Novel self-expansion screen pipe

A self-expanding, screen-tube technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high cost, poor sand control effect, and complicated oil and gas well completion operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

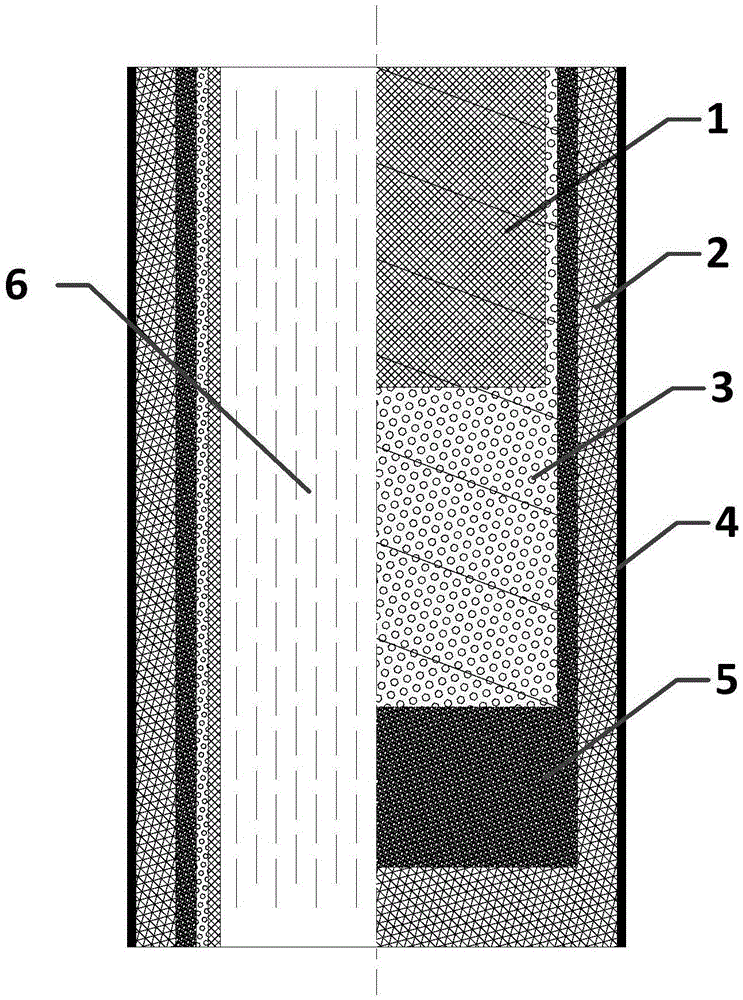

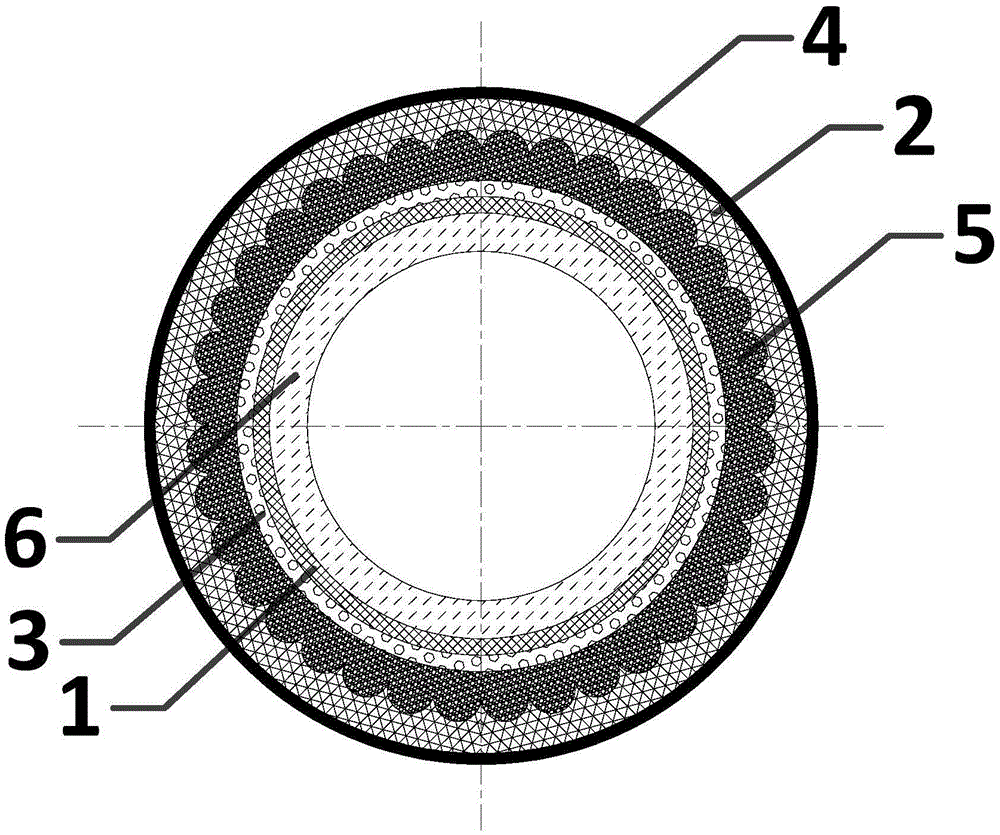

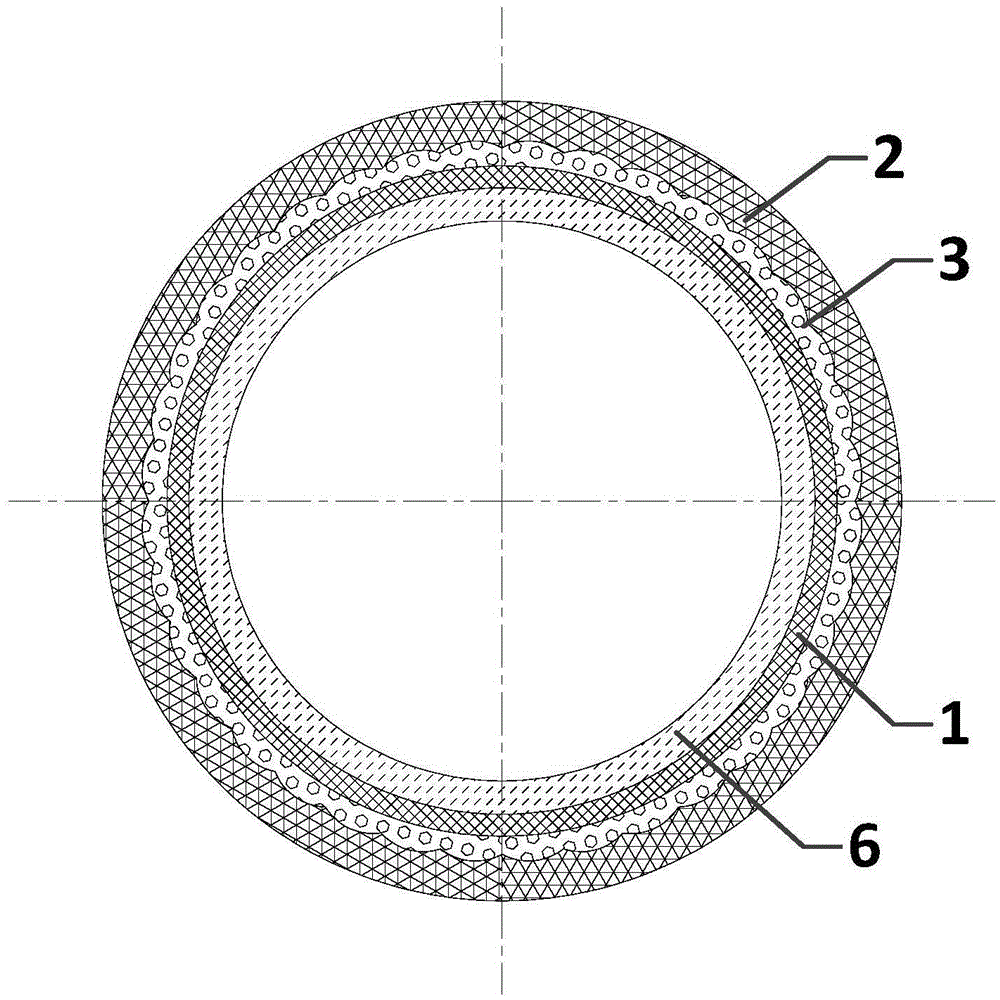

[0023] A new type of self-expanding screen, such as figure 1 , 2 As shown, from the inside to the outside, it includes a shape memory alloy slotted base pipe 6, a metal screen, a water-dissolving filling layer 5, a shape-memory polymer layer 2 and a water-dissolving protective layer 4,

[0024] The shape-memory alloy slotted base tube 6 is made of shape-memory alloy, which is compressed to the shape before expansion at high temperature, and expands automatically under the influence of temperature after being lowered into the designated position; the material selection of the shape-memory alloy slotted base tube 6 is It is a shape memory alloy made of titanium-nickel-chromium alloy;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com