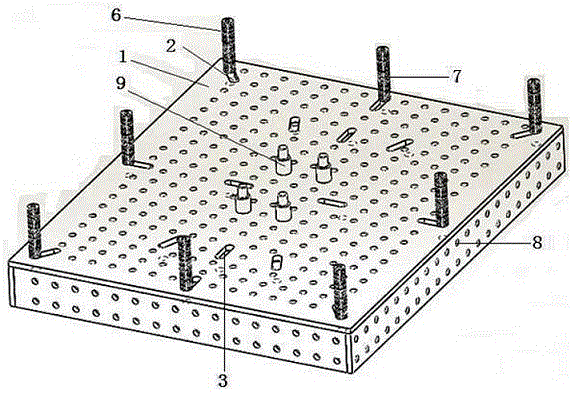

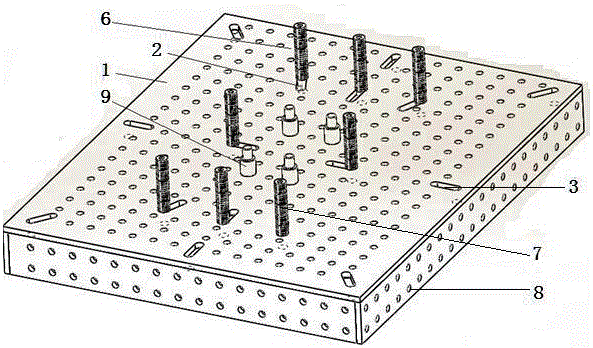

[0022] figure 1 Among them, the paper packaging warpage detector for machinery includes a detection platform 1, and four support columns 9 are fixed at the center of the detection platform 1, and around the support columns 9, according to the standard of small pack cigarette labels and carton pack cigarette labels, According to the detection requirements, 16 detection column adjustment mechanisms 2 are arranged in two layers;

[0023] The detection platform 1 is in the shape of a six-sided three-dimensional plate, and a plurality of small holes 8 are evenly arranged on the five surfaces except the bottom surface. It is convenient to detect the ventilation in the platform 1, so as to ensure that the temperature and humidity of the detected paper are uniform.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com