Intelligentized airflow-regulated system facing closed type three-dimensional seedling raising platform

A technology for air flow regulation and wind direction regulation, applied in the field of air flow regulation system and plant factory system module, can solve the problems of poor seedling development, inability to simulate natural wind, underdeveloped root system of seedlings in plant factories, etc. rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

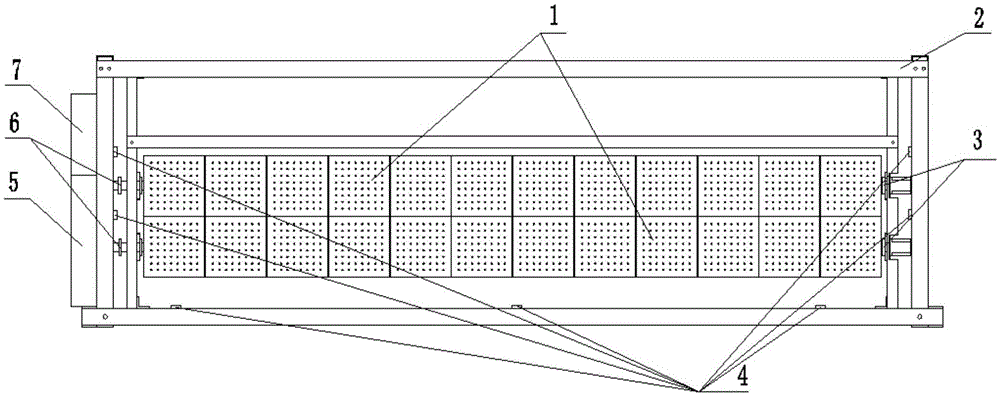

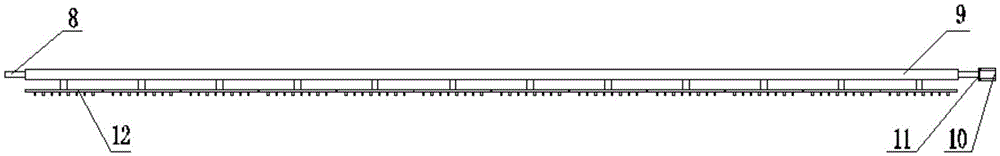

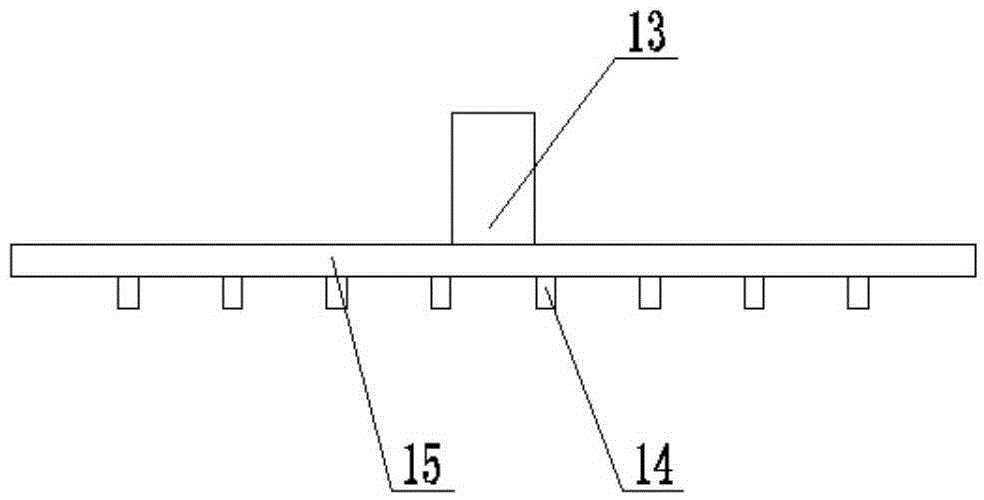

[0017] The invention relates to an intelligent airflow control system based on plant factory technology. The system is composed of a wind power supply unit, a wind direction adjustment unit, an electric control unit and a drive unit; the frame (2) of the system is made of steel profiles. The wind sensor (4) is installed on the front column and beam of the frame (2), the wind power supply unit (5) and the electric control and drive unit (7) are installed on the left side of the frame (2), and the wind direction adjustment unit (1) passes through The tubular air duct (9) of the air direction adjustment unit is connected to the rear side of the frame (2) by the bearing (3), and the air outlet plate (12) is arranged and connected to the air direction adjustment unit tubular air duct (9) by using the air outlet plate joint (13) to face the frame (2) On the inner s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com