Feed end liner for semi-automatic mill in beneficiation plant and machining process of feed end liner

A technology for processing technology and feeding end, which is applied in the field of liner plate for feeding end of semi-automatic mill in mineral processing plant and its processing technology, which can solve problems affecting the civilized production of modern enterprises, waste of manpower, material and financial resources, large amount of maintenance and replacement, etc. problems, to achieve the effect of improving initial hardness and overall mechanical properties, improving efficiency, and avoiding duplication of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

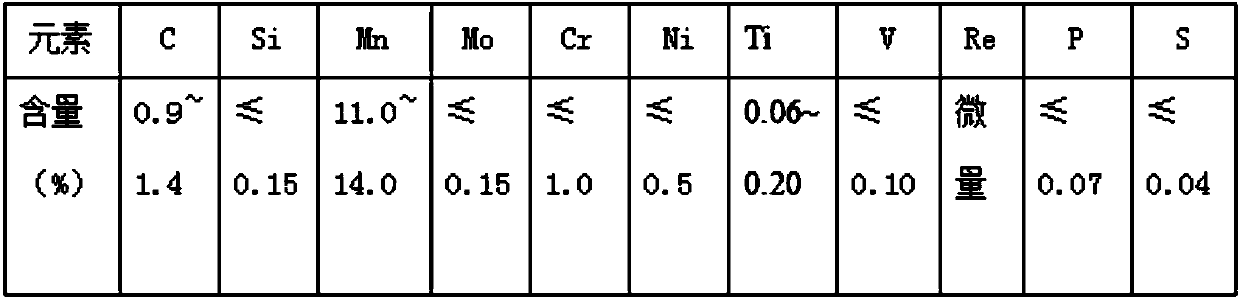

[0035] The liner at the feed end is composed of the following components in mass fraction: 0.705% C, 0.242% Si, 0.628% Mn, 2.15% Cr, 0.266% Mo, 0.0311% P, 0.110% S.

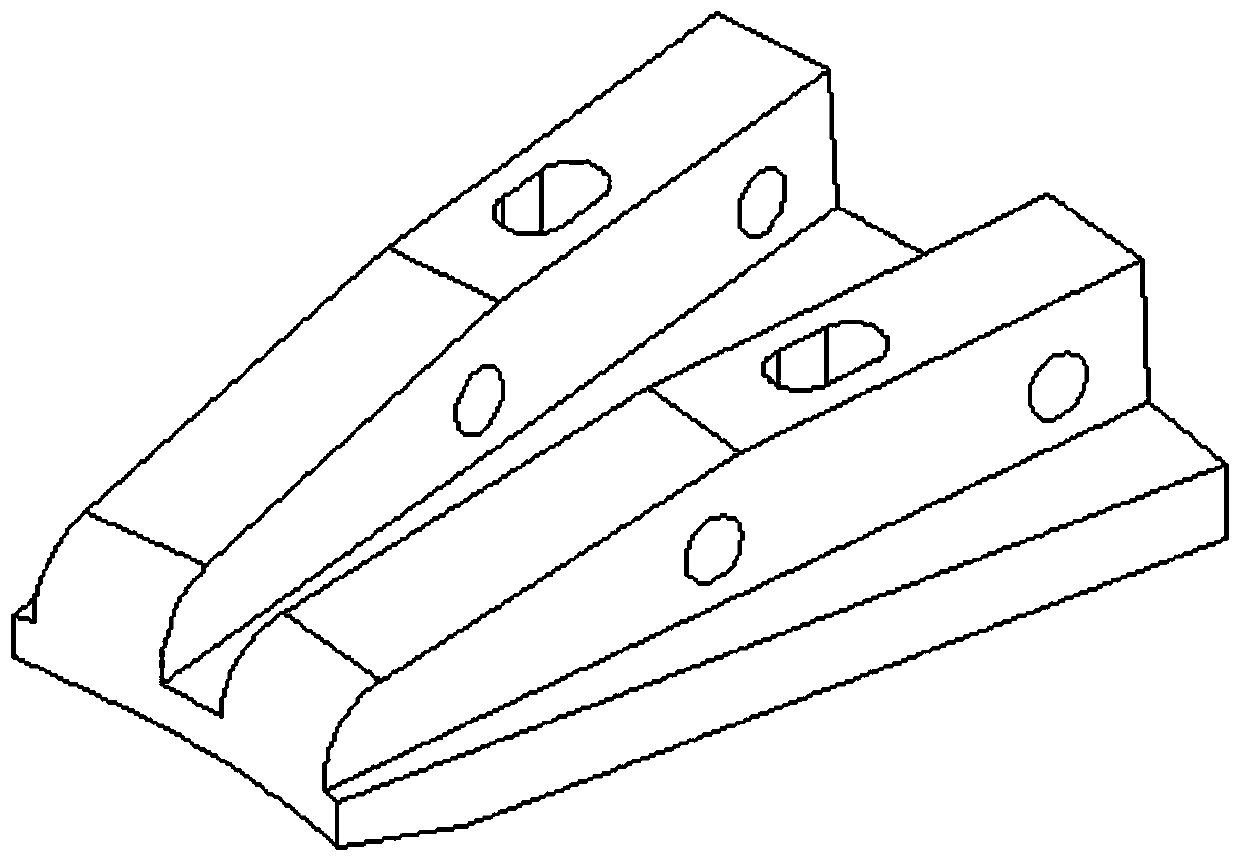

[0036] The liner at the feed end is 1410mm long and 440mm wide. The 80mm protrusion on one side of the liner is a lifting strip. There are two bolt holes in the middle of the liner with a distance of 870mm. The cylinder liner is fixed by two M58 flat head bolts. On the barrel; the thickness of the liner at the feed end is 70mm, the hardness of the liner is HRC48-52, and the wear-resistant liner and the barrel are fixed with high-strength bolts.

[0037] During processing, product size chain confirmation;

[0038] The second step, the mold model production;

[0039] The third step, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com