Uniform-airflow-type efficient tobacco baking room and low-temperature tobacco baking technology

A flue-cured tobacco room and uniform technology, applied in the field of flue-cured tobacco, can solve the problems of insufficient aroma, long flue-cured tobacco time, unbalanced temperature and humidity, etc., and achieve the effects of higher drying efficiency, high drying efficiency and temperature balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

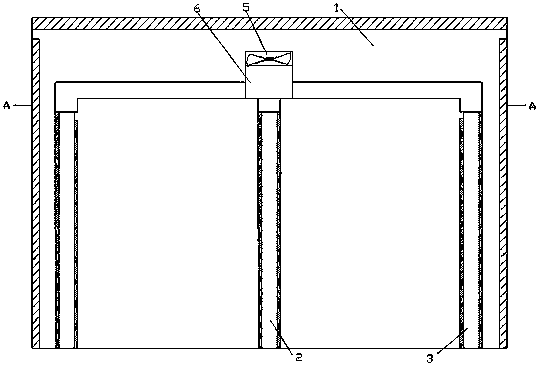

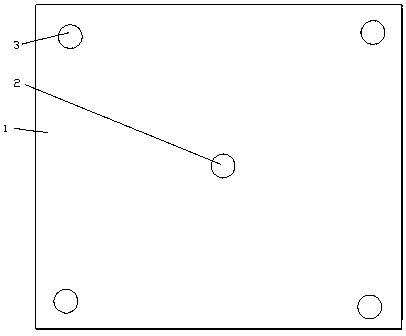

[0037] The high-efficiency flue-cured room with uniform airflow includes a flue-cured room body 1, and a heating device is installed in the flue-cured room body 1. The heating device can use various devices, which is an existing technology and is not limited here. Set the main air duct 2, the auxiliary air duct 3, the sub-air box 6, and the fan 5. The main air duct 2 is vertically arranged at the center of the flue-cured tobacco room body 1. The number of auxiliary air ducts 3 is more than three, and they are respectively 2 Distributed at equal distances around the main air duct 2, the main air duct 2 and the auxiliary air duct 3 communicate with the air distribution box 6, and the air distribution box 6 communicates with the fan 5; the main air duct 2 and the auxiliary air duct 3 are provided with holes . A tobacco-curing rack 4 is arranged between the main air duct 2 and the auxiliary air duct 3, and tobacco leaves are hung on the tobacco-curing rack 4 for curing.

[0038] ...

Embodiment 2

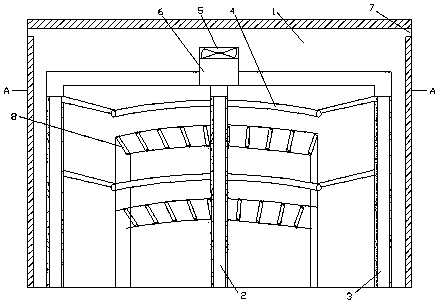

[0040] The high-efficiency flue-cured room with uniform airflow includes a flue-cured room body 1, and a heating device is installed in the flue-cured room body 1. The heating device can use various devices, which is an existing technology and is not limited here. Set the main air duct 2, the auxiliary air duct 3, the sub-air box 6, and the fan 5. The main air duct 2 is vertically arranged at the center of the flue-cured tobacco room body 1. The number of auxiliary air ducts 3 is more than three, and they are respectively 2 Distributed at equal distances around the main air duct 2 , the main air duct 2 and the auxiliary air duct 3 communicate with the sub-air box 6 , and the sub-air box 6 communicates with the fan 5 . Holes are arranged on the main air duct 2 and the auxiliary air duct 3, and the holes on the main air duct 2 are more than three, which are equidistantly arranged along the circumference of the main air duct 2; the holes of the auxiliary air duct 3 are facing away...

Embodiment 3

[0043] The high-efficiency flue-cured room with uniform airflow includes a flue-cured room body 1, and a heating device is installed in the flue-cured room body 1. The heating device can use various devices, which is an existing technology and is not limited here. Set the main air duct 2, the auxiliary air duct 3, the sub-air box 6, and the fan 5. The main air duct 2 is vertically arranged at the center of the flue-cured tobacco room body 1. The number of auxiliary air ducts 3 is more than three, and they are respectively 2 Distributed at equal distances around the main air duct 2 , the main air duct 2 and the auxiliary air duct 3 communicate with the sub-air box 6 , and the sub-air box 6 communicates with the fan 5 . Holes are arranged on the main air duct 2 and the auxiliary air duct 3, and the holes on the main air duct 2 are more than three, which are equidistantly arranged along the circumference of the main air duct 2; the holes of the auxiliary air duct 3 are facing away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com